Explosion-proof heater

A technology of heaters and heating tubes, which is applied in the direction of air heaters, fluid heaters, lighting and heating equipment, etc., and can solve the problems of low heating effect, general heat dissipation performance, and low speed of air flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

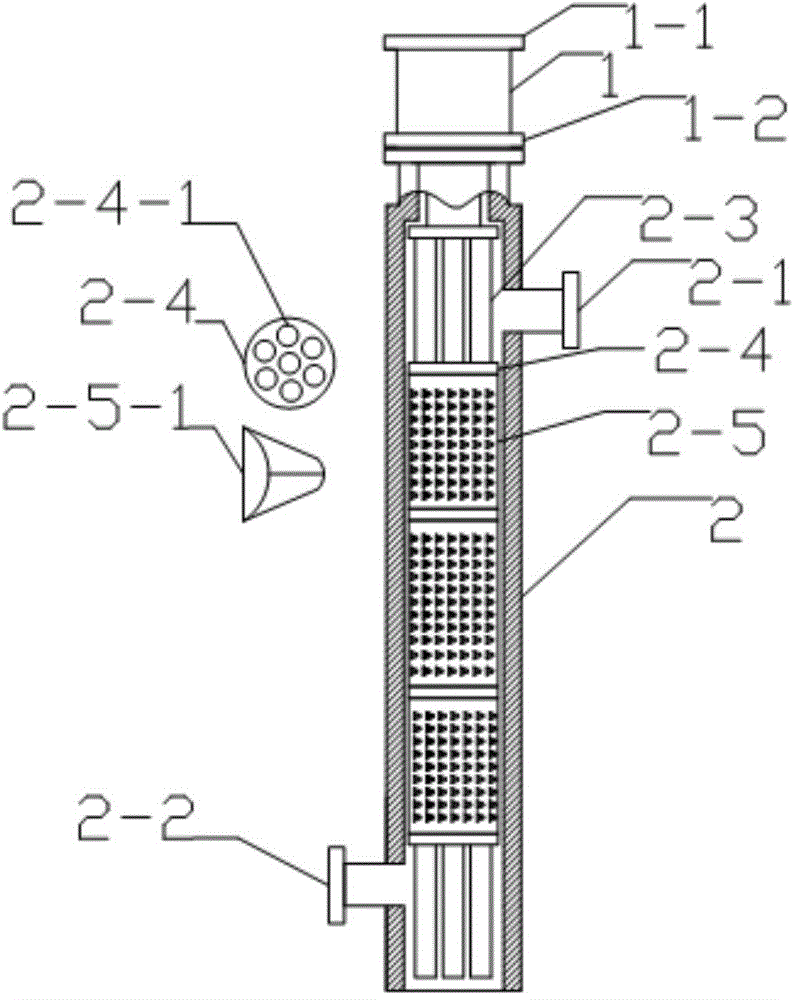

[0024] An explosion-proof heater, including a wire base 1 and a heating pipe body 2; the wire base 1 has built-in wiring lines, and also includes an upper flange 1-1 and a lower flange 1-2, and the upper flange 1- 1 Connect the terminal block 1 with the control box of the explosion-proof heater, and the lower flange 1-2 connects the terminal block 1 with the heating tube body 2; the heating tube body 2 includes The air inlet 2-2, the air outlet 2-1 near the upper end of the heating tube body, the heating tube 2-3 built in the heating tube body, the heating tube fixing plate 2-4 and the mesh liner 2-5; The heating tube 2-3 has a built-in heating wire and an insulating material filled around the heating wire; the heating tube fixing plate 2-4 is flat and cylindrical, and is uniform along the axial direction of the heating tube 2-3. distribution, the number is two or more, there is a through hole 2-4-1, the heating tube 2-3 passes through the through hole 2-4-1, and the heating t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com