Method for recirculating blast furnace gas, and associated device

A blast furnace gas recirculation technology, applied to blast furnaces, blast furnace details, blast furnace parts, etc., can solve problems such as flow control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

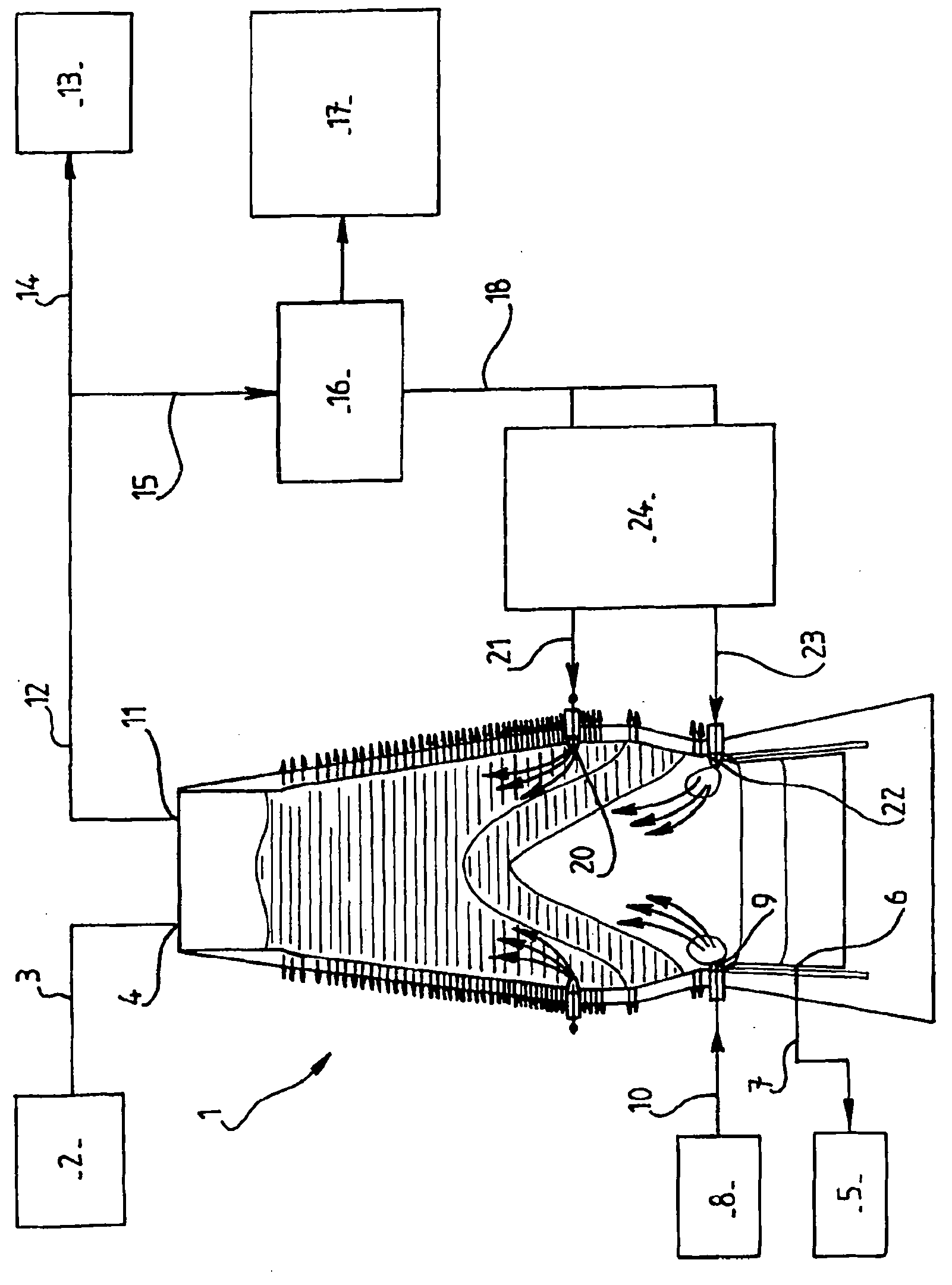

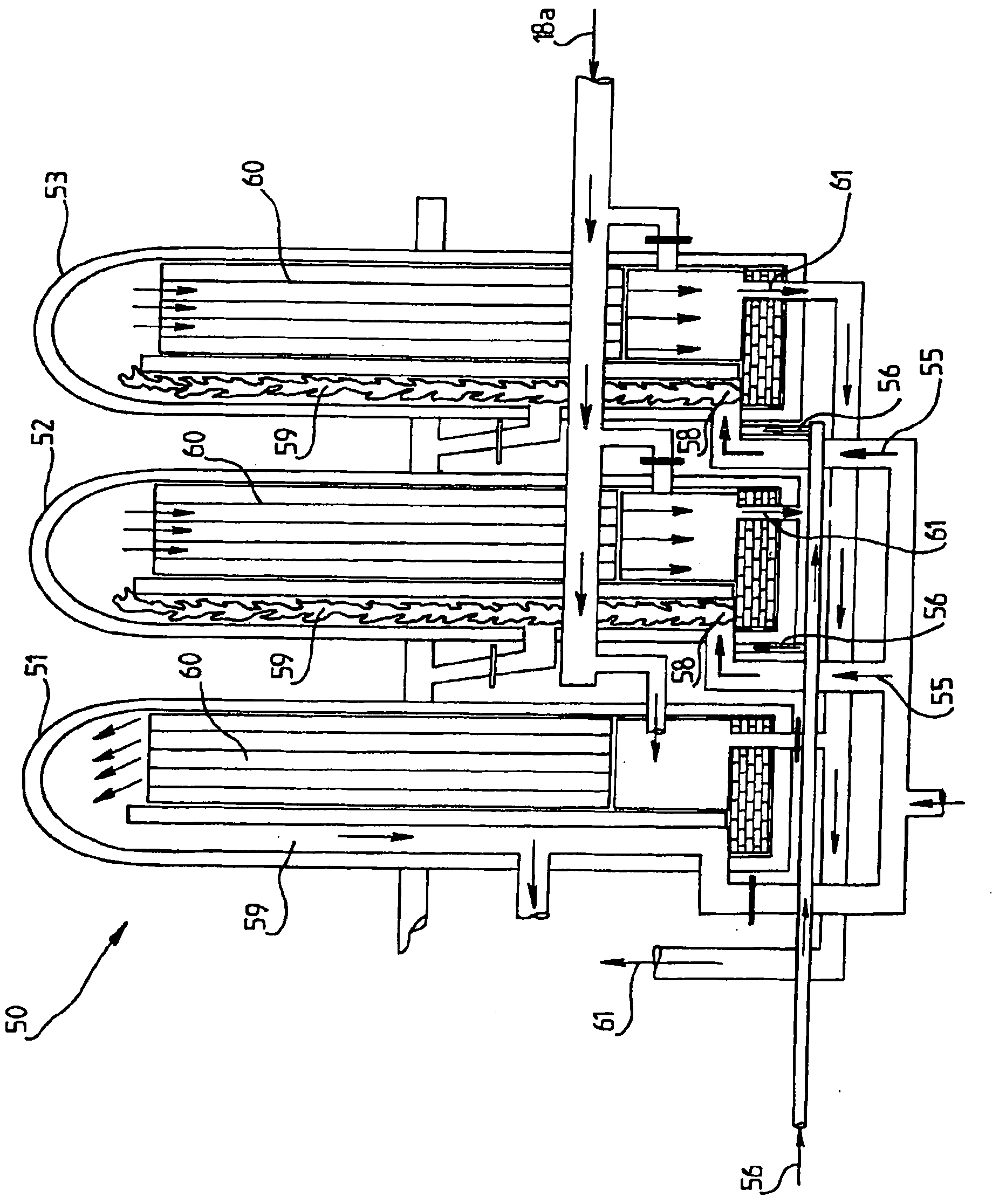

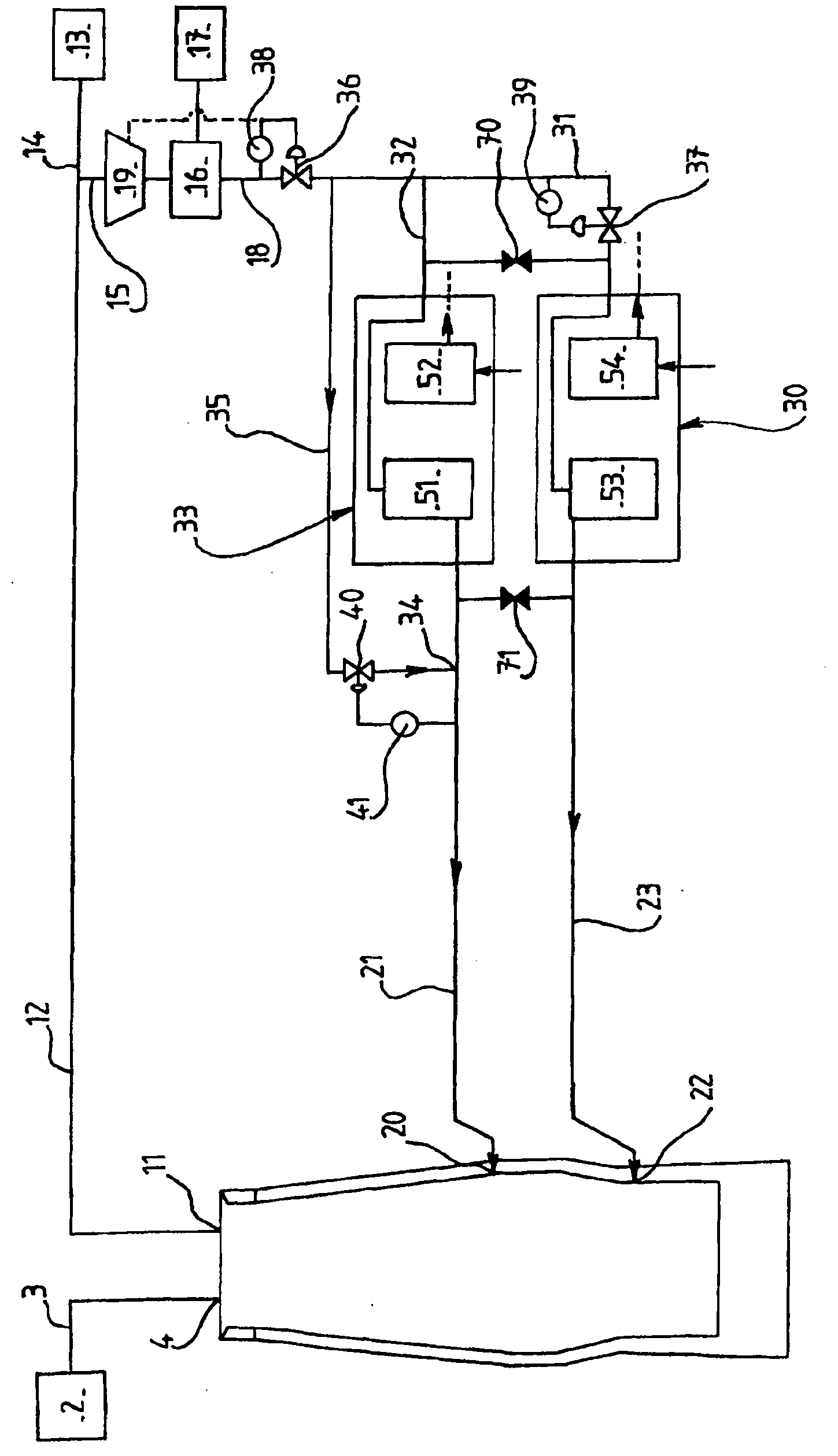

[0057] figure 1 , image 3 and Figure 4 Common elements of the devices bear the same designation. For reasons of simplicity, the injection of combustion-supporting fuel and the recovery of pig iron and slag are not included in the image 3 and Figure 4 shown above, but the steps present in the methods shown on these drawings are quite obvious.

[0058] refer to image 3 , blast furnace 1 is supplied with coke, iron ore, pellets and sinter 2 at point 4 via line 3 .

[0059] Top gas is recovered via line 12 at point 11 in the upper part of the blast furnace. A portion 13 of these top gases is conveyed via pipeline 14 to another plant on site. The other part is recycled in the blast furnace through line 15.

[0060] The part of the top gas for recirculation is passed in a compressor 19 and through a CO 2 Purifier 16 to purify CO 2 , such as an amine adsorption unit, a VPSA, a PSA, or one of these units combined with an additional refrigeration step. exist image 3 I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com