Method for controlling an internal combustion engine

A technology of internal combustion engine and pre-control value, applied in electrical control, engine control, fuel injection control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

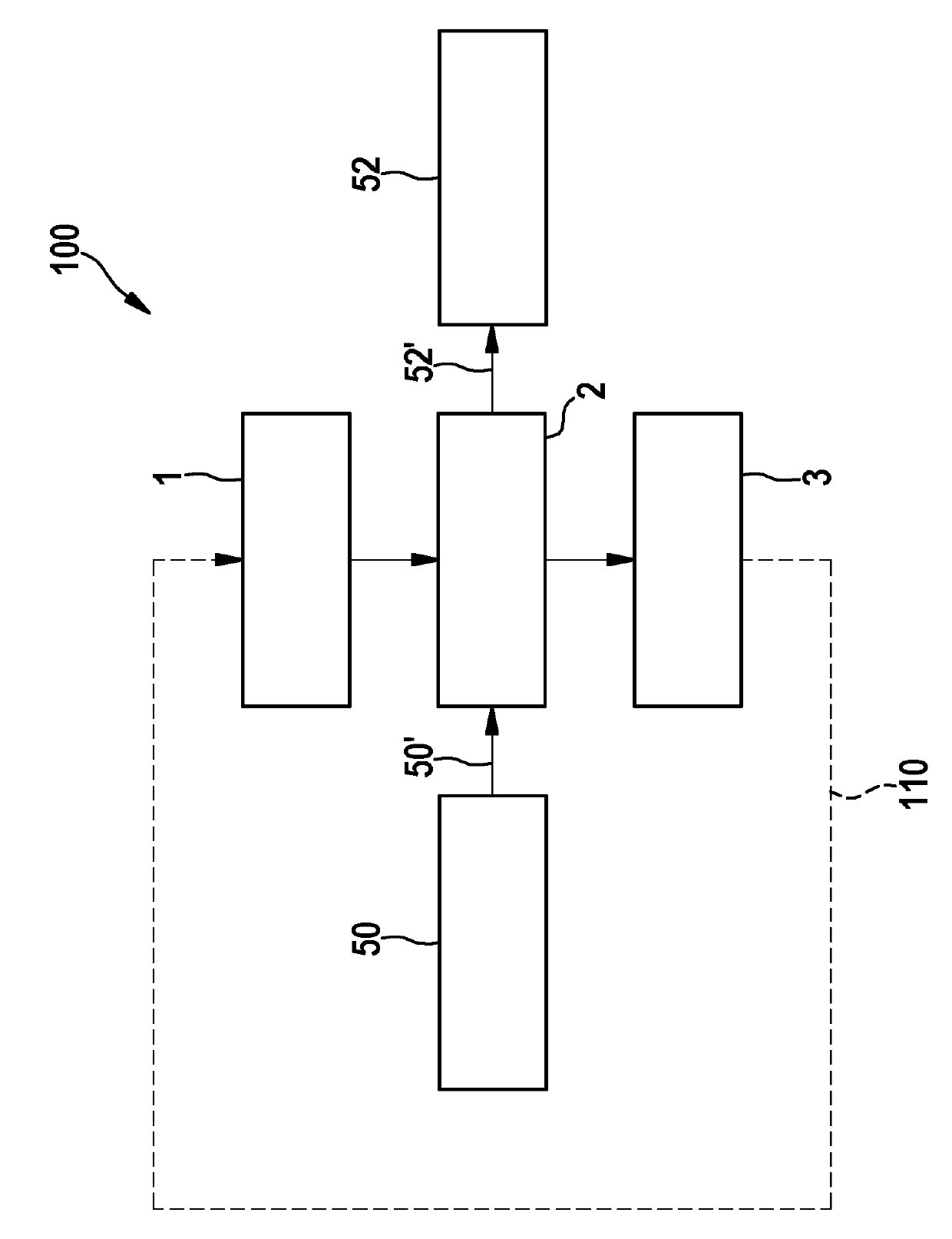

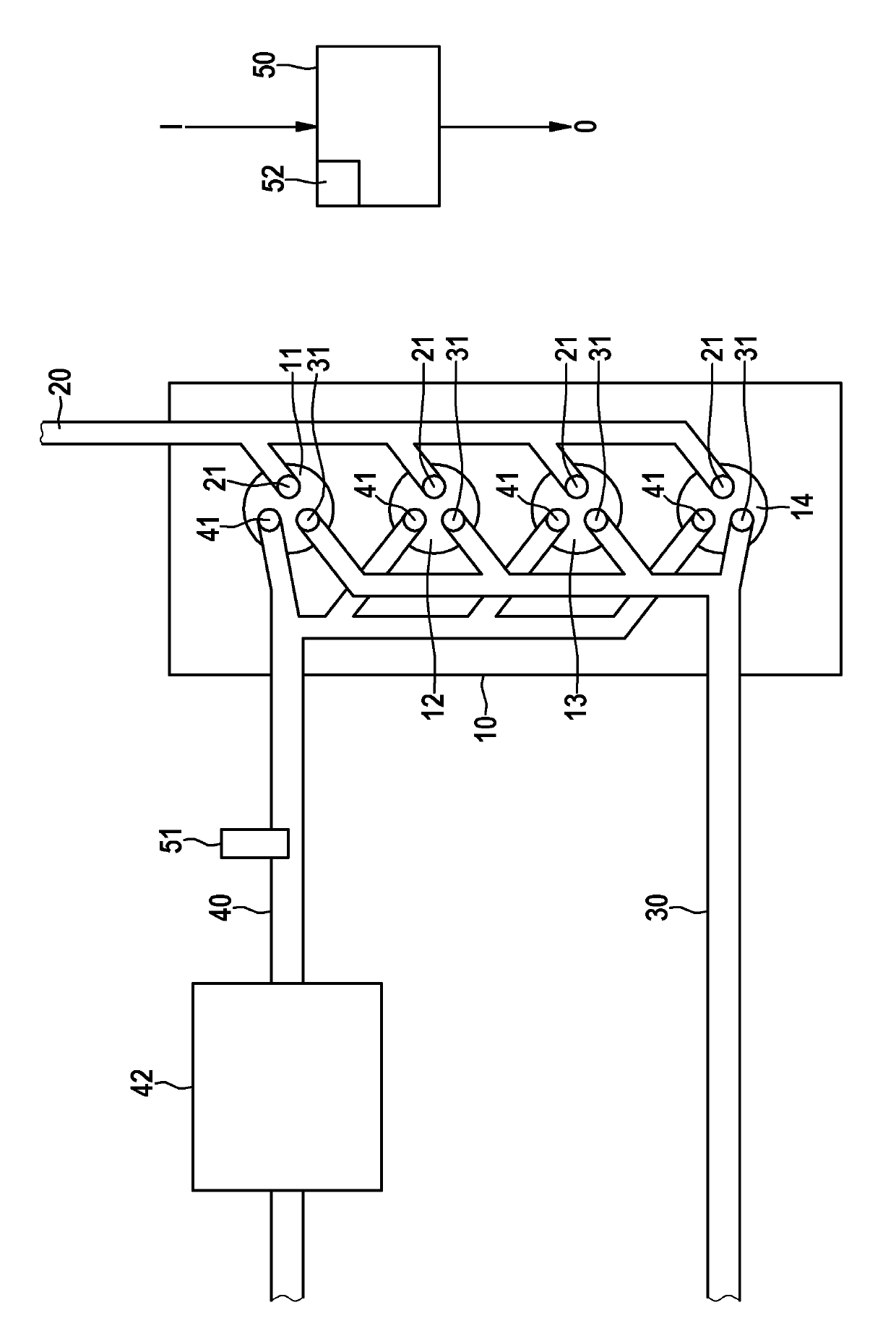

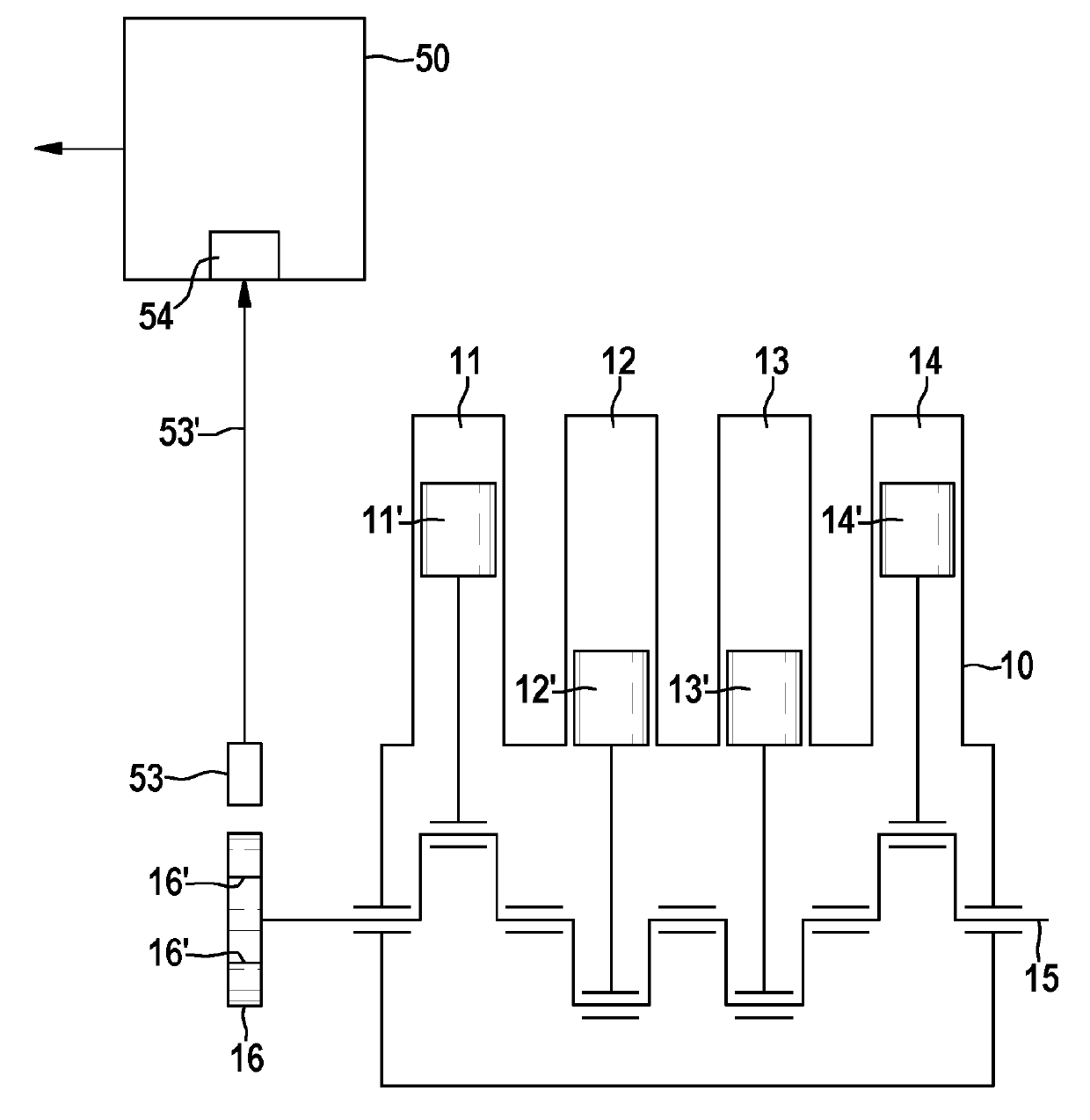

[0030] exist figure 1 shows schematically in plan view a section of a motor vehicle having an internal combustion engine 10 with a fuel system 20 , an air supply system 30 and an exhaust system 40 as well as a computing unit 50 which serves as A controller for operating the motor vehicle. Internal combustion engine 10 is preferably designed as an Otto engine with direct fuel injection. In the exemplary embodiment shown, internal combustion engine 10 comprises four cylinders 11 , 12 , 13 , 14 , but any other number of cylinders is also possible. Fuel is supplied via fuel system 20 and injected into cylinders 11 , 12 , 13 , 14 via corresponding injection valves 21 .

[0031] Air is supplied to the cylinders 11 , 12 , 13 , 14 via the air supply system 30 , wherein an intake valve 31 is provided for each of the cylinders 11 , 12 , 13 , 14 . Combustion exhaust gases are discharged from cylinders 11 , 12 , 13 , 14 via exhaust valves 41 and are output via exhaust system 40 . Arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com