Patents

Literature

64results about "Better energy source" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

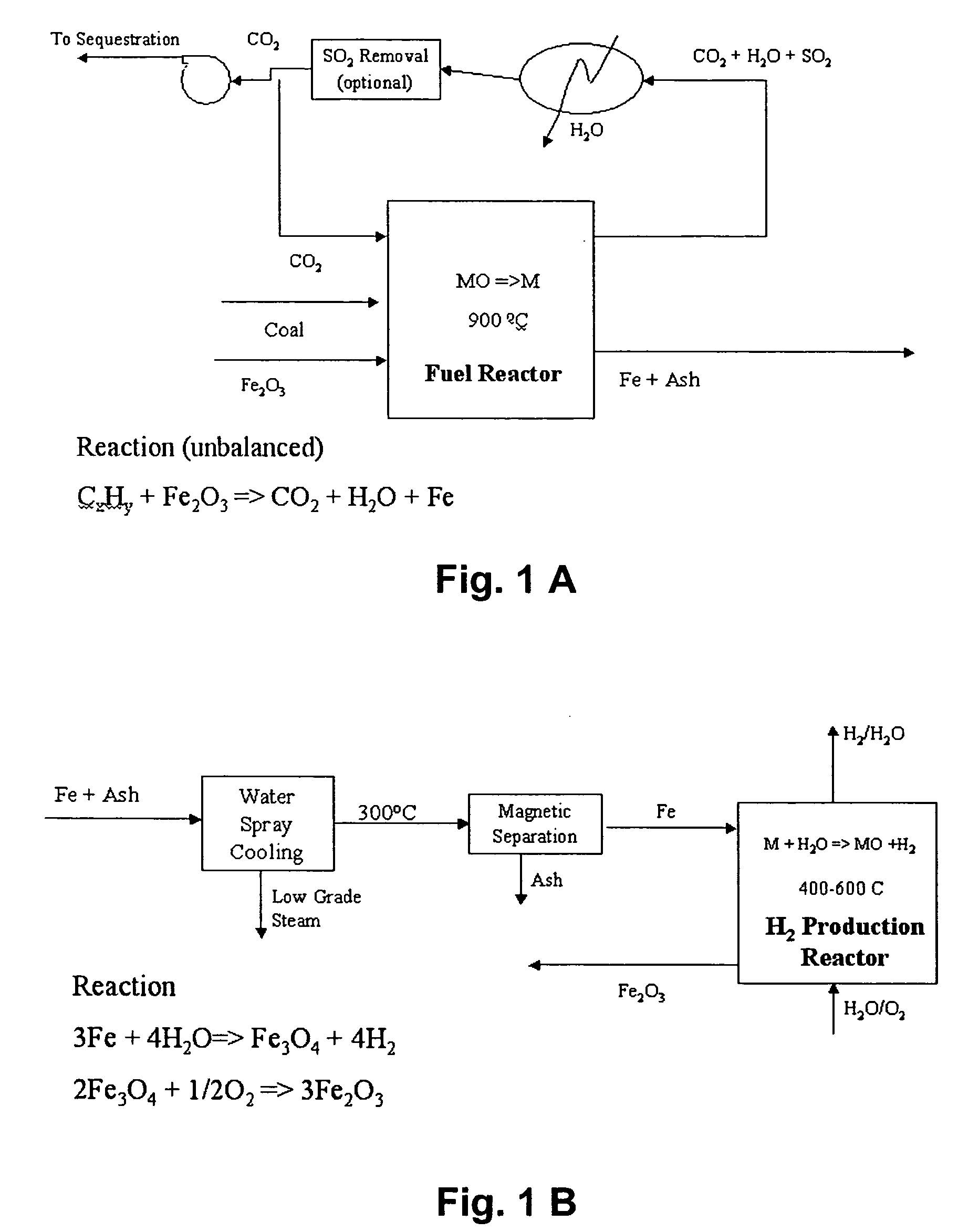

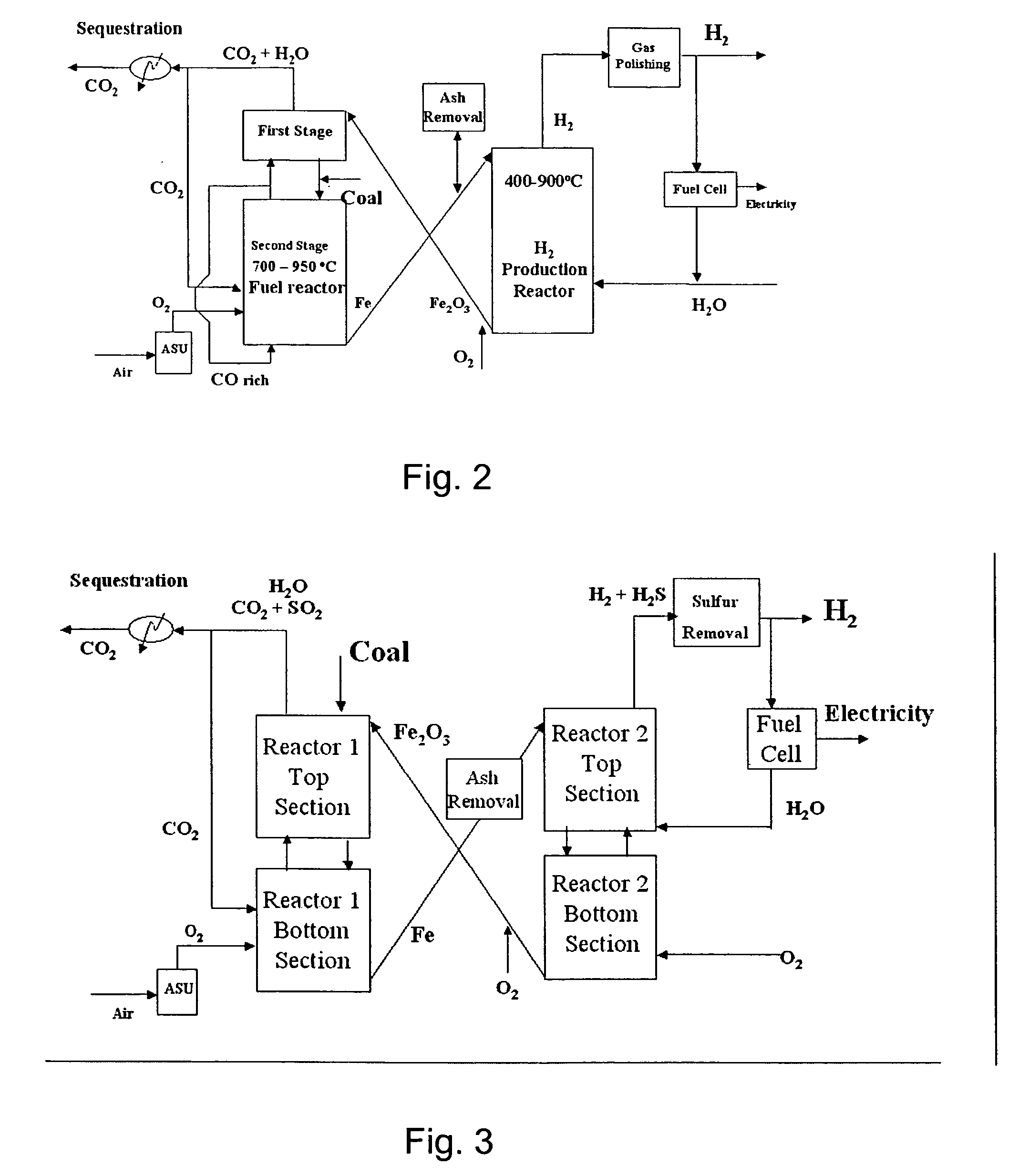

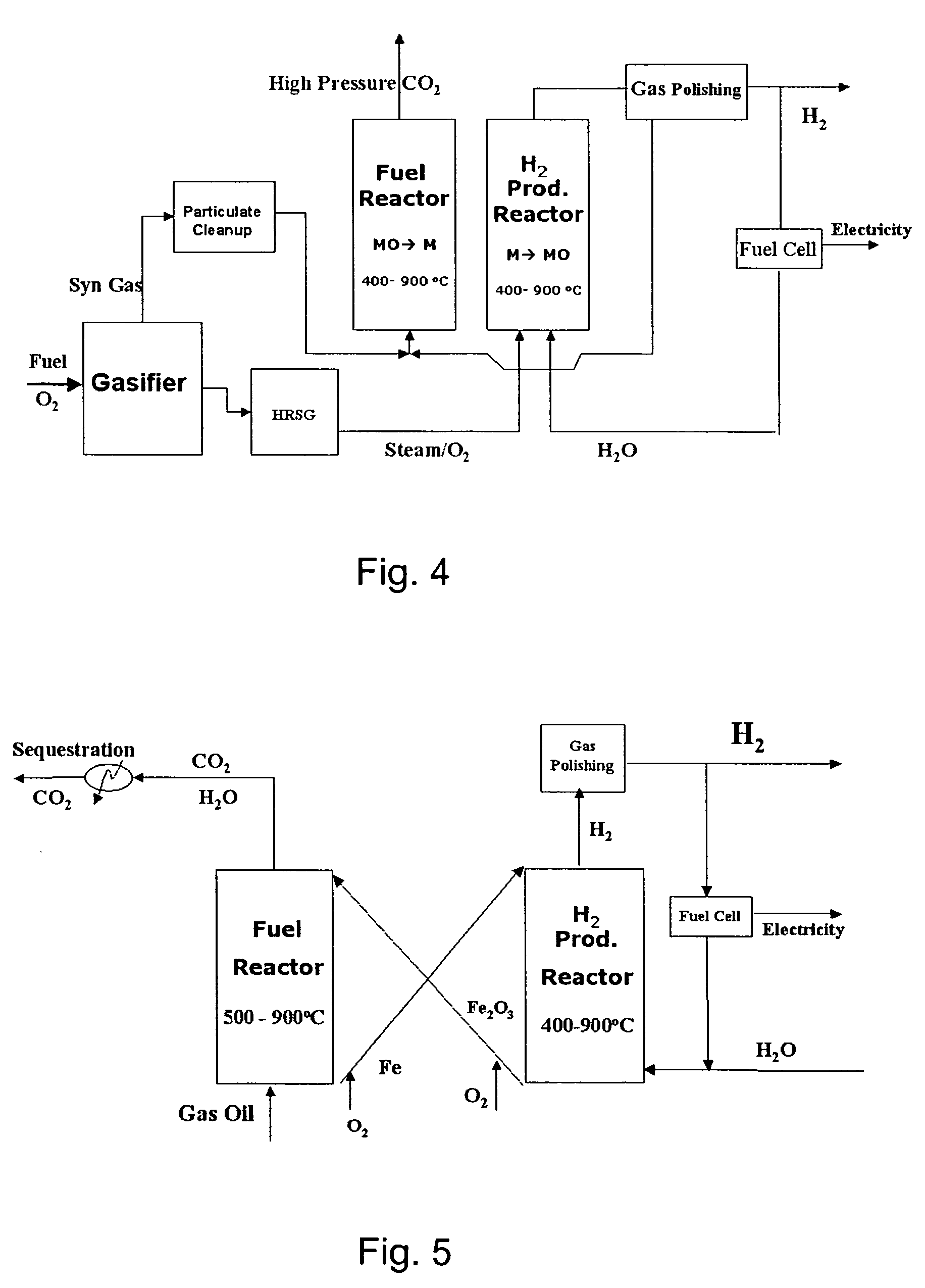

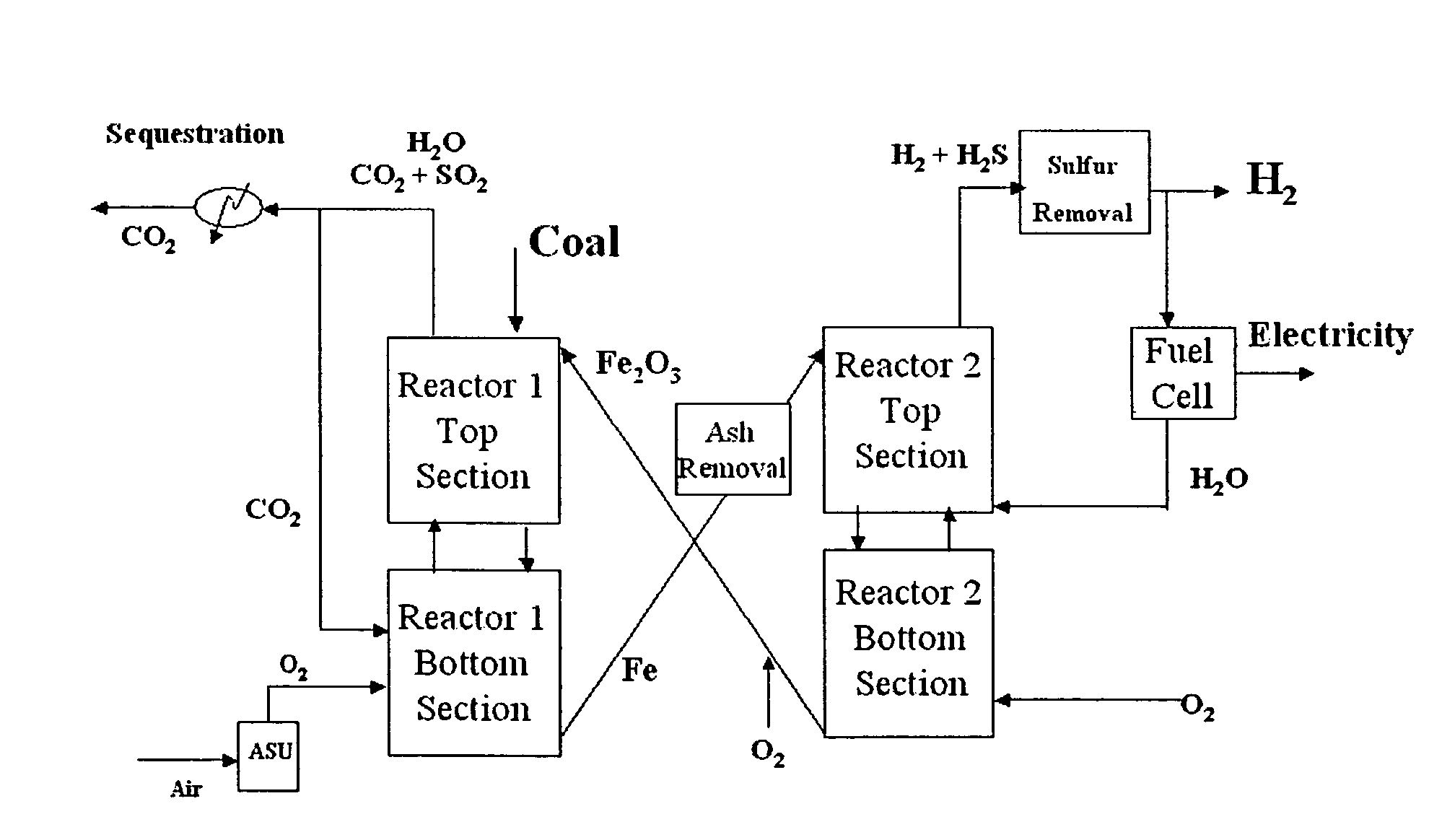

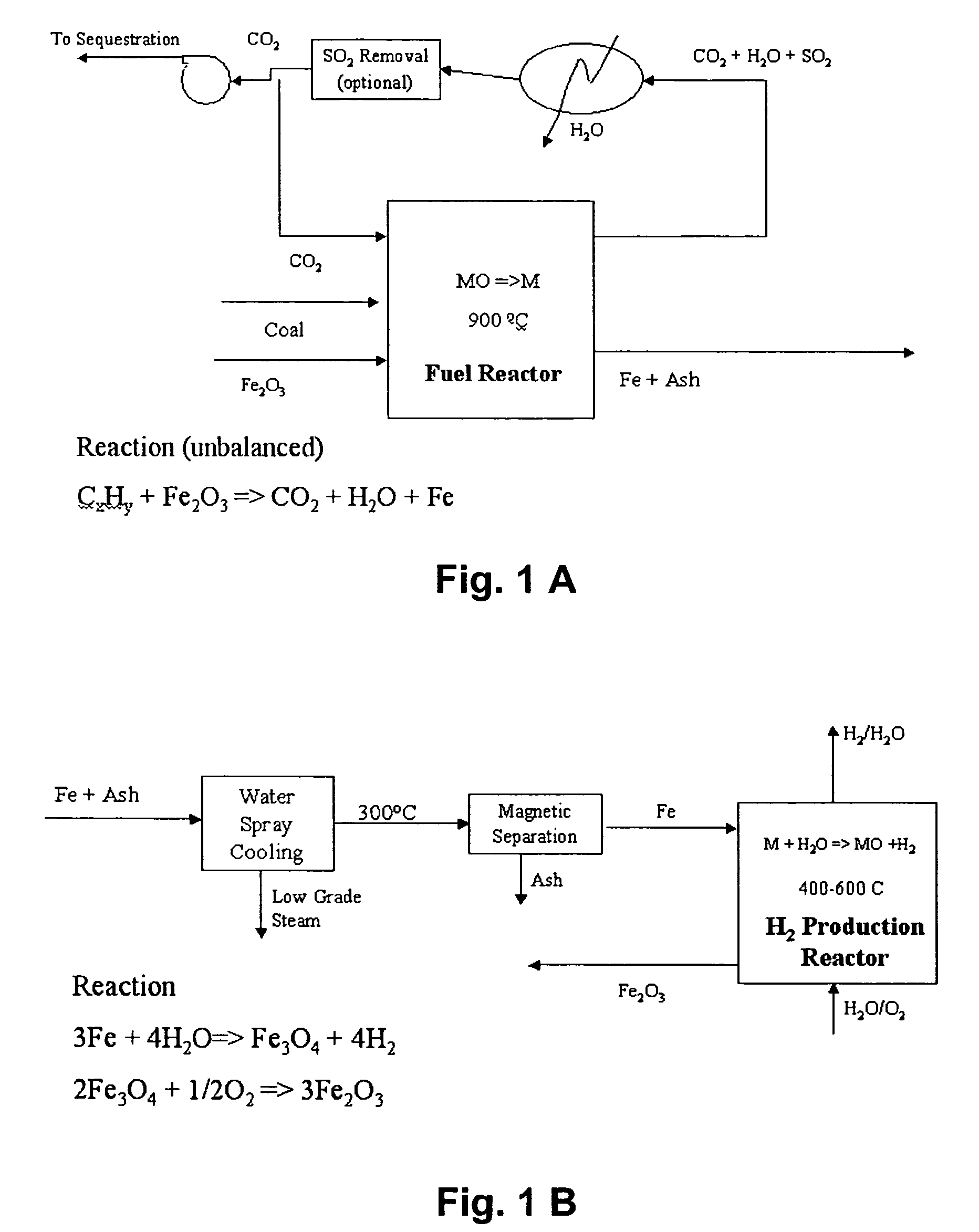

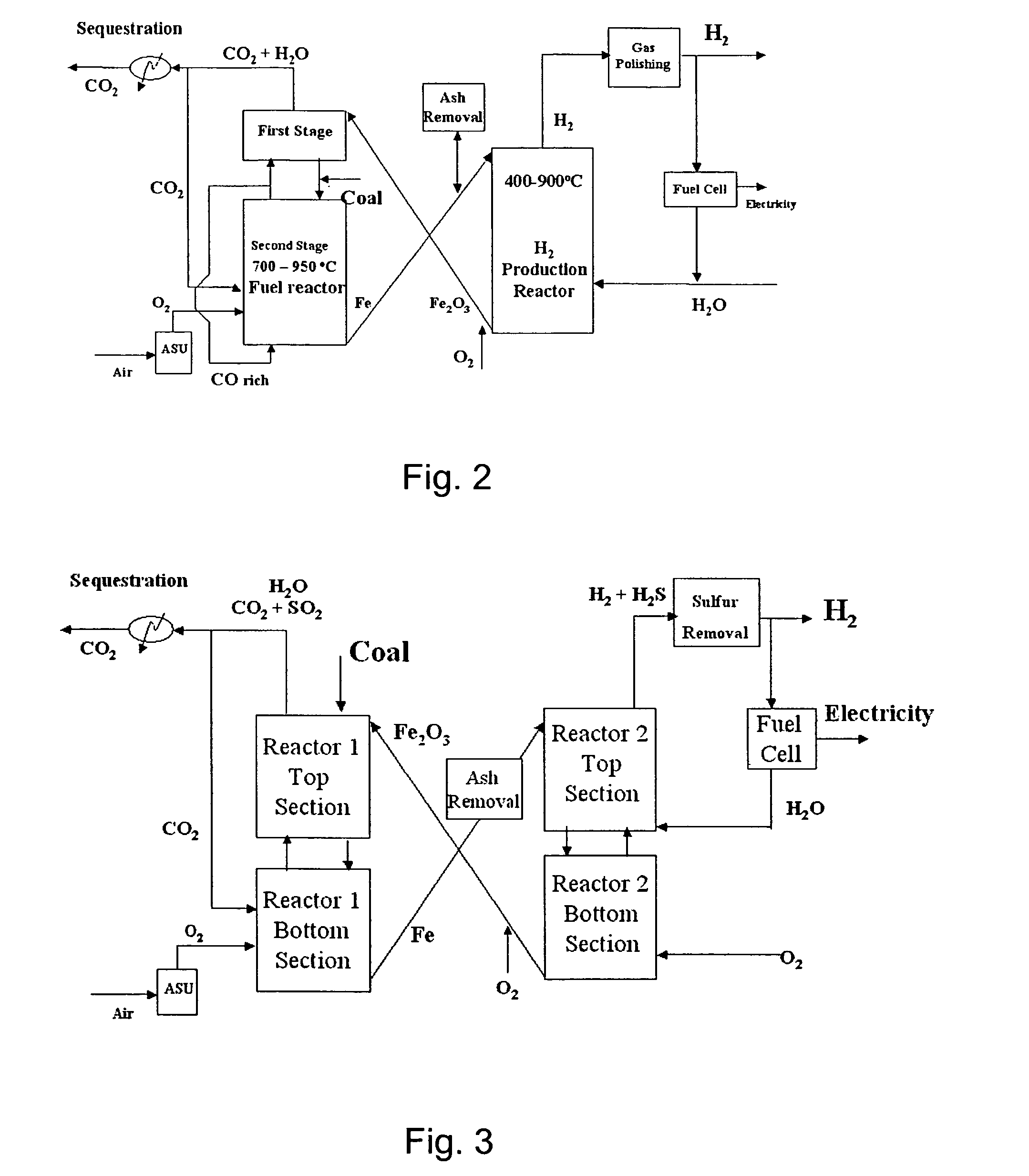

Combustion looping using composite oxygen carriers

ActiveUS20050175533A1Increase surface areaImprove energy conversion efficiencyHydrogen productionIndirect carbon-dioxide mitigationHydrogenCombustion

A method for producing hydrogen gas is provided and comprises reducing a metal oxide in a reduction reaction between a carbon-based fuel and a metal oxide to provide a reduced metal or metal oxide having a lower oxidation state, and oxidizing the reduced metal or metal oxide to produce hydrogen and a metal oxide having a higher oxidation state. The metal or metal oxide is provided in the form of a porous composite of a ceramic material containing the metal or metal oxide. The porous composite may comprise either a monolith, pellets, or particles.

Owner:OHIO STATE INNOVATION FOUND

Combustion looping using composite oxygen carriers

ActiveUS7767191B2Increase surface areaImprove energy conversion efficiencyHydrogen productionIndirect carbon-dioxide mitigationHydrogenCombustion

A method for producing hydrogen gas is provided and comprises reducing a metal oxide in a reduction reaction between a carbon-based fuel and a metal oxide to provide a reduced metal or metal oxide having a lower oxidation state, and oxidizing the reduced metal or metal oxide to produce hydrogen and a metal oxide having a higher oxidation state. The metal or metal oxide is provided in the form of a porous composite of a ceramic material containing the metal or metal oxide. The porous composite may comprise either a monolith, pellets, or particles.

Owner:OHIO STATE INNOVATION FOUND

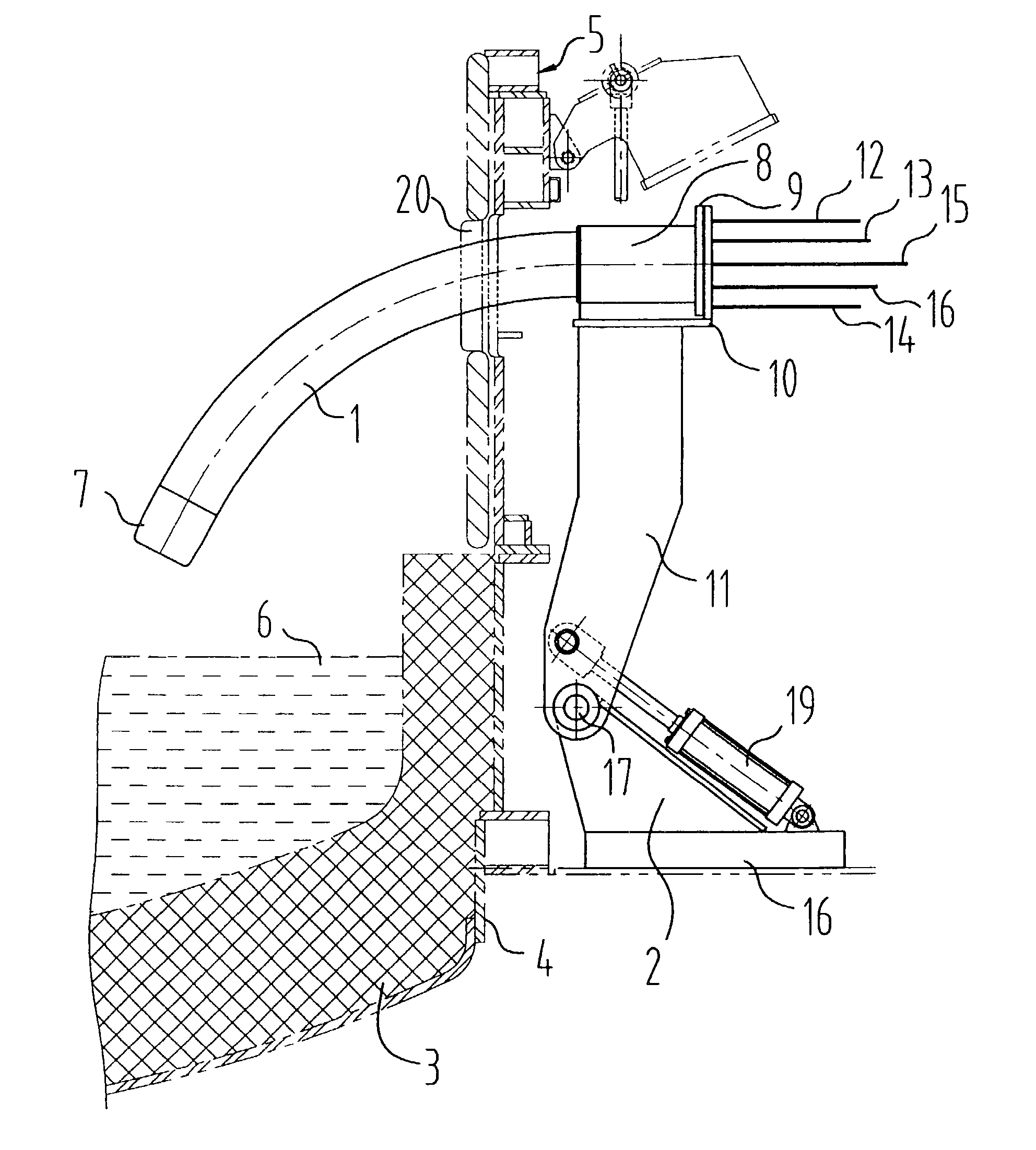

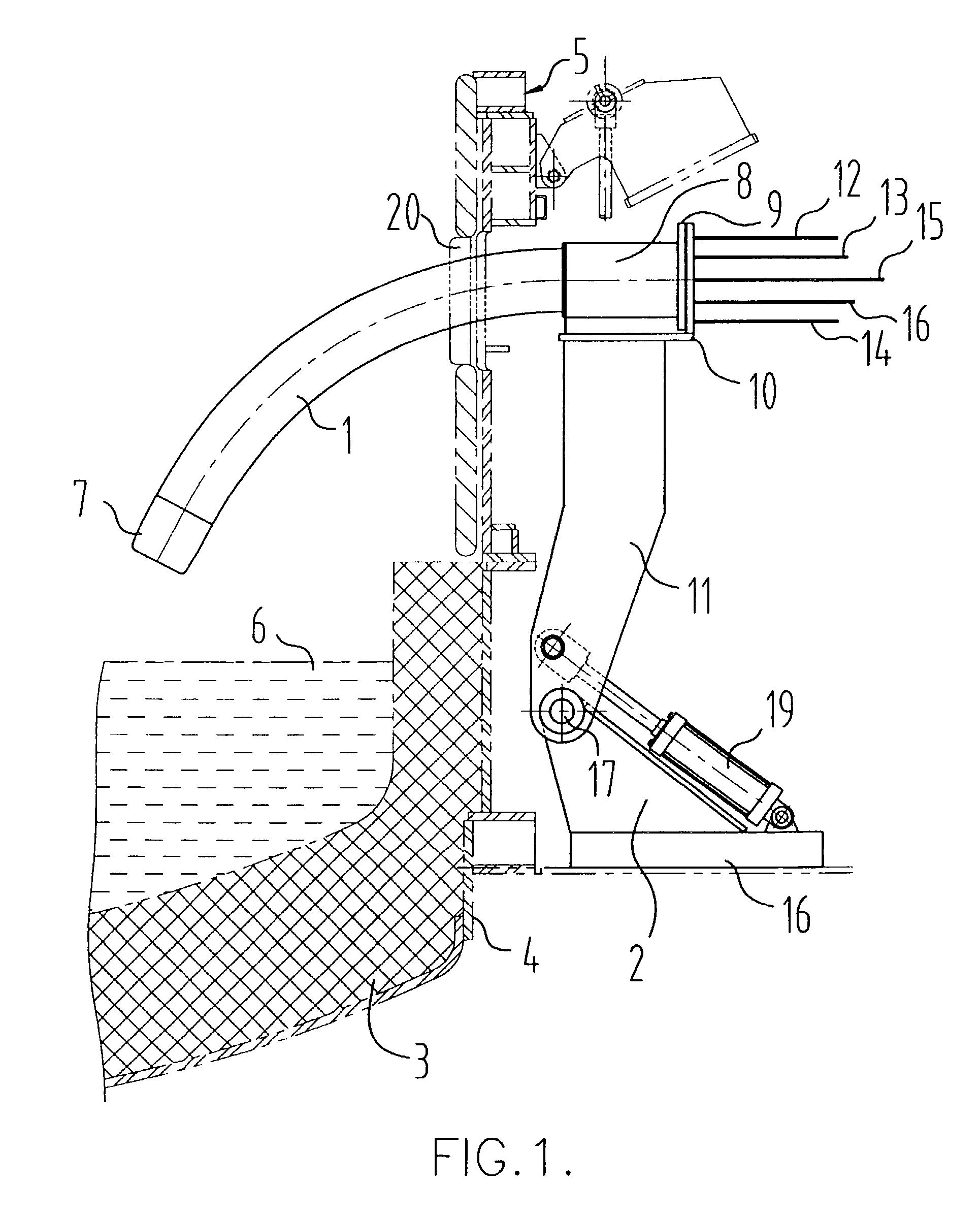

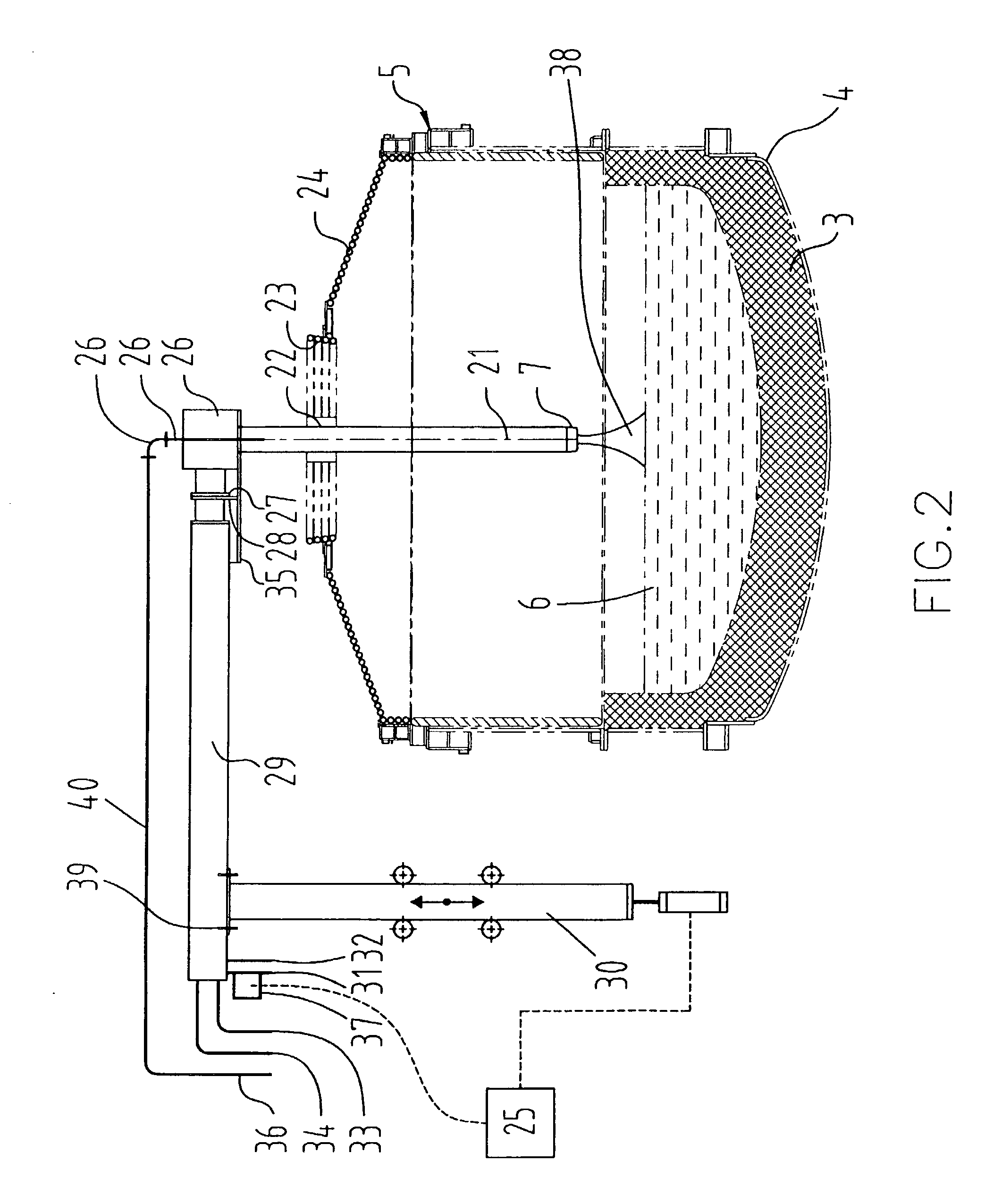

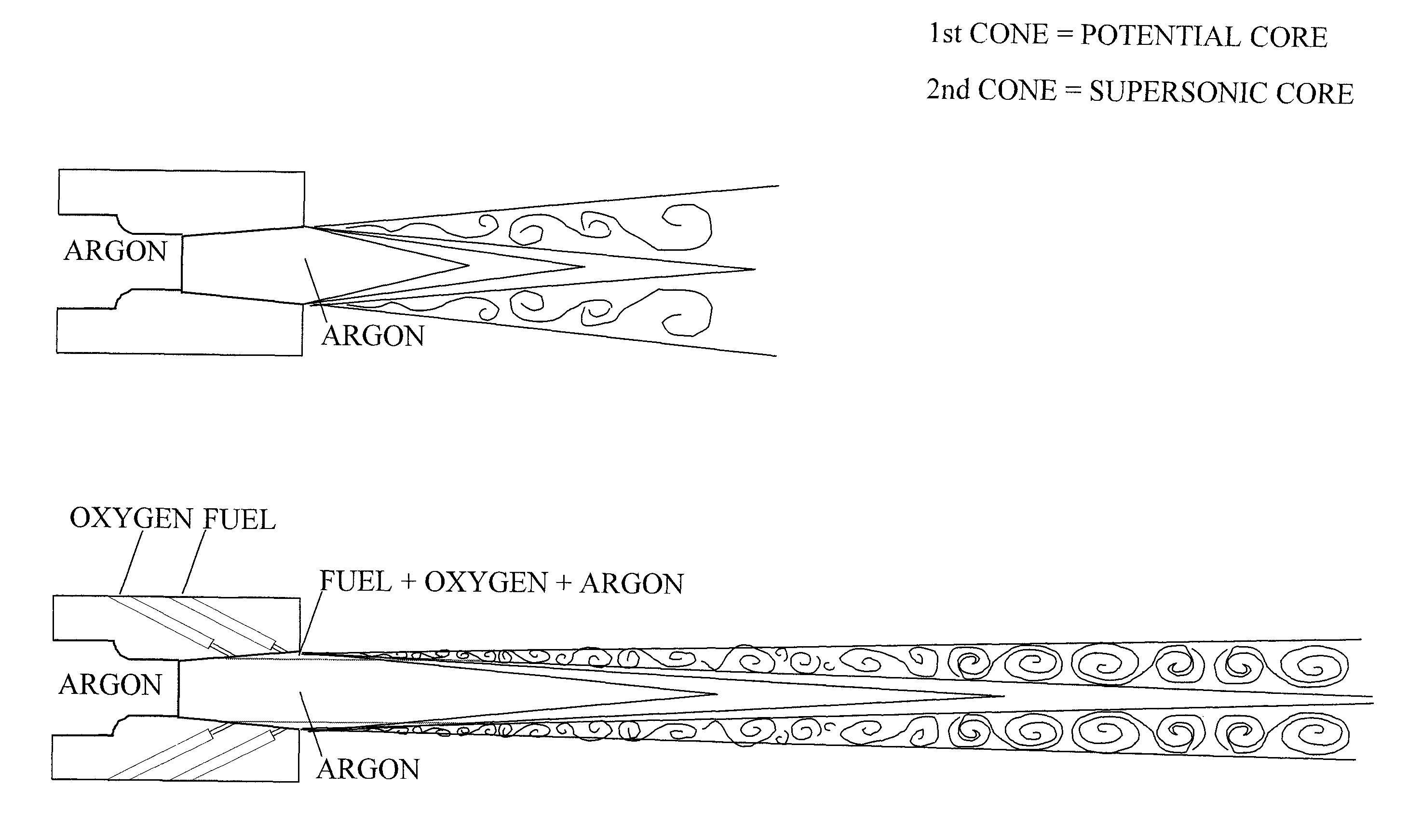

Multi-purpose, multi-oxy-fuel, power burner/injector/oxygen lance device

InactiveUS20030075843A1Reduce the numberSmall sizeTuyeresCharge manipulationSteelmakingLiquid medium

