High-efficiency waterproof and compression-resistant alloy powder for concrete and preparation method thereof

A concrete and alloy powder technology, which is applied in the field of building materials, can solve the problems of affecting the durability of concrete, affecting or reducing concrete, etc., and achieve the effect of waterproof and anti-penetration, reducing the total porosity, and preventing cold shrinkage cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

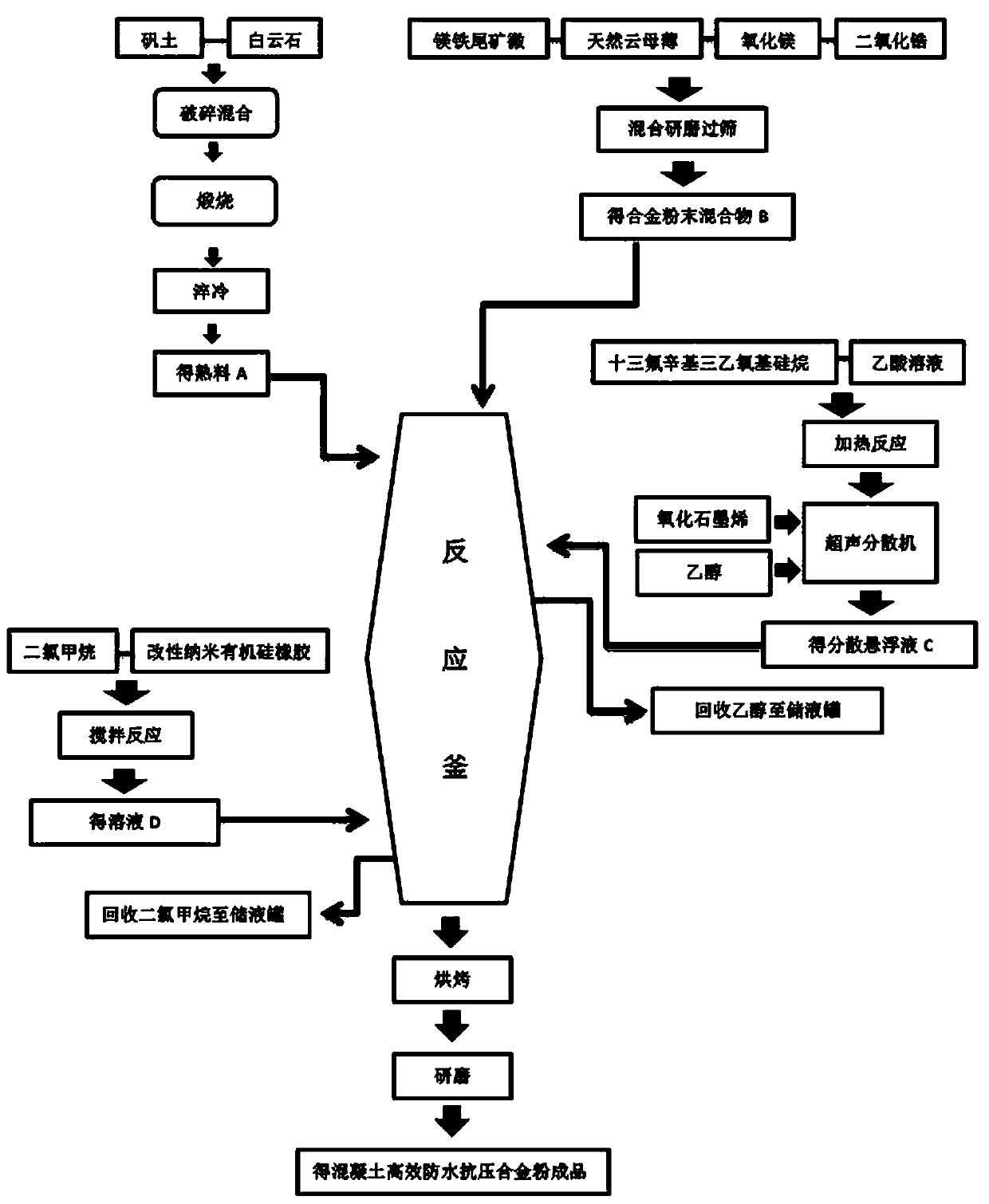

[0032] A method for preparing the above-mentioned high-efficiency waterproof and compression-resistant alloy powder for concrete, comprising the following steps:

[0033] (1) Crushing and mixing bauxite and dolomite, grinding together, calcining and quenching to obtain clinker A of expansive material and hard material;

