Side-blowing spray gun for melting furnace and application method thereof

A smelting furnace and spray gun technology, applied in combustion methods, furnaces, crucible furnaces, etc., can solve the problems of short service life, poor safety performance, and easy burning of spray guns, and achieve improved melting efficiency, improved service life, and good combustion effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

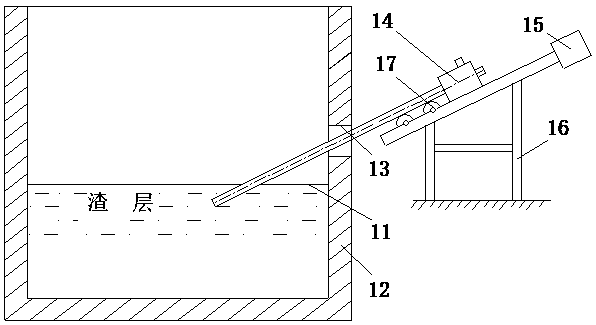

[0037] Embodiment 1: including side blowing spray gun and the using method of side blowing spray gun.

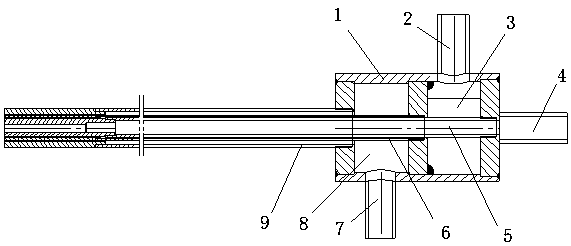

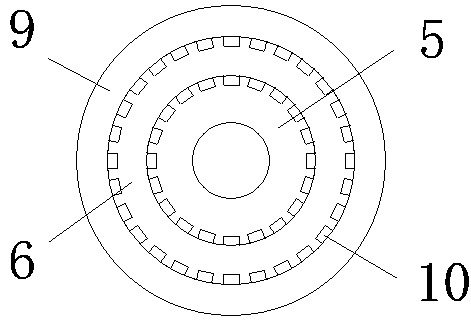

[0038]The side blowing spray gun includes: gas collector 1, combustible gas inlet 2, combustible gas chamber 3, oxygen or oxygen-enriched air inlet 4, oxygen or oxygen-enriched air pipe 5, combustible gas pipe 6, compressed cooling air inlet 7, compressed cooling air chamber 8 and compressed cooling air pipe 9; there are combustible gas chamber 3 and compressed cooling air chamber 8 in the gas collection cylinder 1; combustible gas inlet 2, oxygen or oxygen-enriched air inlet 4 and compressed cooling air inlet 7 are connected to the gas collection cylinder, oxygen or The oxygen-enriched air inlet 4 is located at one end of the gas collector 1, and the combustible gas inlet 2 and the compressed cooling air inlet 7 are correspondingly connected to the combustible gas chamber 3 and the compressed cooling air chamber 8; the oxygen or oxygen-enriched air pipe 5 passes through the ...

Embodiment 2

[0054] Embodiment 2: be the embodiment that manually feeds the side blowing spray gun, other is the same with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com