A multi-purpose, multi-oxy-fuel High Temperature Power Burner / Injector / Oxygen Lance, Mechanical System Apparatus Device, for steelmaking from recycled scrap and / or virgin ferrous charge, which can be employed in multi-oxy-fuel (natural gas; pulverized carbonaceous matter; heavy oil), especially by Oxygen Combusted mixture of Natural Gas / Pulverized Carbonaceous Matter in High Temperature Power Burner Mode, for efficient and rapid melting of solid ferrous charge (cold or preheated) in a special steelmaking Metallurgical Furnace or Open Hearth Furnace, Tandem Furnace, BOF, EAF, as its augmenting or only source of thermal energy; more than one Device in Oxygen-Natural Gas / Pulverized Carbonaceous Matter Power Burner Mode, can be employed as the only source of thermal energy in a modified, originally Electric Arc Furnace, as total replacement of Graphite Electrodes and Electric Arc System, the replacement being noticeably more primary energy efficient than the thermal energy provided by Graphite Electrode / Arc System; it also can be employed in an Solid Particles Injector Mode, for injecting of adequately granulated carbonaceous materials or lime into the molten steel for its carburizing or for foamy slag control; further it can be employed in a natural gas shrouded, pulsating oxygen stream, for vertically to the charge oriented soft blow supersonic Oxygen Injection Lance Mode, for decarburization of the molten metal contained in the hearth of the metallurgical furnace and foamy slag control; in one of the embodiments-generally arcuate-pivotally mounted, liquid media cooled composite body, is pivoted into and out of a furnace vessel through a small opening in the shell wall for auto-regulated constant optimal positioning of the Composite Body Tip against solid or molten charge, in each and all multi-purpose modes; furthermore, when inserted into the furnace vessel, the arcuate composite body can be rotated about its longitudinal axis for directing the oxy-fuel high temperature flame towards unmolten charge in the furnace; in an other-generally linear-embodiment, the liquid cooled composite body is attached to the mast type carrier allowing vertical movement of the composite body which enters the furnace vessel through a small opening in the furnace roof; the bimetallic, liquid cooled special tip assembly of both-arcuate and linear embodiments-of the composite body includes easy replaceable, independent, multi-opening nozzles, mounted in a protective, retracted position inside of the liquid cooled special tip assembly.

Owner:EMPCO (CANADA) LTD

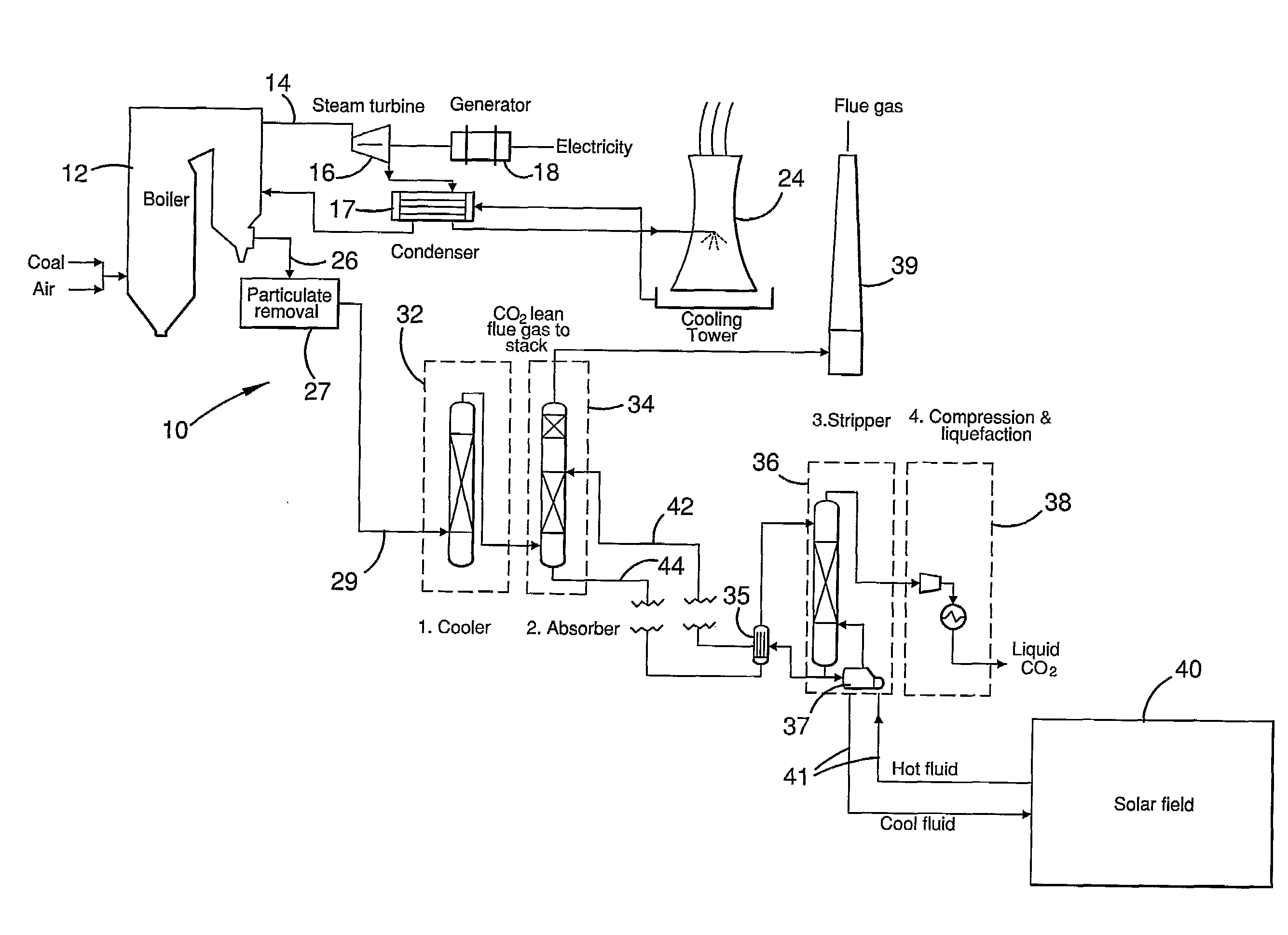

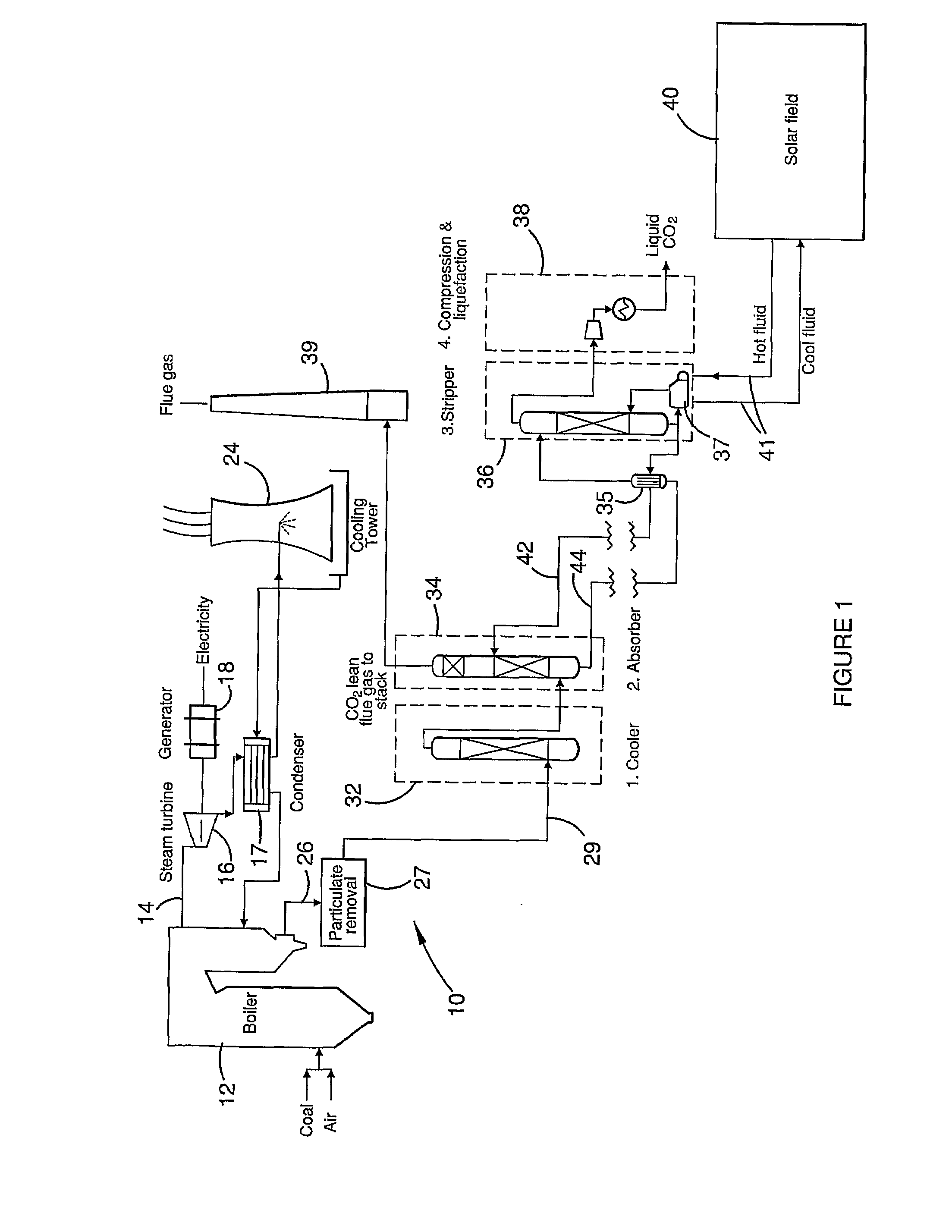

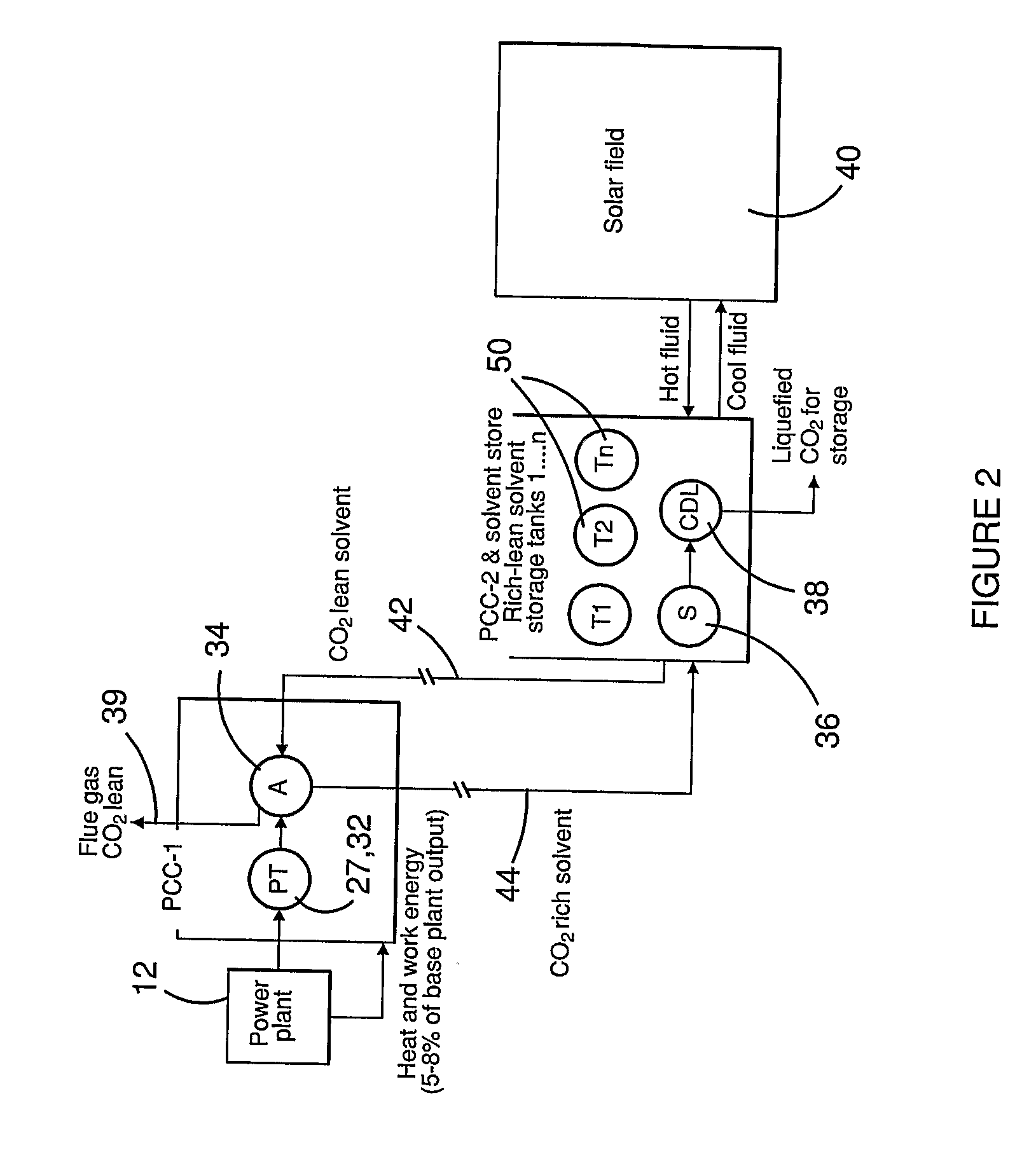

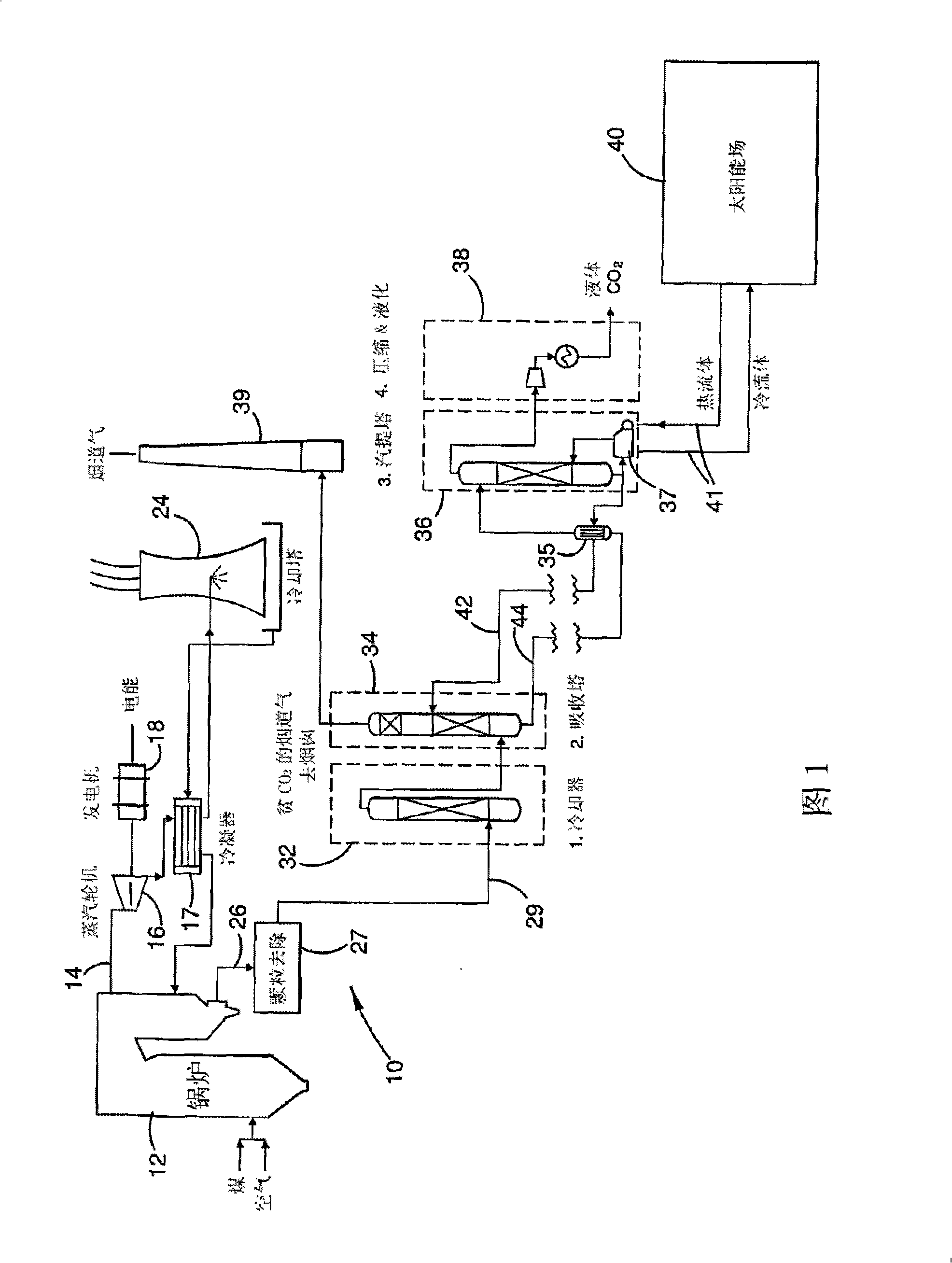

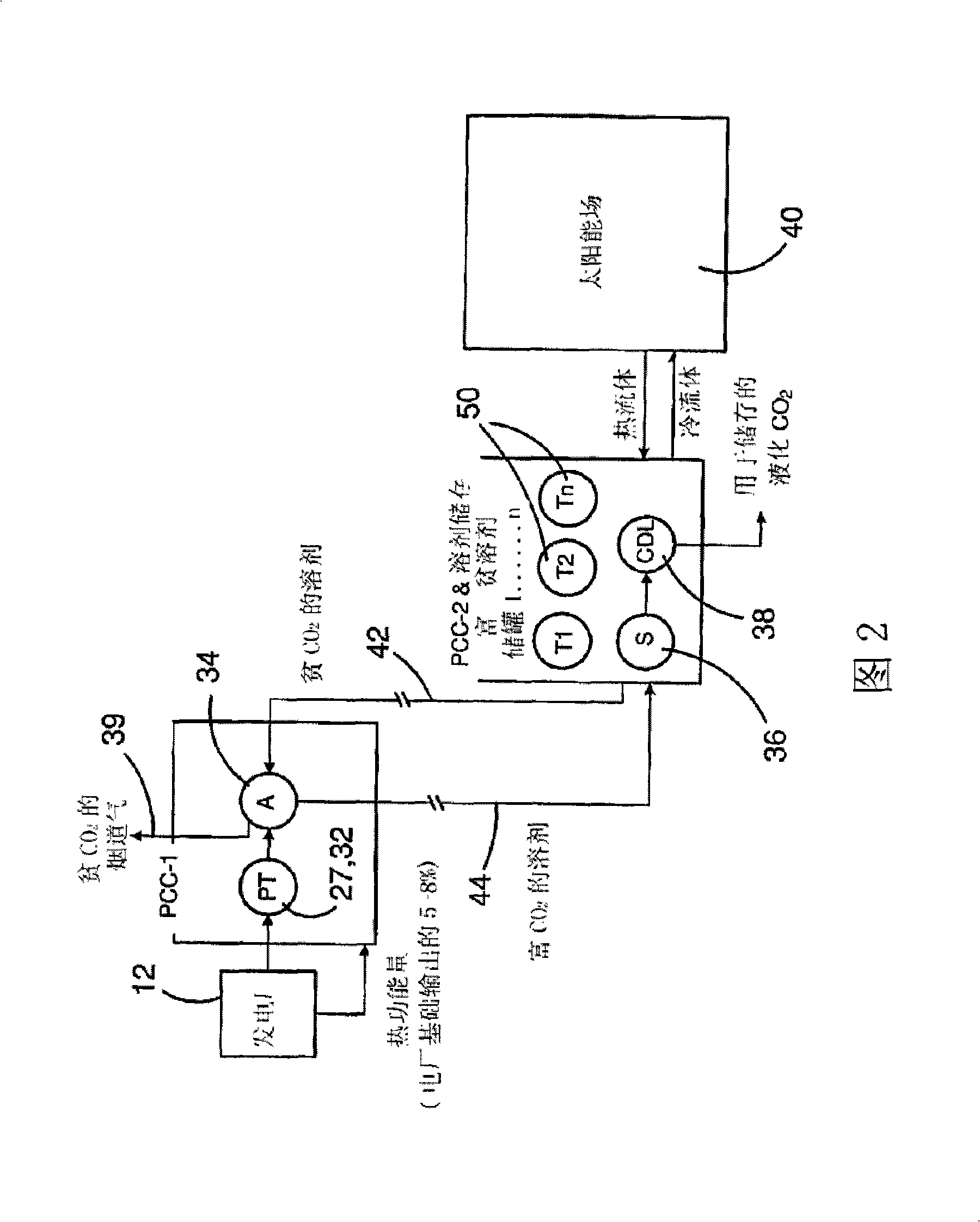

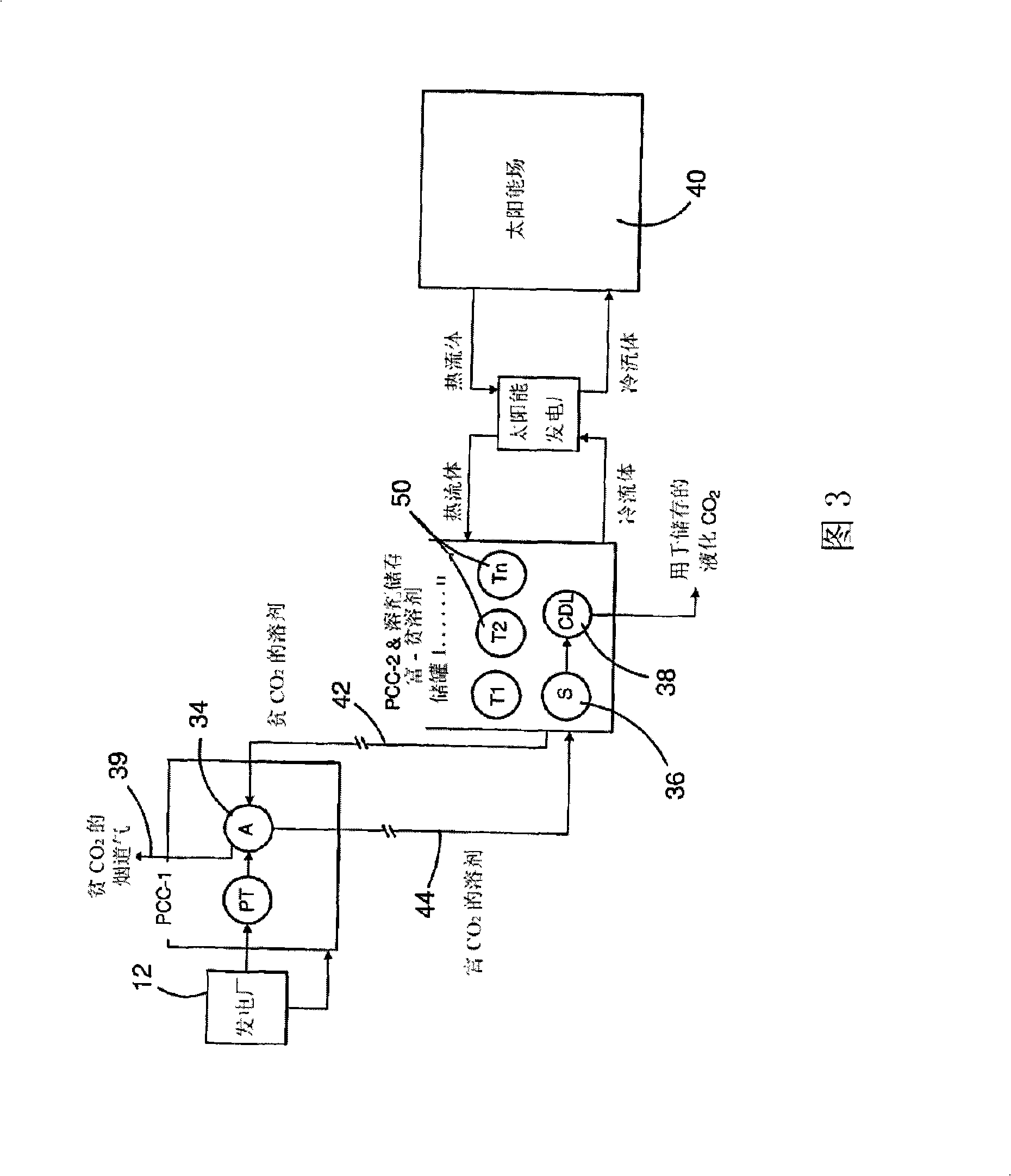

Co2 capture using solar thermal energy

InactiveUS20100005966A1Efficiently employedImprove efficiencySolar heating energyLiquid degasificationThermal energyWorking fluid

At an absorber station, CO2 is absorbed from a gas stream into a suitable solvent whereby to convert the solvent into a CO2-enriched medium, which is conveyed to a desorber station, typically nearer to a solar energy field than to the absorber station. Working fluid, heated in the solar energy field by insolation, is employed to effect desorption of CO2 from the CO2-enriched medium, whereby to produce separate CO2 and regenerated solvent streams. The regenerated solvent stream is recycled to the absorber station. The CO2-enriched medium and / or the regenerated solvent stream may be selectively accumulated so as to respectively optimise the timing and rate of absorption and desorption of CO2 and / or to provide a storage of solar energy.

