Method and device for utilizing heat transported by a discontinuous flow of exhaust gases

A technology of exhaust gas flow and airflow, applied in thermal storage equipment, lighting and heating equipment, waste heat treatment, etc., can solve the problems of applying electric energy and uneven exhaust gas flow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

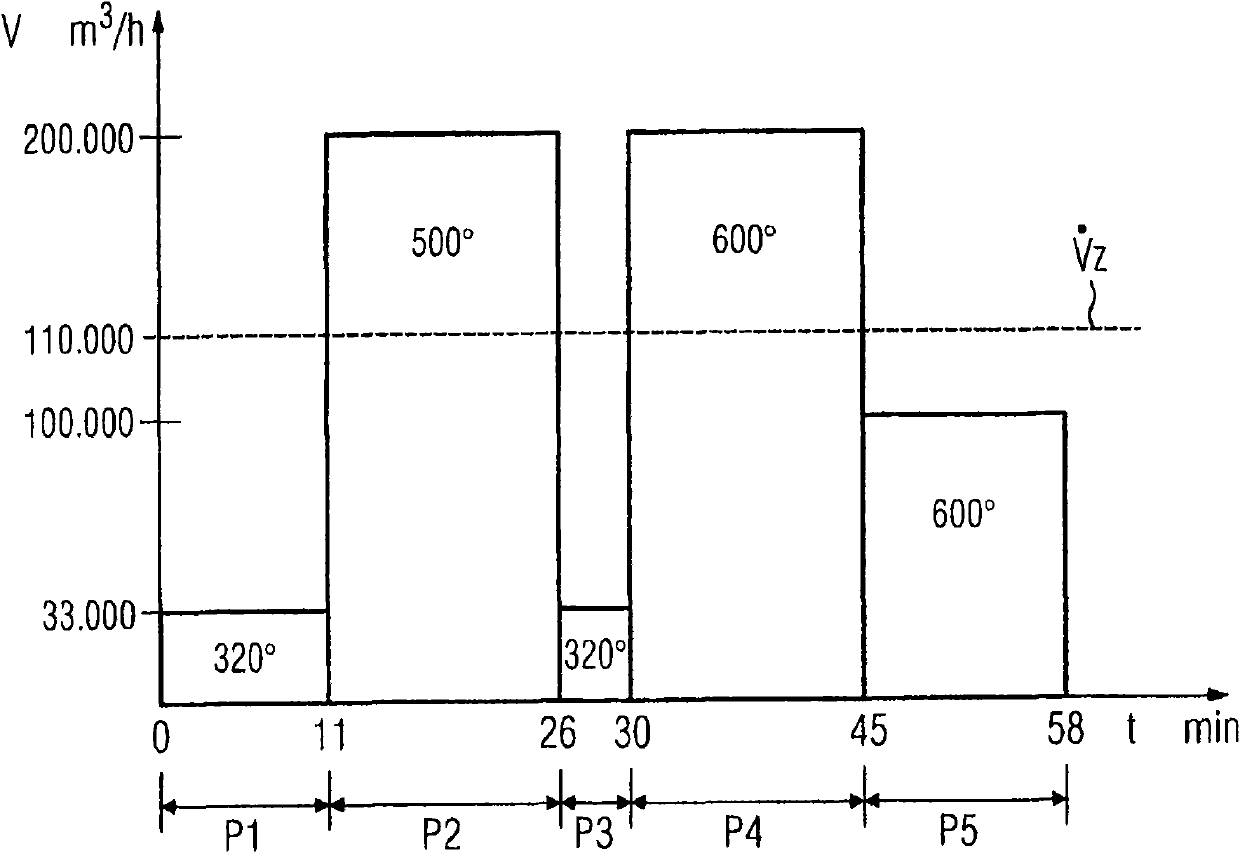

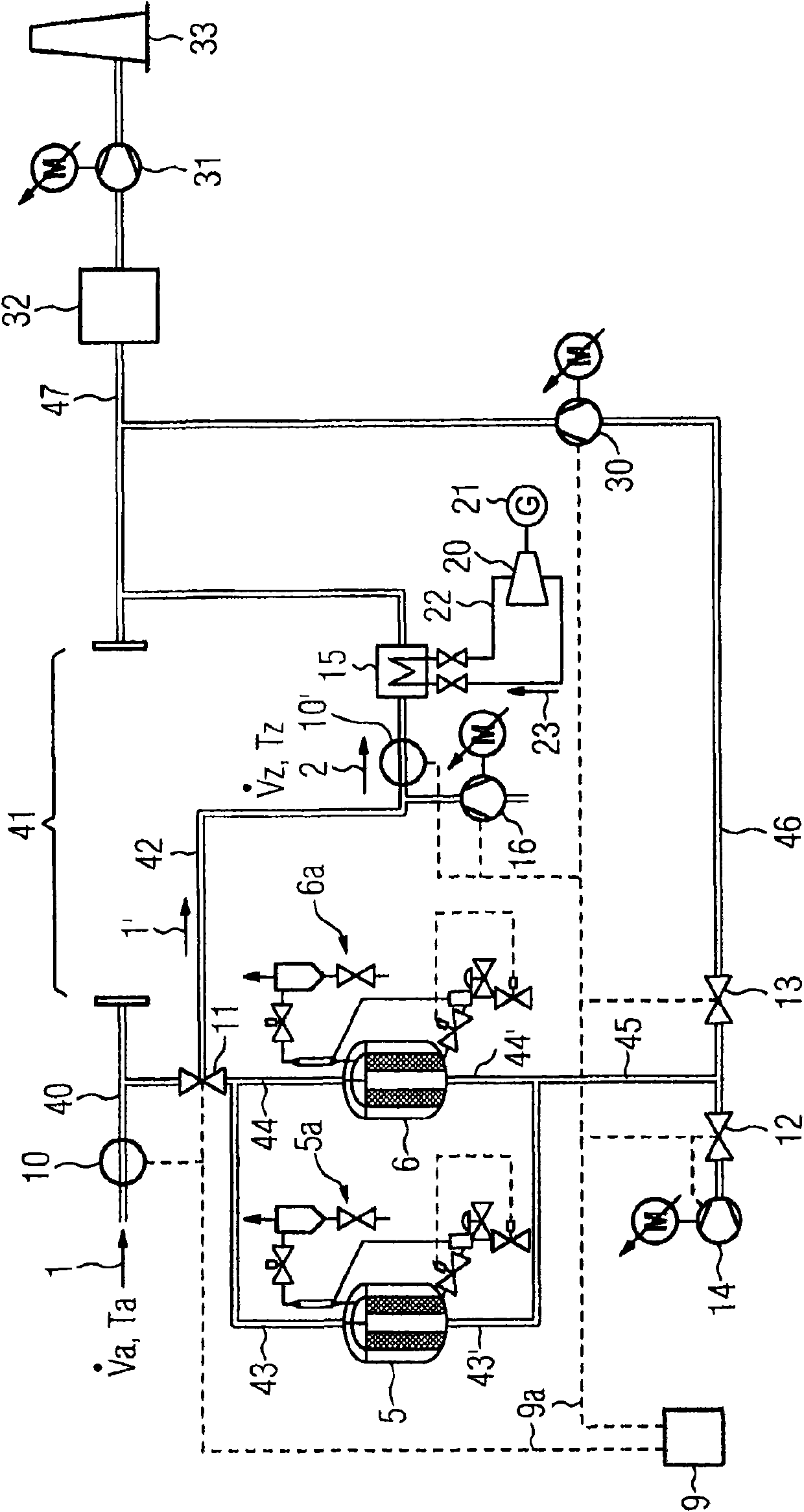

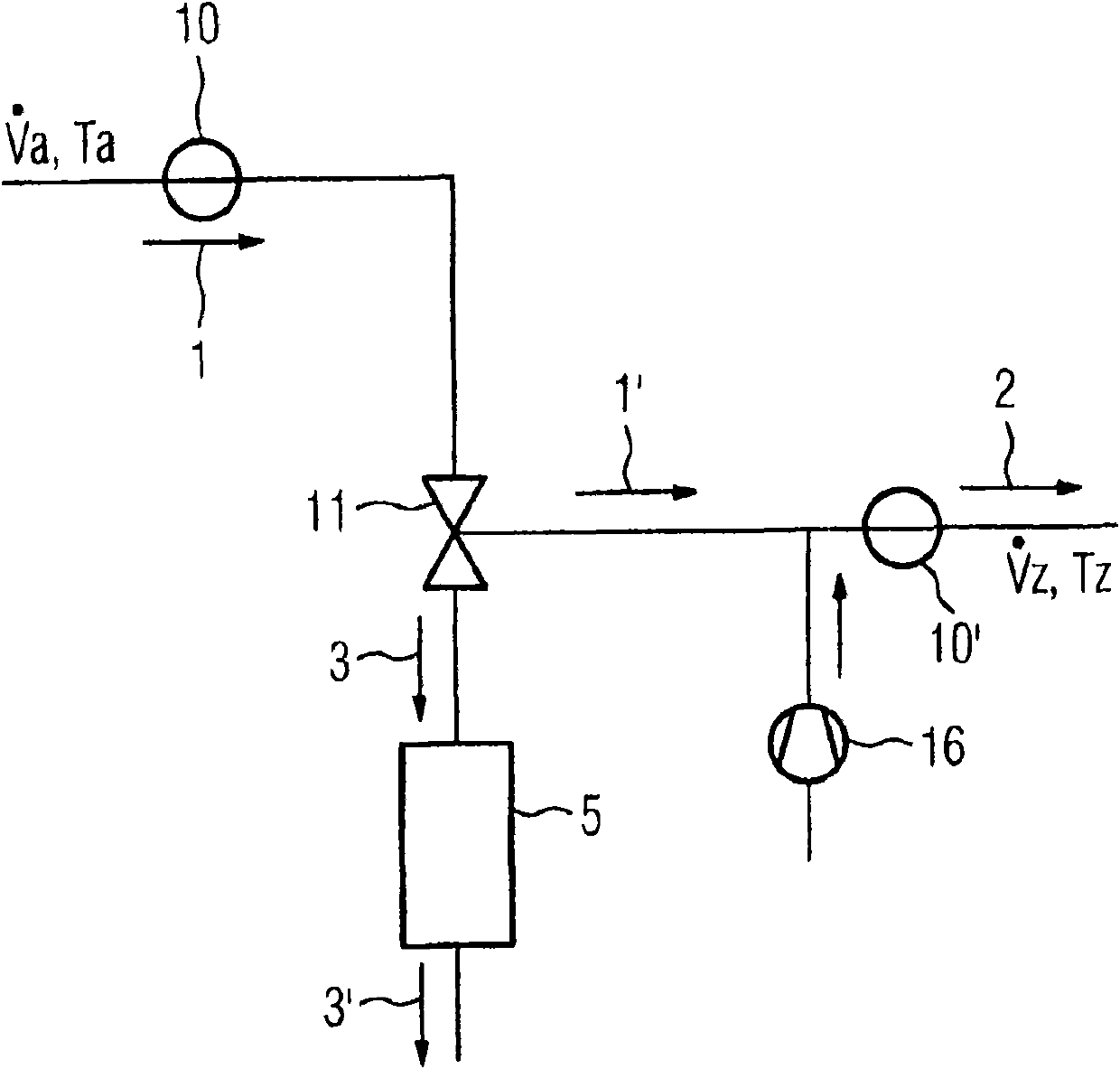

[0025] figure 1 The time curve of the volume flow of the discontinuous exhaust gas flow is shown (see below figure 2 denoted by 1), as it does in the exhaust gas stream produced by the operation of the electric arc furnace in a steel plant. Depending on the operating phase of the furnace, the exhaust gas flow has different volume flows and exhaust gas temperatures in successive operating phases P1 to P5 , but they are constant within an operating phase.

[0026] In the first operating phase P1, liquid steel flows out and fills the first waste basket again. During this phase P1, which lasts 11 minutes, the exhaust stream 1 has 33000m 3 / h volume flow and a temperature Ta of 320°C.

[0027] In the following second operating phase P2, the first melting process takes place, in which due to the volume flow and the jump in temperature Ta make the transition to this second operating phase P2 obvious. In the second operating phase P2, exhaust gas flow 1 has a duration of 15 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com