Double-wheel drive single-rail conveyor and over-bending control method thereof

A single-rail conveyor and two-wheel drive technology, which is applied to conveyor control devices, conveyor objects, transportation and packaging, etc., can solve the problems of easy damage to hardware and large speed fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

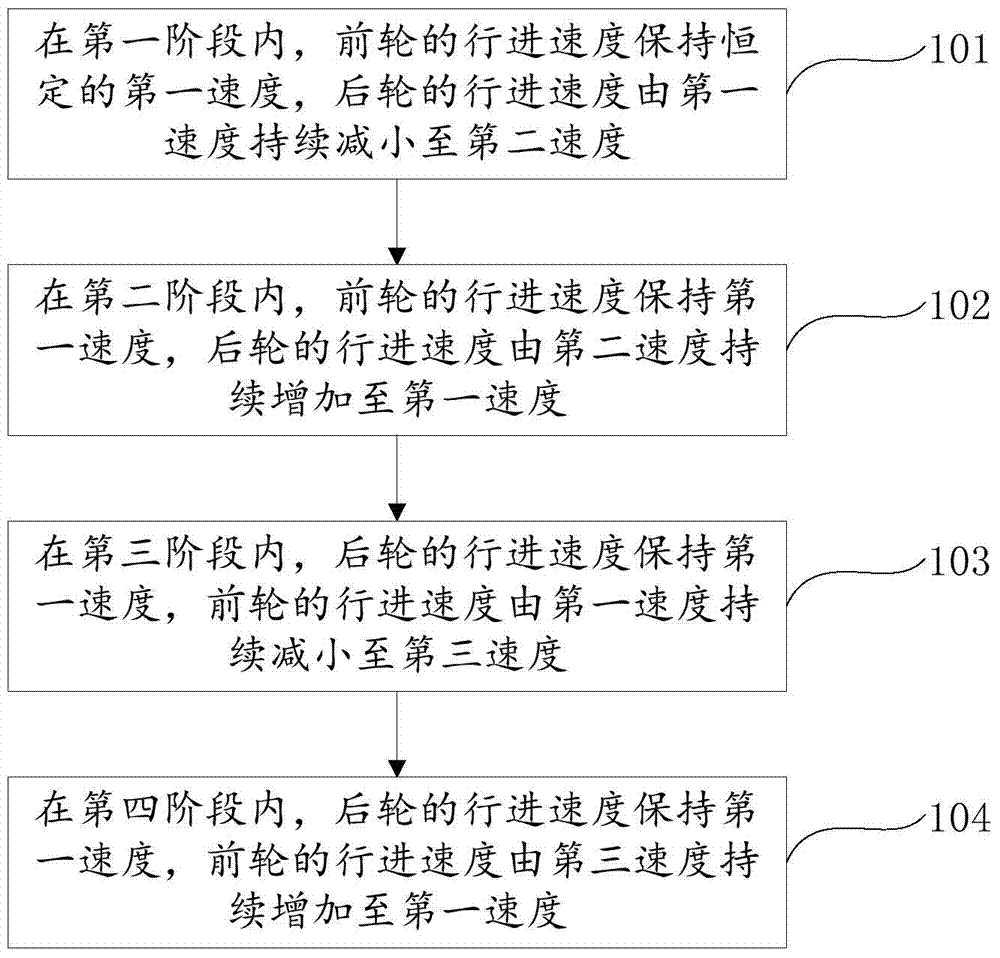

[0053]An embodiment of the present invention provides a method for cornering control of a two-wheel drive monorail conveyor. The method is applicable to the scene where the front and rear track of the monorail conveyor is greater than the turning radius of the curve. The control process of the method is divided into four stages. In this stage, the speed of the front wheel or the rear wheel is changed to ensure the smooth and stable walking of the monorail conveyor during the turning process.

[0054] The specific steps of the method are as follows figure 1 shown, including:

[0055] Step 101, in the first stage, the traveling speed of the front wheels is maintained at a constant first speed, and the traveling speed of the rear wheels is continuously reduced from the first speed to a second speed.