Owner:COMMONWEALTH SCI & IND RES ORG

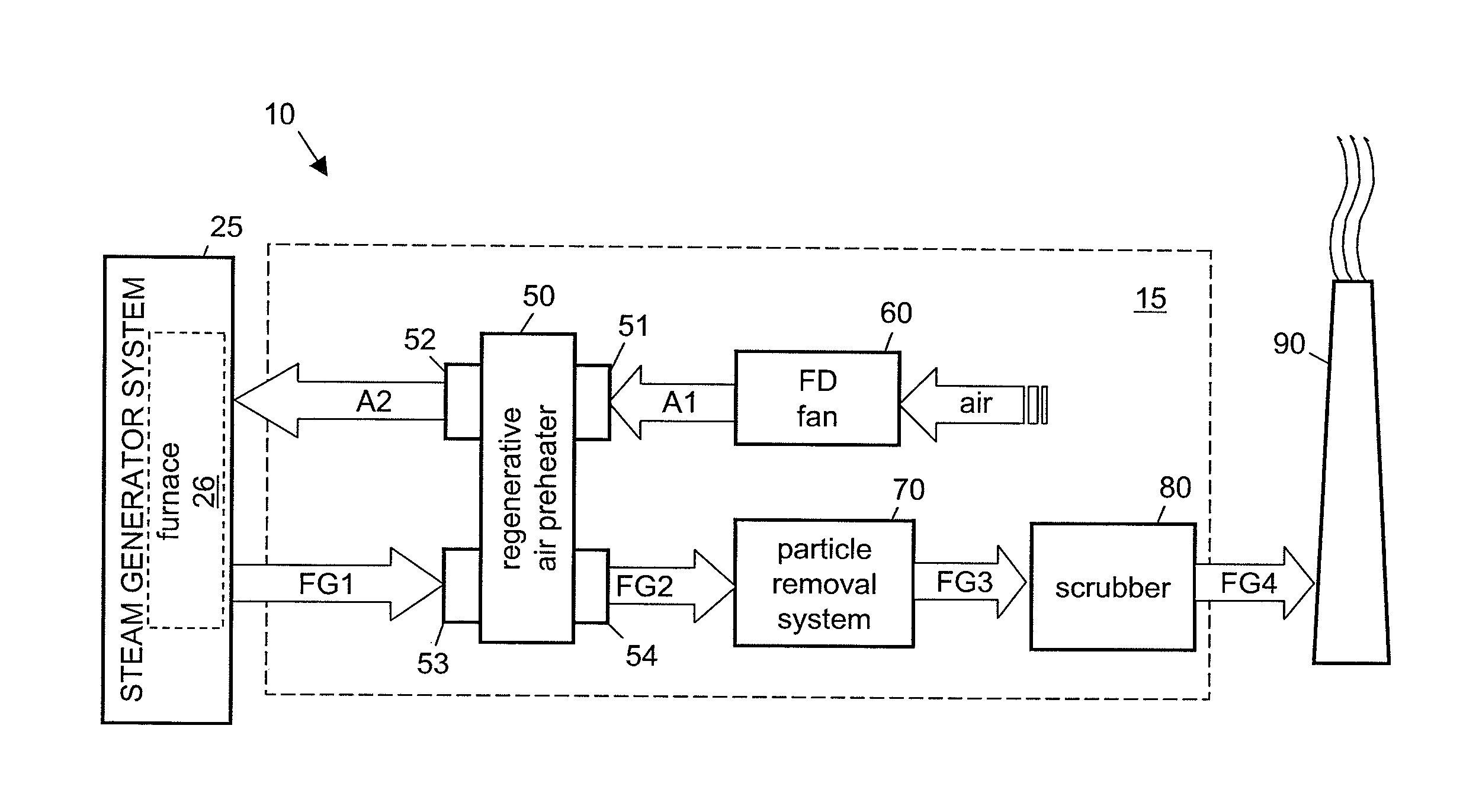

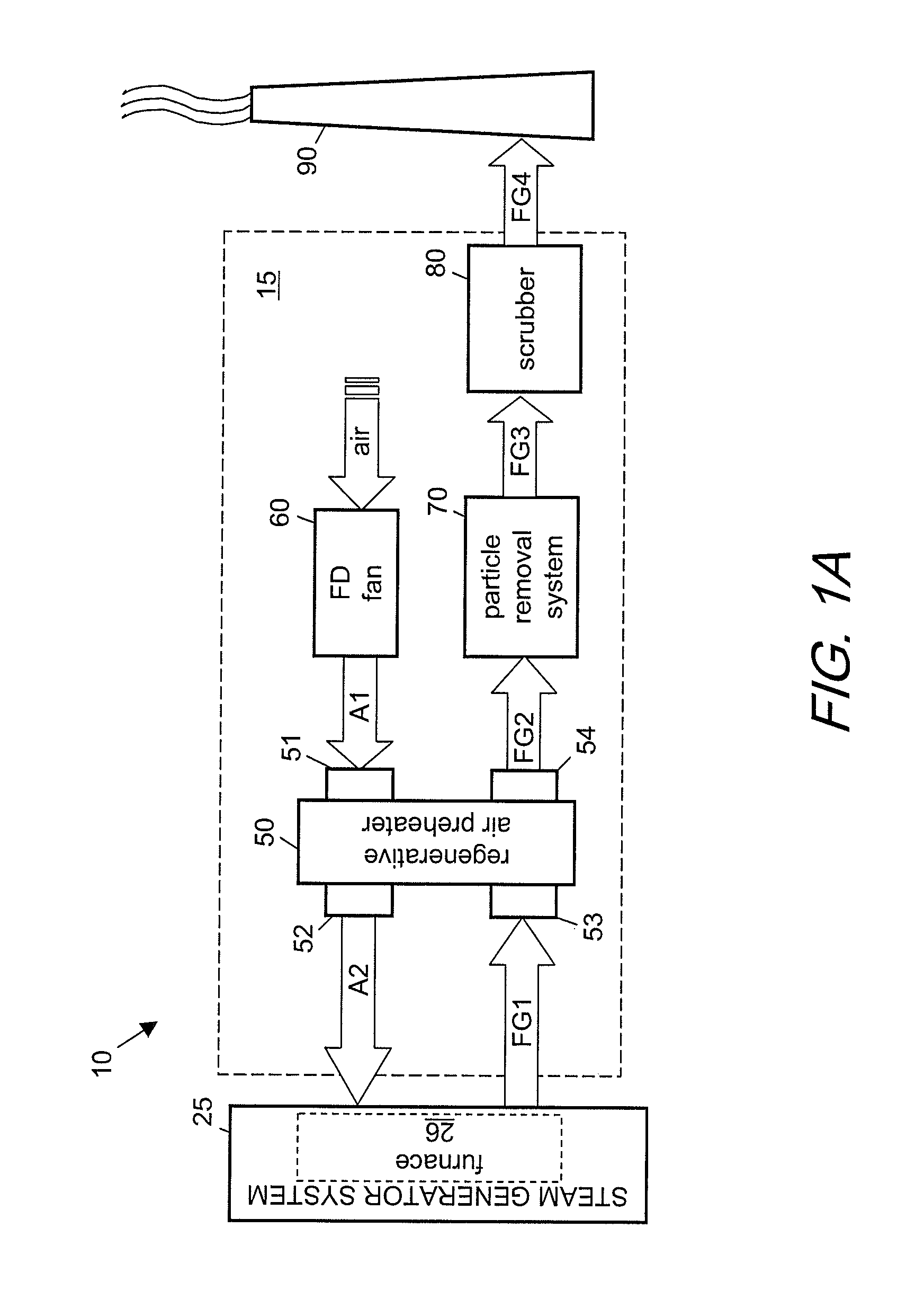

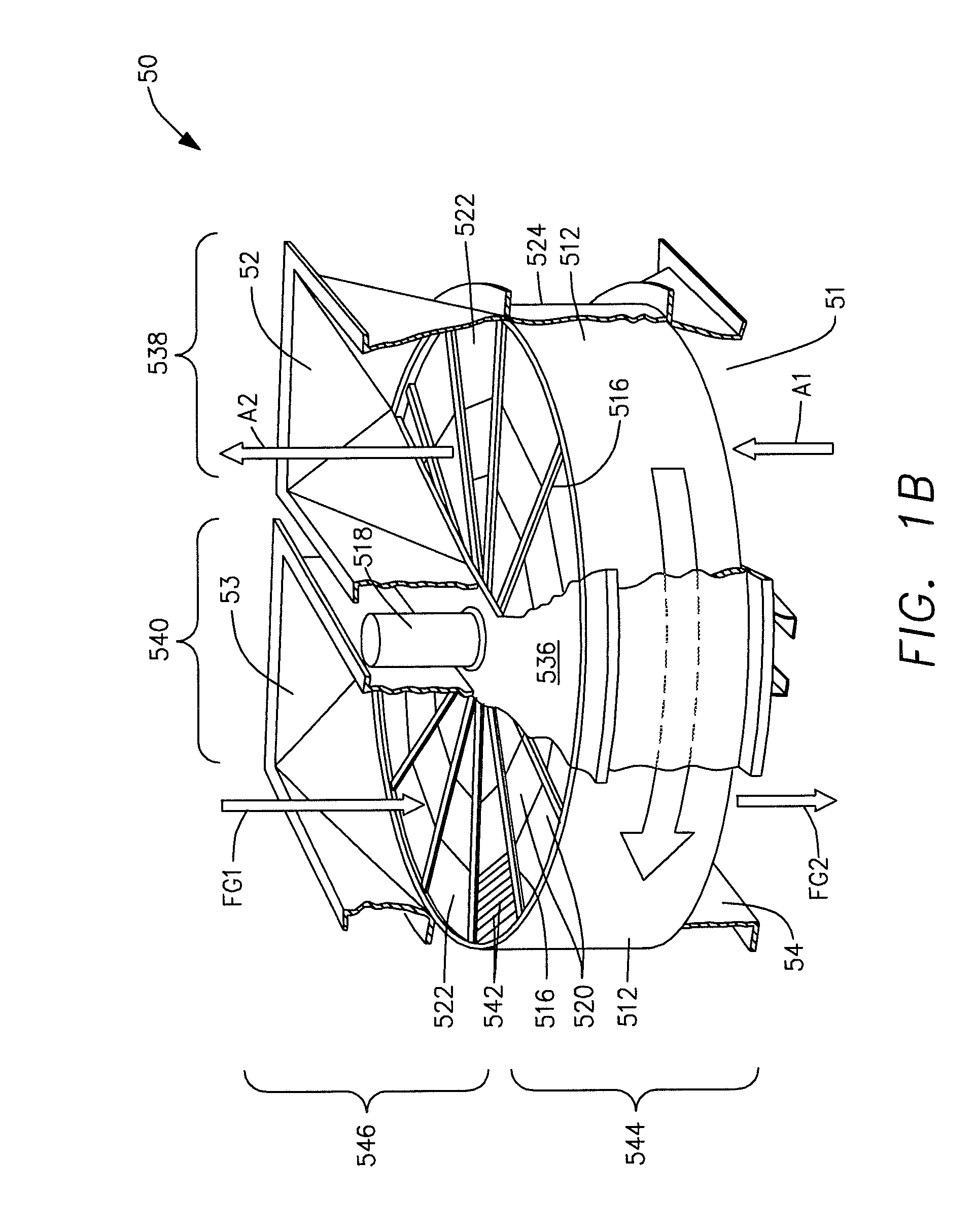

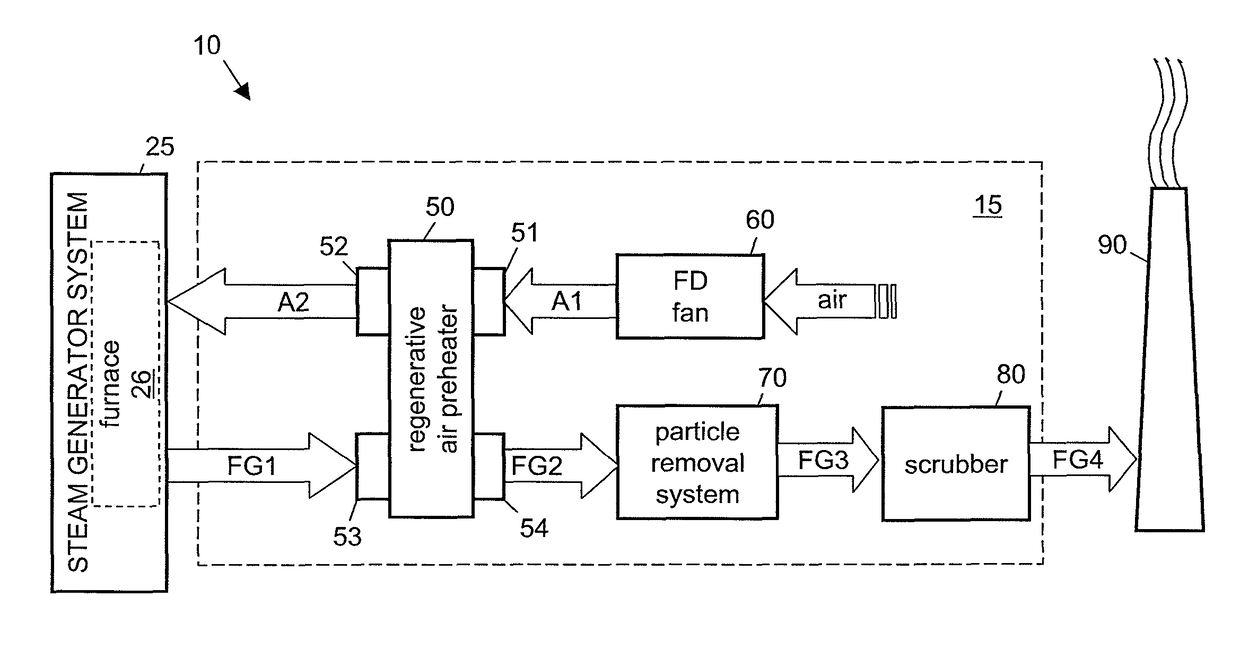

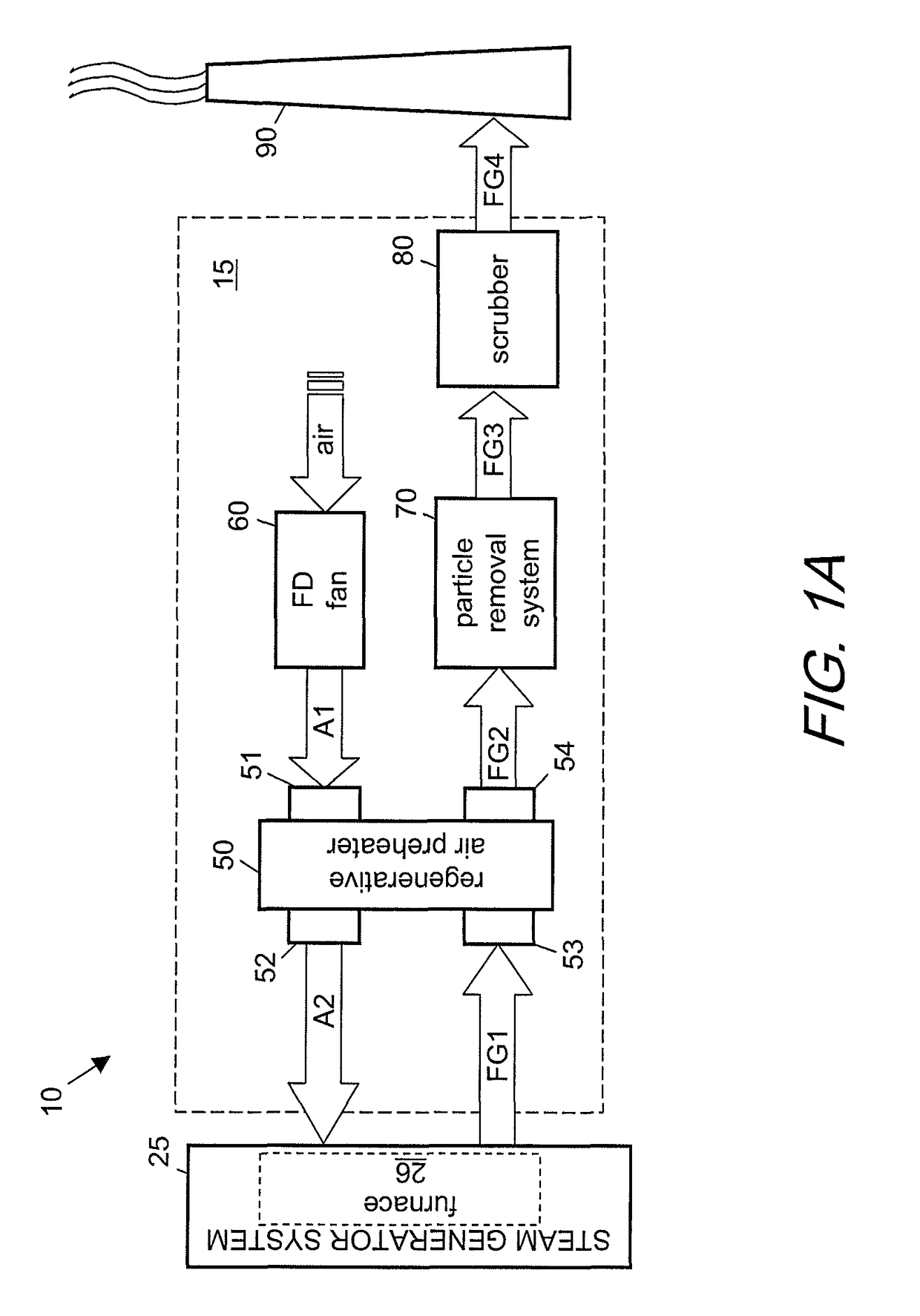

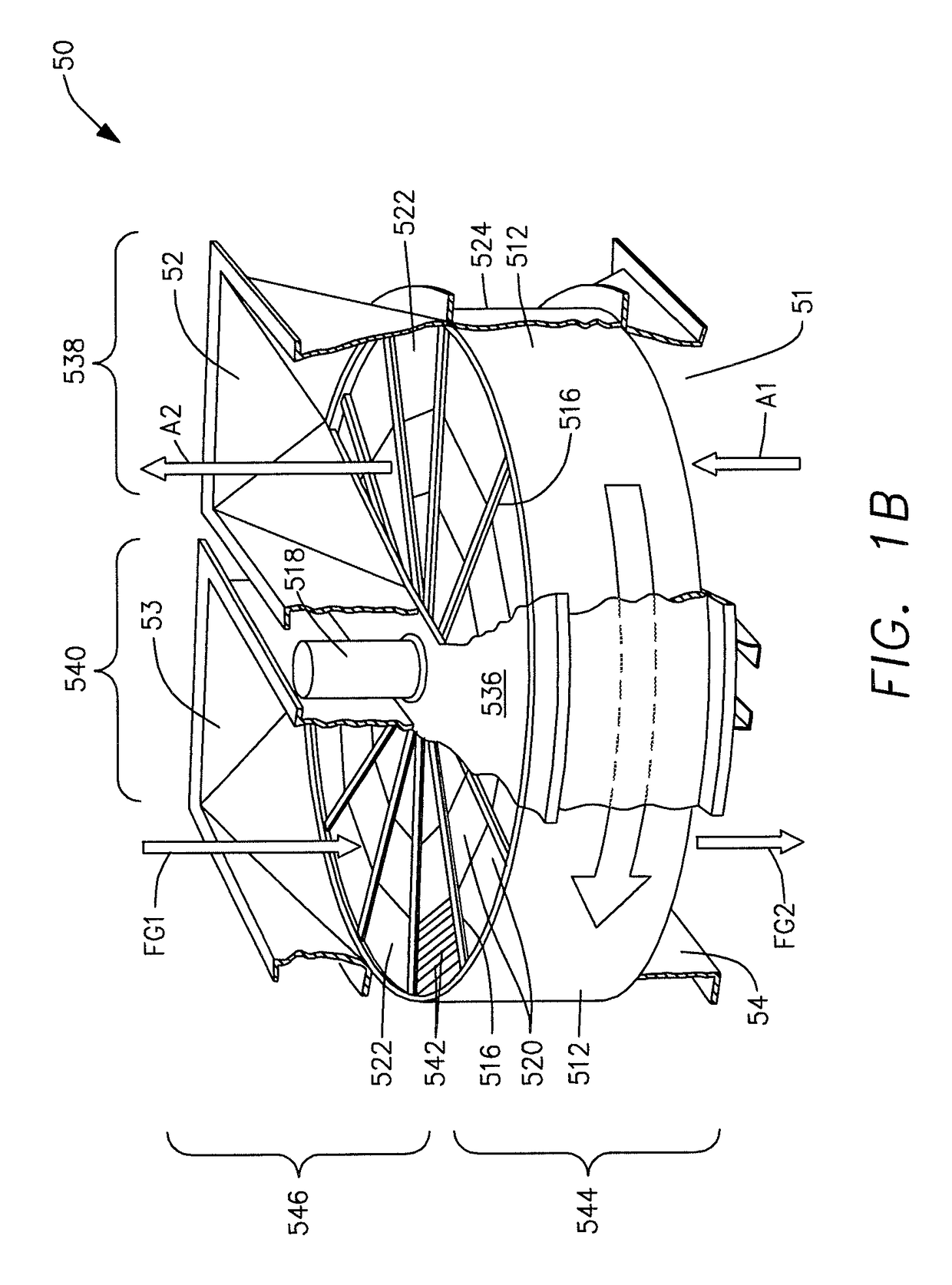

Exhaust processing and heat recovery system

InactiveUS20110073023A1Reduce accumulationImprove thermal efficiencyBurnersBlast furnace detailsThermal energyAir preheater

A thermally efficiency regenerative air preheater 250 extracts more thermal energy from the flue gas exiting a solid fuel fired furnace 26 by employing an alkaline injection system 276. This mitigates acid fouling by selectively injecting different sized alkaline particles 275 into the air preheater 250. Small particles provide nucleation sites for condensation and neutralization of acid vapors. Large particles are injected to contact and selectively adhere to the heat exchange elements 542 and neutralize liquid acid that condenses there. When the deposit accumulation exceeds a threshold, the apparatus generates and utilizes a higher relative percentage of large particles. Similarly, a larger relative percentage of small particles are used in other cases. Mitigation of the fouling conditions permits the redesign of the air preheater 250 to achieve the transfer of more heat from the flue resulting in a lower flue gas outlet temperature without excessive fouling.

Owner:ALSTOM ENERGY TECH AG

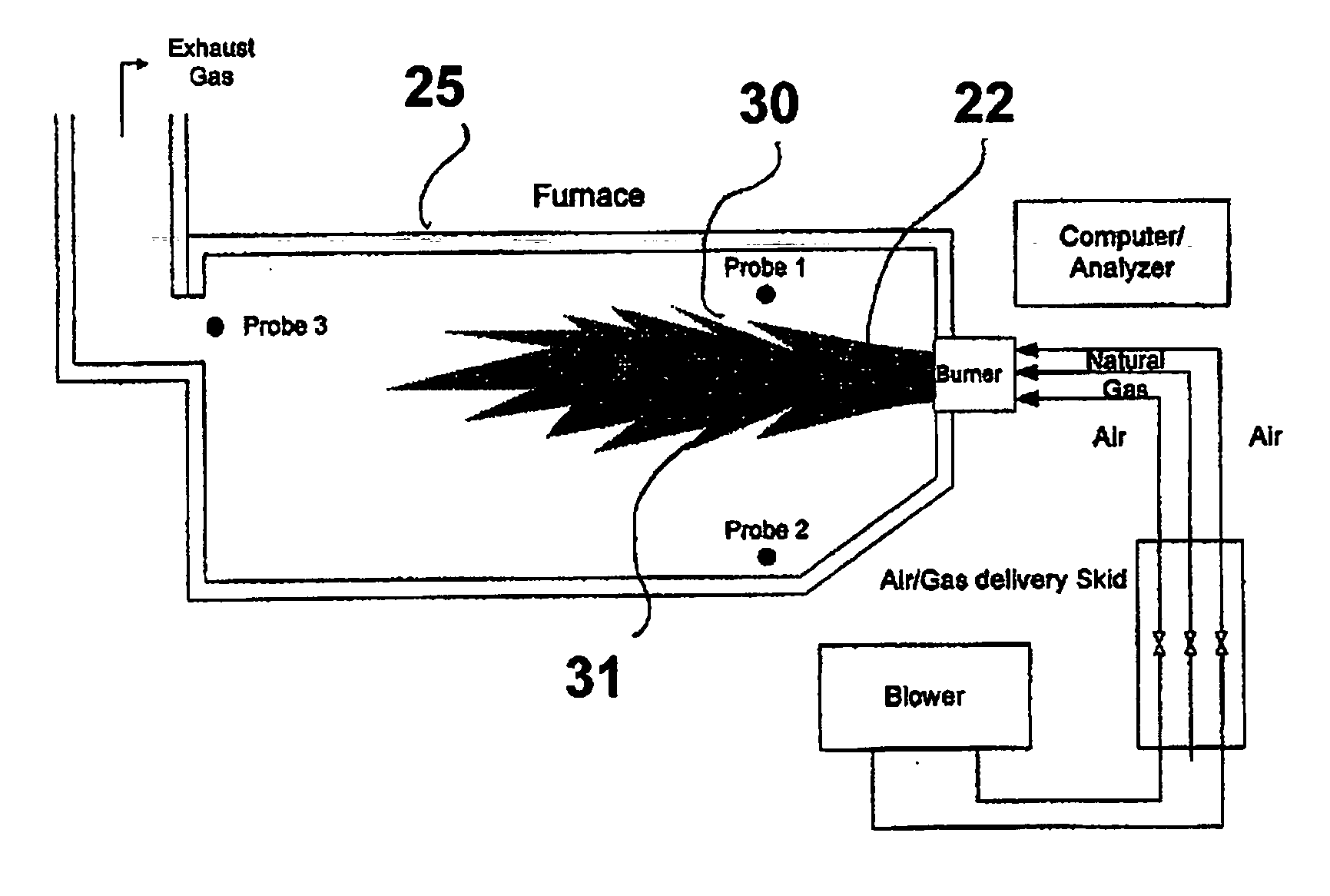

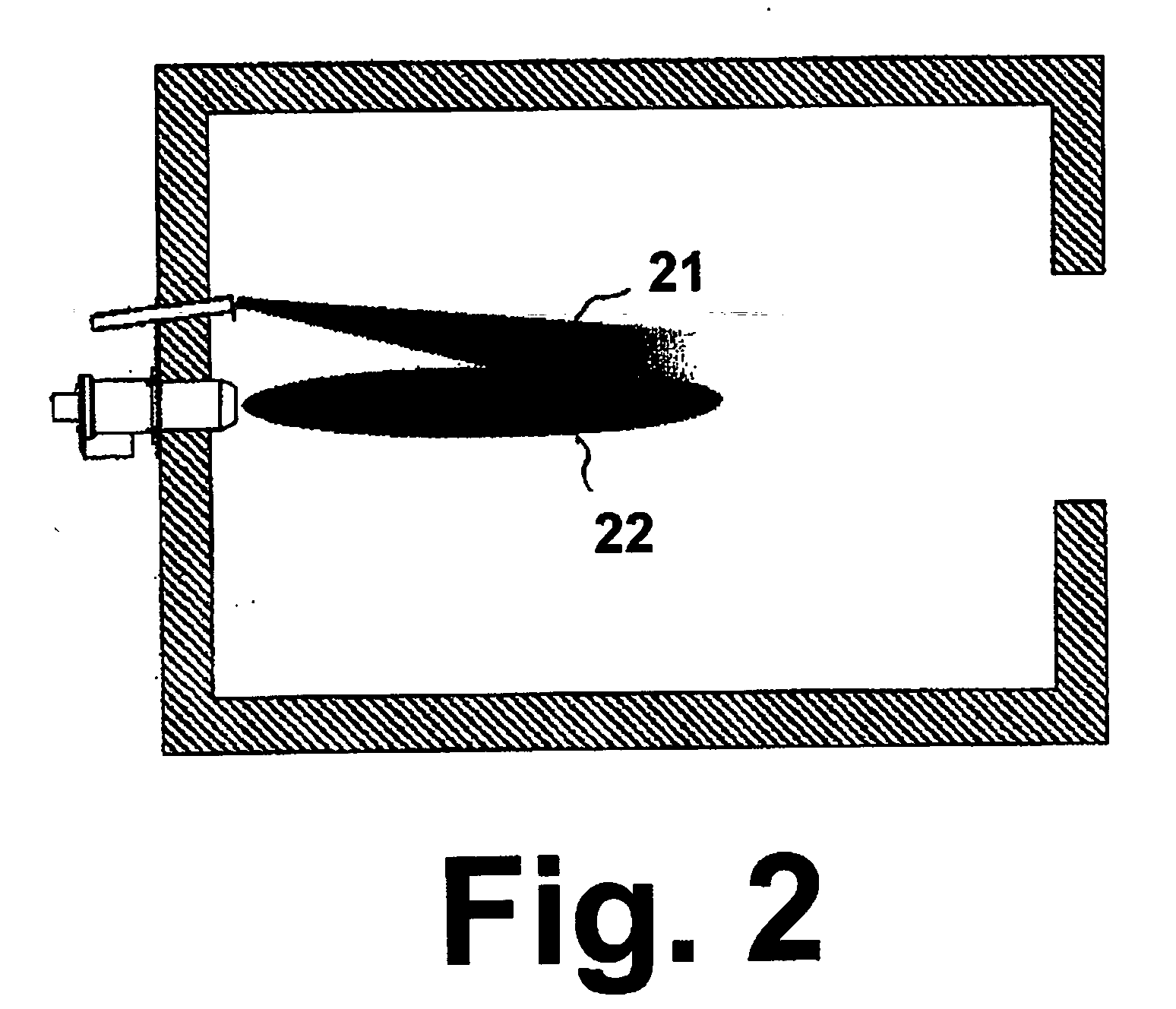

Low velocity staged combustion for furnace atmosphere control

An improved staged combustion method useful with oxy-fuel combustion and in a furnace which contains a charge, wherein substoichiometric combustion and low velocity injection of fuel and primary and secondary oxidant are carried out in an orientation which forms a reducing atmosphere proximate the charge surface.

Owner:KOBAYASHI & CO LTD

CO2 capture using solar thermal energy

InactiveCN101516473AReduce lossesImprove efficiencySolar heating energyCarbon compoundsThermal energyWorking fluid

At an absorber station, CO2 is absorbed from a gas stream into a suitable solvent whereby to convert the solvent into a CO2-enriched medium, which is conveyed to a desorber station, typically nearer to a solar energy field than to the absorber station. Working fluid, heated in the solar energy field by insolation, is employed to effect desorption of CO2 from the CO2-enriched medium, whereby to produce separate CO2 and regenerated solvent streams. The regenerated solvent stream is recycled to the absorber station. The CO2-enriched medium and / or the regenerated solvent stream may be selectively accumulated so as to respectively optimise the timing and rate of absorption and desorption of CO2 and / or to provide a storage of solar energy.

Owner:COMMONWEALTH SCI & IND RES ORG

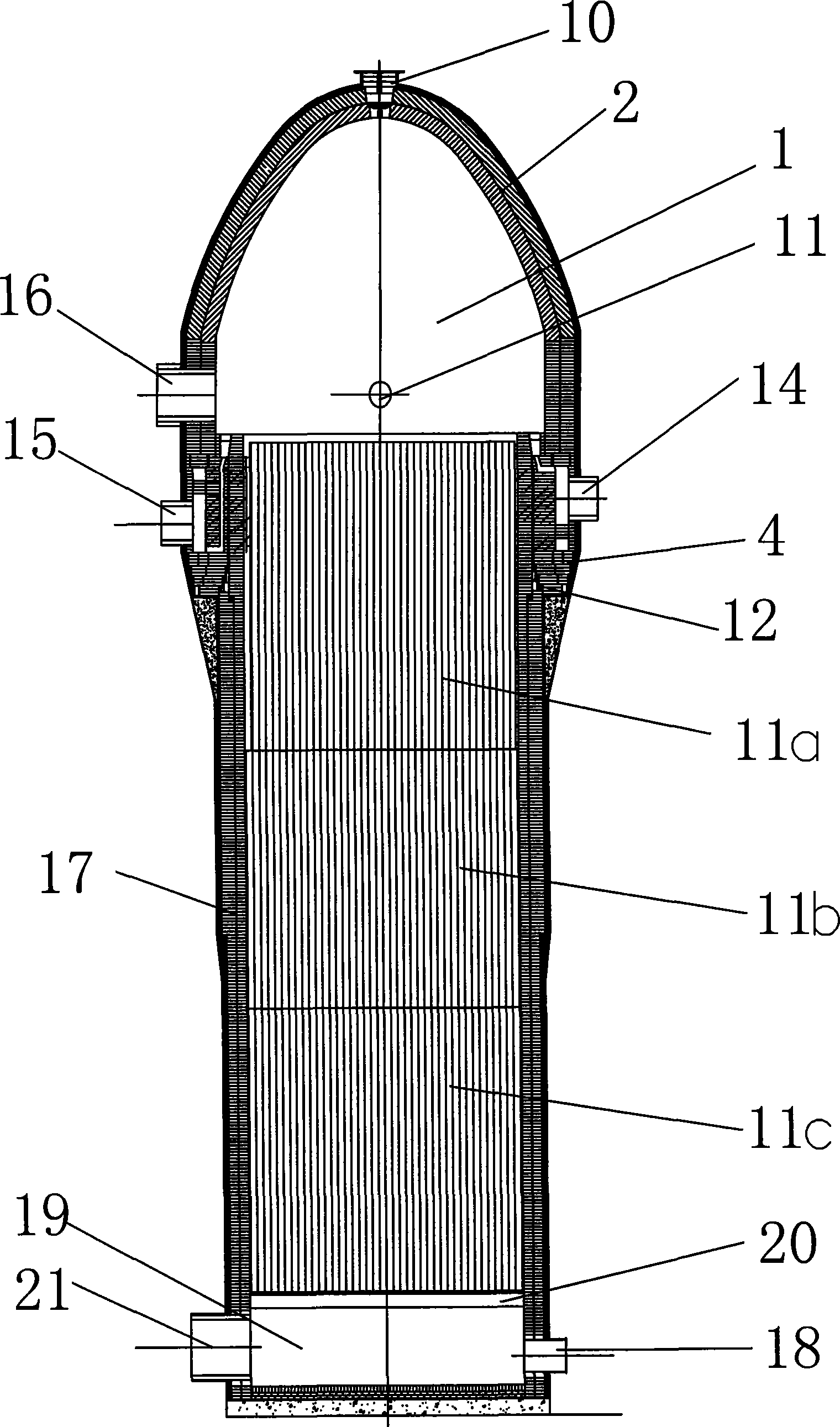

Top burning hot blast stove using annular airflow spray upward with premixing combustion and reflux heating

ActiveCN101381786AFixing Poor MixingResolve Insufficient CombustionBrick-hot blast stovesCombustion processSocial benefitsCombustor

The invention relates to a top-firing hot blast furnace which adopts upper spraying, premixing, firing, reflux and heating by annular airflow and effectively solves the problems of the rationality and stability of the fluid flow in the hot blast furnace and the sufficiency and uniformity of the mixing of different fluids. The top-firing hot blast furnace has the following structure: a vault is positioned on a burner of the upper part of a furnace body; the lower part of a furnace grate under the furnace body is provided with a cold wind chamber; a flue gas outlet pipe and a cold wind inlet pipe are arranged on the sidewall of the cold wind chamber; a combustion chamber is formed between a straight cylinder part on the upper part of the burner and the vault; a hot blast outlet pipe is arranged on the straight cylinder part; the lower part of the burner is provided with a heat storage chamber; the outer wall of the burner is positioned on an outer supporting annular plate of the upper part of the furnace body; the inside of the burner is separated into a coal gas distribution circuit and an air distribution circuit by a partition wall of an oblique circuit; the outer ends of the coal gas distribution circuit and the air distribution circuit are provided with a coal gas inlet pipe and an air inlet pipe respectively; a conduit is formed between the upper parts of the outer wall and the inner wall of the burner; the coal gas distribution circuit and the air distribution circuit are connected with an annular airflow premixing conduit through the respective nozzle tube distributed on the peripheral wall of the burner; and a flow equalizing and obstructing baffle plate is formed between the upper part of the conduit and the combustion chamber. The top-firing hot blast furnace has good economical and social benefits.

Owner:河南省豫兴热风炉工程技术有限公司

Heavy austempered ductile iron components

A component for wind turbines includes cast austempered ductile iron containing about 3.0 to about 3.8 weight percent carbon, about 1.9 to about 2.8 weight percent silicon, up to about 0.3 weight percent manganese, up to about 0.8 weight percent copper, up to about 2.0 weight percent nickel, up to about 0.3 weight percent molybdenum, about 0.03 to about 0.06 weight percent magnesium, less than about 0.05 weight percent chromium, less than about 0.02 weight percent vanadium, and less than about 0.01 weight percent sulfur. The component is preferably a drive shaft or gearbox component having a mass of more than about 3 tons. A method of manufacturing the component is also provided.

