Multi-stage ladder tooth type mixer for integrated afterburner

A technology of afterburner and mixer, applied in the direction of combustion chamber, continuous combustion chamber, combustion method, etc., can solve the problems of affecting the combustion efficiency of the afterburner, affecting the thrust performance of the engine, and keeping the total pressure loss high. Achieve the effect of improving thermal mixing efficiency, suppressing noise, and reducing total pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

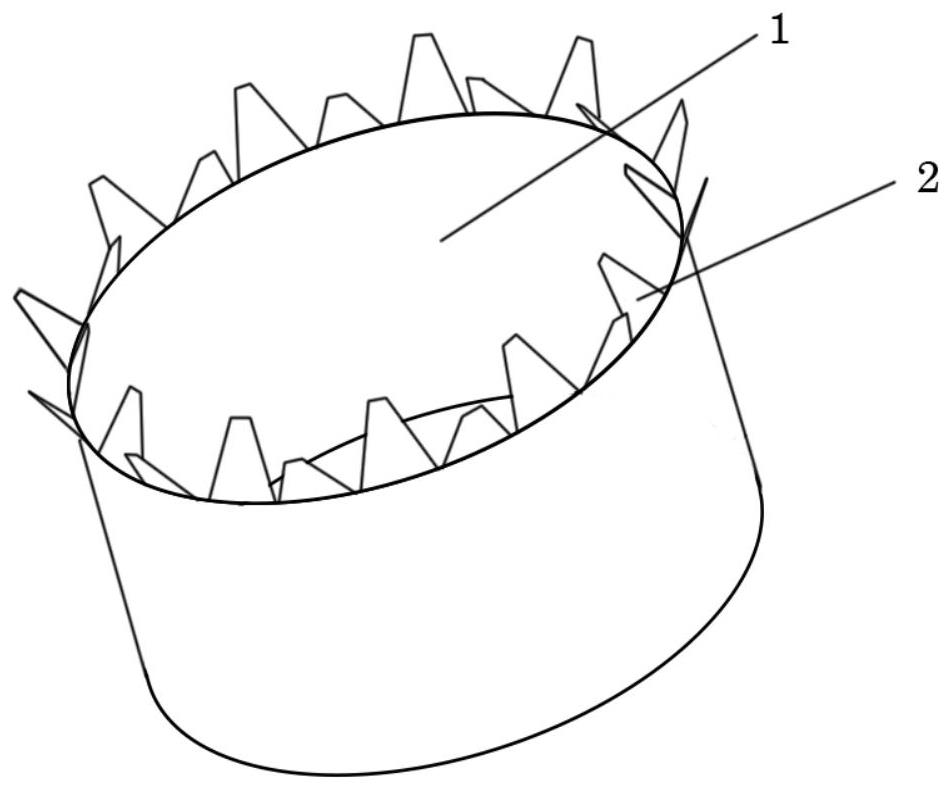

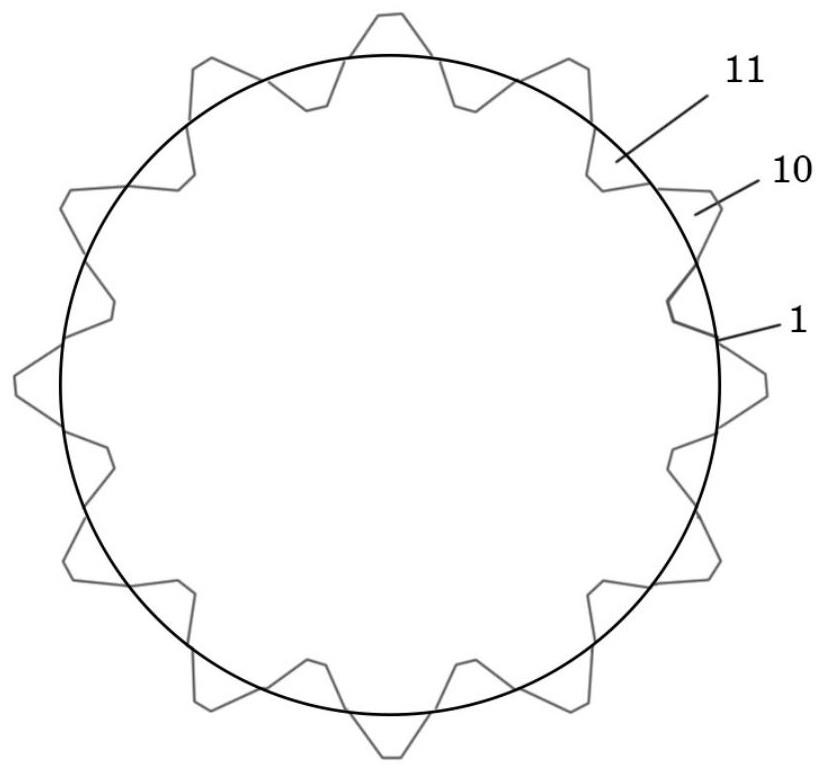

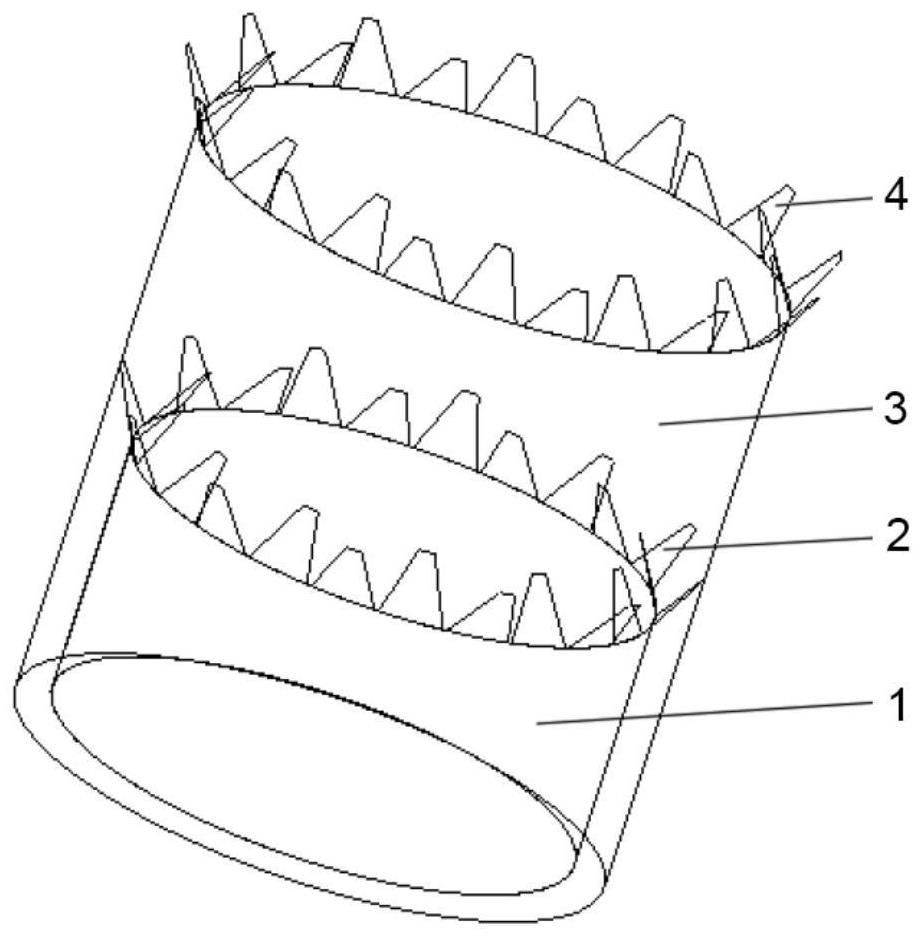

[0022] The multi-stage ladder-toothed mixer described in the embodiment of the present invention includes two-stage mixing sections, and each stage of mixing section is composed of ladder-toothed crown mixers of different sizes, figure 1 with 2 It is a three-dimensional view and a top view of the stepped tooth mixer in the primary mixing section of the embodiment of the present invention. The ladder-tooth crown mixer is composed of closely arranged inner and outer inclined ladder teeth on the outlet end face of the mixing section of each stage. When the gas flows through these staggered ladder teeth structures, it induces a flow direction vortex, which strengthens the internal and external duct flow. Blend. The structure of the first-stage blending section is similar to that of the ladder tooth mixer in the second-stage blending section. Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com