[0034] (2) Mixing, grinding and sieving magnesium iron silicate tailings fine powder, natural mica flakes, magnesium oxide and zirconium dioxide to obtain alloy powder mixture B;

[0035] (3) Add tridecafluorooctyltriethoxysilane to acetic acid solution and stir for reaction, then add ethanol and graphene oxide powder for ultrasonic dispersion to obtain dispersion suspension C;

[0036] (4) Put the modified nano-silica rubber and dichloromethane in the reaction kettle and fully stir the reaction to obtain the dispersion D;

[0037](5) Put the clinker A prepared in step (1) and the alloy powder mixture B prepared in step (2) into a high-speed stirring reactor,...

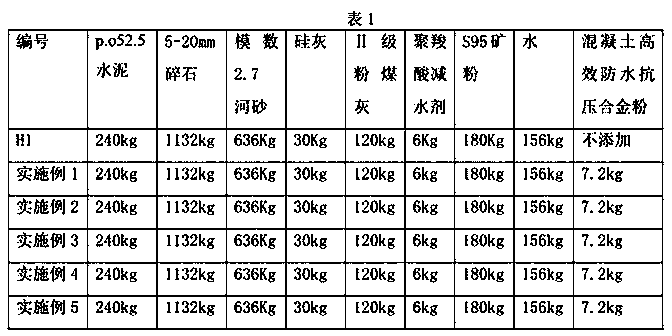

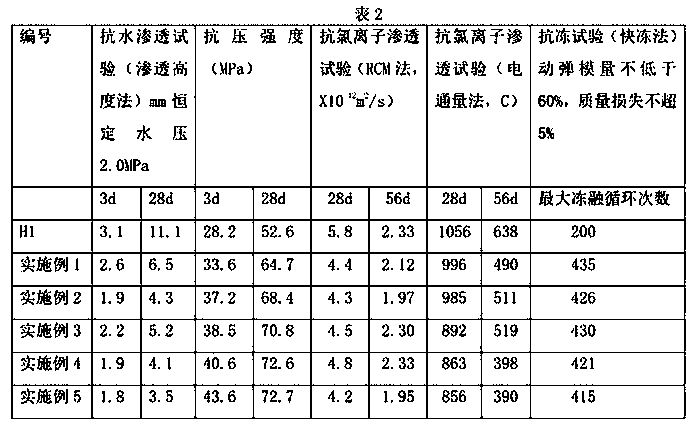

Embodiment 1

[0040] A high-efficiency waterproof and compression-resistant alloy powder for concrete, which is made of the following raw materials in parts by weight: 60 parts of magnesium-iron silicate tailings micropowder, 8 parts of bauxite, 5 parts of dolomite, and 10 parts of natural mica flakes , 3 parts of magnesium oxide, 3 parts of zirconium dioxide, 0.5 part of graphene oxide powder, 0.5 part of tridecafluorooctyltriethoxysilane, and 10 parts of modified nano-silicone rubber.

[0041] The preparation method of the concrete high-efficiency waterproof and compression-resistant alloy powder as described above comprises the following steps:

[0042] (1) Crush and mix 8 parts by weight of bauxite and 5 parts of dolomite, and grind them together to form a specific surface area of 200m 2 / kg of raw meal powder, placed in a rotary kiln at 850°C for 20 minutes, heated to 1000°C at a rate of 10°C / min, and then calcined for 30 minutes. Material A;

[0043] (2) In parts by weight, 60 par...

Embodiment 2

[0048] A high-efficiency waterproof and compression-resistant alloy powder for concrete, which is made of the following raw materials in parts by weight: 35 parts of magnesium-iron silicate tailings micropowder, 12 parts of bauxite, 10 parts of dolomite, and 11 parts of natural mica flakes , 8 parts of magnesium oxide, 8 parts of zirconium dioxide, 3 parts of graphene oxide powder, 3 parts of tridecafluorooctyltriethoxysilane, and 10 parts of modified nano-silicone rubber.

[0049] The preparation method of the concrete high-efficiency waterproof and compression-resistant alloy powder as described above comprises the following steps:

[0050] (1) Crush and mix 12 parts by weight of bauxite and 10 parts of dolomite, and grind them together to form a specific surface area of 200m 2 / kg of raw meal powder, placed in a rotary kiln at a temperature of 900°C for 15 minutes, then raised to 1050°C at a rate of 10°C / min and calcined for 30 minutes. Material A;

[0051] (2) In parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com