Dynamic simulation test device and method for ultra-wideband radio fuze

A dynamic simulation and testing device technology, applied in fuzes, offensive equipment, weapon accessories, etc., can solve the problems of not covering performance indicators, difficult to obtain measured values, complex systems, etc., to achieve rapid and automatic calculation of blast height, improve test efficiency and , deploy simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

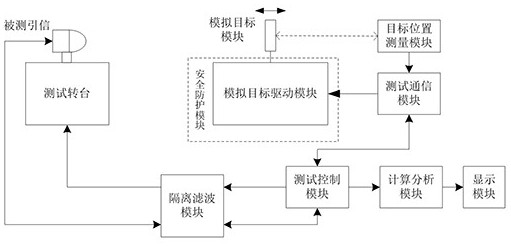

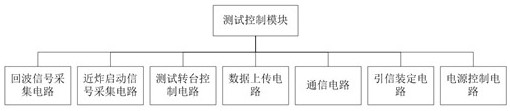

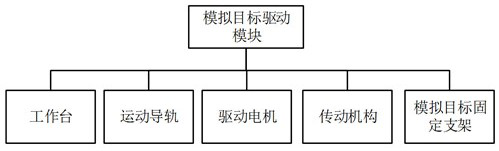

[0042] Such as Figure 4As shown, it is an ultra-wideband radio fuze dynamic simulation test device, including a test control module, a motor slide rail module and its controller, a corner reflector, a laser ranging module, an infrared communication module, a calculation and analysis module, a safety protection module, an isolation filter module, fuze test turntable, display module, the test control module is connected to the fuze test turntable in one direction through the isolation filter module, and is connected to the tested fuze in two directions, and the test control module is connected to the calculation and analysis module in one direction through the data line, The motor slide rail module and its controller are fixedly connected to the corner reflector through a mechanical structure, and the corner reflector reflects the echo signal when the electromagnetic wave of the fuze under test is irradiated, and the laser ranging module uses a real-time measurement corner refle...

Embodiment 2

[0059] Such as Figure 5 As shown, it is an ultra-wideband radio fuze dynamic simulation test device, including a test control module, a motor slide rail module and its controller, a metal plate, a resistive displacement sensor, a wireless communication module, a calculation and analysis module, a safety protection module, and an isolation filter module, a fuze test turntable, and a display module. The test control module is unidirectionally connected to the fuze test turntable through the isolation filter module, and is bidirectionally connected to the tested fuze. The test control module is unidirectionally connected to the calculation and analysis module through a data line. The motor slide rail module and its controller are fixedly connected to the metal plate through the mechanical structure. The metal plate reflects the echo signal when the electromagnetic wave of the fuze under test is irradiated. The resistive displacement sensor is installed on the slide rail to measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com