Owner:GENERAL ELECTRIC CO

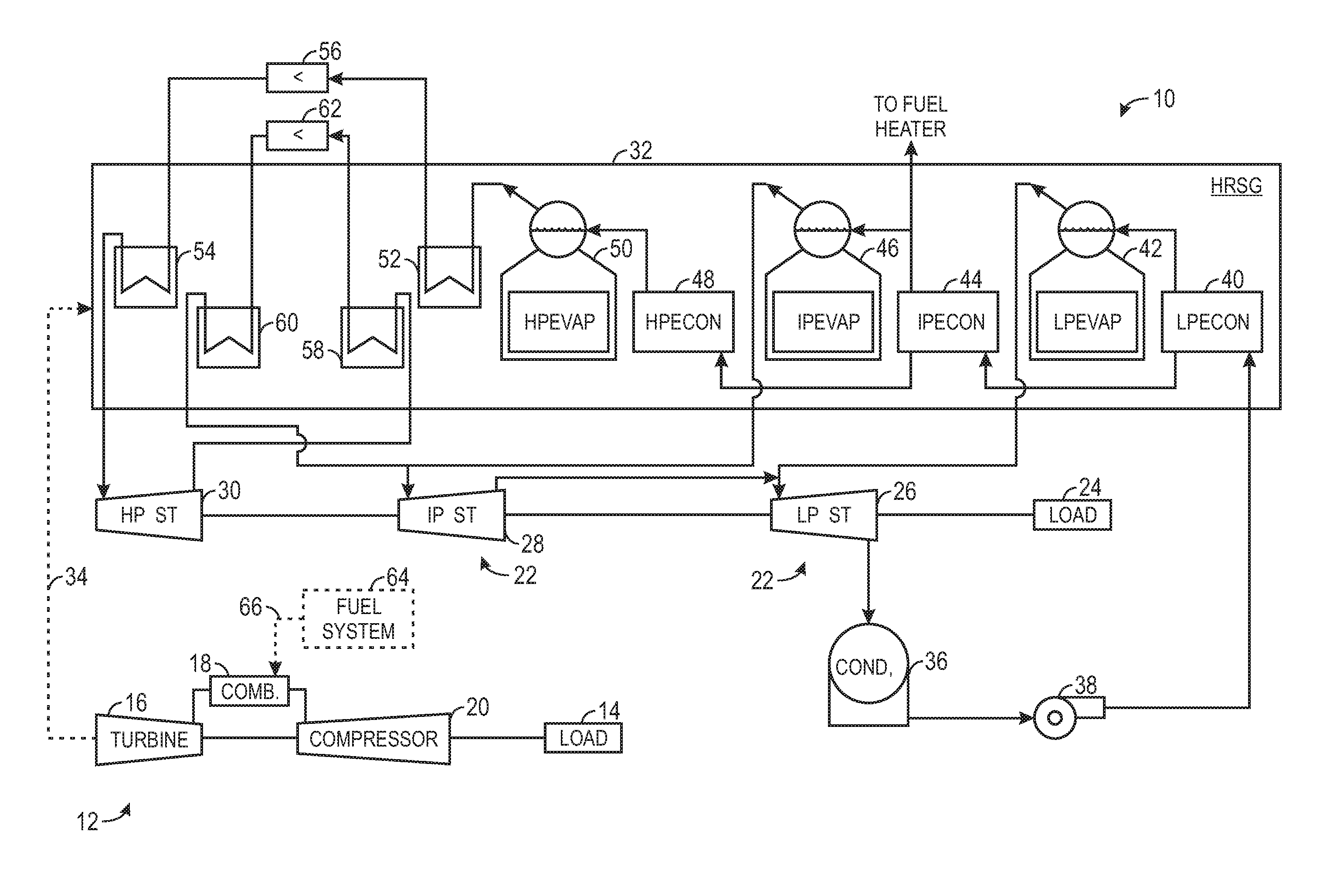

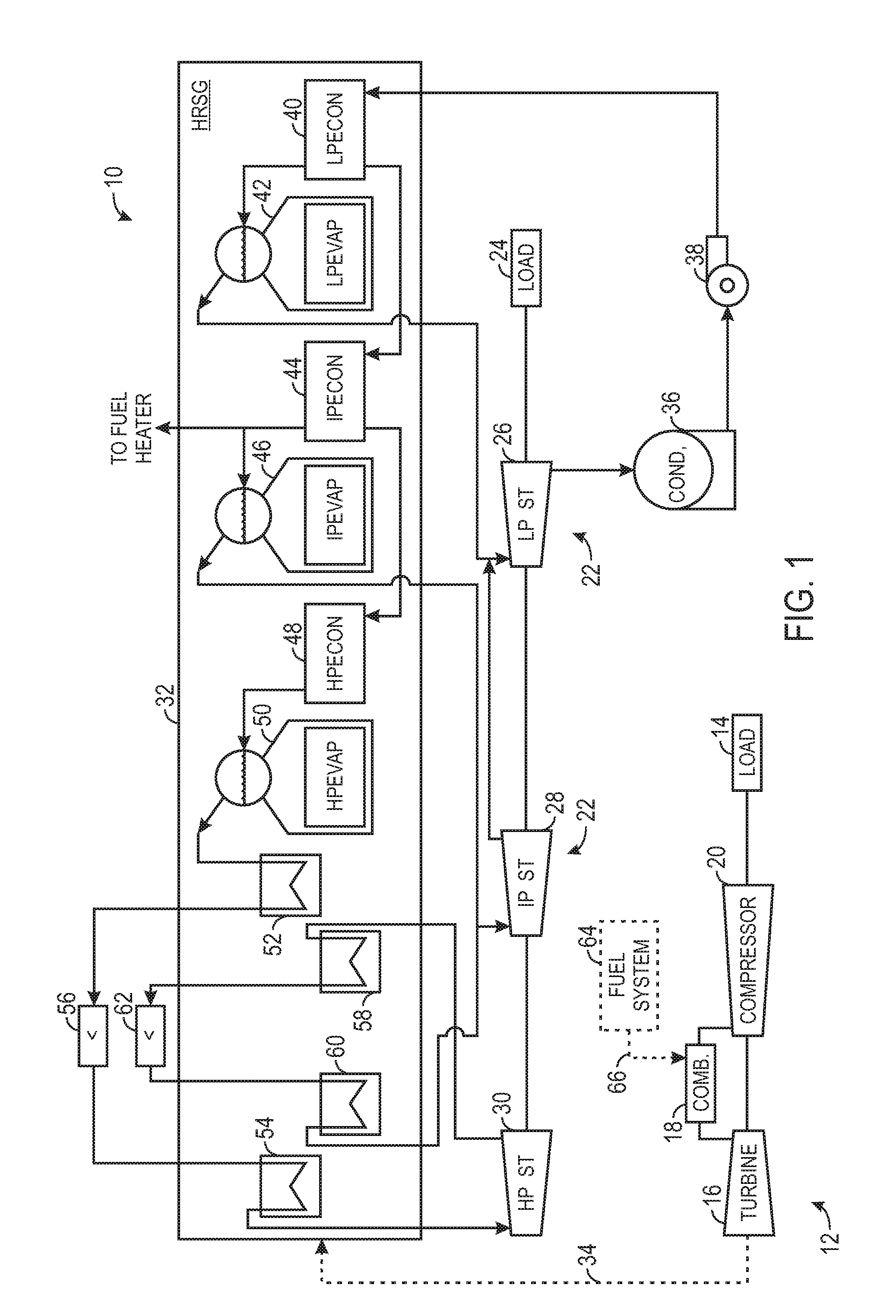

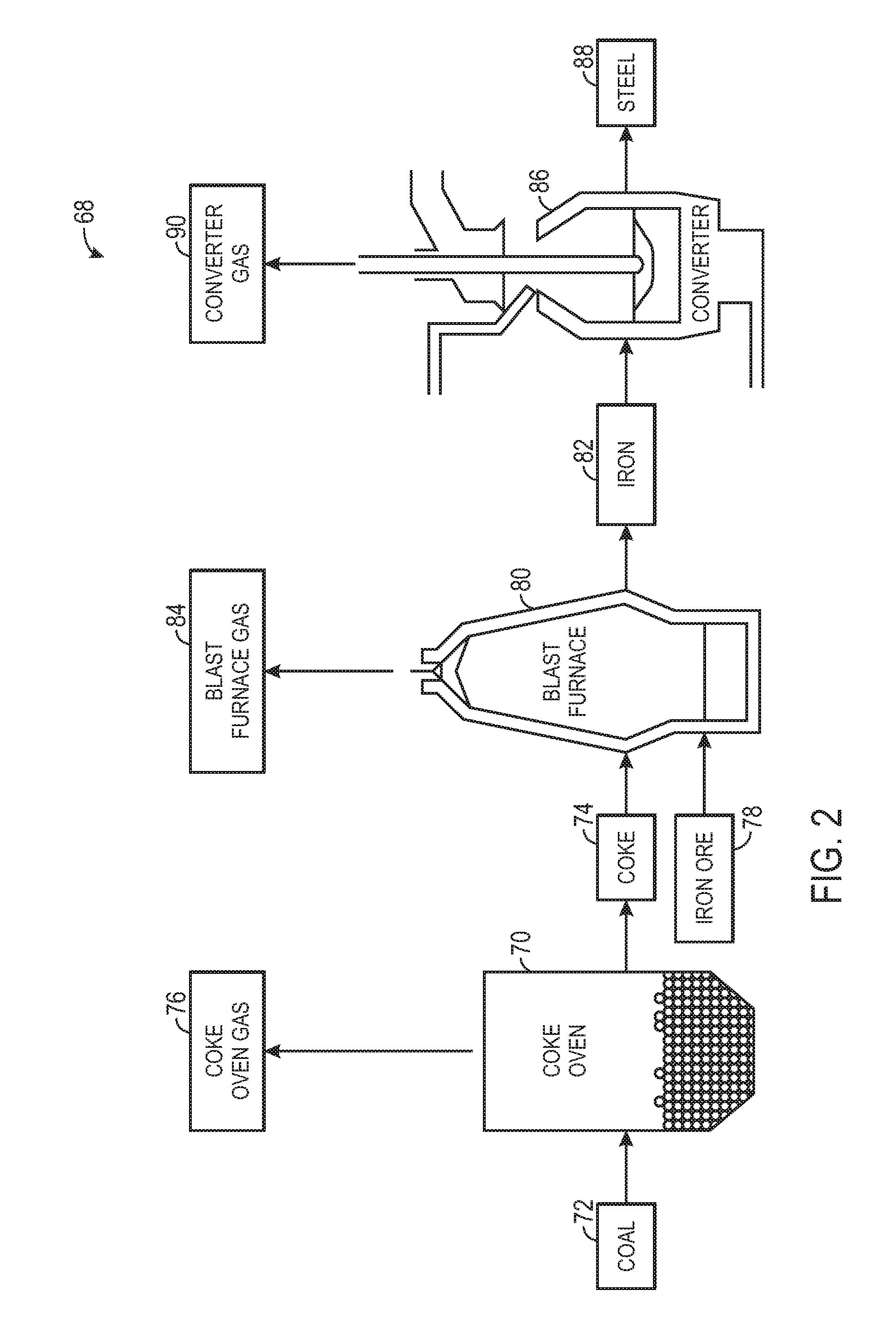

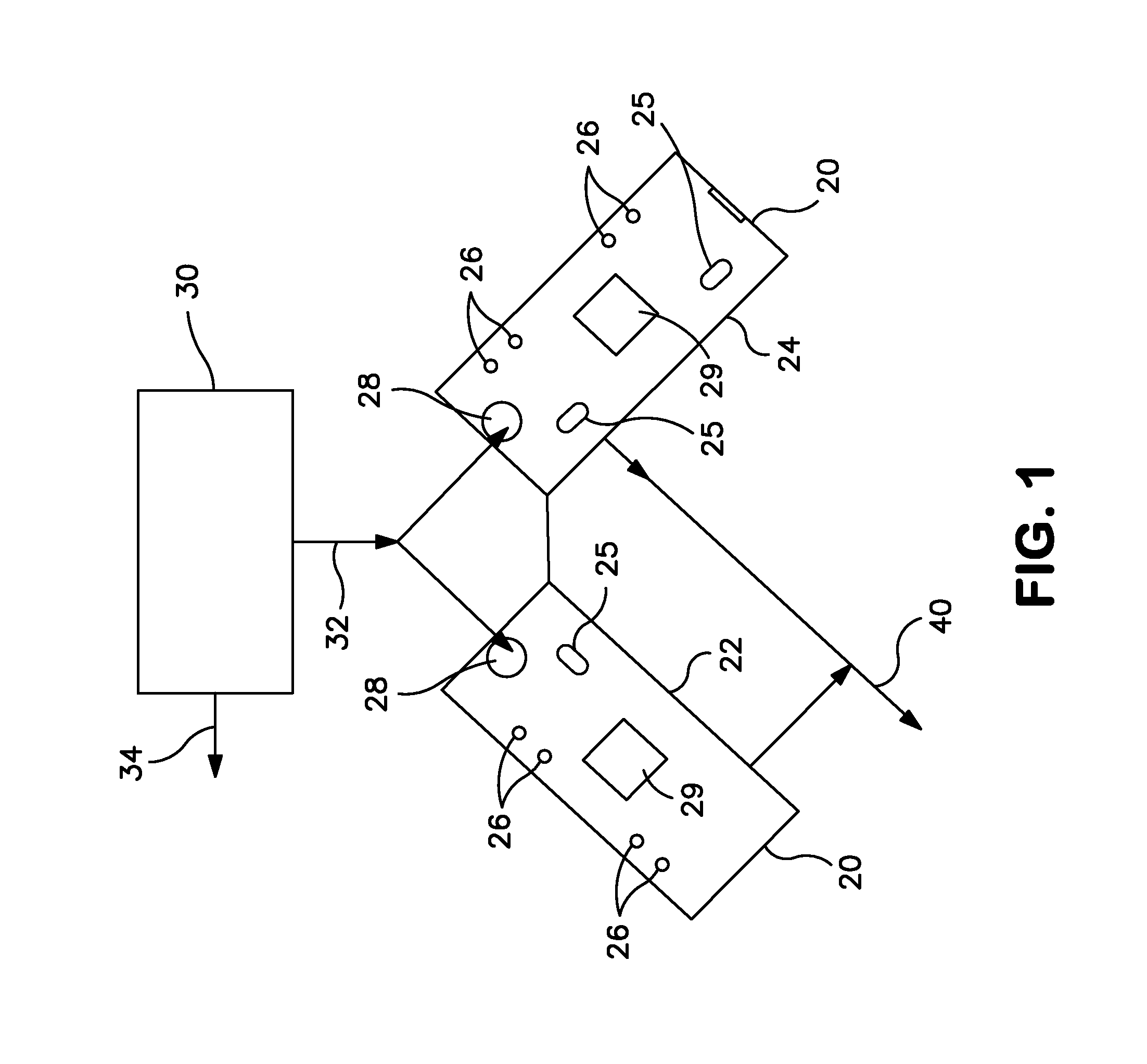

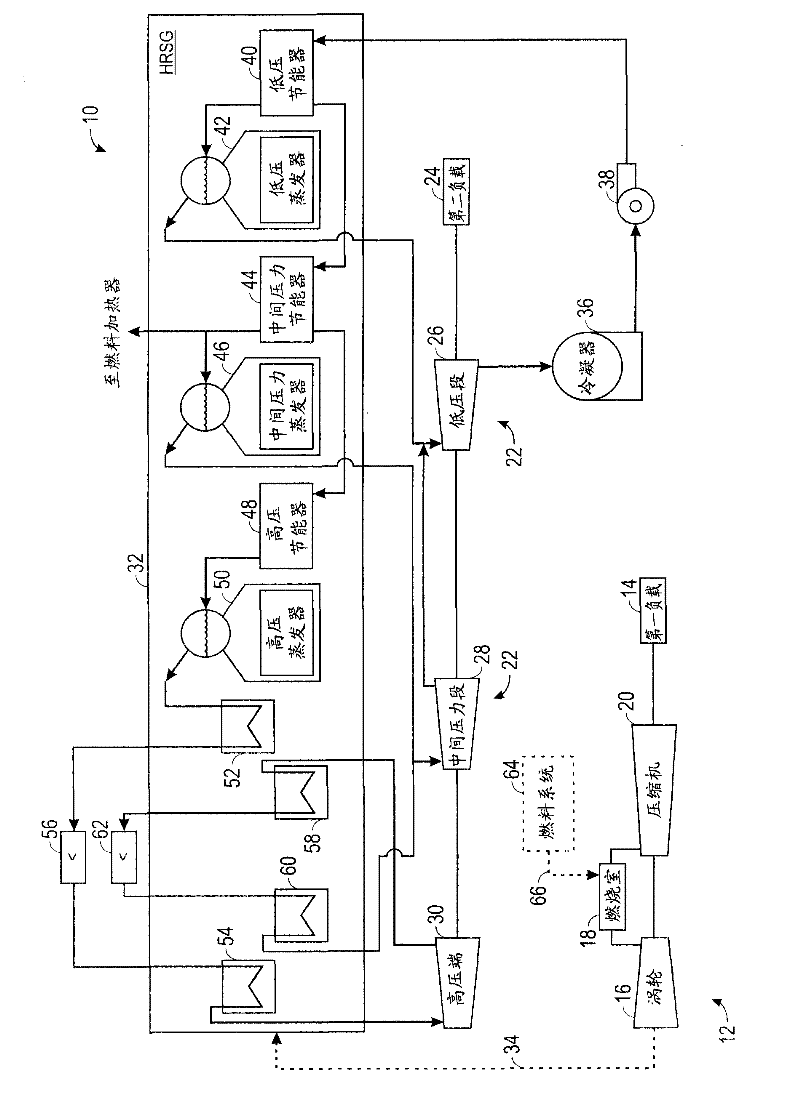

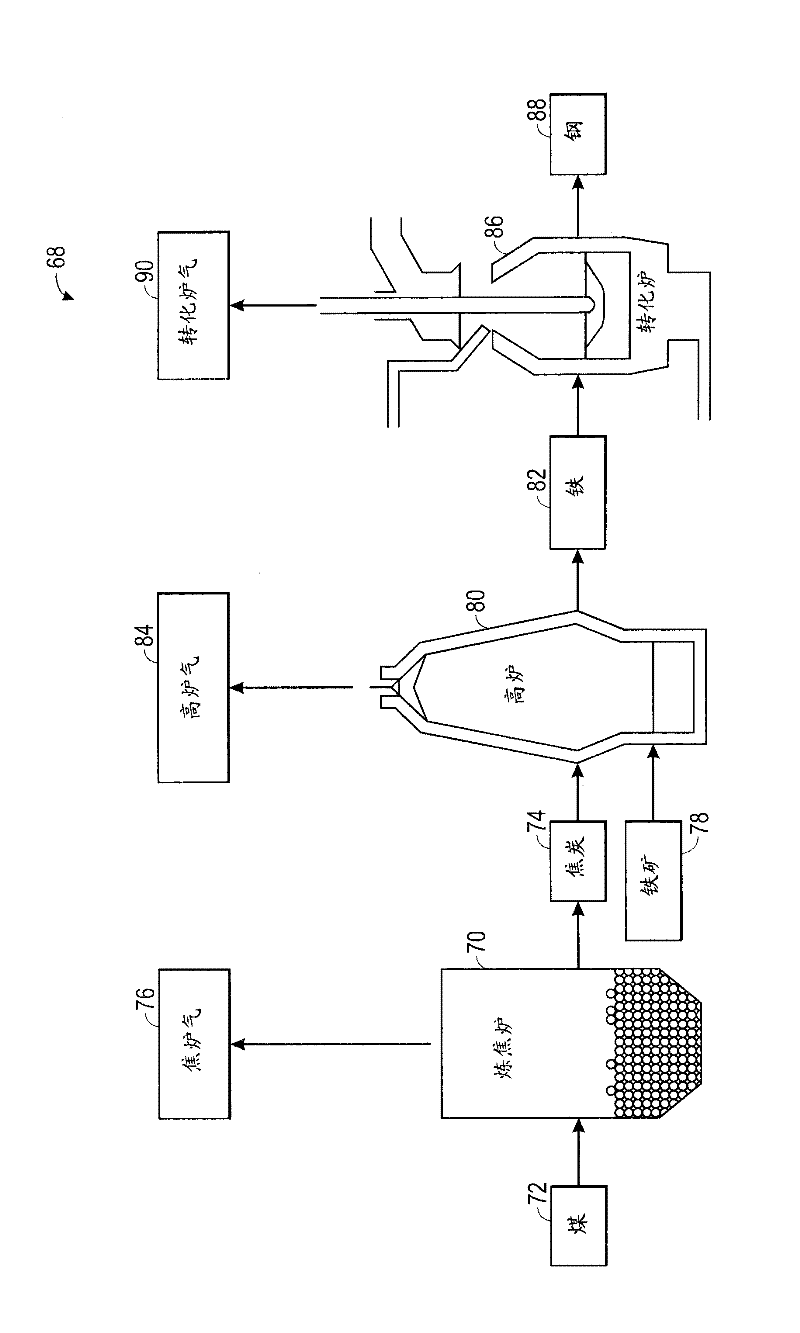

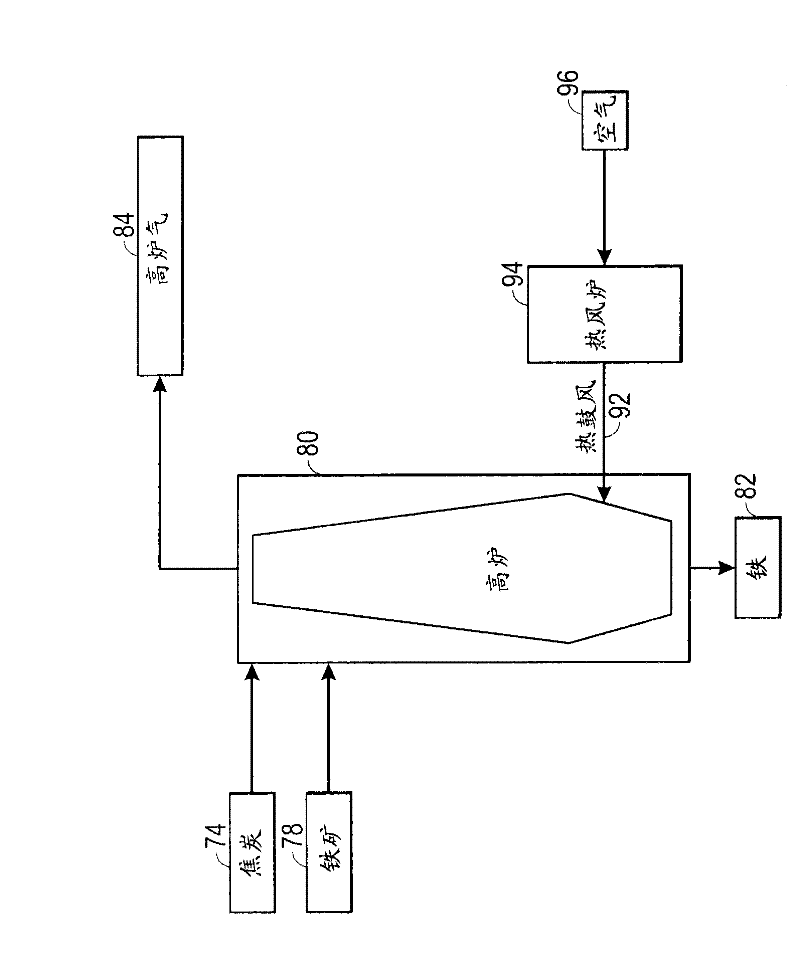

Gas turbine exhaust as hot blast for a blast furnace

In certain exemplary embodiments, a system includes a gas turbine system having a turbine, combustor, and a compressor. The system also includes an output flow path from the gas turbine system. The system further includes a blast furnace coupled to the output flow path, wherein output flow path is configured to deliver heated air or exhaust gas from the gas turbine system directly to the blast furnace as a blast heat source.

Owner:GENERAL ELECTRIC CO

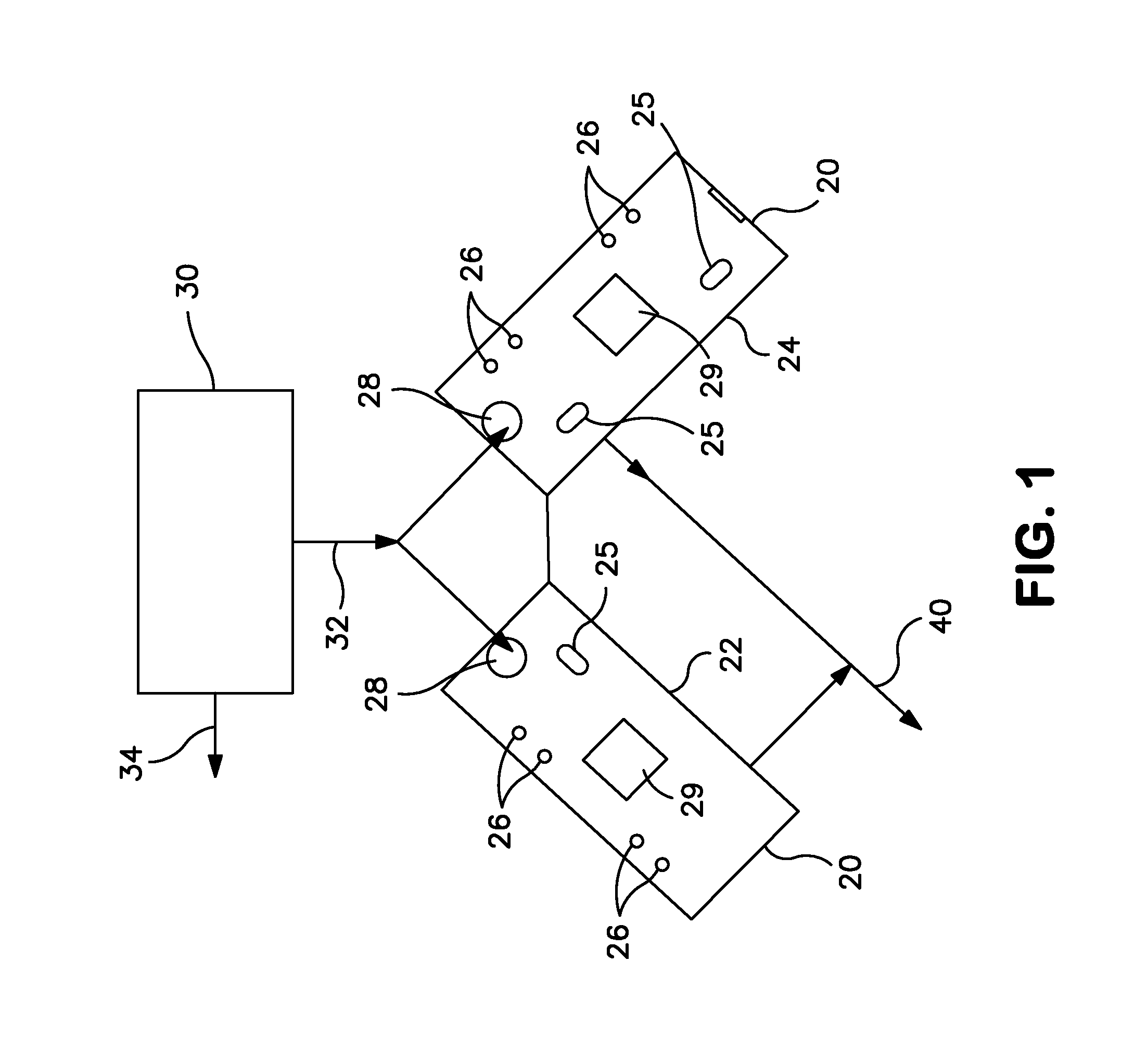

Flex-flame burner and combustion method

InactiveUS20060272453A1Reduce amountSolving inefficienciesBetter energy sourceIndirect carbon-dioxide mitigationCombustionMetal alloy

A combustion method and apparatus which produce a hybrid flame for heating metals and metal alloys, which hybrid flame has the characteristic of having an oxidant-lean portion proximate the metal or metal alloy and having an oxidant-rich portion disposed above the oxidant lean portion. This hybrid flame is produced by introducing fuel and primary combustion oxidant into the furnace chamber containing the metal or metal alloy in a substoichiometric ratio to produce a fuel-rich flame and by introducing a secondary combustion oxidant into the furnace chamber above the fuel-rich flame in a manner whereby mixing of the secondary combustion oxidant with the fuel-rich-flame is delayed for a portion of the length of the flame.

Owner:GAS TECH INST

Copper anode refining system and method

A method and system for the copper anode refining is provided in which coherent jet technology is employed to heat the molten blister copper and / or melt scrap copper charges using a melting flame, oxidize the sulfur in the molten blister copper, and reduce the oxygen in the molten blister copper using top-blown coherent jet gas streams from one or more multi-functional, coherent jet lance assemblies. The present system and method employs a microprocessor-based controller operatively controlling the flow of an oxygen-containing gas, an inert gas, a reducing agent and a fuel to the coherent jet lance. The disclosed copper anode refining system and method greatly improves copper production while lowering oxidation / reduction cycle times and minimizing NOx emissions.

Owner:PRAXAIR TECH INC

Double-melting-bath organic solid waste blowing gasification device

PendingCN110396435AWon't clogEasy to replaceGasifier mechanical detailsChemical industryHydrogenCombustible gas

The invention discloses a double-melting-bath organic solid waste blowing gasification device, and belongs to the field of organic solid waste harmlessness, quantitative reduction, resource, and energy processing adsorption, and organic matter ultrahigh temperature monoatomic cracking gasification preparation of synthetic gas. According to the double-melting-bath organic solid waste blowing gasification device, a liquid surface adjusting furnace is communicated with the bottom of a vapourizing furnace, and contains 1200 to 1700 DEG C molten iron based alloy liquid covered with a molten liquidstate slag layer; the gas pressure or liquid amount above the liquid level adjusting furnace is increased, so that the molten liquid surface in the vapourizing furnace is raised, a material spray gunis immersed, immersion spraying of organic particles for gasification into the melting bath is carried out, at the same time, gasification agent oxygen gas and oxygen-enriched air are blew into molten, organic matter gasification into synthetic gas rich in CO and hydrogen gas is realized, most inorganic matters enter into molten slag, and are discharged regularly with accumulation of slag liquid;molten iron liquid amount is maintained to be constant, conversion of most organic waste into clean combustible gas is realized, and the obtained clean combustible gas is taken as fuel gas or chemicalproduct synthetic gas.

