A motor servo controller and its control method

A technology of servo controller and control method, which is applied in the direction of AC motor control, motor generator/starter, starter of a single multi-phase induction motor, etc. problem, to achieve the effect of improving the dynamic response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

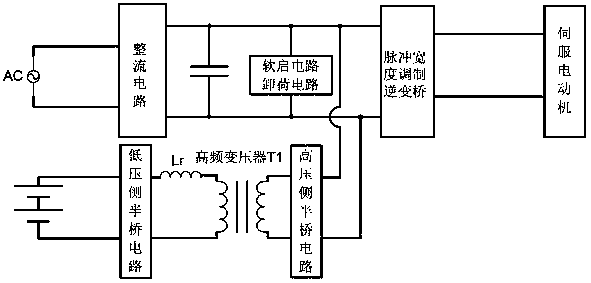

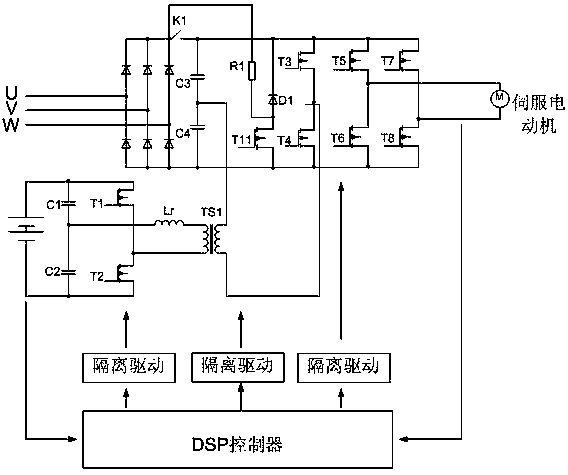

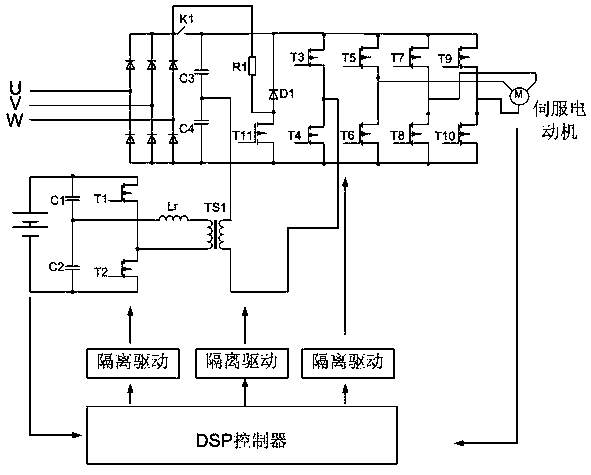

[0041] see Figure 1-Figure 3 , a motor servo controller, including a servo motor, a backup power supply, a soft start circuit, an unloading circuit and a rectification circuit connected to an alternating current, is characterized in that: it also includes a pulse width modulation inverter bridge and is used to give the backup A DC-DC half-bridge soft-switching high-frequency circuit for power supply charging and discharging. The DC-DC half-bridge soft-switching high-frequency circuit includes a low-voltage side half-bridge circuit, a high-frequency transformer, and a high-voltage side half-bridge circuit. The low-voltage side half-bridge circuit The bridge circuit is connected to the high-voltage side half-bridge circuit through a high-frequency transformer, the backup power supply is connected to the low-voltage side half-bridge circuit, the high-voltage side half-bridge circuit is connected to the DC terminal of the pulse width modulation inverter bridge, and the pulse width...

Embodiment 2

[0052] A control method for a motor servo controller, comprising the steps of:

[0053] a. Overvoltage protection steps: during the power-on phase, the soft-start relay K1 is disconnected, and the power resistor R1 charges the DC bus capacitors C3 and C4. After fully charged, the soft-start relay K1 is closed; during the operation phase, the DC bus capacitors C3 and C4 When the terminal voltage reaches the set maximum protection threshold voltage value of the switching device T11, the energy is discharged through the power resistor R1 to complete the overvoltage protection;

[0054] b. The charging step of the backup power grid. When the backup power is insufficient, the DC-DC half-bridge soft-switching high-frequency circuit takes power from the DC bus, and converts high-voltage power into low-voltage DC through a high-frequency transformer to charge the backup power;

[0055] c. The energy feedback charging step of the backup power supply. When the energy needs to be transfe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com