Prestressed concrete mansard rigid-frame beam

A concrete, polyline-shaped technology, applied in the field of rigid frame beams, can solve problems such as unfavorable earthquake resistance, large inertial force, and self-heavy beam body, and achieve the effect of saving the volume of formwork materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

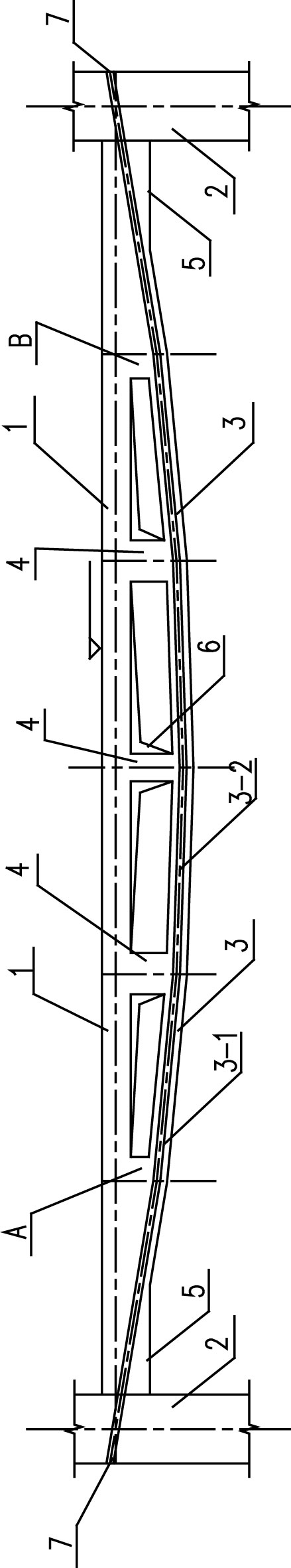

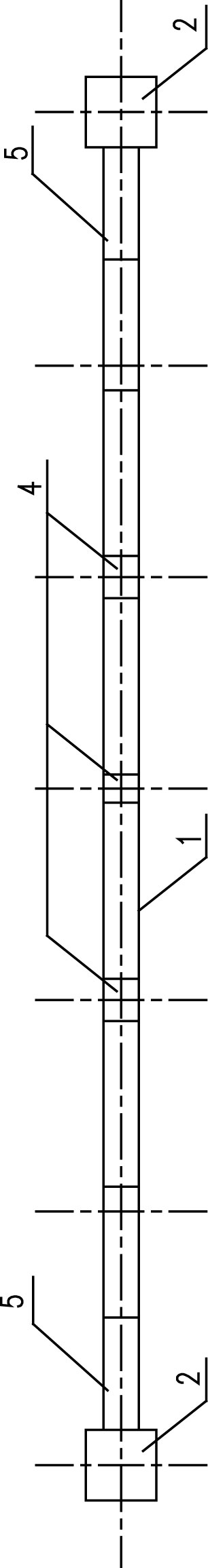

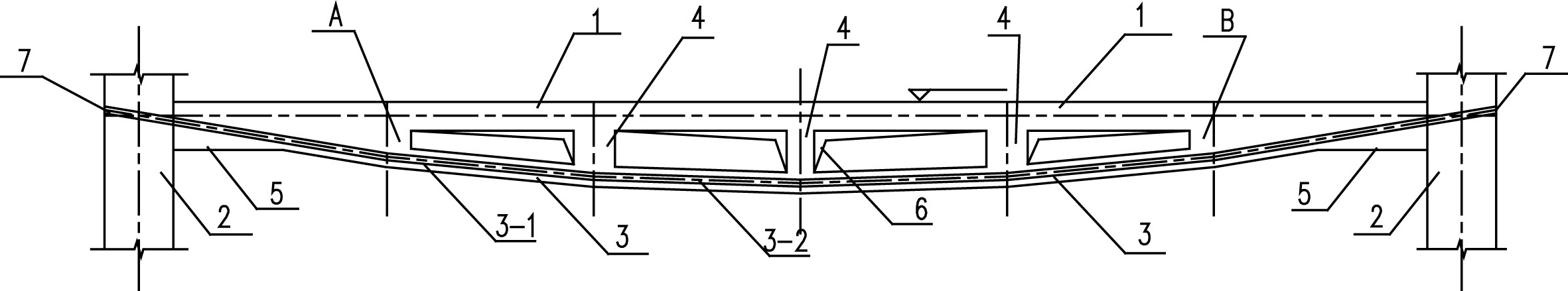

[0009] Specific implementation mode one: as figure 1 As shown, the prestressed concrete broken-line rigid frame beam described in this embodiment includes an upper beam 1 and a plurality of columns 4 with different heights, and the rigid frame beam also includes a lower folded beam 3 and two sections of flat beams 5. The lower folded beam 3 is a beam body formed by connecting a plurality of straight beams 3-1 end-to-end in sequence, and the lower folded beam 3 is located below the upper beam 1, and the outline formed by the two is in an inferior arc shape. , one end of the lower folded beam 3 is rigidly connected to one end of the upper beam 1 to form a first node A, and the other end of the lower folded beam 3 is rigidly connected to the other end of the upper beam 1 to form a second node B, and the upper beam 1 A section of flat beam 5 is respectively arranged at both ends of the two sections of flat beam 5, and one end of one flat section beam 5 in the two sections of flat ...

specific Embodiment approach 2

[0011] Specific implementation mode two: as figure 1 As shown, the cross-sectional area of the flat beam 5 in this embodiment is not less than the sum of the cross-sectional areas of the upper beam 1 and the lower folded beam 3, and the height of the cross-section of the flat beam 5 is not less than that of the upper beam 1 and the lower folded beam 3 The sum of section heights. Guarantee like this that the bearing strength of the flat section beam 5 is not less than other positions. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0012] Specific implementation mode three: as figure 1 As shown, the rigid frame beam in this embodiment also includes two frame columns 2, and the other end of one of the two flat section beams 5 is rigidly connected to the inner side wall of one frame column 2, and the two sections of flat section beams 5 are rigidly connected into one body. The other end of the other flat segment beam 5 among the segment beams 5 is rigidly connected to the inner side wall of the other frame column 2 as a whole. The frame column 2 is a commonly used vertical load-bearing member, and connects adjacent span beam ends in the horizontal direction to form continuous multi-span. Other components and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com