Fabricated concrete orthogonal-diagonal lattice space grid box type tube-in-tube structure and making method thereof

An orthogonal oblique laying and space grid technology, applied in the direction of building structure and construction, can solve the problems of transportation, installation and fabrication, difficulty in reducing project cost, etc., so as to facilitate horizontal crossing of pipelines and improve construction quality , mechanical properties and the effect of improving lateral stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

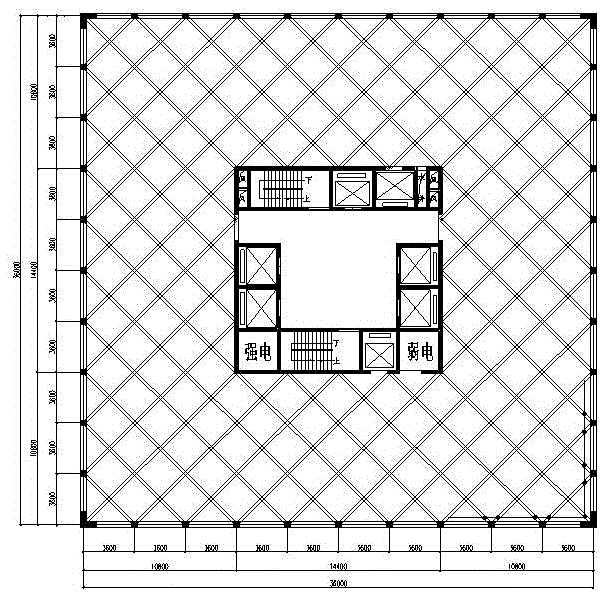

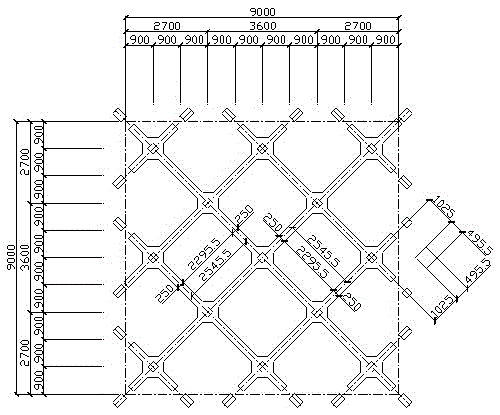

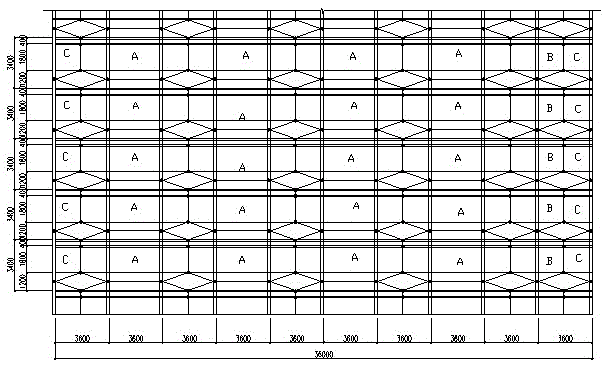

[0040] Example 1, prefabricated concrete orthogonal inclined space grid box-type tube-in-tube structure, one end of the vierendeel beam of the floor is rigidly connected with the surrounding grid frame columns two-to-one, and the other end of the vierendeel beam is also connected to the core tube for shear force Two-to-one rigid connection of the wall; the horizontal hollow floor and the surrounding grid-style frame are unitized and prefabricated, and then installed in layers, and the surrounding grid-style frame column-column network a 1 with floor grid a 2 = a 1 sian 45°, the upper and lower chords of the vierendeel beams are rigidly connected with the surrounding lattice frame columns and the surrounding shear walls of the central core tube, and the shear walls of the central concrete core tube correspond to the surrounding lattice frame columns through the vierendeel beams Rigid connection, the hollow floor is rigidly connected to the external grid frame column and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com