Low velocity staged combustion for furnace atmosphere control

a technology of low-speed staged combustion and furnace atmosphere control, which is applied in the direction of combustion types, furnaces, lighting and heating apparatuses, etc., can solve the problems of loss of metal or surface defects, color change of glass products, and significant heat in the melting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

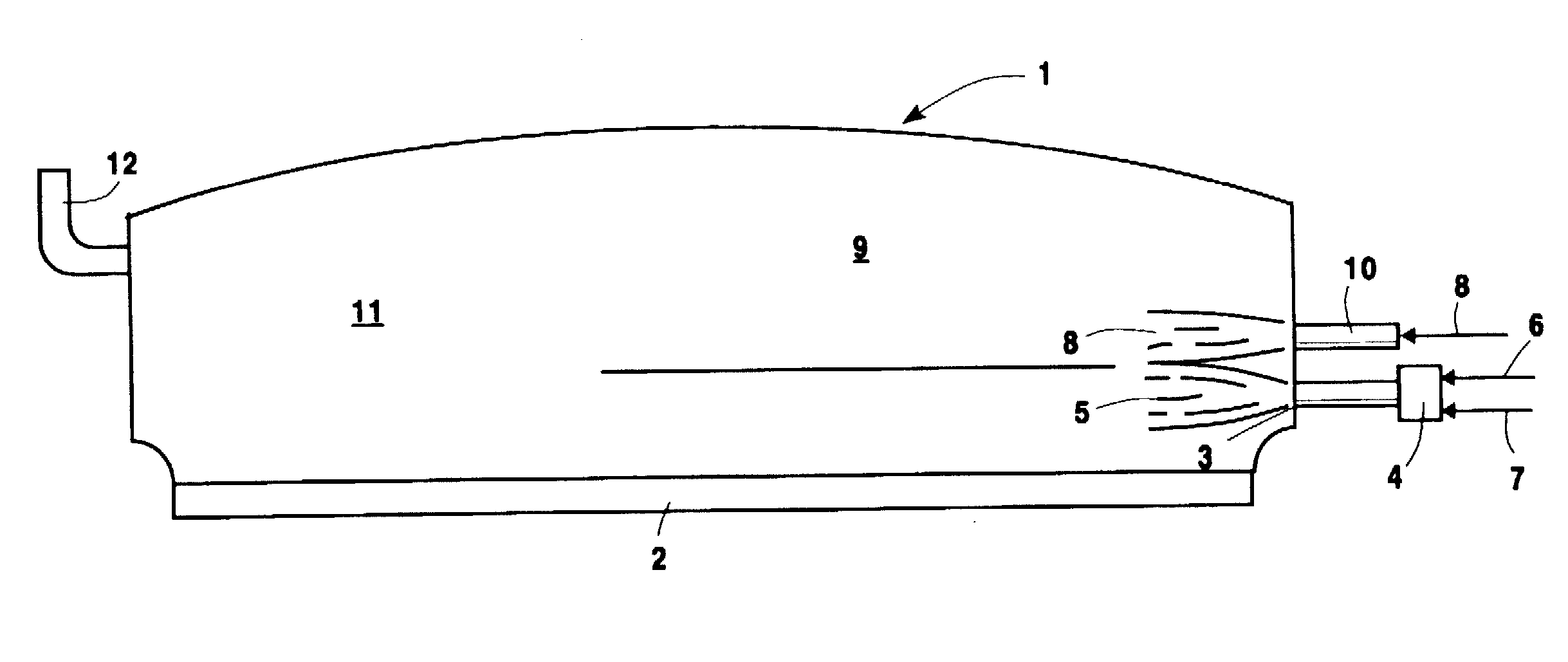

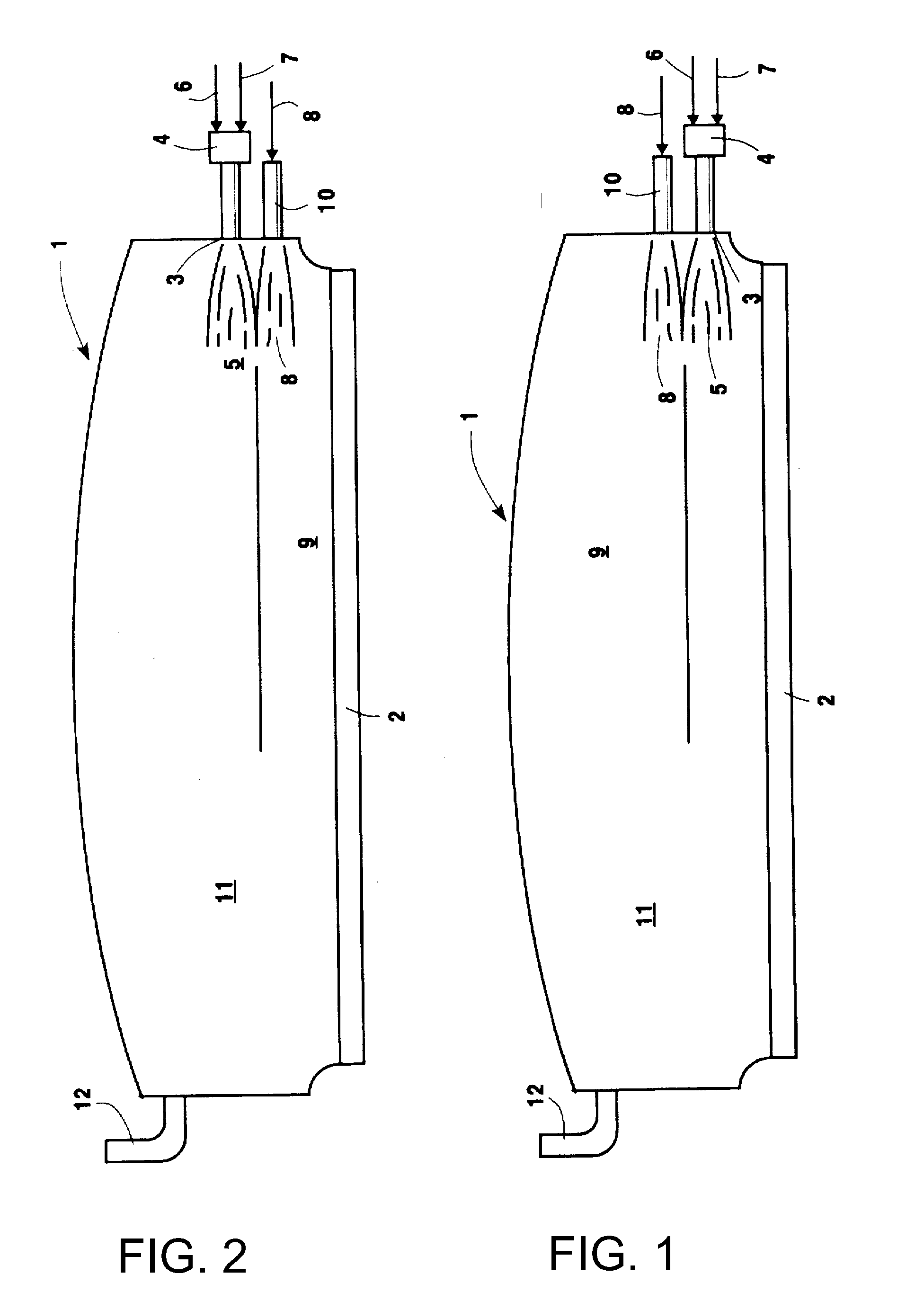

[0028]The invention will be described in detail with reference to Figure, in which is shown industrial furnace 1 which contains a charge 2. Any industrial furnace or one or more zones of an industrial furnace which is heated by one or more burners may be used in the practice of this invention. Examples of such furnaces include a steel reheating furnace wherein the charge is steel, an aluminum melting furnace wherein the charge is aluminum, a glass melting furnace wherein the charge comprises glassmaking materials, and a cement kiln wherein the charge comprises cement.

[0029]Preferred examples are charges which are either susceptible to oxidation or reduction under the conditions that prevail when combustion is occurring in the furnace. A particularly preferred example that is susceptible for oxidation is a charge comprising iron in its reduced form, or iron in its reduced form mixed with carbonaceous matter such as coke or charcoal. A particularly preferred example that is susceptibl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com