Owner:杭州吉幔铁氢能科技有限公司

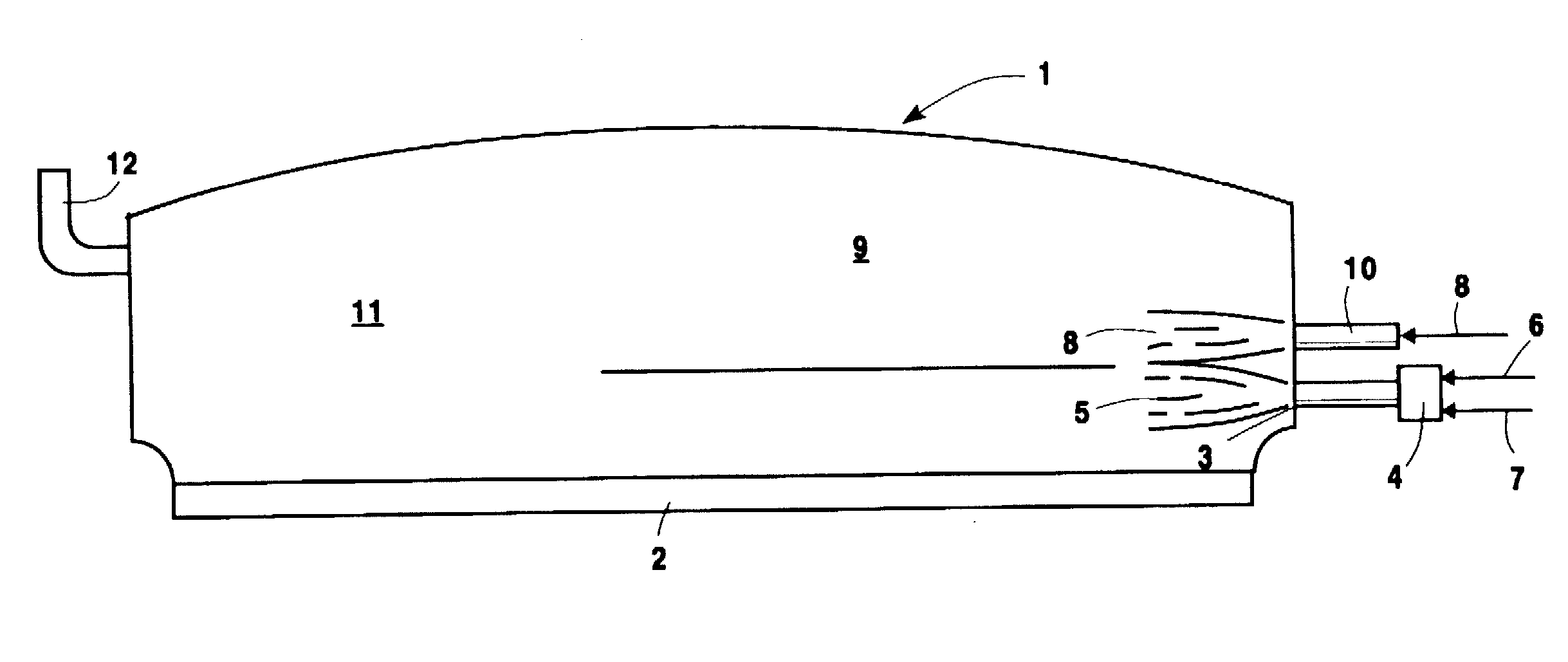

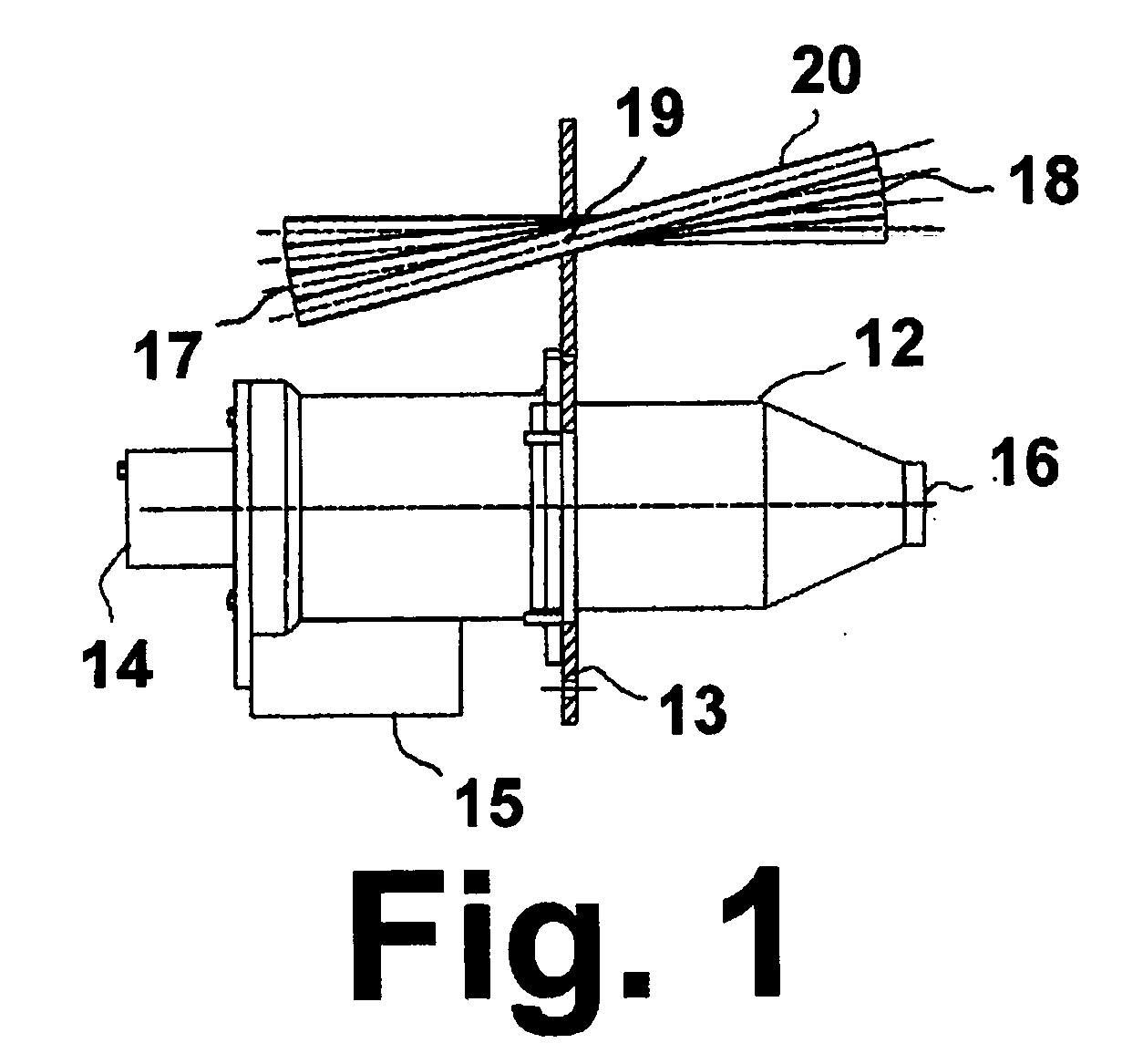

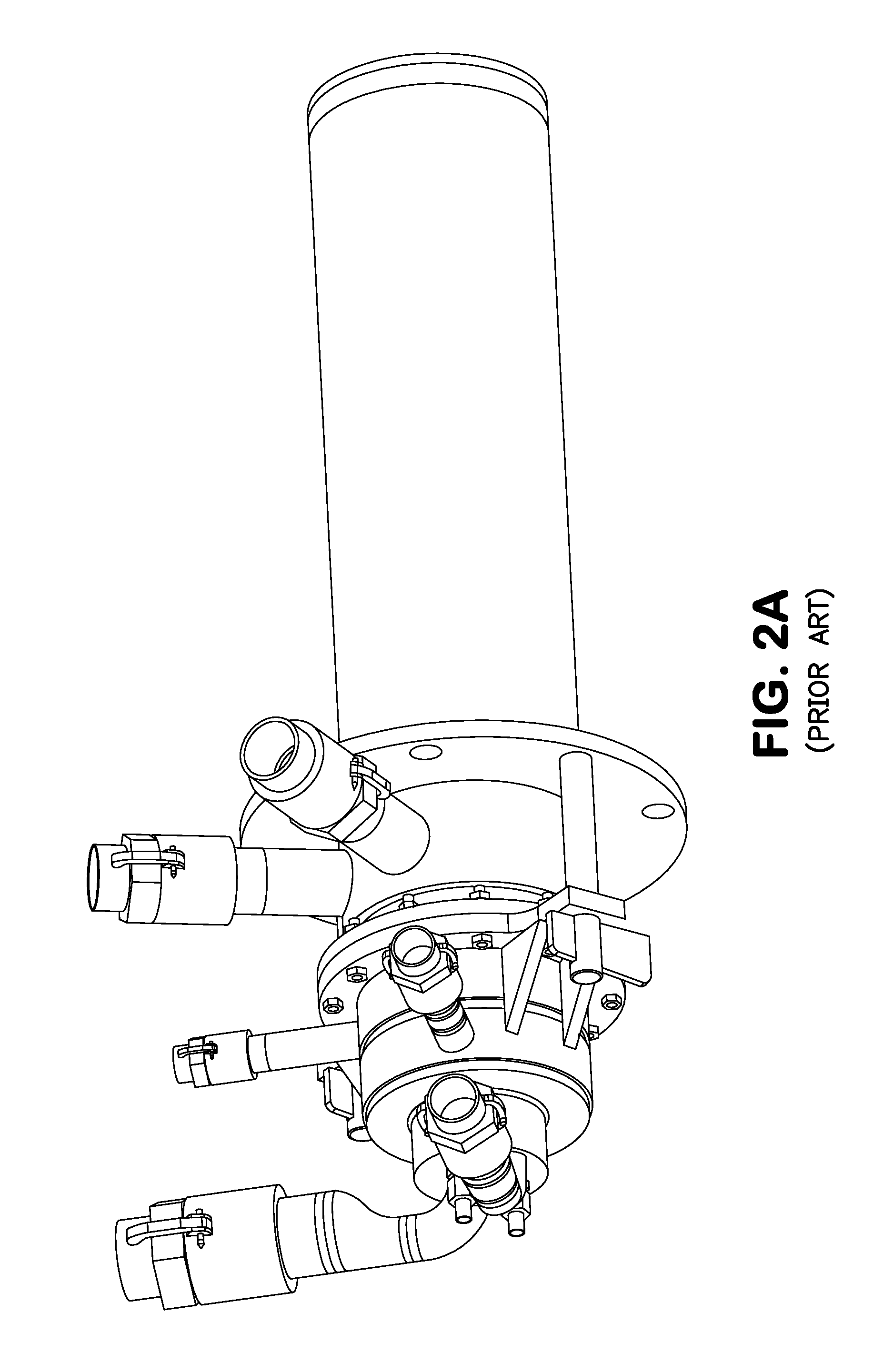

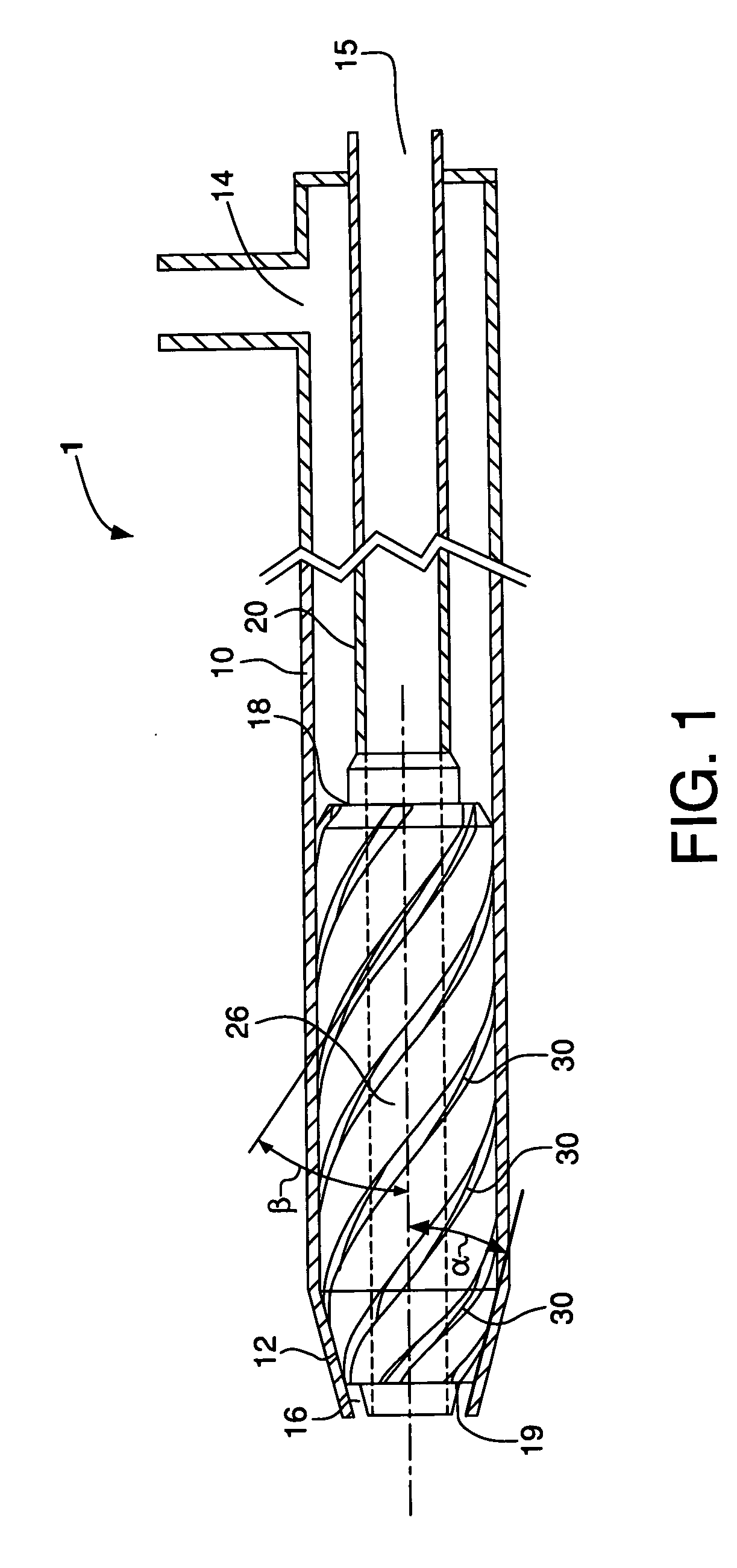

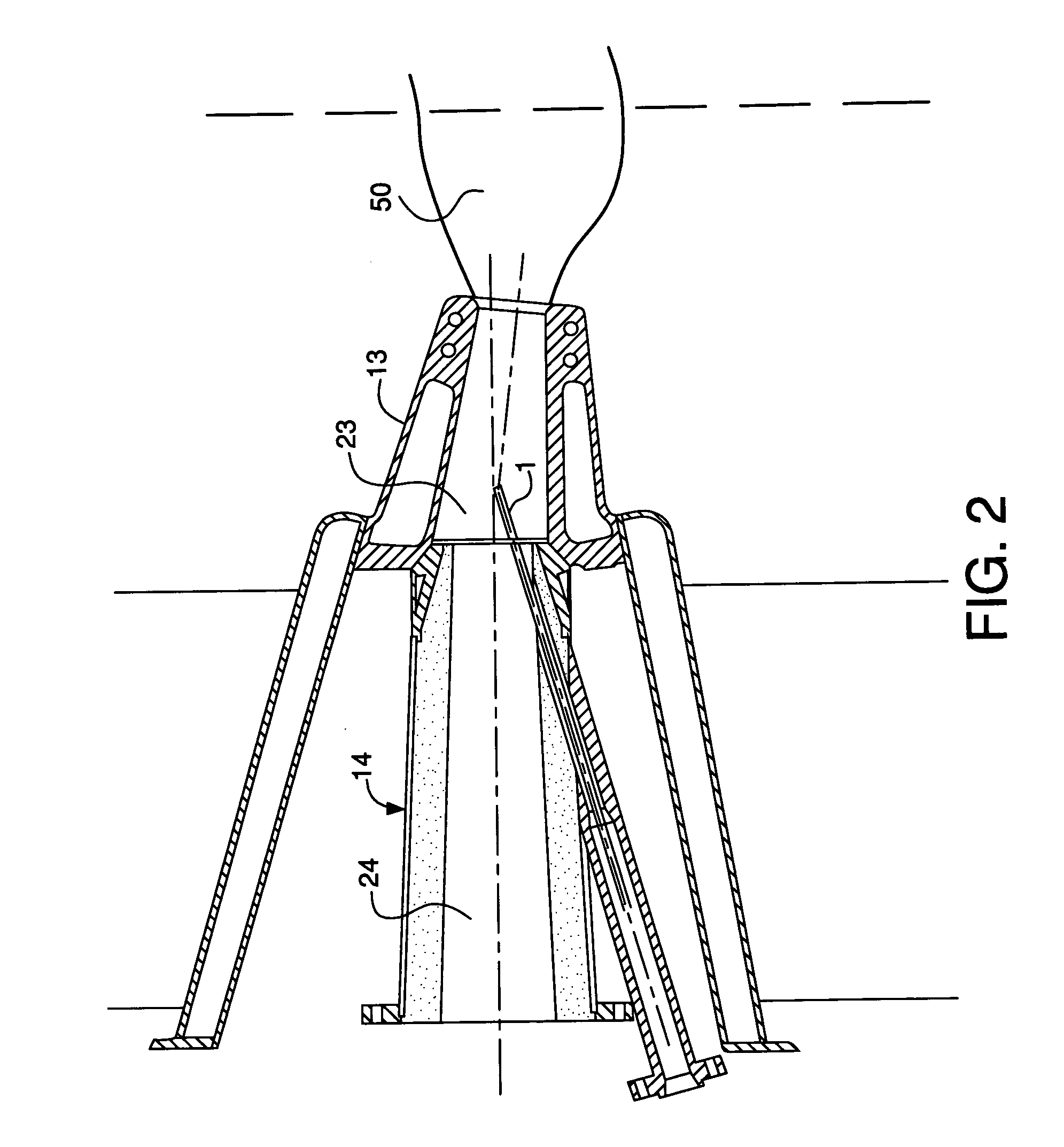

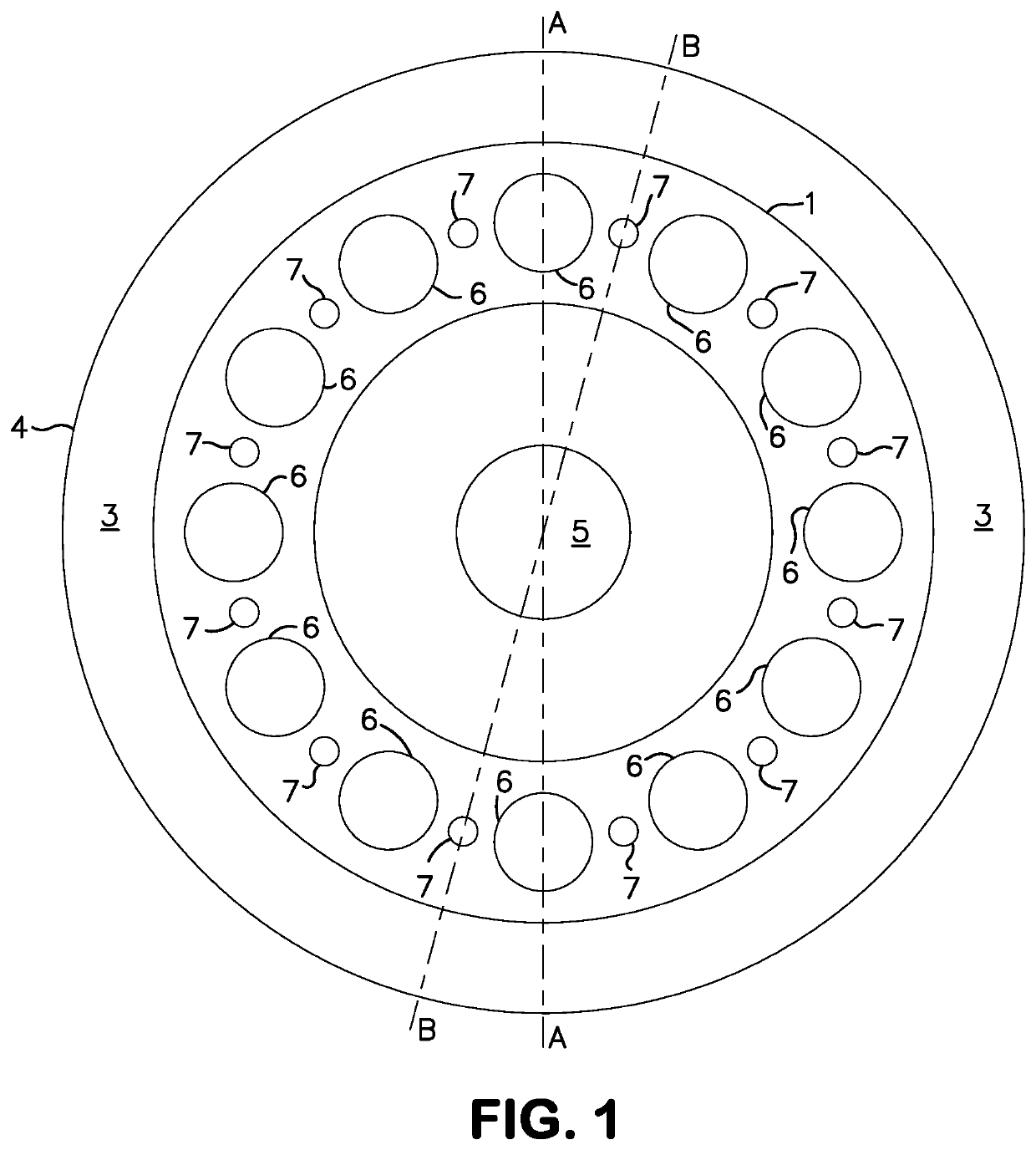

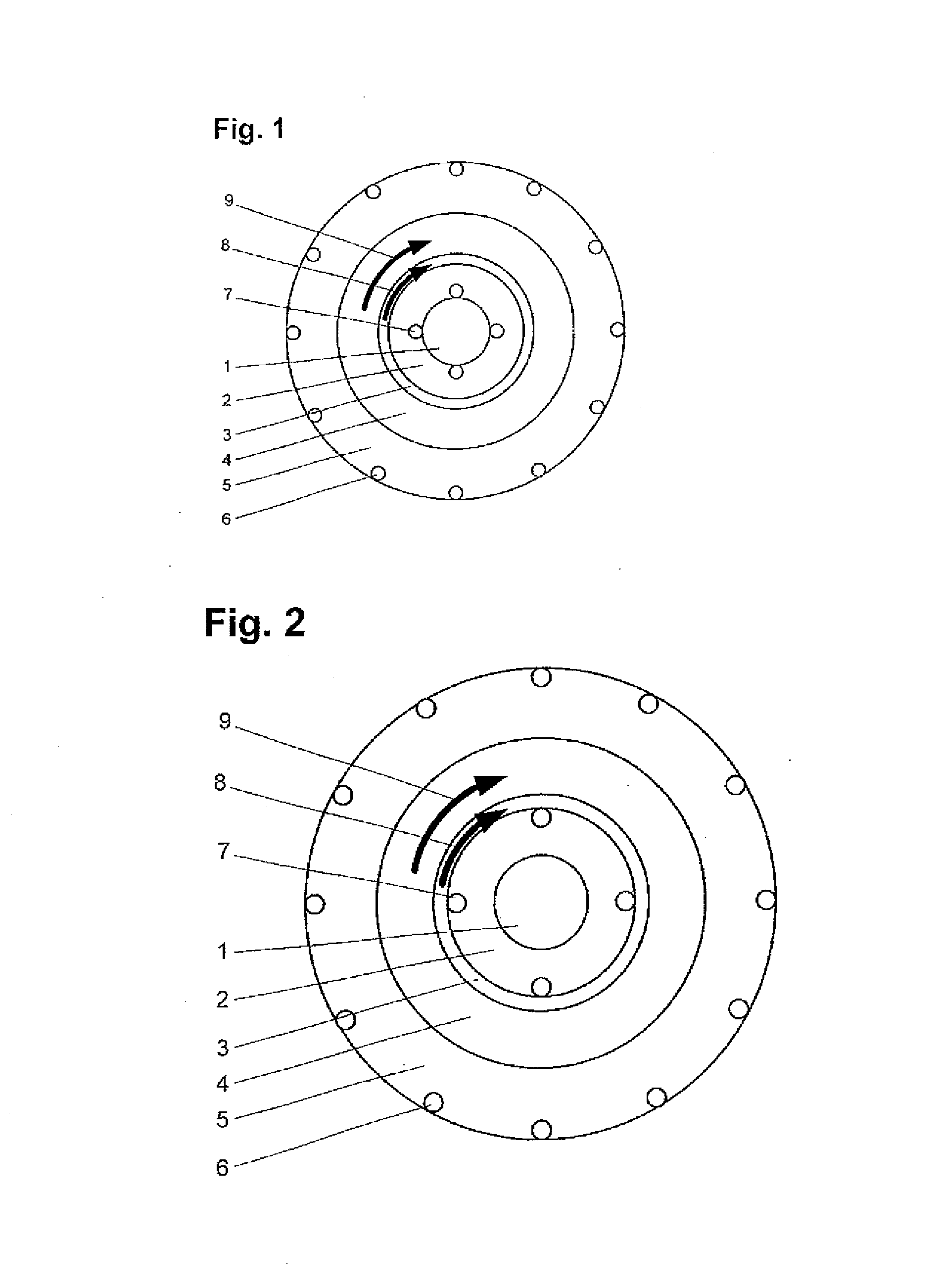

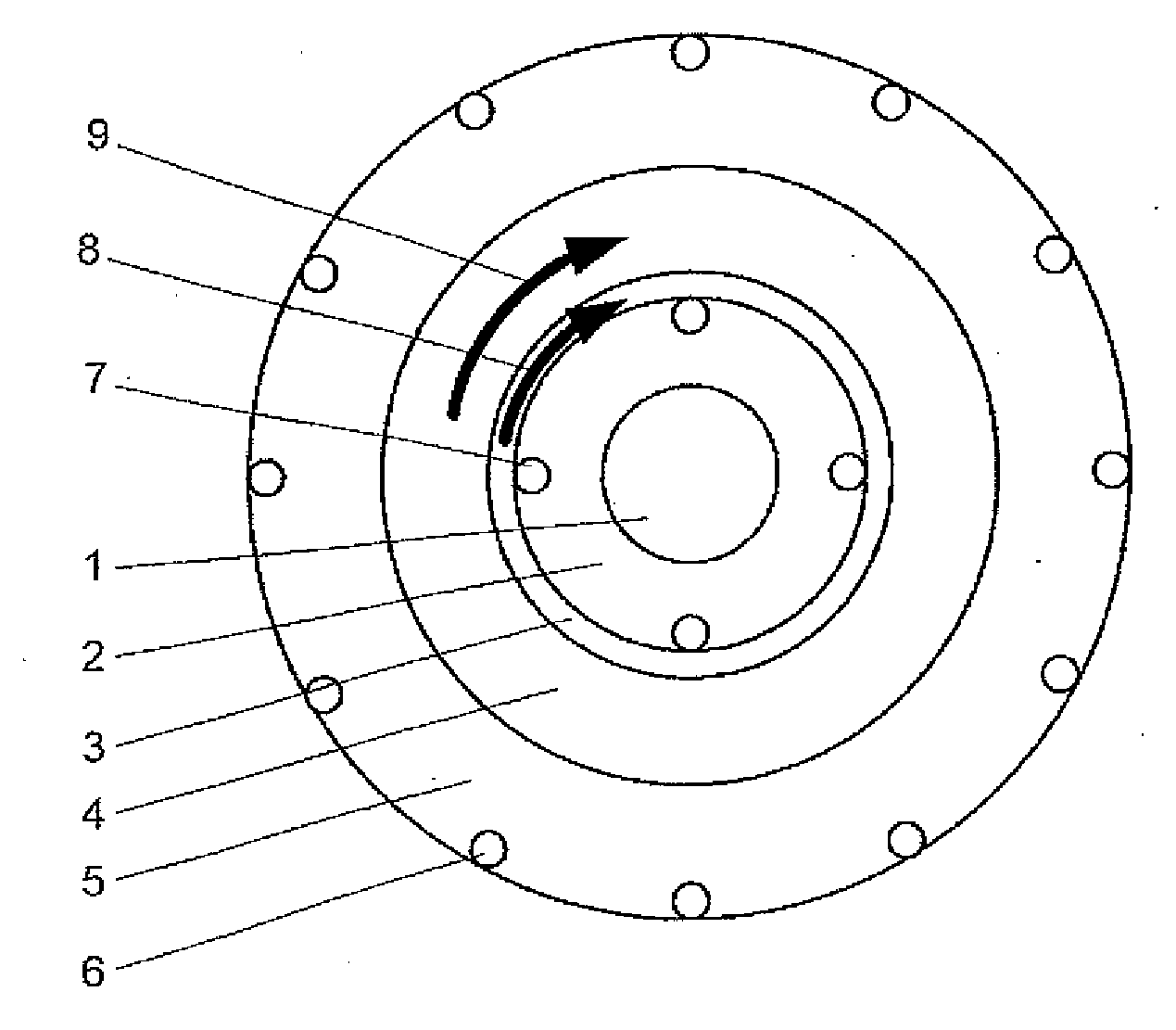

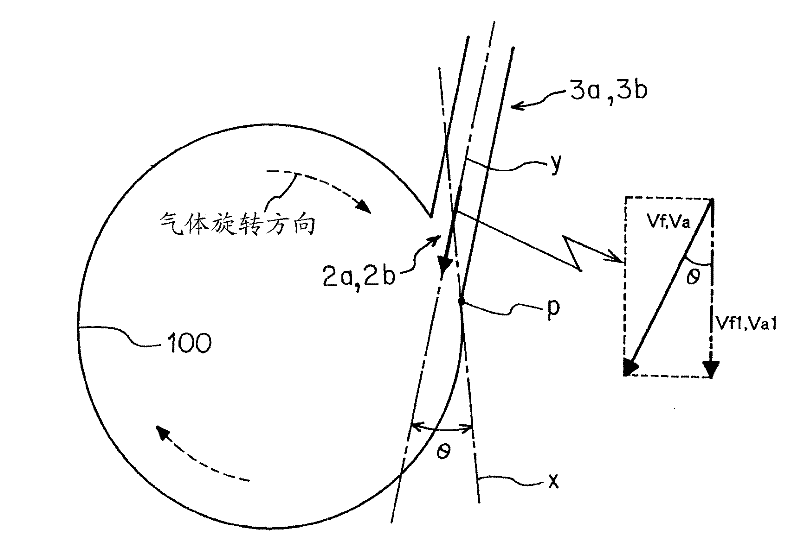

Oxidant-swirled fossil fuel injector for a shaft furnace

An injector for injecting a swirling oxidant around a fossil fuel into a shaft furnace has a converging nozzle to improve combustion of the fossil fuel and reduce carbon soot formation. Fossil fuels, for example pulverized coal, may be introduced into the blast passageway and / or raceway cavity of a shaft furnace such as a blast furnace or cupola, to reduce the amount of coke needed for operation. Oxidant, which may be industrial grade oxygen, is swirled around the fossil fuel through a converging nozzle to improve the combustion of the fossil fuel thereby permitting increased substitution of fossil fuel for coke.

