Automatic damping deceleration carbon-free trolley based on rack method

A carbon-free car and automatic damping technology, which is applied in the transmission of toys, toy cars, transmission devices, etc., can solve the problems that affect the technical performance and obstacle avoidance ability of the car, have no climbing ability, drift in the driving direction and roll over, etc. Achieve the effect of solving the driving direction drift and rollover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

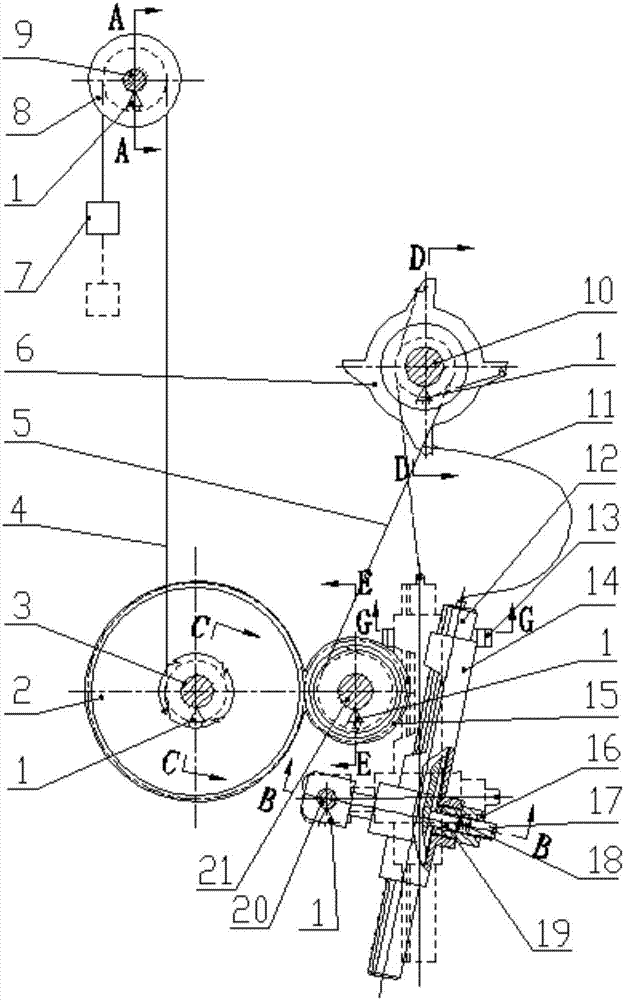

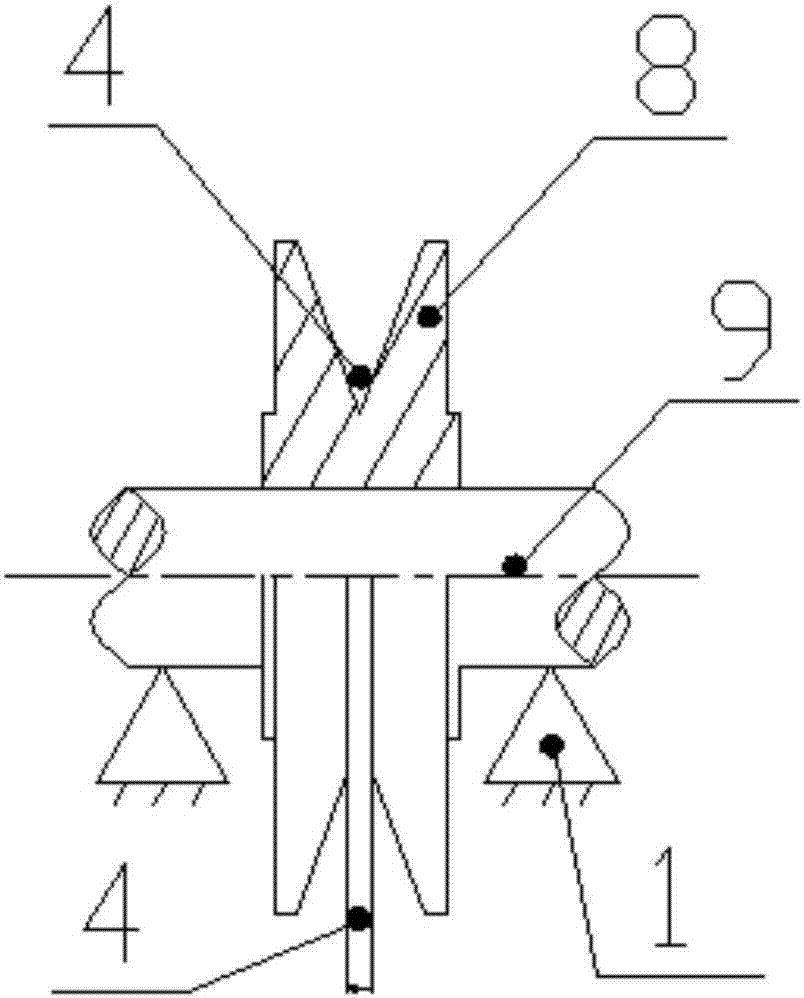

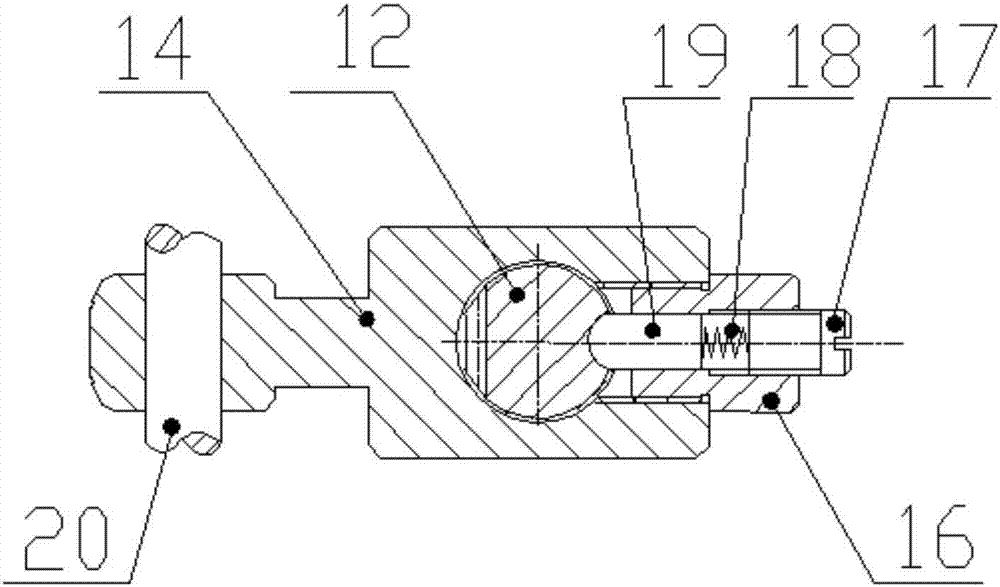

[0023] Such as figure 1 As shown, a carbon-free trolley includes a vehicle frame 1, a large gear 2 and a pinion 15 mounted on the frame 1 that are engaged with each other, a potential energy transmission mechanism that drives the rotation of the large gear 2, and an automatic damping reduction mechanism. The automatic damping deceleration mechanism is composed of a rack outer body assembly, a threaded sleeve body assembly, a damping body assembly and a timely meshing moving body.

[0024] Wherein, the mutually meshing bull gear 2 and pinion 15 right ends installed on the vehicle frame 1 are respectively provided with winding wheels, and the right sides of the winding wheels are respectively provided with hanging slots, so that the pinions are driven by the bull gears, Accelerate the reverse rotation to form a gear transmission mechanism.

[0025] The lower end of the main line 4 is provided with an annular ring and is wrapped around the reel with a wire hanging groove of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com