Method for the open-loop and closed-loop control of an internal combustion engine with a generator and asynchronous machine, open-loop and closed-loop control unit, and internal combustion engine

An open-loop control and closed-loop control technology, which is applied in the control of generators, internal combustion piston engines, electrical control, etc., can solve the problem of high power, achieve the effect of improving load switching ability and avoiding speed fluctuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

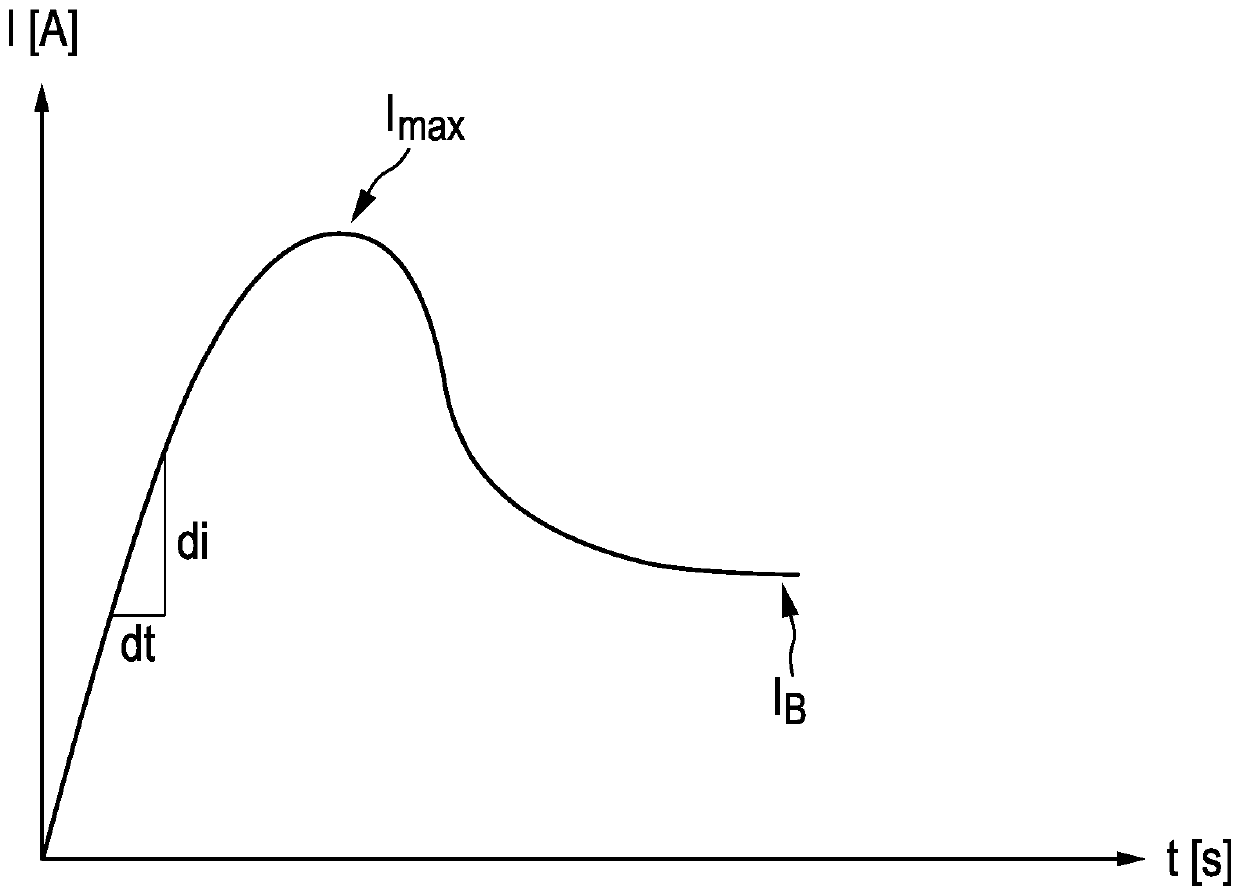

[0029] exist figure 1 The curve of the starting current of an asynchronous machine with respect to time is shown by way of example in . Here, the inrush current I first rises sharply up to the maximum inrush current I max and then descend to operating level I B Above, the asynchronous machine works at the stated operating level after the start-up phase. The sharp rise of the current curve at the beginning of the starting phase is expressed by the gradient di / dt, that is to say the change of the characteristic variable over a certain time interval. According to the invention, the increase is detected as an electrical characteristic variable change, and as soon as the characteristic variable change is above a first limit value, a changeover from standard speed regulation of the internal combustion engine connected to the asynchronous machine to feedforward control is carried out. In this case, the setpoint injection quantity for the internal combustion engine is determined wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com