Owner:AIR PROD & CHEM INC

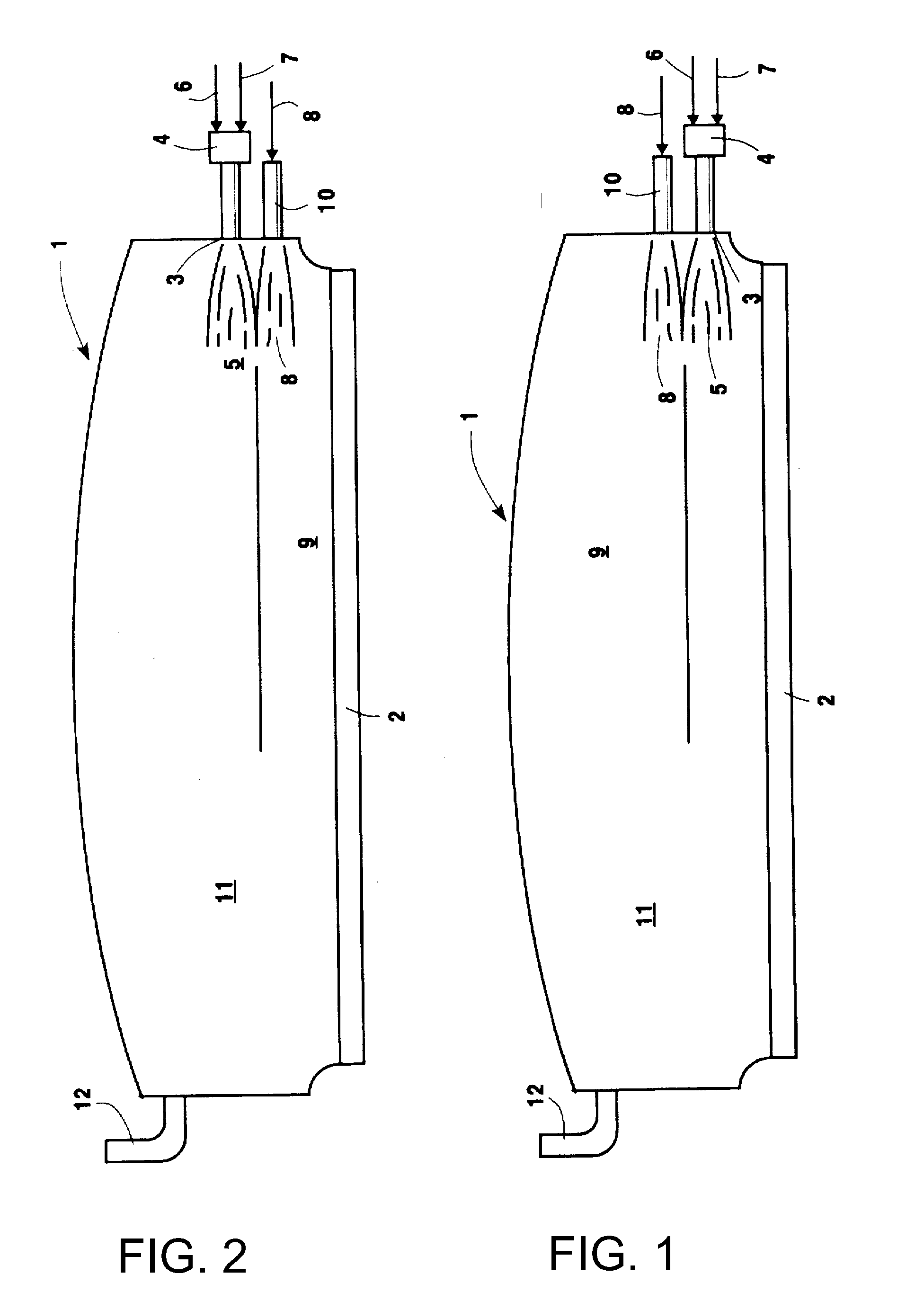

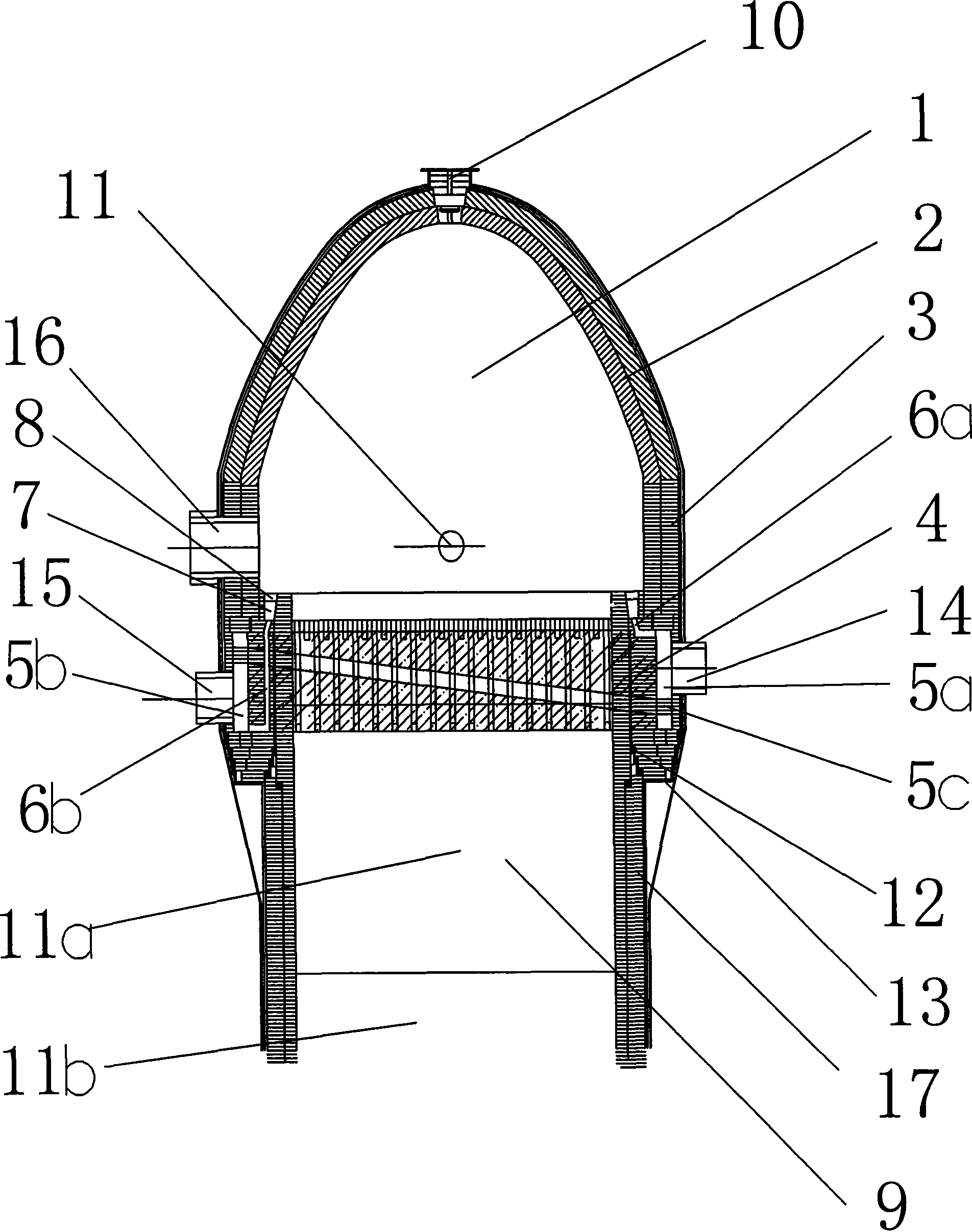

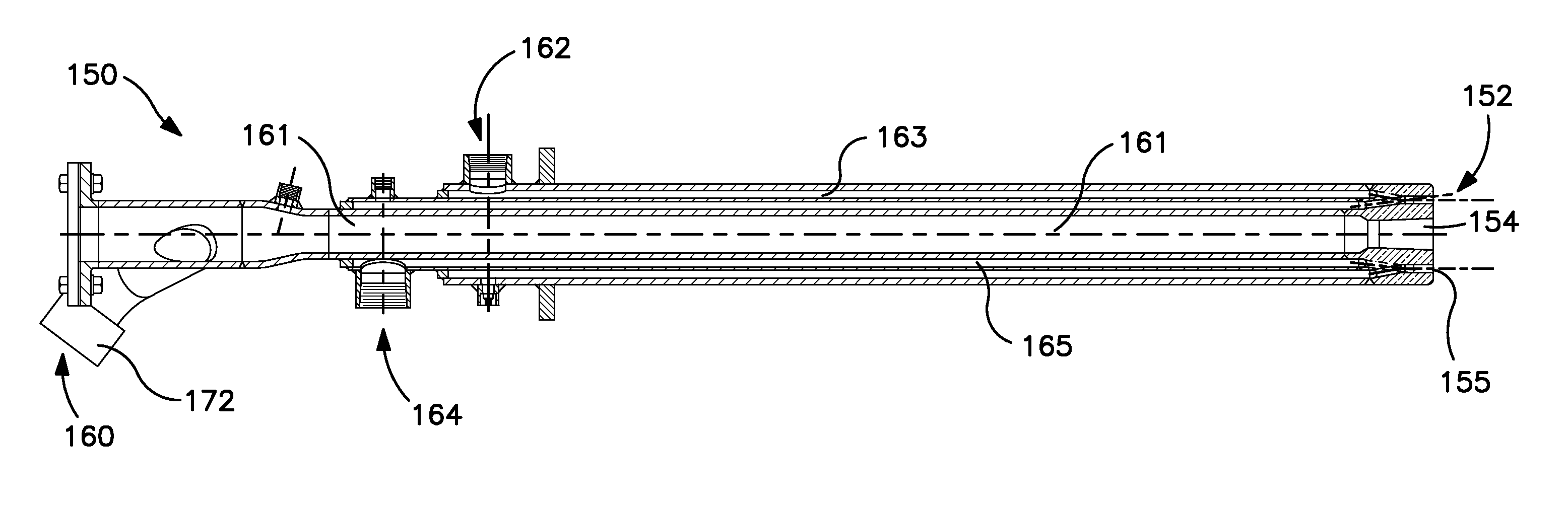

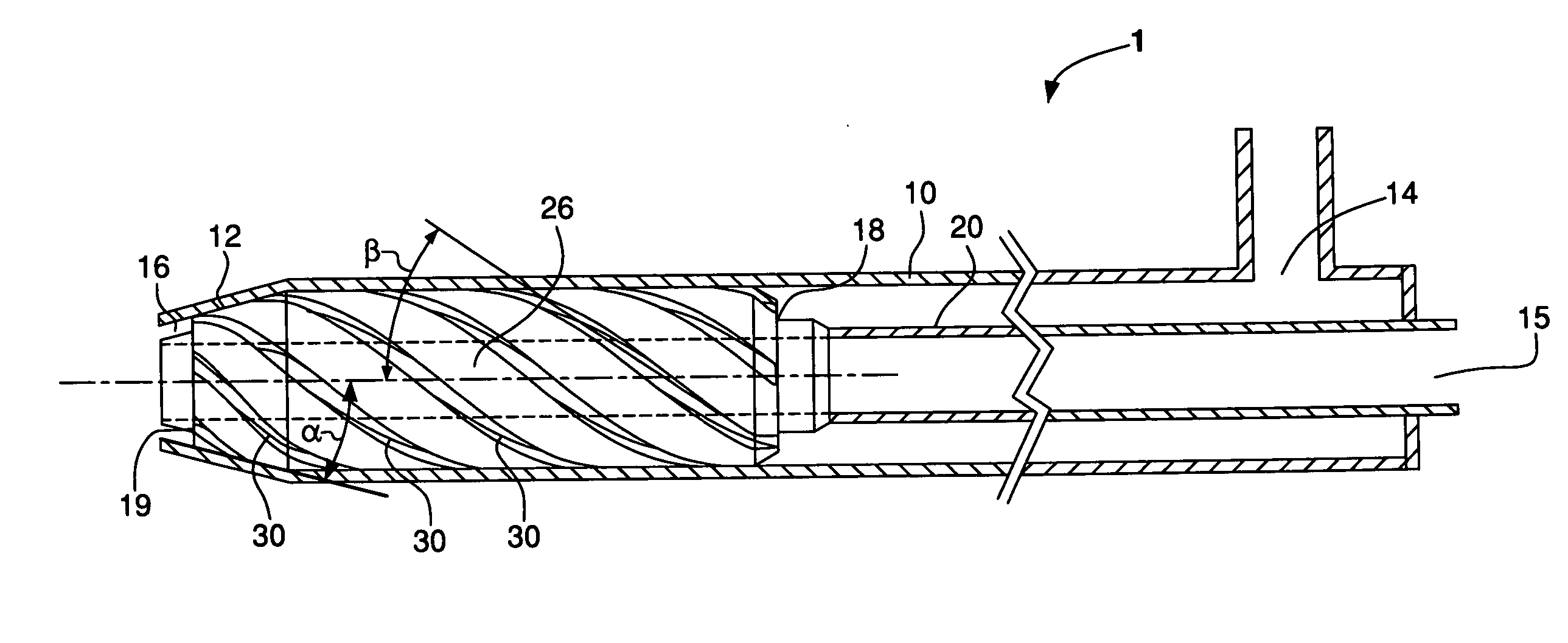

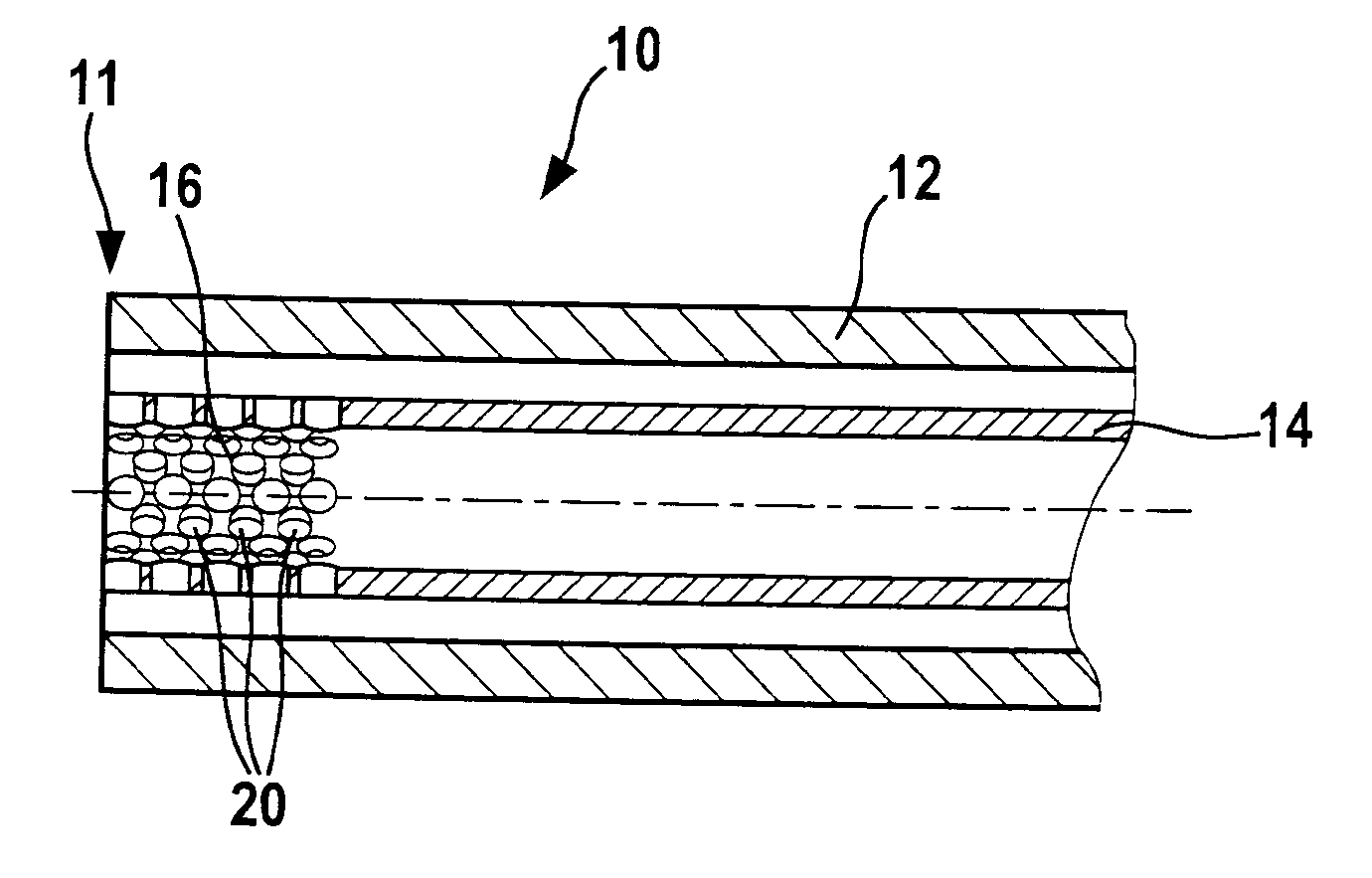

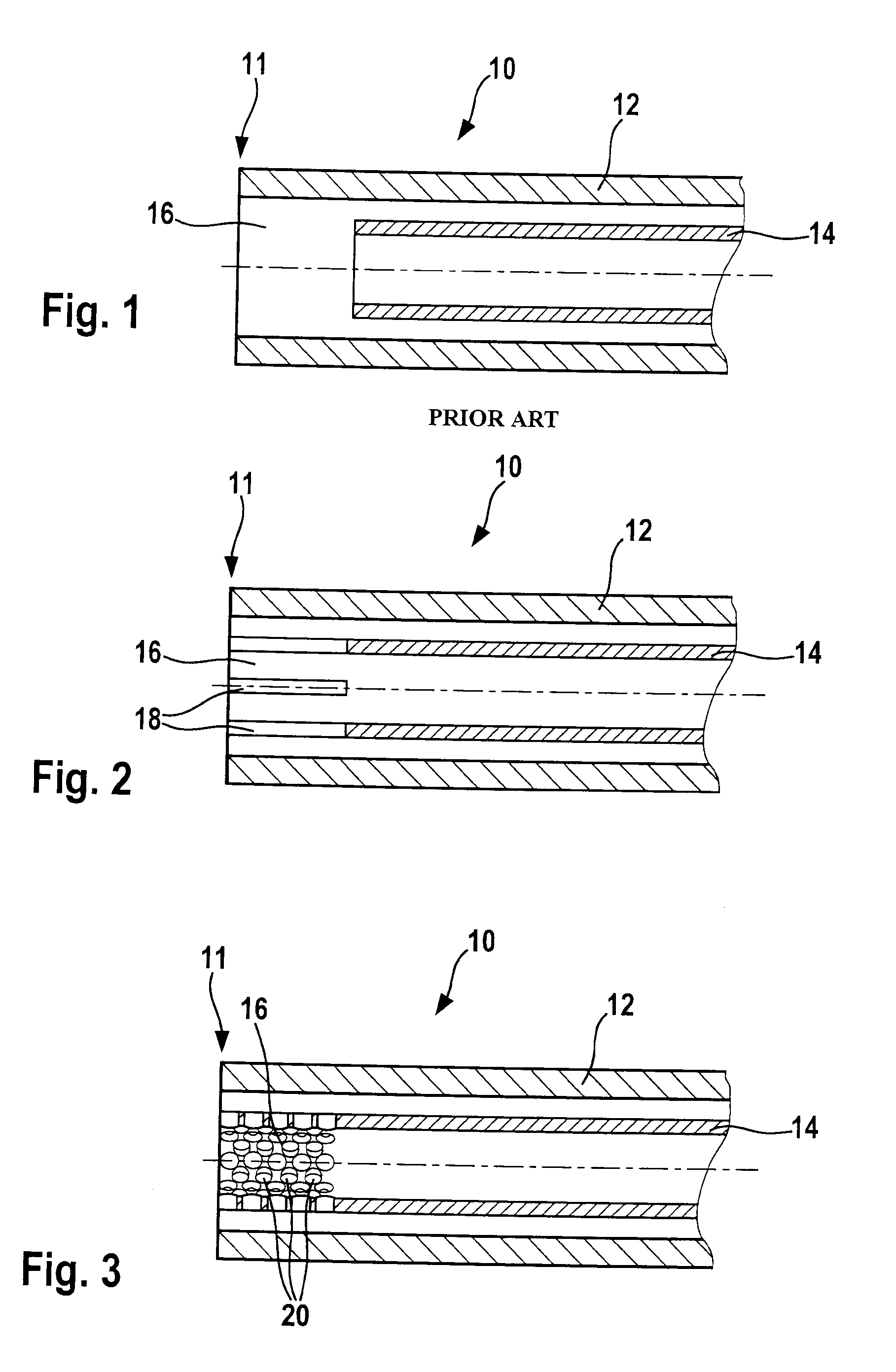

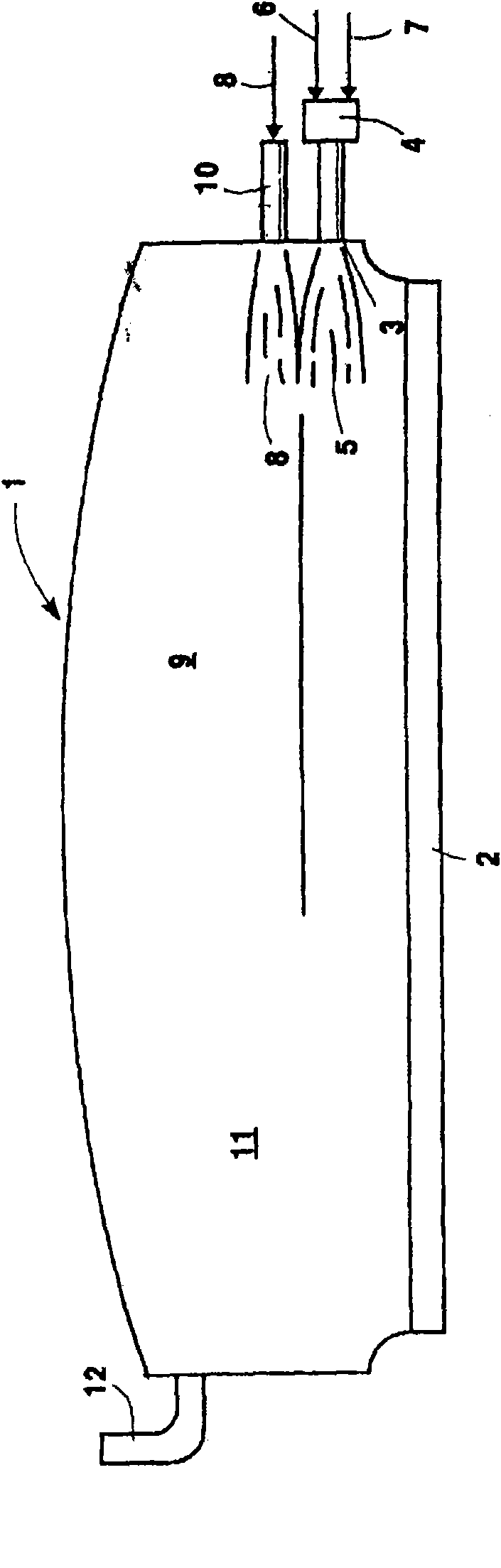

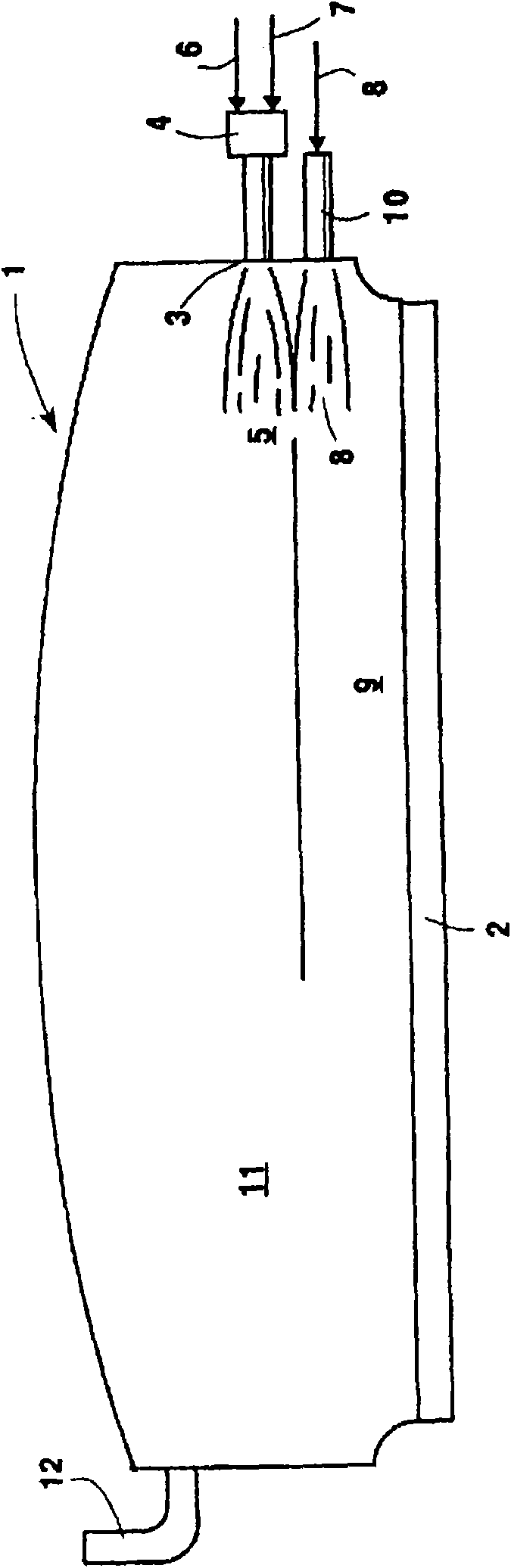

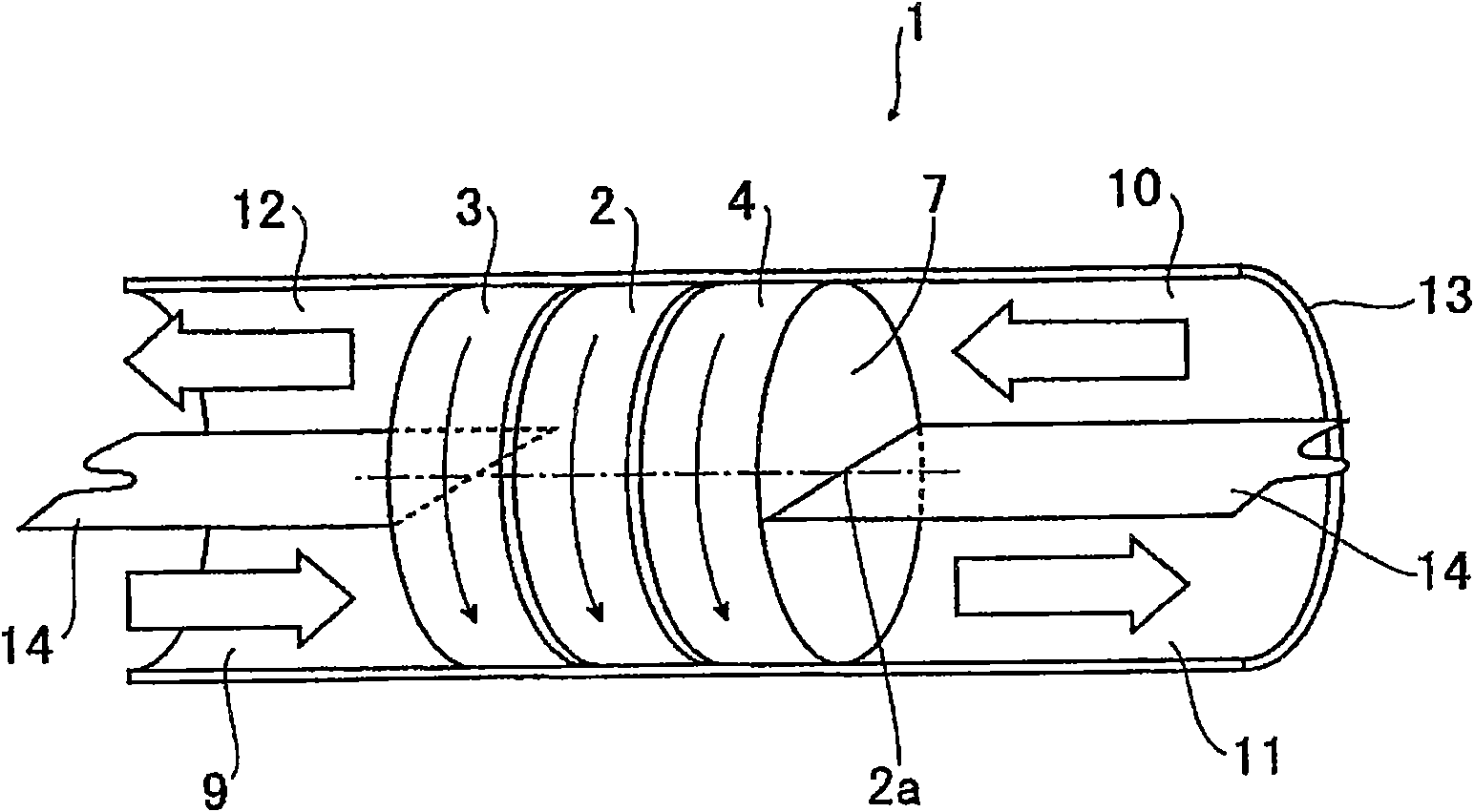

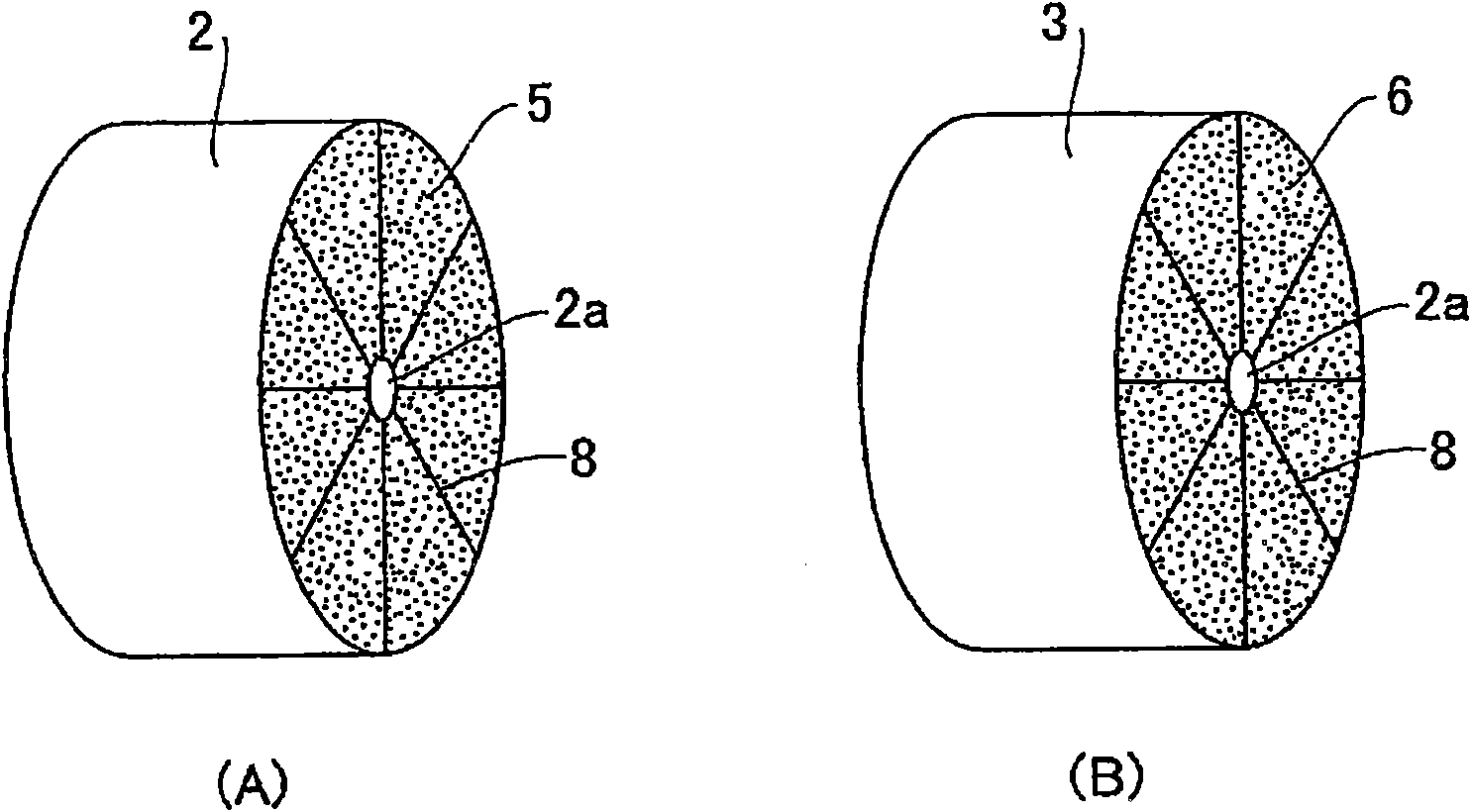

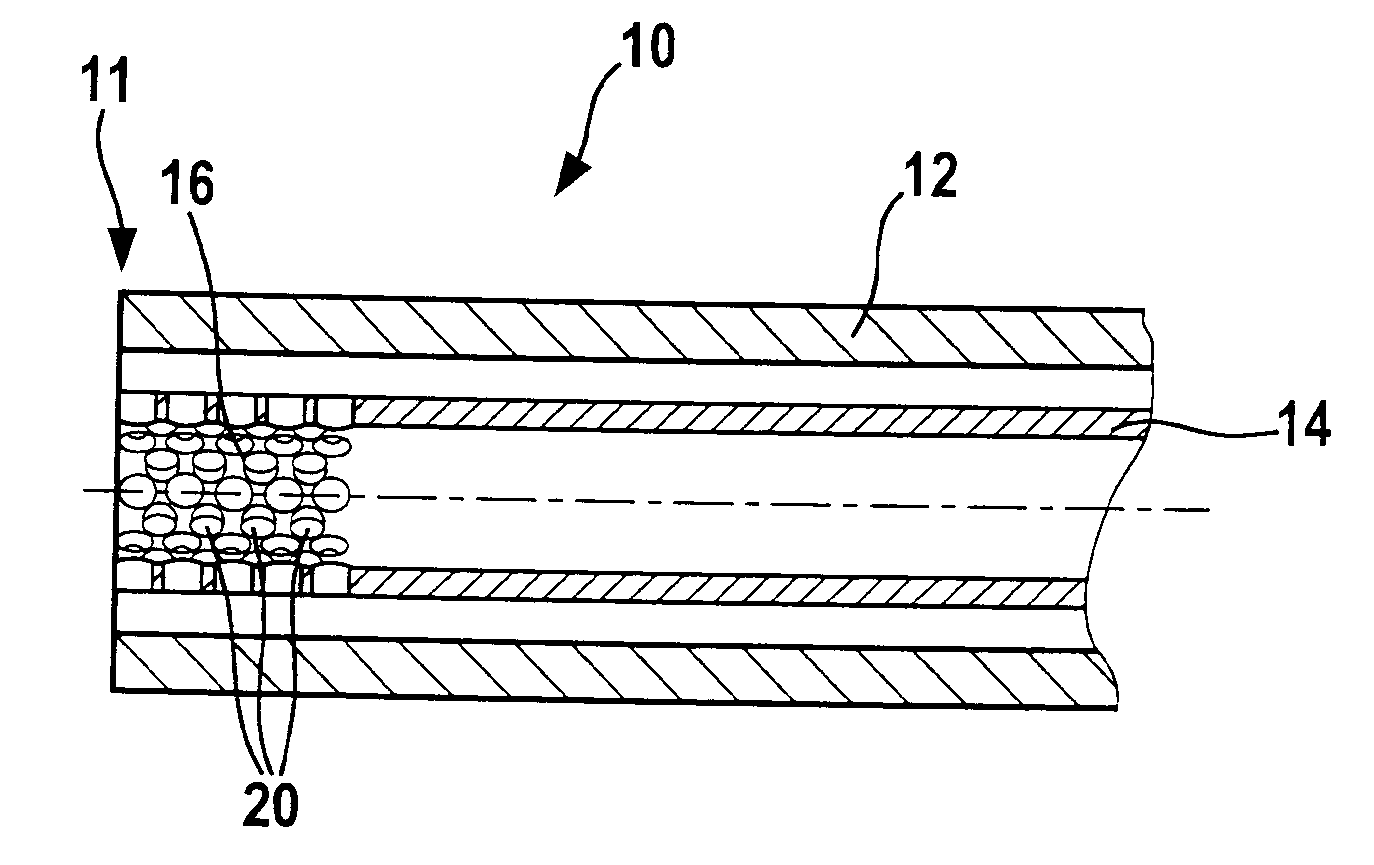

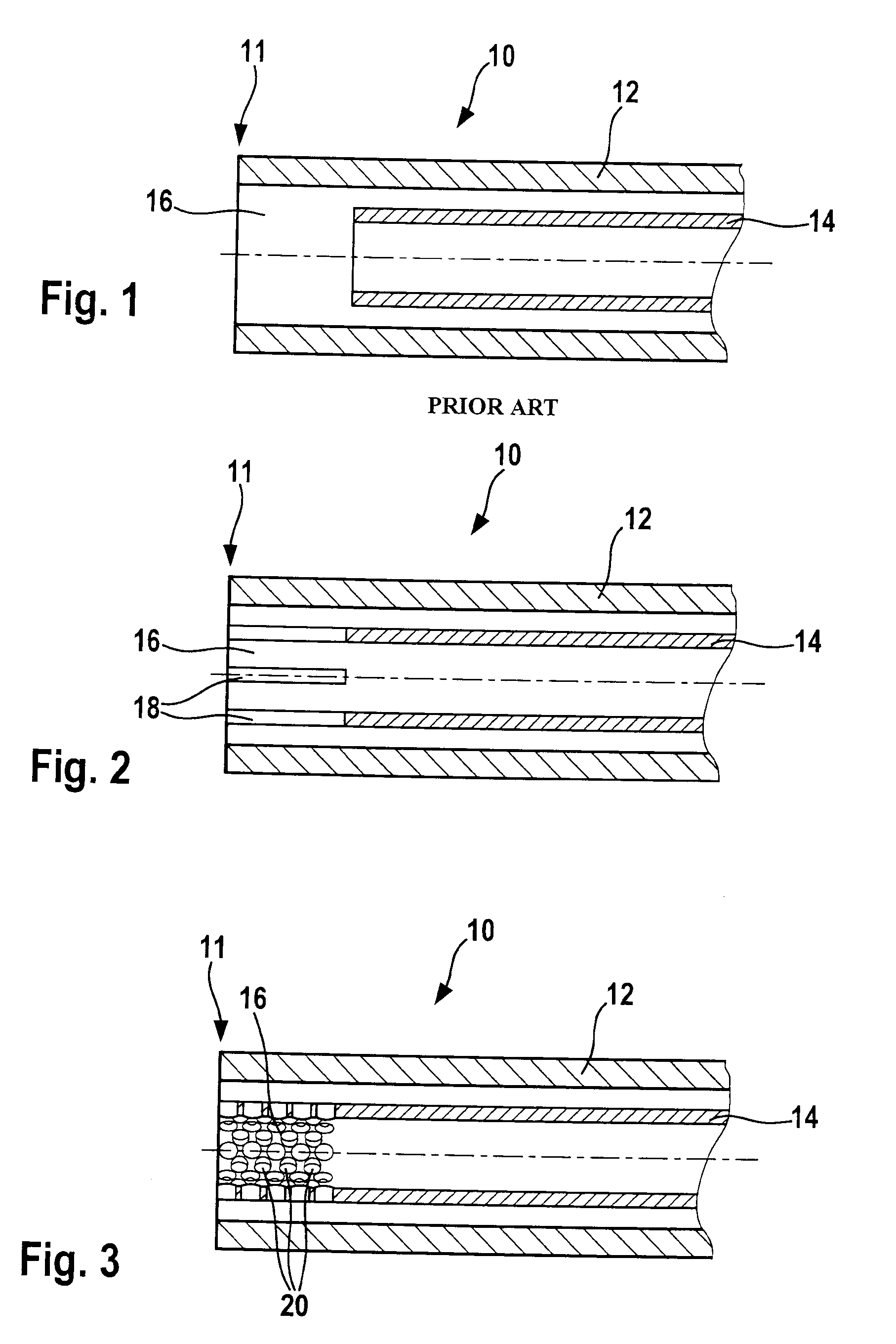

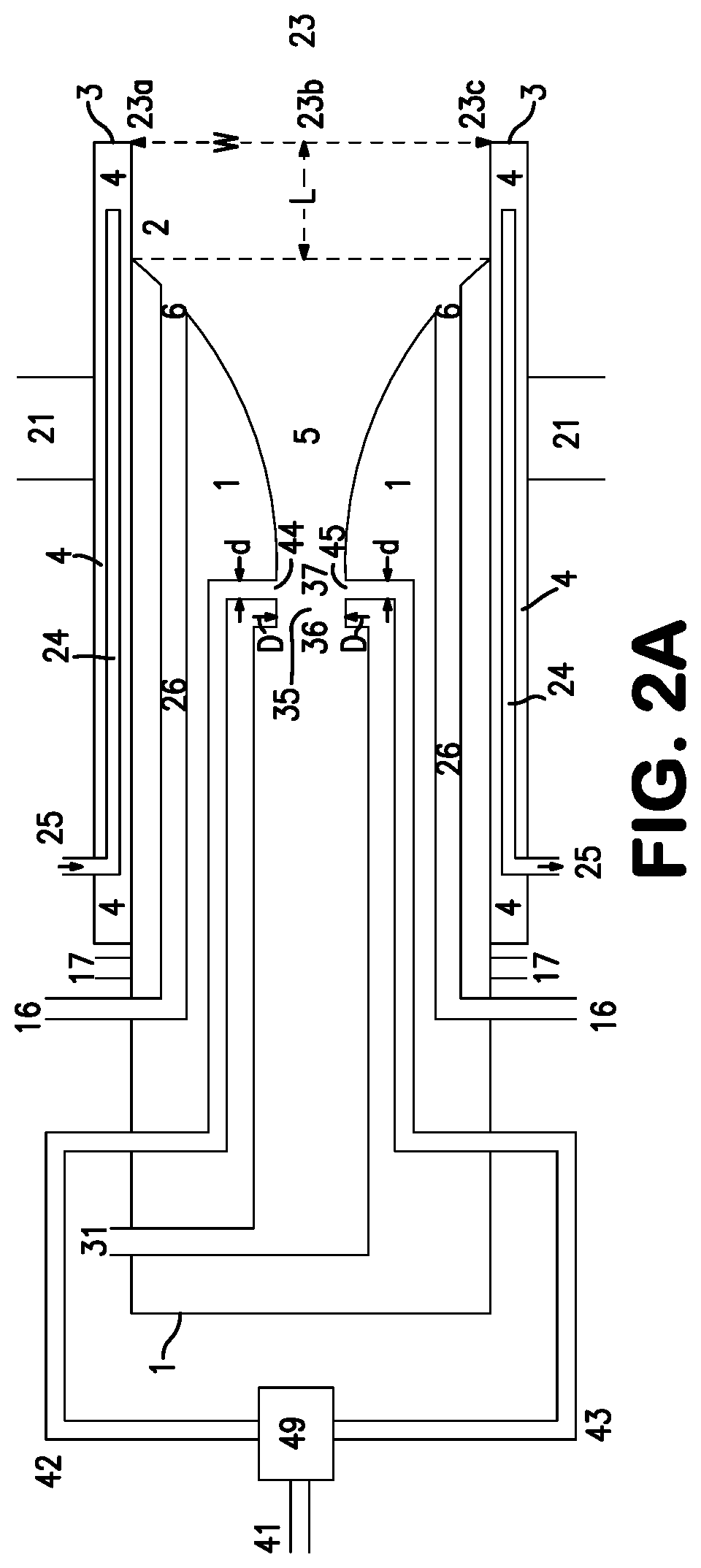

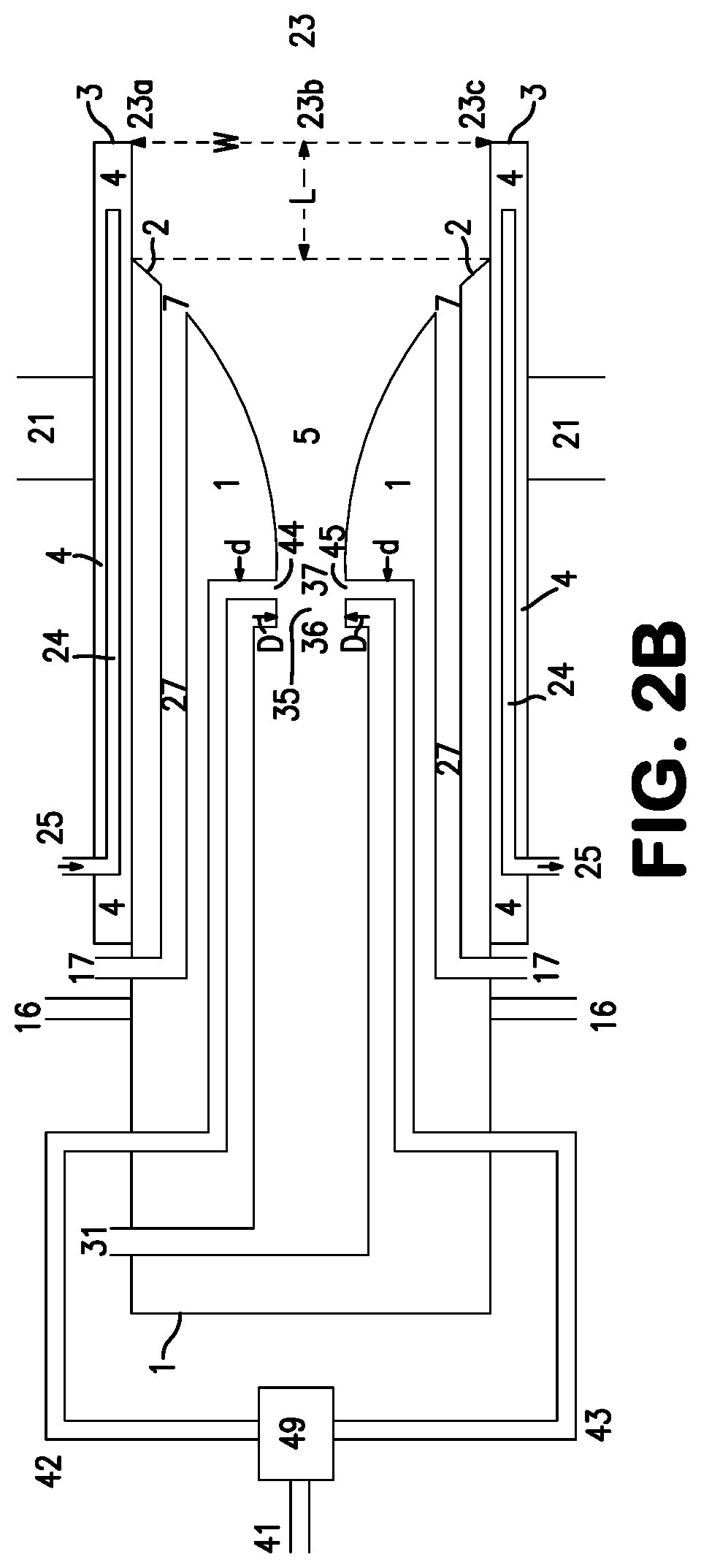

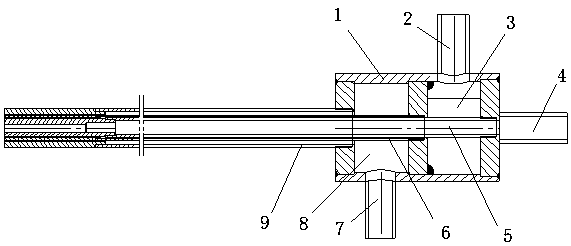

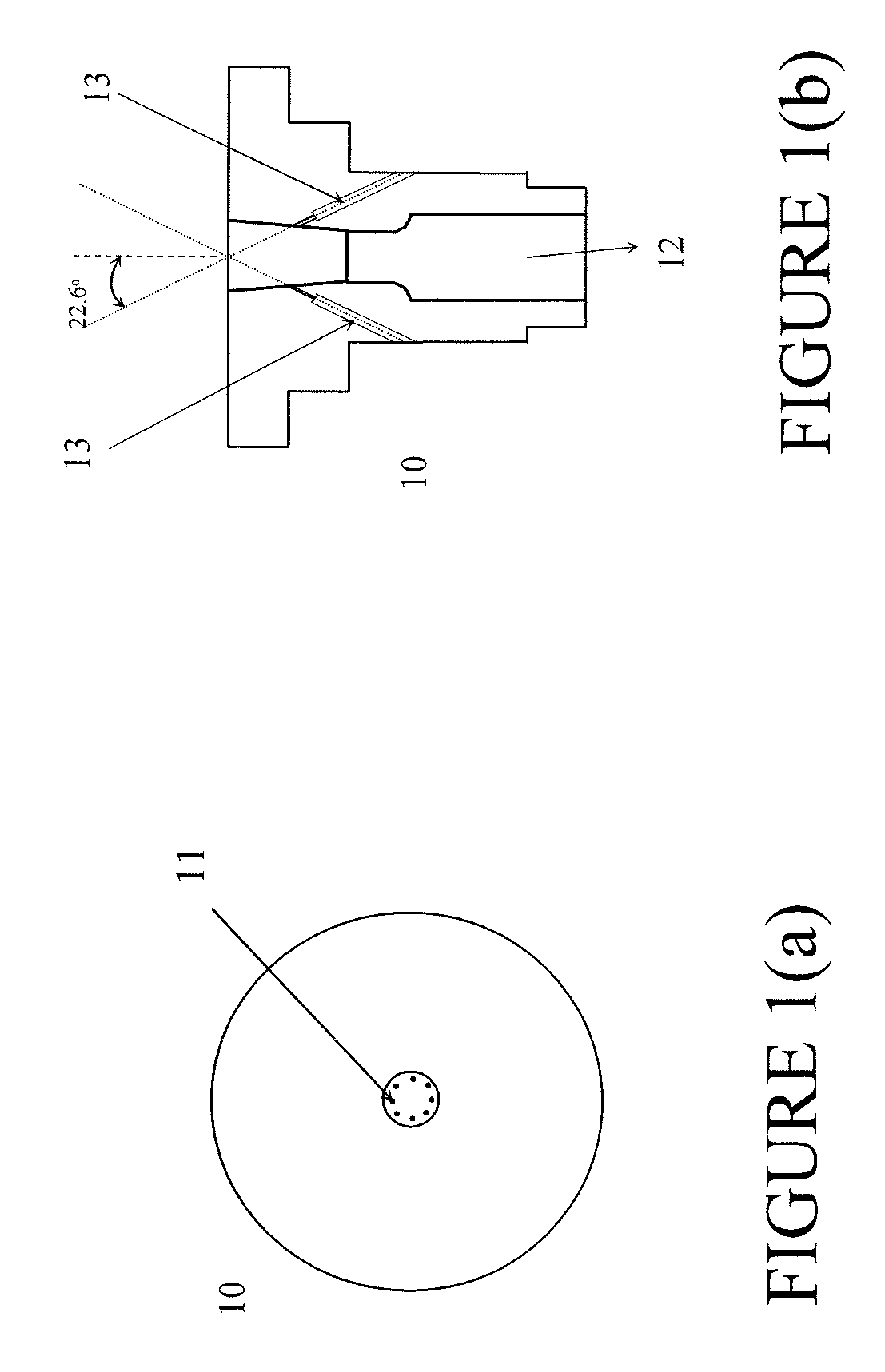

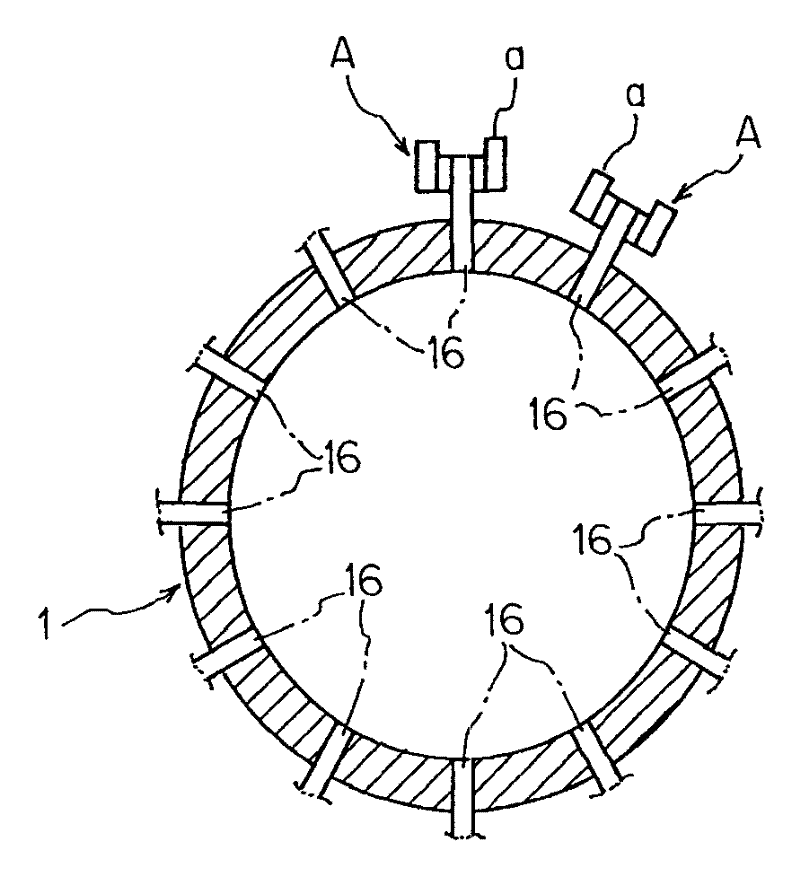

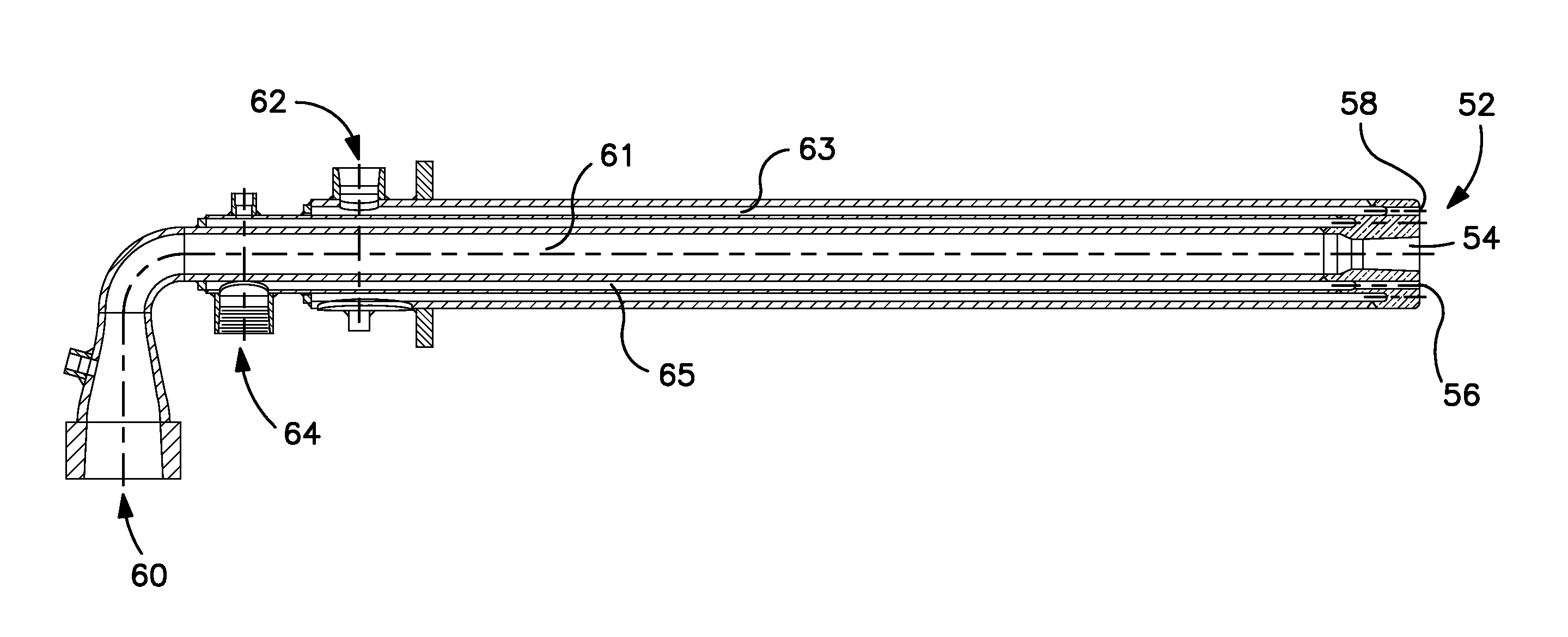

Pulverized coal injection lance

The present invention proposes a pulverized coal injection lance (10) for feeding pulverized coal from a rear end of the lance (10) to a front end (11) of the lance (10). The lance (10) comprises an outer pipe (12) for conveying combustive gas, and an inner pipe (14), coaxially arranged within the outer pipe (12), for conveying pulverized coal. The inner pipe (14) forms a separation wall for separating the pulverized coal from the combustive gas. The separation wall is at least partially discontinued in a region near the front end (11) of the lance (10), thereby forming a mixing region (16) within the pulverized coal injection lance (10). According to an important aspect of the invention, the outer pipe (12) and the inner pipe (14) have substantially the same length and wherein the inner pipe (14) comprises at least one lateral opening (18, 20) for allowing pulverized coal and combustive gas to come into contact within the pulverized coal injection lance (10) near the front end (11).

Owner:PAUL WURTH SA

Low velocity staged combustion for furnace atmosphere control

An improved staged combustion method useful with oxy-fuel combustion and in a furnace which contains a charge, wherein substoichiometric combustion and low velocity injection of fuel and primary and secondary oxidant are carried out in an orientation which forms a reducing atmosphere proximate the charge surface.

