Rotatable engineering machinery rotation constant power control method, system and engineering machinery

A technology of constant power control and construction machinery, applied in the field of rotary constant power control of rotatable construction machinery, rotary constant power control system, and rotary control of rotatable construction machinery, can solve the problems of insufficient precision and pertinence, rough control methods, inability to Targeted control of the rotating speed and other issues of the slewing mechanism to achieve the effect of fine control and good pertinence, ensuring high efficiency and avoiding fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and the protection scope of the present invention is not limited to the following specific embodiments. .

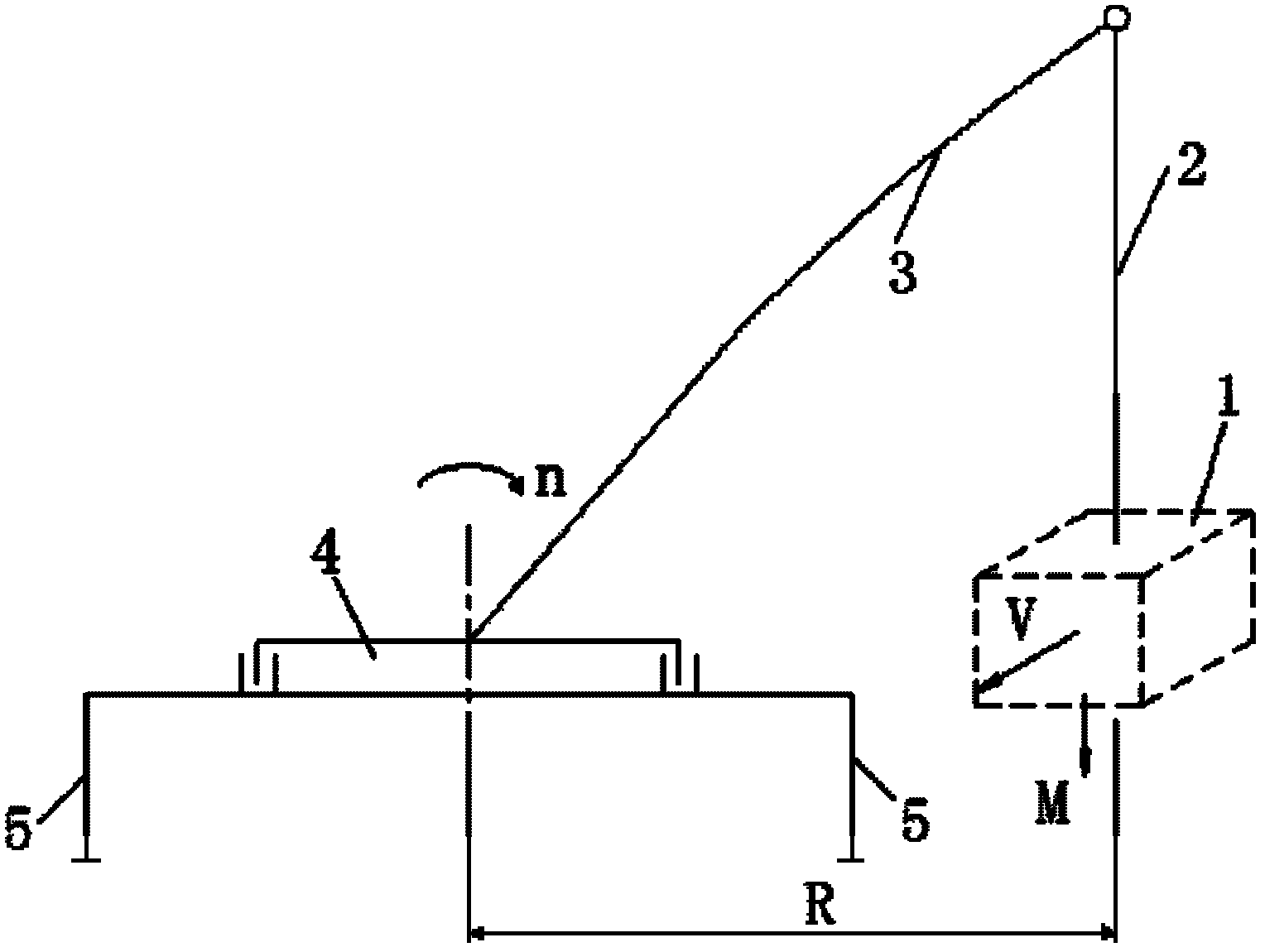

[0038] First of all, it should be noted that although the crane is mainly used as an example in the following description, it is obvious to those skilled in the art that the slewing constant power control method and its control system of the present invention can be widely applied to various cranes that need to be lifted. Heavy rotatable construction machinery, such as single-bucket excavators, etc. In addition, in the following description, some well-known technical contents will be appropriately briefly described.