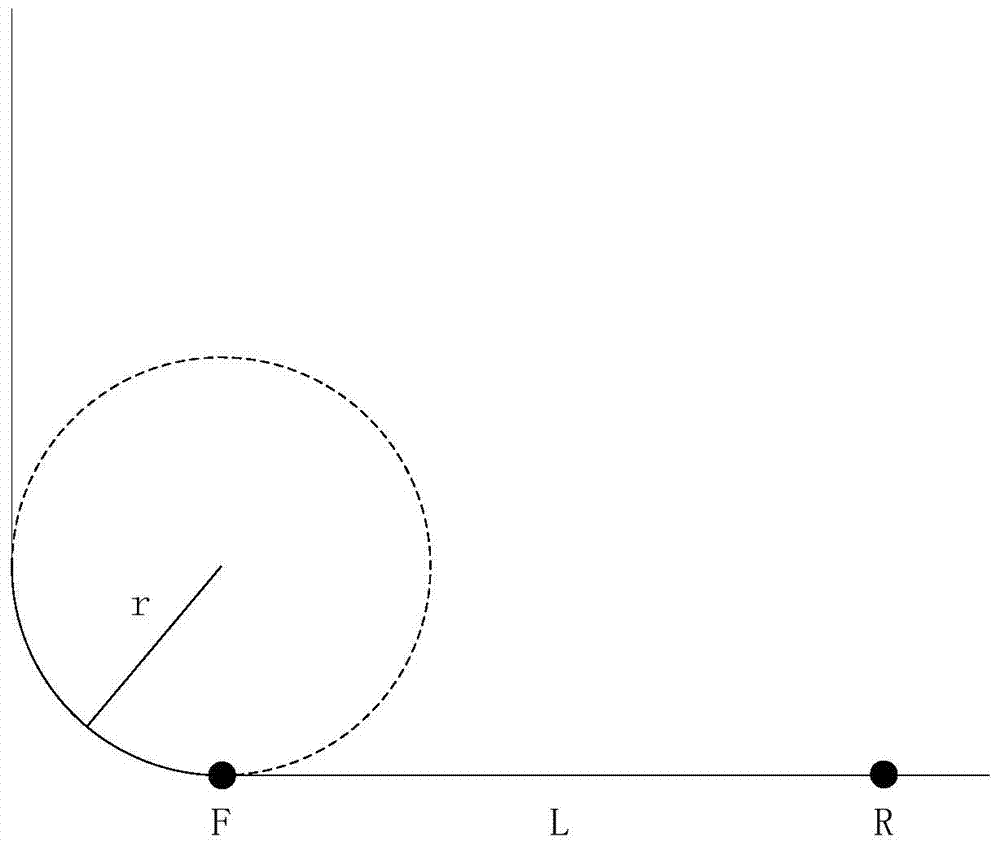

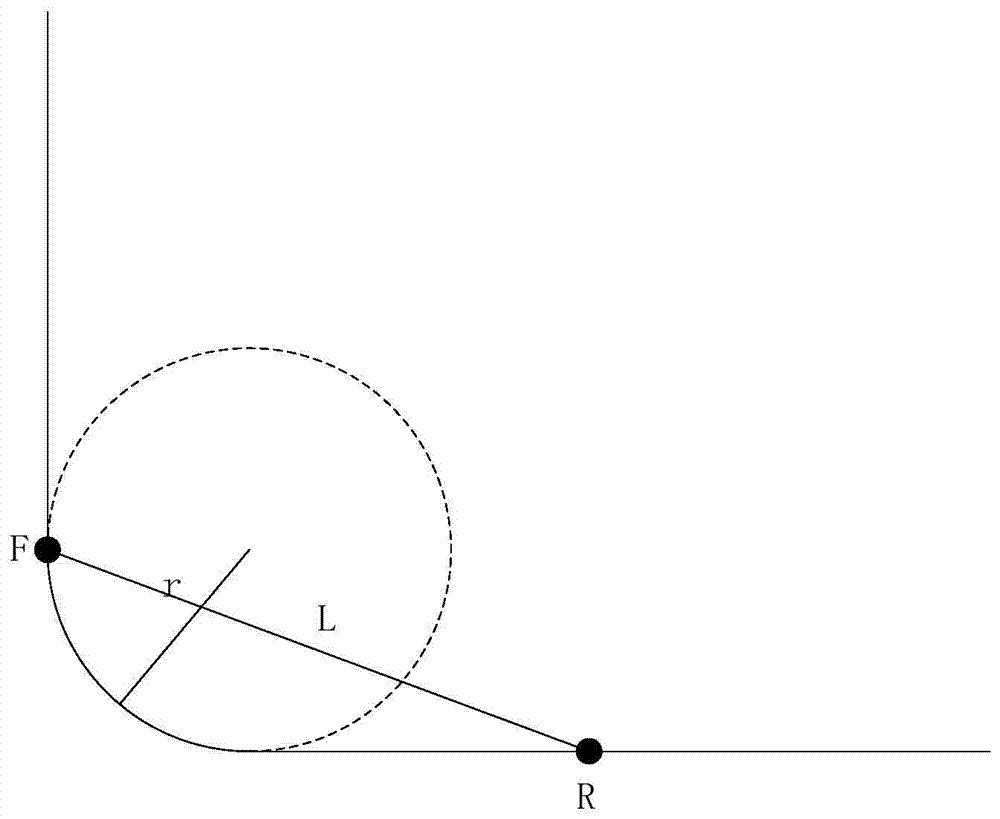

[0056] Among them, the first stage is the time from when the front wheels drive into the curve to when the front wheels drive out of the curve, figure 2 with image 3 The travel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com