Owner:PRAXAIR TECH INC

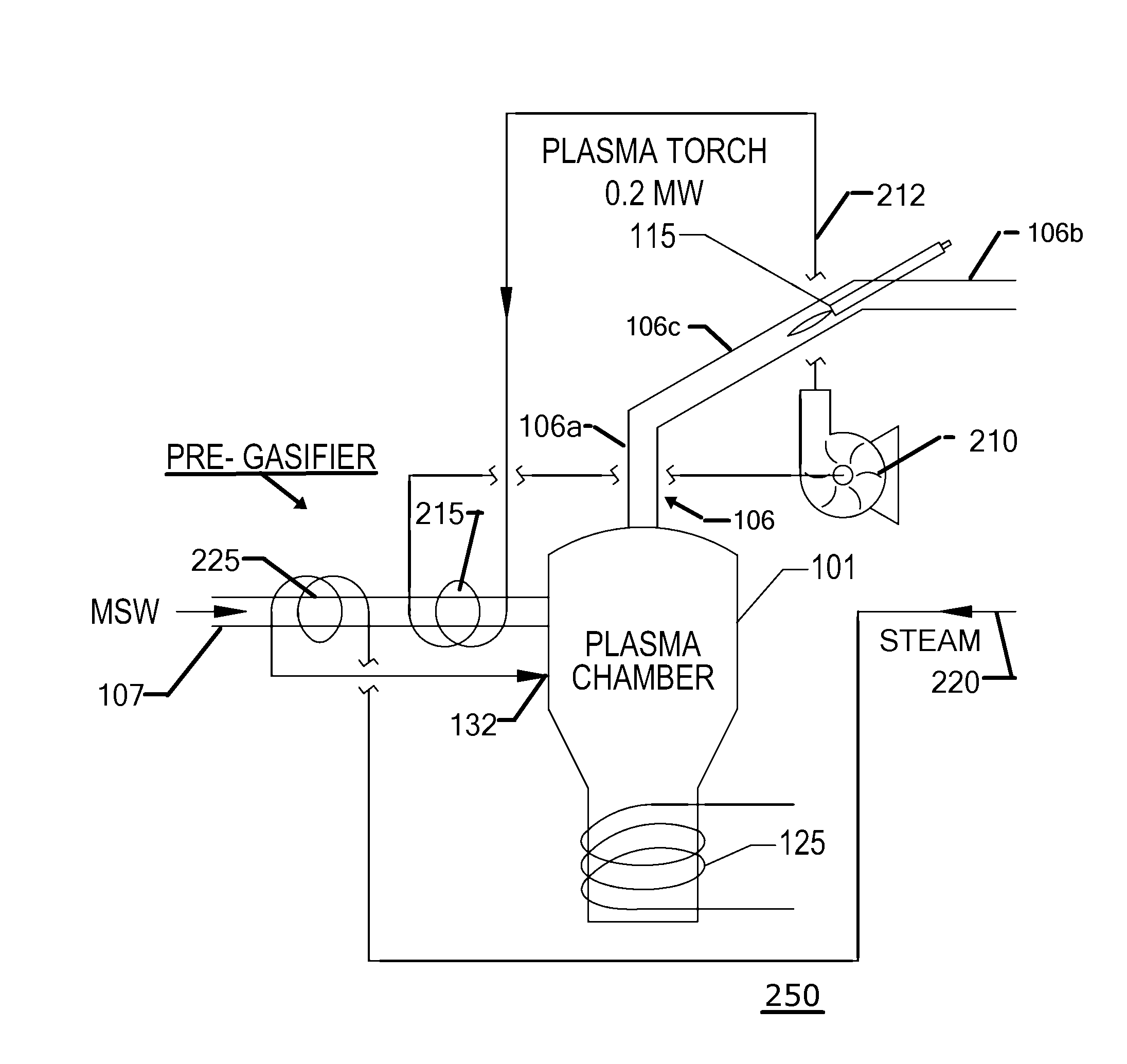

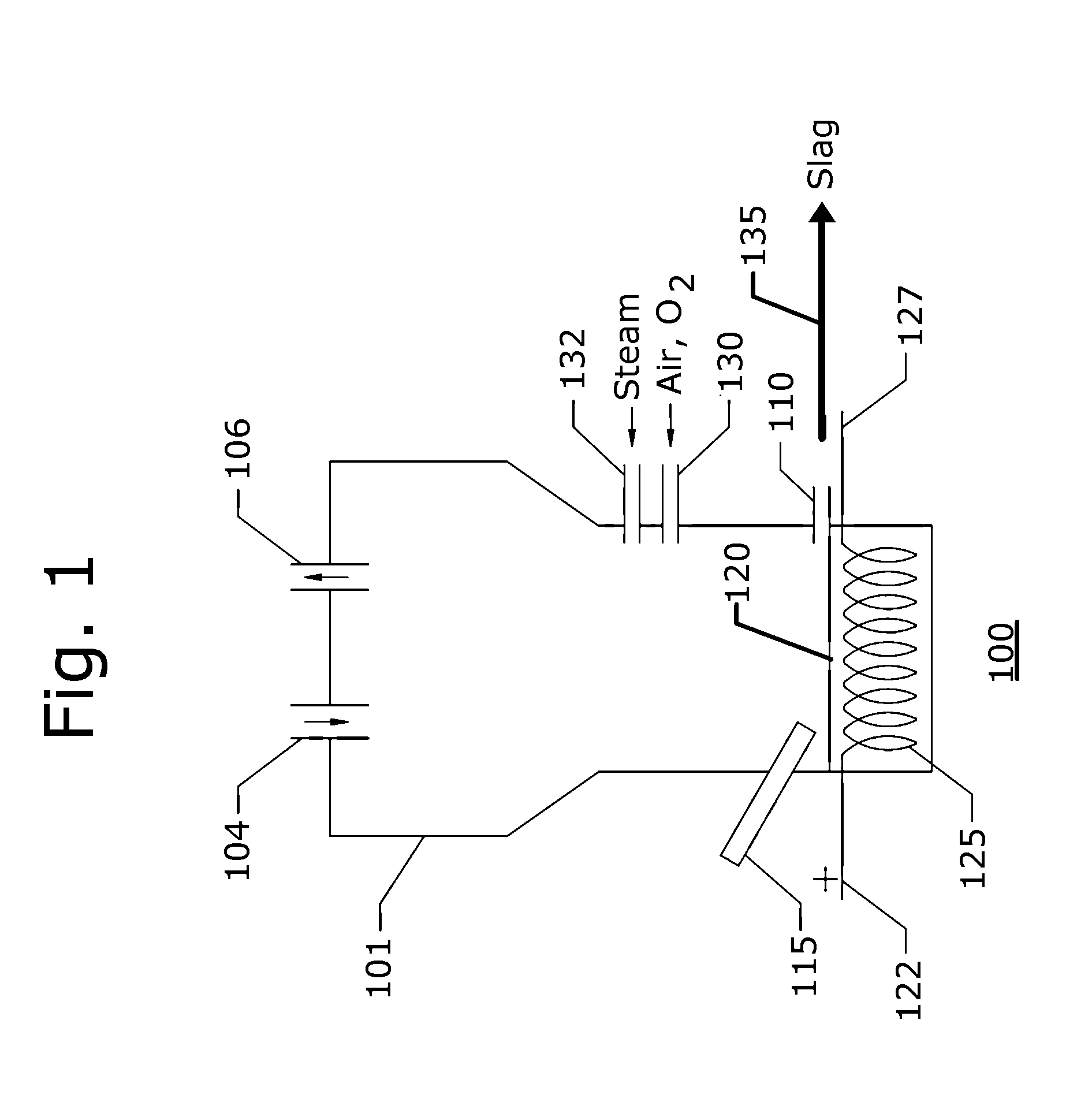

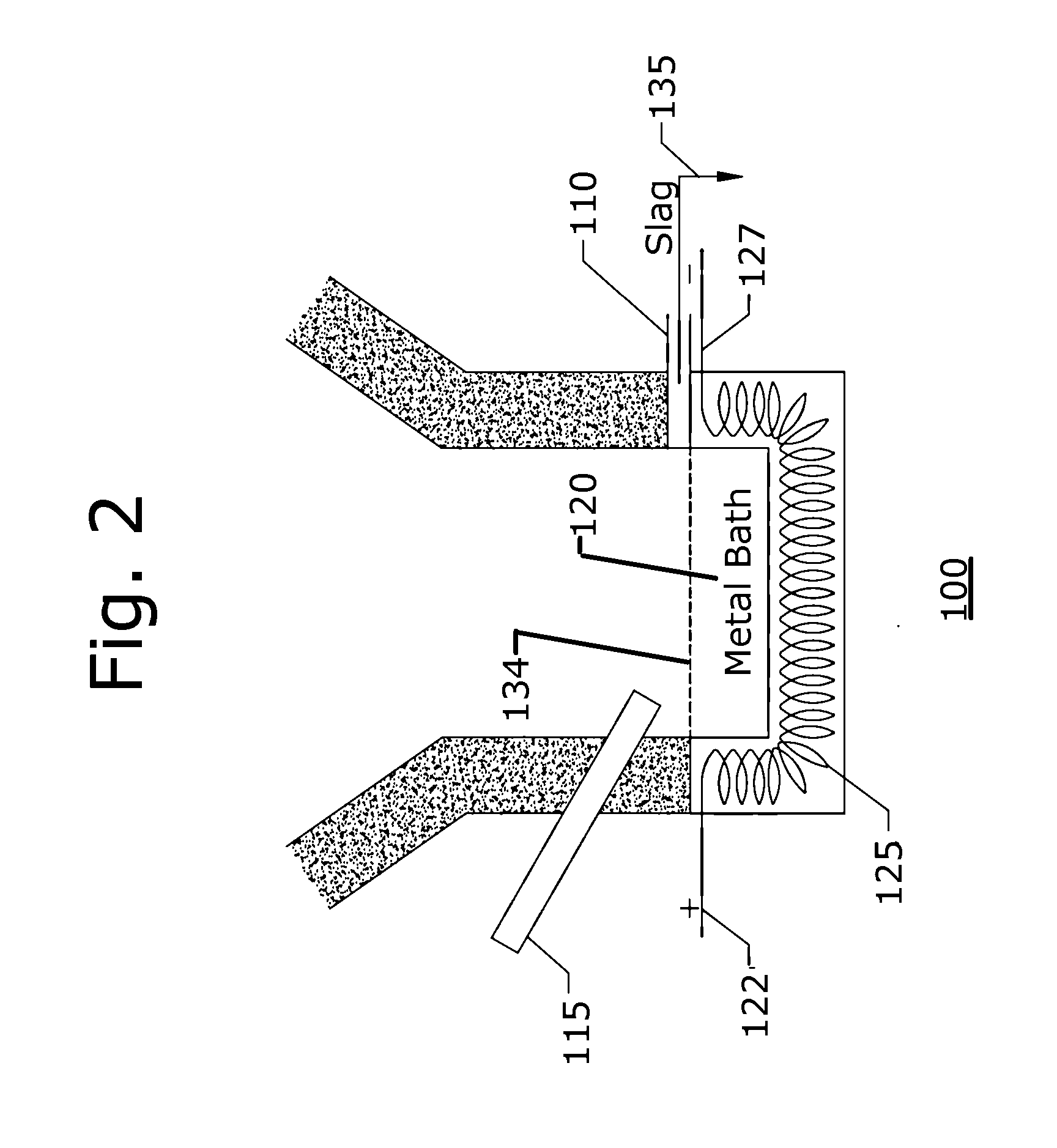

Inductive Bath Plasma Cupola

ActiveUS20140166934A1Reduce particulate and emissionWell mixedOther chemical processesEnergy inputSyngasCupola

A method of generating syngas as a primary product from renewable feedstock, fossil fuels, or hazardous waste with the use of a cupola. The cupola operates selectably on inductive heat alone, chemically assisted heat, or plasma assisted heat. Additionally, the operation of the cupola is augmented by the use of direct acting carbon or graphite rods that carry electrical current for additional heat generation into the metal bath that is influenced by the inductive element. The method includes the steps of providing a cupola for containing a metal bath; and operating an inductive element to react with the metal bath. Feedstock in the form of a combination of fossil fuel, a hazardous waste, and a hazardous material is supplied to the cupola. A plasma torch operates on the metal bath selectably directly and indirectly. Steam, air, oxygen enriched air, and oxygen are supplied in selectable combinations.

Owner:PLASMA TECH HLDG LLC

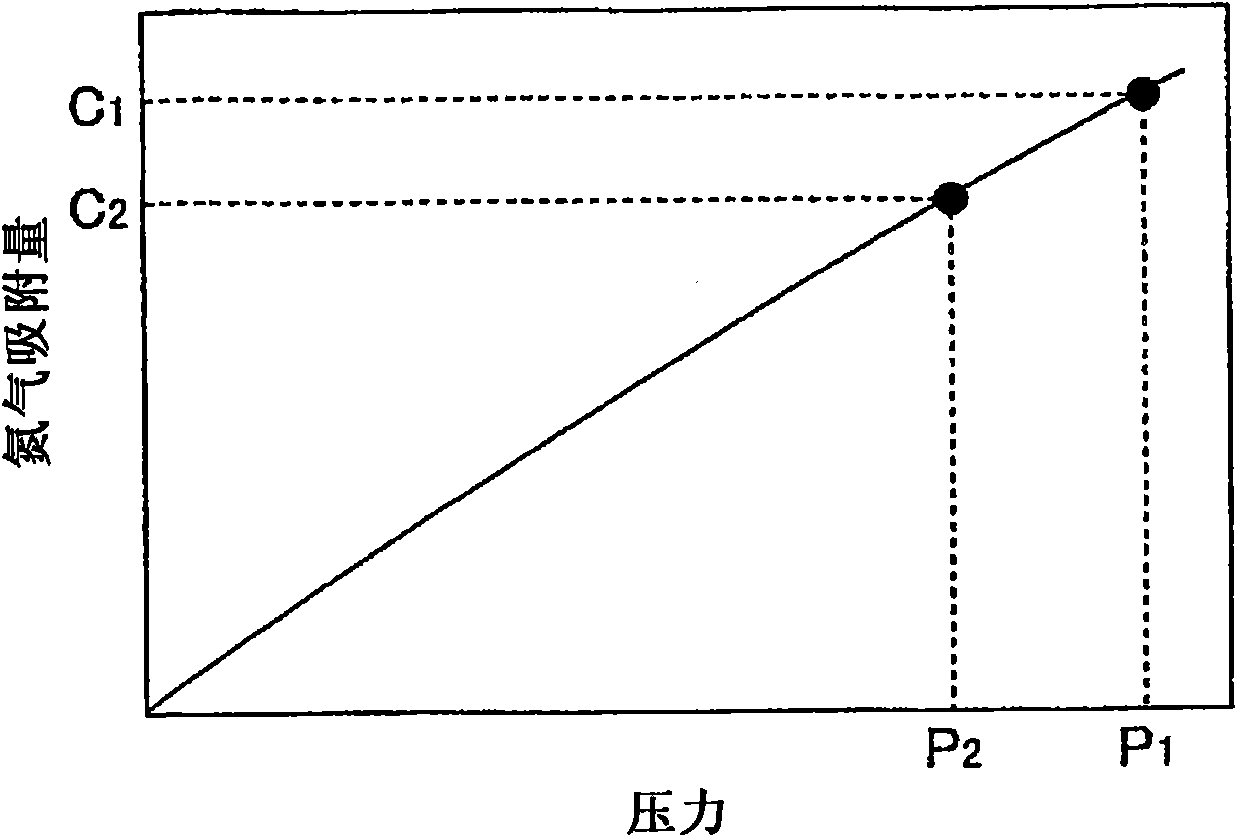

Method of separating blast furnace gas

ActiveCN101978078AEfficient separationLow costBlast furnace detailsHydrogen/synthetic gas productionNitrogenProduct gas

A method of separating a blast furnace gas which comprises: a step in which oxygen-enriched air having an oxygen concentration of at least 25 vol.% is yielded; a step in which the oxygen-enriched air is blown into a blast furnace through a tuyere disposed in a lower part of the blast furnace; and a step in which carbon dioxide and nitrogen are separated and removed from a blast furnace gas discharged from the top of the blast furnace, thereby generating a modified blast furnace gas.

