CO2 capture using solar thermal energy

A solar energy, CO2 technology, applied in the direction of solar thermal energy, solar thermal collectors using working fluid, solar thermal devices, etc., can solve problems such as reduced thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

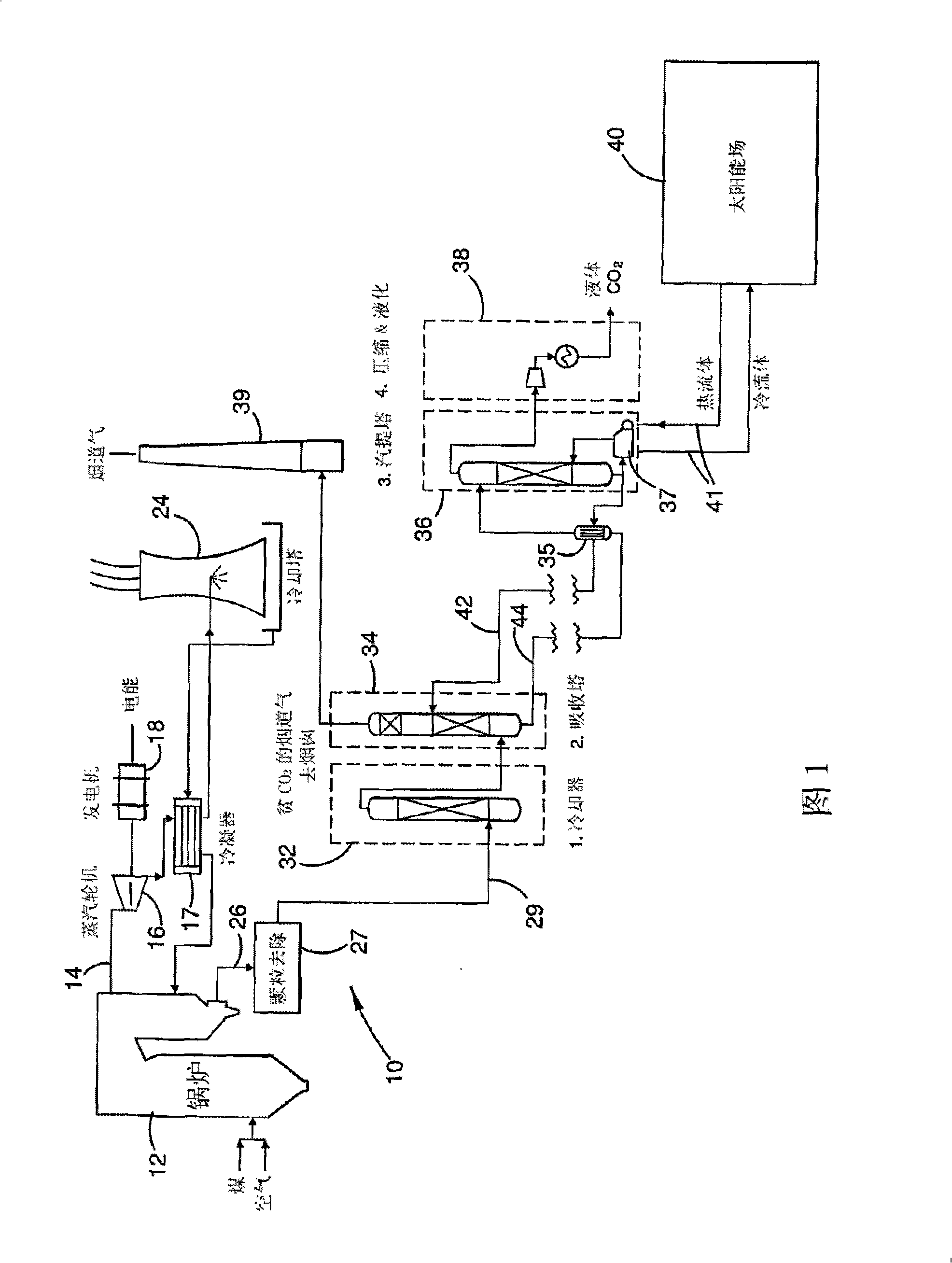

[0059] figure 1 The basic architecture of a coal fired power plant 10 is shown. The coal and air are sent to a large scale boiler system 12 which heats large volumes of water to generate steam 14 for driving a steam turbine 16 . However, the turbine 16 powers a generator 18 which produces electrical energy as its output. Steam recovered from the turbine 16 is circulated back to the boiler through a condenser 17 connected to a cooling tower 24 .

[0060] The flue gas 26 from the boiler 12 is treated (at 27) to remove most of the particulates and such as SO 2 and SO 3 Other impurities such as , are then passed at 29 to a four-stage plant for post-combustion capture of carbon dioxide. At stage 1 (indicated at 32), the cleaned flue gas is cooled to a suitable solvent system for efficient absorption of CO from the gas 2 temperature. These solvents are also sometimes called adsorbents. At stage 2 (including absorption stage 34), the cleaned and cooled flue gas is purified by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com