Engine thermolator assembly

A thermostat and engine technology, applied in the cooling of engine components, machines/engines, engines, etc., can solve the problems of reducing user comfort, coolant temperature fluctuations, speed fluctuations, etc., to avoid a sharp drop in temperature and reduce fuel consumption and emissions, to avoid the effect of speed fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

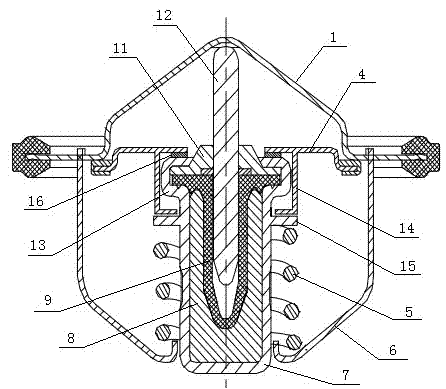

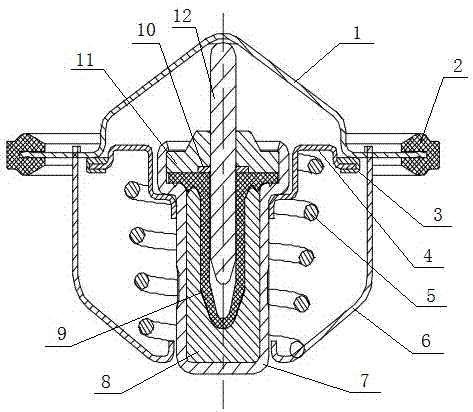

[0013] In order to further explain the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings.

[0014] see figure 1 As shown, the double-valve engine thermostat assembly includes a cover plate 1, a bracket 6, a ejection mechanism, and a valve 4 linked with the ejection mechanism. The cover plate 1 and the bracket 6 are riveted as one, and the ejection mechanism The mechanism includes an induction body 7, an induction body cover 11, a rubber hose 9, a push rod 12 and a spring 5, and a first shoulder 13 is provided on the upper end of the induction body 7, and the induction body cover 11 is located at the upper end of the induction body 7, forming a joint with the induction body. A wax chamber, the rubber tube 9 is located in the wax chamber, the wax chamber is filled with paraffin 8, the lower end of the push rod 12 is located in the rubber tube 9, and its upper end passes through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com