Owner:JFE STEEL CORP

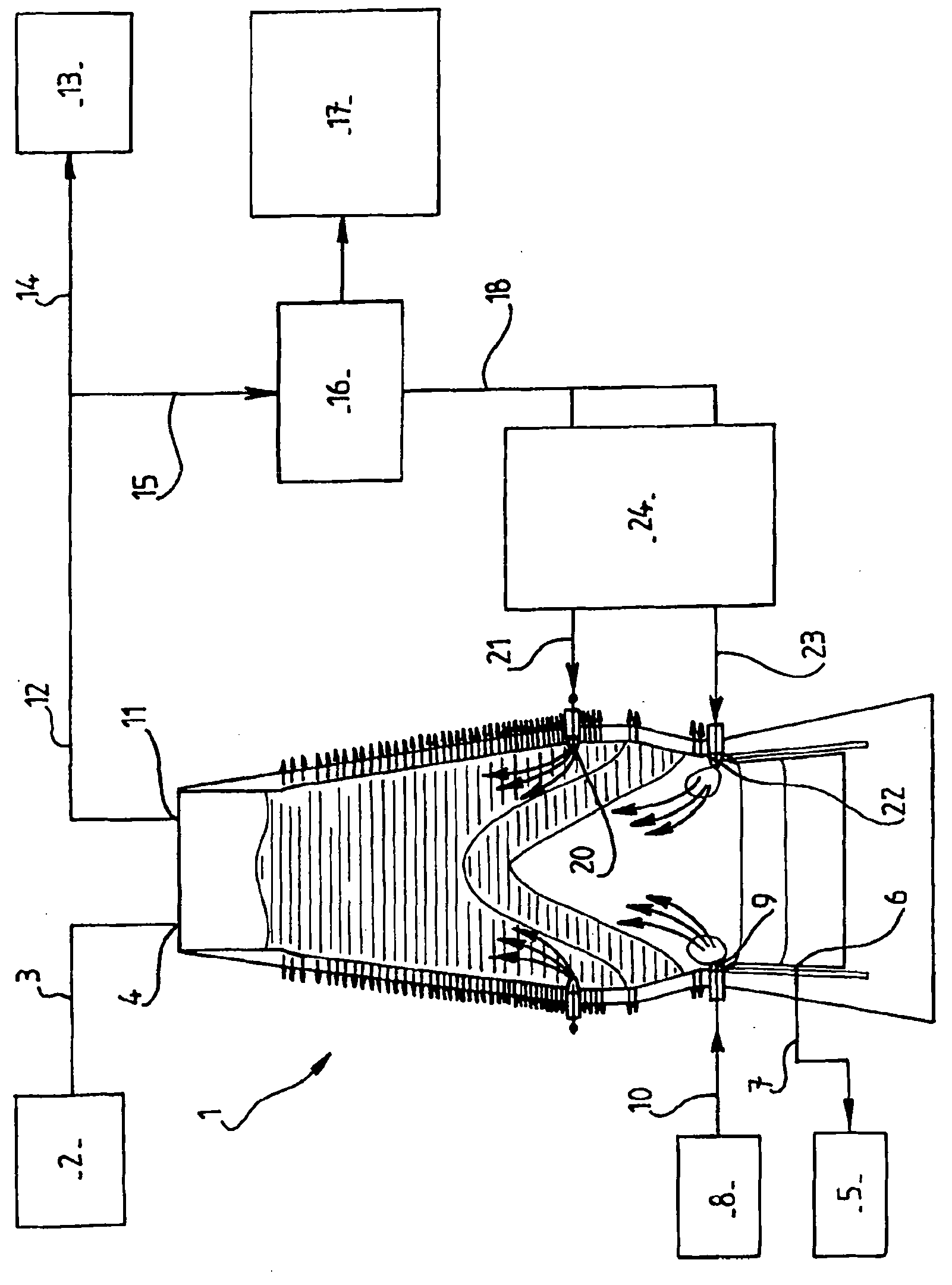

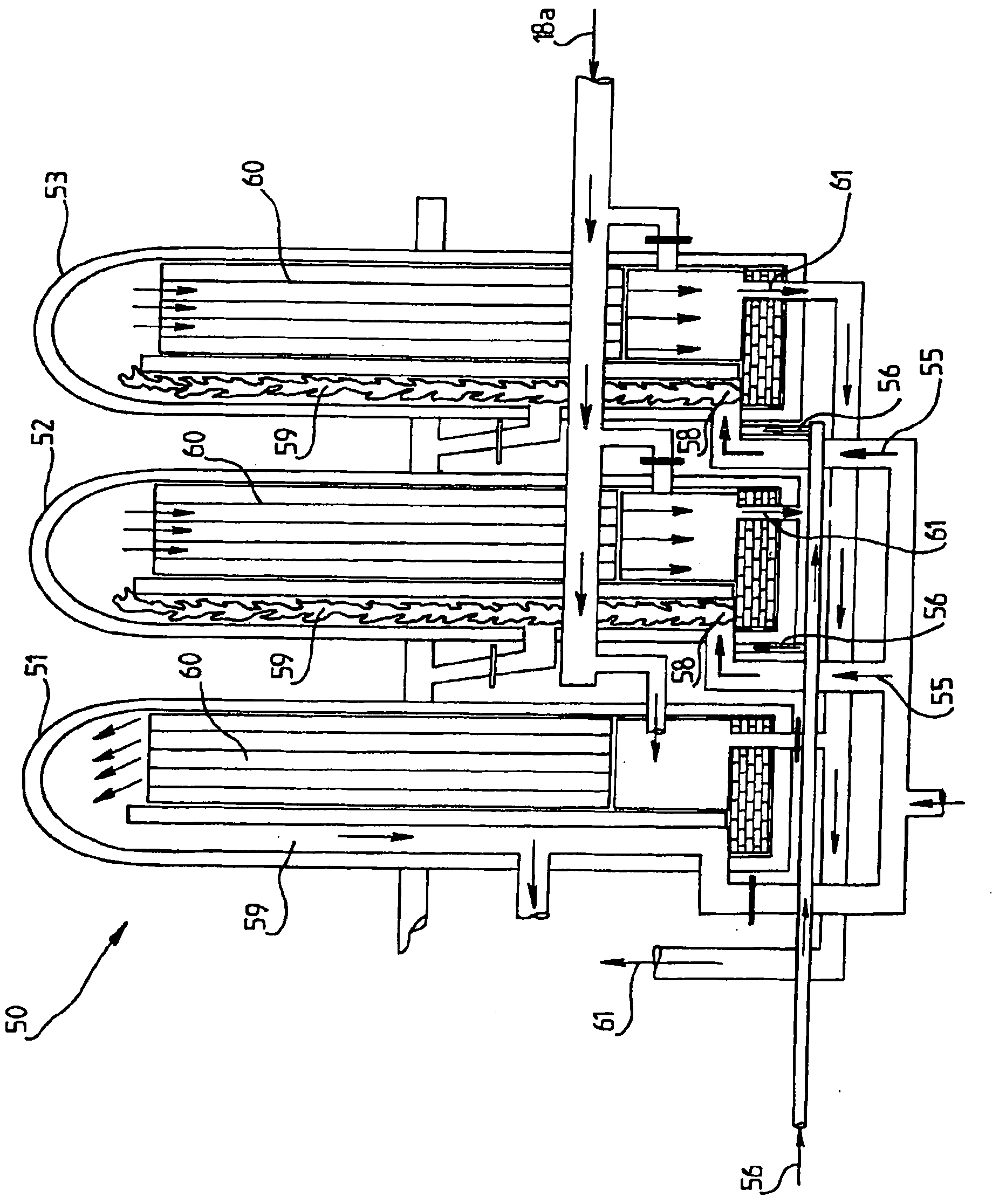

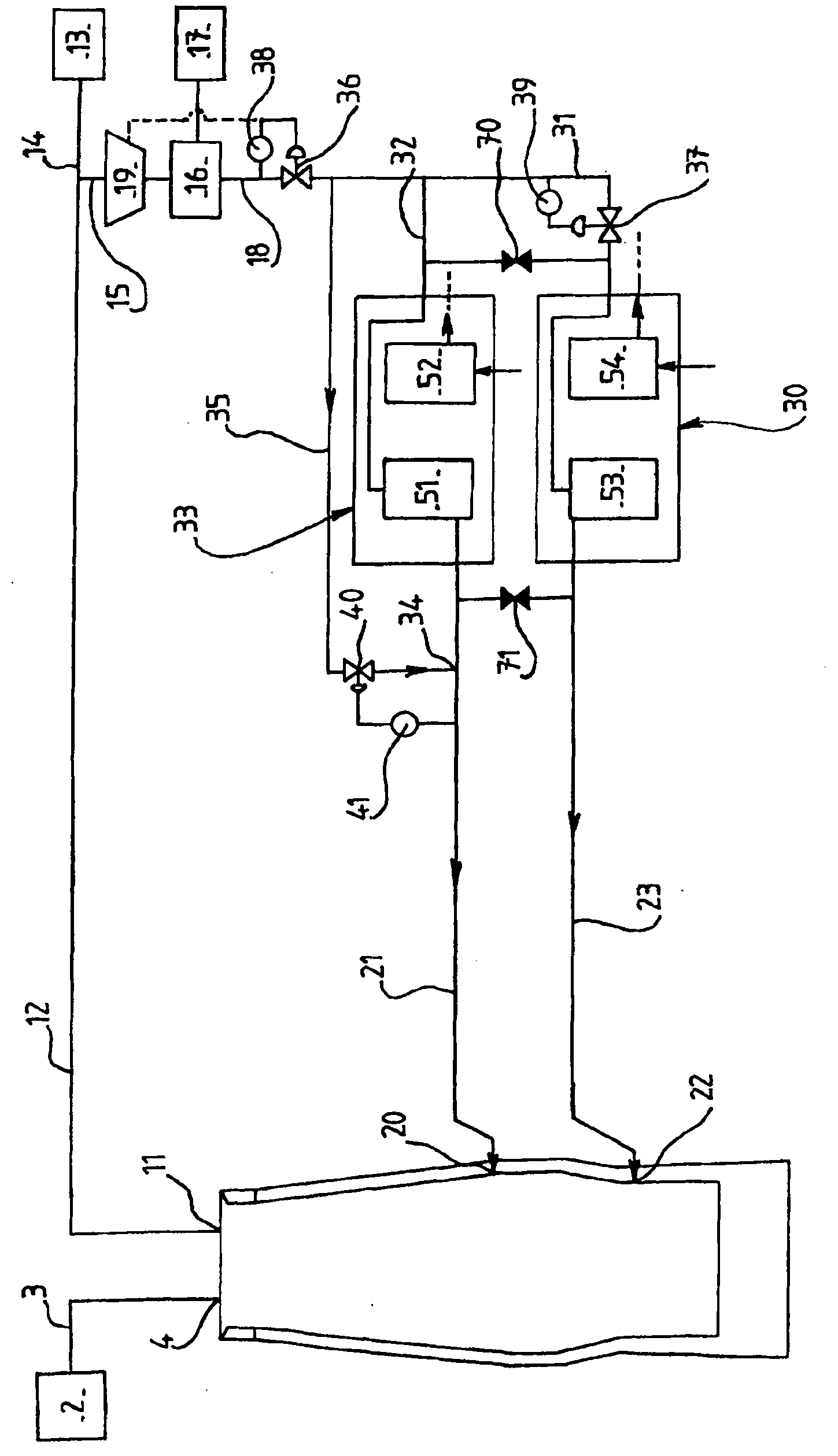

Method for recirculating blast furnace gas, and associated device

The invention mainly relates to a method for recirculating gas from a blast furnace in which at least part of the gases from the blast furnace are subjected to a CO2 purification step so as to create a gas that is rich in CO, which is then reinjected, at a first top injection point located above the base of the blast furnace and at a temperature of between 700 and 1000 DEG C, through a top injection line, and through a second bottom injection point at the base of the blast furnace at a temperature of between 1000 DEG C and 1300 DEG C through a bottom injection line, wherein the gases from the top and bottom injection lines are heated with reheaters from which gases are discharged at a temperature of between 1000 DEG C and 1300 DEG C. The method of the invention is essentially characterized in that part of the CO-rich gas (18) being discharged from the purification step is directly injected into the top injection line (21) via a cold gas injection line (35) so as to result in a temperature of between 700 and 1000 DEG C at the first top injection point (20), and in that the gas flow control in the bottom (22) and top (20) injection points takes place upstream from the reheater system (30,33; 45). The invention also relates to a device for implementing the abovementioned method.

Owner:ARCELORMITTAL INVESTIGACION Y DESARROLLO SL

Heavy austempered ductile iron components

The invention relates to heavy austempered ductile iron components. A component for wind turbines includes cast austempered ductile iron containing about 3.0 to about 3.8 weight percent carbon, about 1.9 to about 2.8 weight percent silicon, up to about 0.3 weight percent manganese, up to about 0.8 weight percent copper, up to about 2.0 weight percent nickel, up to about 0.3 weight percent molybdenum, about 0.03 to about 0.06 weight percent magnesium, less than about 0.05 weight percent chromium, less than about 0.02 weight percent vanadium, and less than about 0.01 weight percent sulfur. The component is preferably a drive shaft or gearbox component having a mass of more than about 3 tons. A method of manufacturing the component is also provided.

Owner:GENERAL ELECTRIC CO

Pulverized coal injection lance

ActiveUS8080200B2Improve efficiencyImprove stabilityFurnace componentsTuyeresCombustible gasEngineering

The present invention proposes a pulverized coal injection lance (10) for feeding pulverized coal from a rear end of the lance (10) to a front end (11) of the lance (10). The lance (10) comprises an outer pipe (12) for conveying combustive gas, and an inner pipe (14), coaxially arranged within the outer pipe (12), for conveying pulverized coal. The inner pipe (14) forms a separation wall for separating the pulverized coal from the combustive gas. The separation wall is at least partially discontinued in a region near the front end (11) of the lance (10), thereby forming a mixing region (16) within the pulverized coal injection lance (10). According to an important aspect of the invention, the outer pipe (12) and the inner pipe (14) have substantially the same length and wherein the inner pipe (14) comprises at least one lateral opening (18, 20) for allowing pulverized coal and combustive gas to come into contact within the pulverized coal injection lance (10) near the front end (11).

Owner:PAUL WURTH SA

Exhaust processing and heat recovery system

InactiveUS9598742B2Reduce accumulationImprove thermal efficiencyBurnersUsing liquid separation agentAir preheaterThermal energy

Owner:ALSTOM ENERGY TECH AG

Fluidic burner with heat stability

A burner comprises a central passageway and outlets for fuel and for stabilizing oxidant arranged peripherally around the central passageway, and comprises outlets within the burner through which biasing gas, such as gas comprising oxygen, can be injected to enable control of the direction of the flame that is generated by combustion of the fuel and the oxidant at the face of the burner.

Owner:PRAXAIR TECH INC

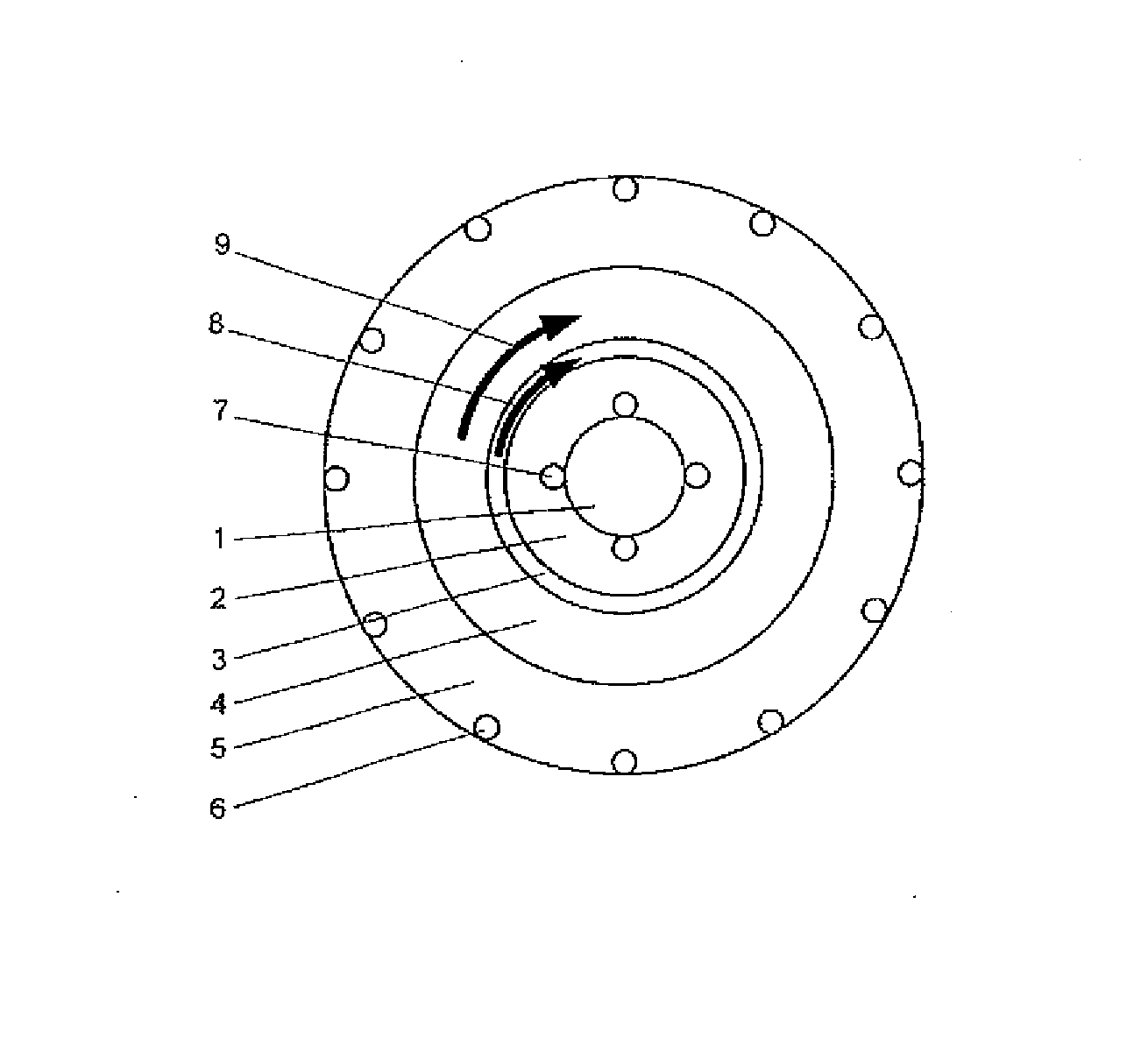

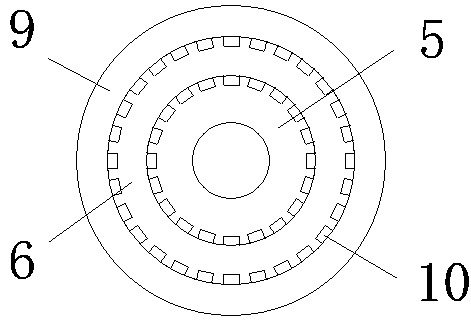

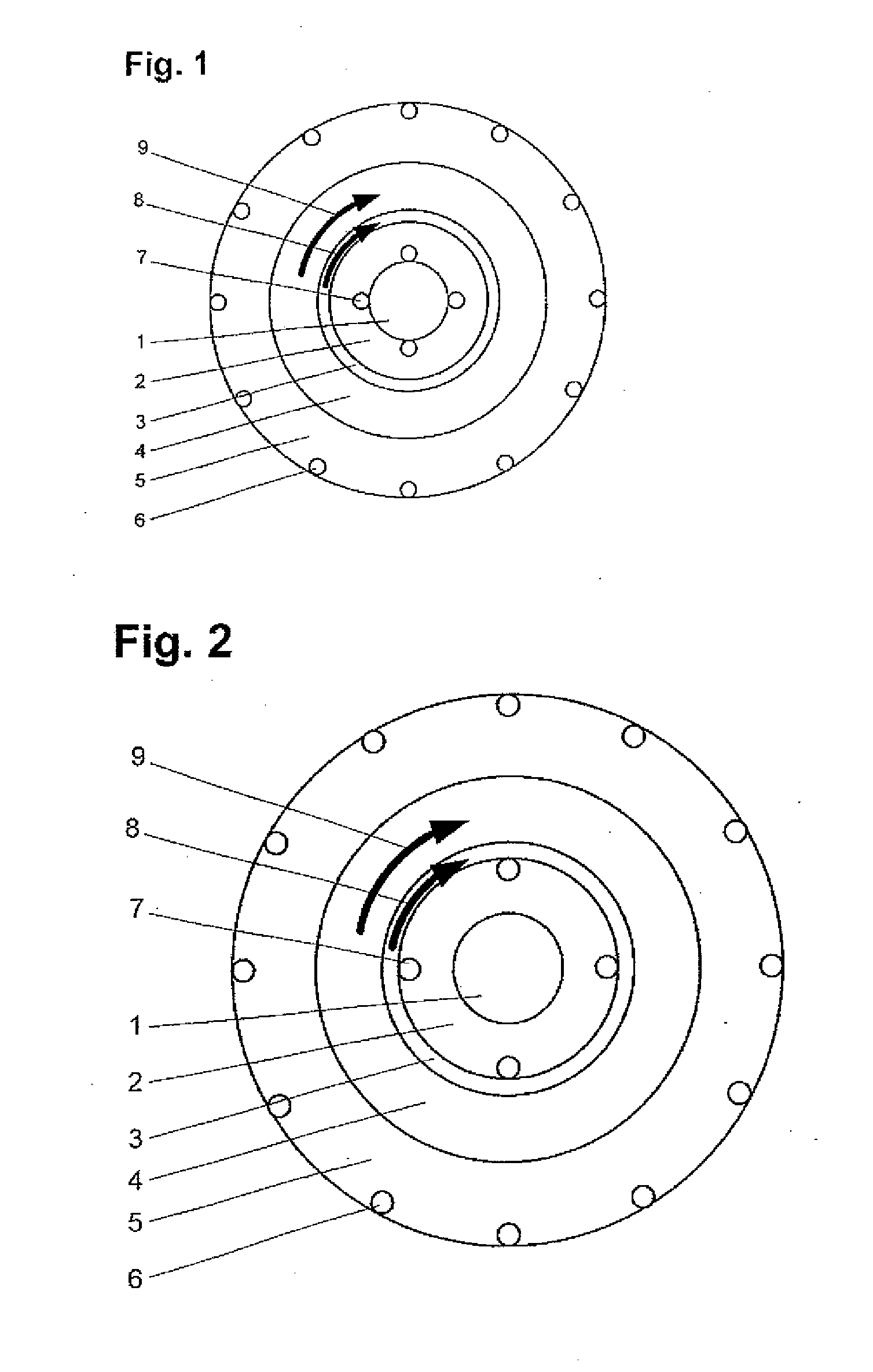

Burner

A burner includes a first fuel feed and a first oxidant feed surrounding the first fuel feed in the shape of a ring. The burner includes a second fuel feed arranged about the first oxidant feed in the shape of a ring, and a second oxidant feed arranged about the second fuel feed in the shape of a ring. In addition, a plurality of oxygen lances are provided, which have a smaller radial distance from the burner centre than the second fuel feed.

Owner:LINDE AG

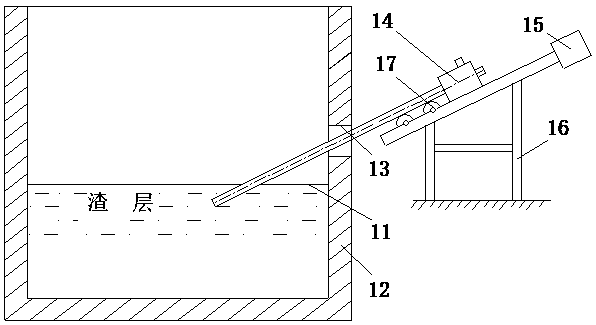

Side-blowing spray gun for melting furnace and application method thereof

ActiveCN109210936AImprove heat transfer performanceEnhanced mass transferStirring devicesCharge manipulationCombustible gasEngineering

The invention relates to a side-blowing spray gun for a melting furnace and an application method thereof, and belongs to a side-blowing spray gun and an application method thereof. According to the invention, a gas connecting cylinder of the side-blowing spray gun is internally provided with a combustible gas chamber and a compressed cooling air chamber; the gas collecting cylinder is connected with a combustible gas inlet, an oxygen inlet and a compressed cooling air inlet, the oxygen inlet is located at one end of the gas collecting cylinder, and the combustible gas inlet and the compressedcooling air inlet are correspondingly connected at the positions of the combustible gas chamber and the compressed cooling air chamber; an oxygen pipe is sleeved in a combustible gas pipe, the oxygenpipe and the combustible gas pipe are sleeved in a compressed cooling air pipe, and there is a gap between the pipes; the oxygen pipe penetrates through the gas collecting cylinder, is connected to the gas collecting cylinder at the position of the oxygen inlet and is communicated with the oxygen inlet; the combustible gas pipe penetrates through the gas collecting cylinder and is connected to apartition between the combustible gas chamber and the compressed cooling air chamber; the compressed cooling air pipe is connected to the bottom end of the gas collecting cylinder; and the other end is a gas output end of the spray gun. The side-blowing spray gun has the advantages of long service life, simple structure, low cost, convenient operation, high stirring power of a molten pool, good effect and low energy consumption.

Owner:JIANGSU NEW CHUNXING RESOURCE RECYCLING CO LTD

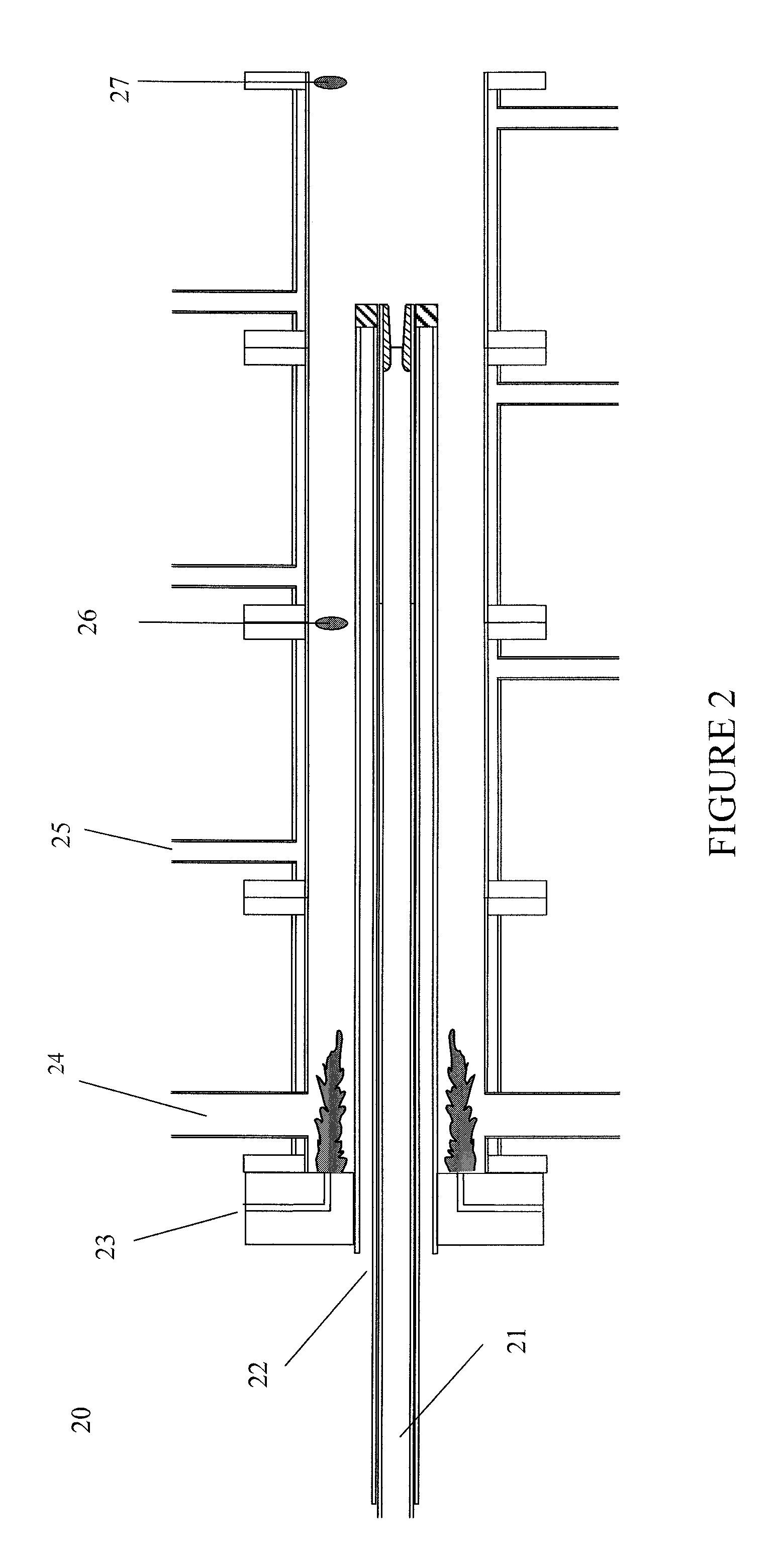

Injection method for inert gas

ActiveUS7959708B2Stable combustionAvoid concentrationTuyeresCharge manipulationBasic oxygen steelmakingOxygen mixture

Owner:PRAXAIR TECH INC

Burner

A burner includes a first fuel feed and a first oxidant feed surrounding the first fuel feed in the shape of a ring. The burner includes a second fuel feed arranged about the first oxidant feed in the shape of a ring, and a second oxidant feed arranged about the second fuel feed in the shape of a ring. In addition, a plurality of oxygen lances are provided, which have a smaller radial distance from the burner centre than the second fuel feed.

Owner:LINDE AG

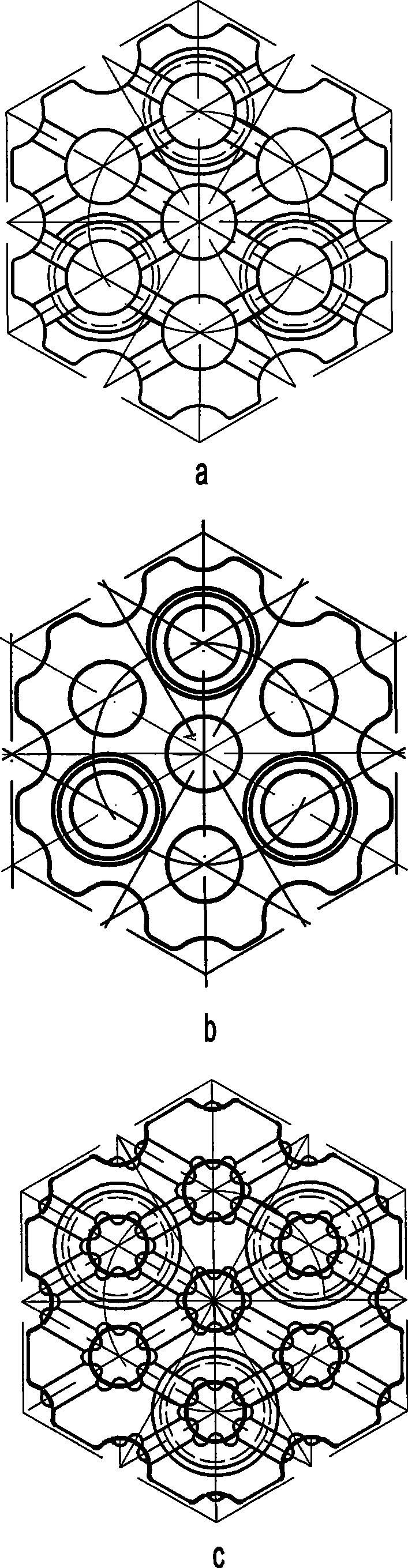

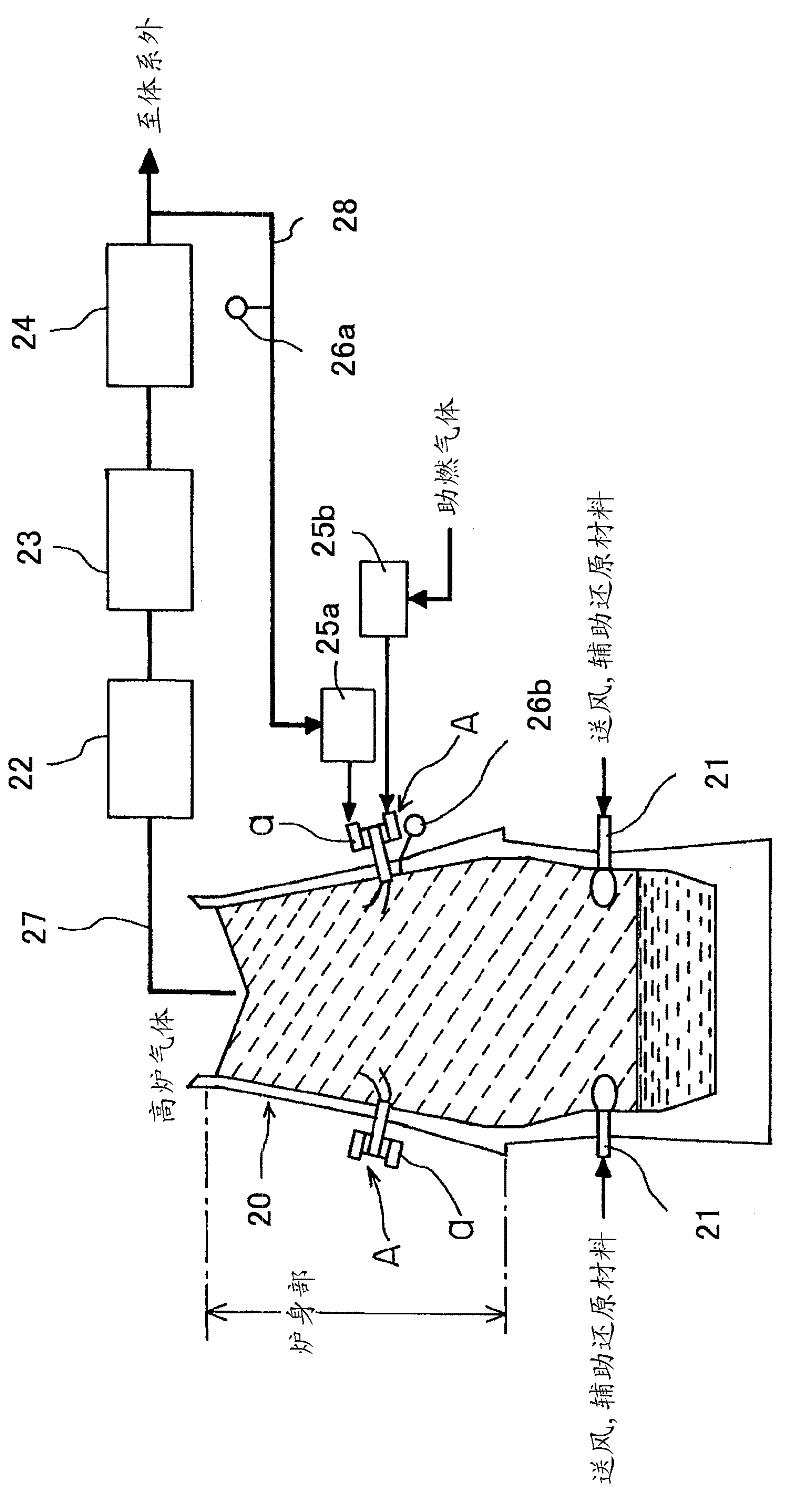

Blast furnace operation method, low-calorific-value gas combustion method for same, and blast furnace equipment

ActiveCN102459652APrevent heating up badInhibition of attachmentTuyeresBlast furnace detailsCombustion chamberEngineering

Air or oxygen-enriched air is suctioned into a blast furnace from a tuyere, and preheated gas is suctioned into the blast furnace from gas inlet parts (A) provided on a shaft section. The gas inlet parts (A) have gas combustion / suction devices (a). In each gas combustion / suction device (a), an aperture is formed on an inner wall of a tubular combustion chamber, said aperture being for suctioning in either a fuel gas and a combustion-assisting gas or a premixed gas comprising a fuel gas and a combustion-assisting gas in a manner such that a swirling gas flow is generated in the combustion chamber. The ends of the aforementioned combustion chambers open into the interior of the blast furnace. The fuel gas from the aforementioned gas combustion / suction devices (a) is suctioned into the blast furnace to serve as preheated gas.

Owner:JFE STEEL CORP

Copper anode refining system and method

Owner:PRAXAIR TECH INC

Gas turbine exhaust as hot blast for a blast furnace

The invention relates to a gas turbine exhaust as hot blast for a blast furnace. In certain exemplary embodiments, a system includes a gas turbine system 12 having a turbine 16, combustor 18, and a compressor 20. The system also includes an output flow path from the gas turbine system 12. The system further includes a blast furnace 80 coupled to the output flow path, wherein output flow path is configured to deliver heated air 102 or exhaust gas 34 from the gas turbine system 12 directly to the blast furnace 80 as a blast heat source.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com