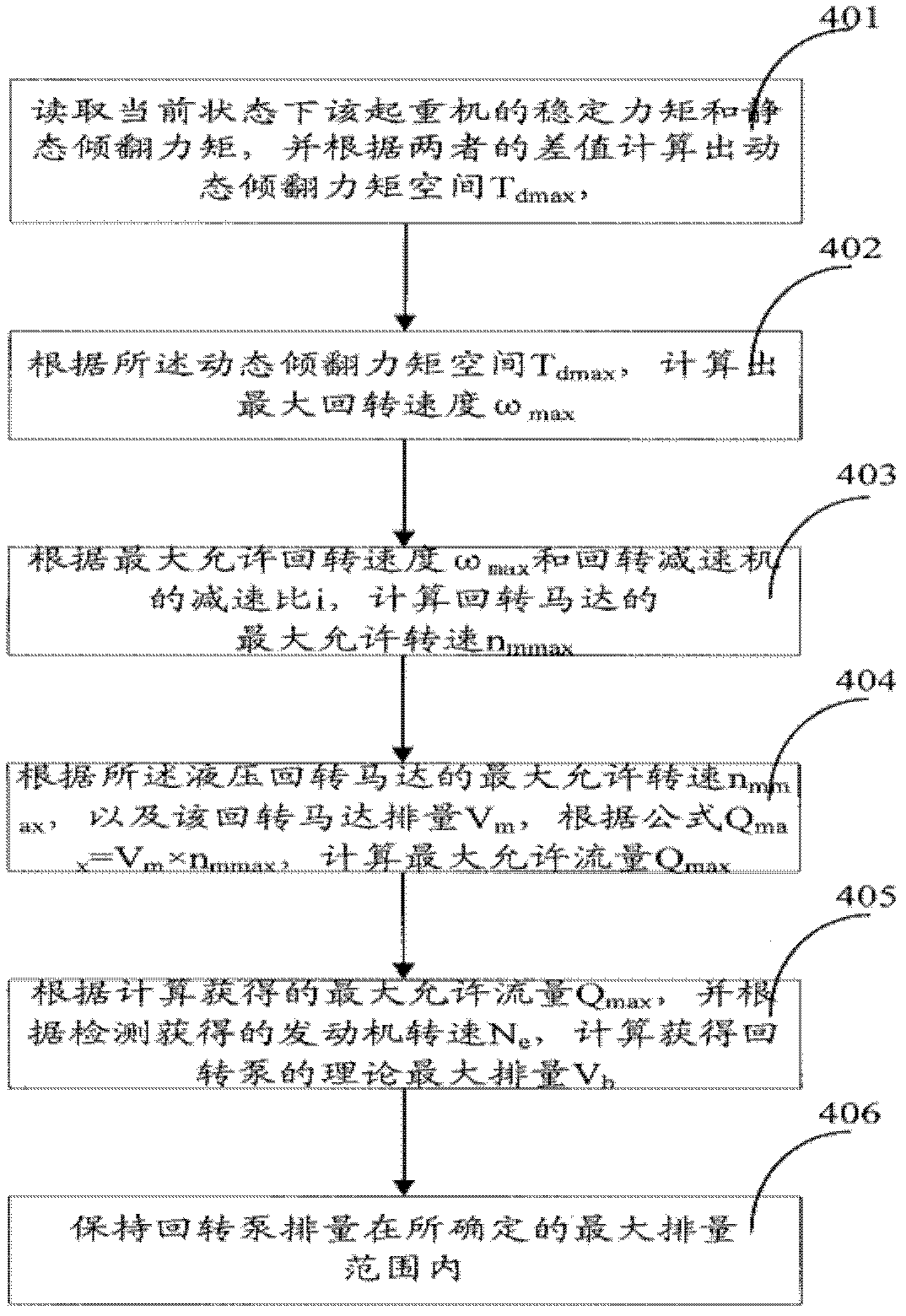

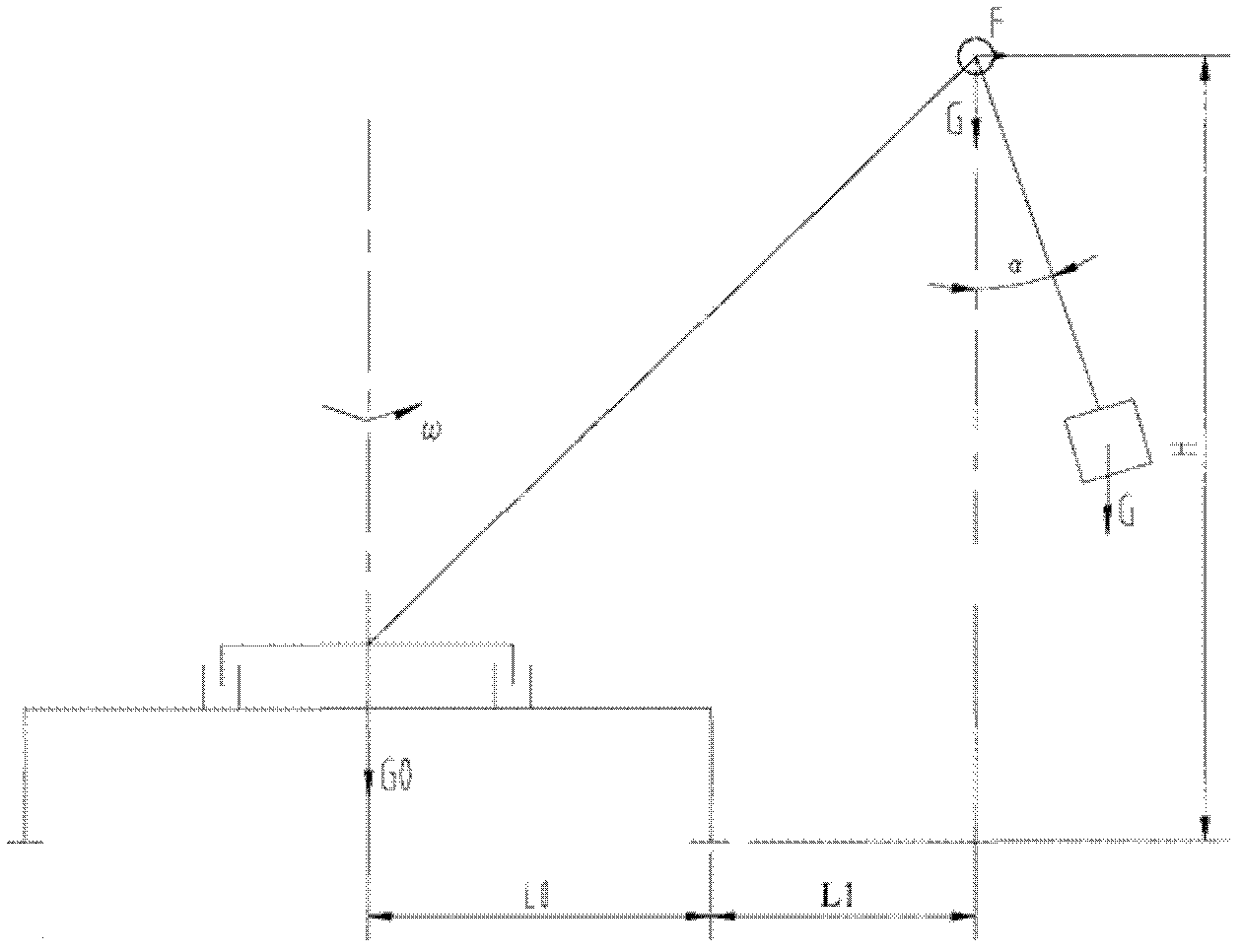

[0039] see image 3 As shown, when a rotatable engineering machine, such as a truck cra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com