Double-melting-bath organic solid waste blowing gasification device

A technology of organic solid waste and gasification device, applied in the details of gasification device, mechanical details of gasification device, molten salt/molten metal gasification, etc., can solve difficult equipment and process, inconvenient operation, sensible heat loss, etc. It can save gas input waste, improve energy utilization efficiency, and facilitate replacement and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

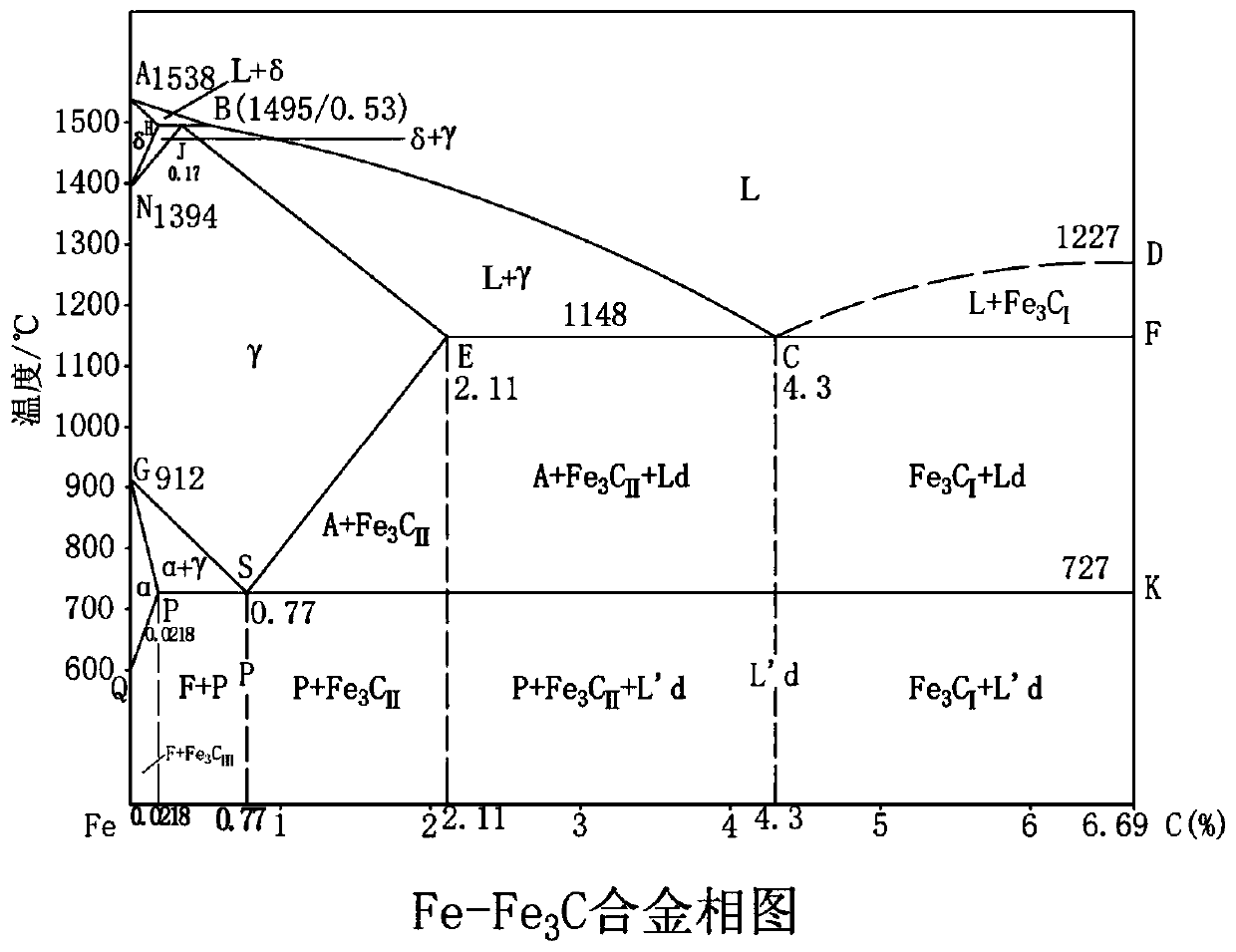

[0083] After the organic particles are injected into the molten iron bath-slag bath at high speed, the hydrocarbons in the organic matter are rapidly cracked by heat, the carbon chain and the hydrocarbon chain are broken, and the hydrogen atoms are combined into hydrogen molecules. The carbon dissolves in the molten iron, and the molten iron can be dissolved The carbon content of the Fe-C alloy is between 3-5%, which greatly reduces the melting point of the Fe-C alloy, and the melting point of the iron-carbon alloy melt with 4.3% carbon is as low as 1148 ° C, such as figure 1 The Fe-C state diagram is shown. This makes it possible to maintain the iron-based alloy as a liquid melt above 1250°C in industry, which not only reduces heat loss, but also ensures the extension of the life of the furnace lining and spray gun. This temperature is relatively thorough for the cracking and gasification of organic matter. However, considering the melting point and fluidity of the slag liqui...

Embodiment 2

[0115] combine Figure 7 , Figure 8 , Figure 9 be explained.

[0116] The liquid level regulating furnace 101 communicates with the bottom of the gasification furnace 201 through a communication pipe 109 . The upper part of the liquid level adjustment furnace 101 is connected with a molten iron injection tank 106, and the molten iron with a pre-melted temperature of 1200-1700°C is put into the molten iron bag 113, and the molten iron is injected into the molten iron from the molten iron bag 113 In the injection tank 106, the molten iron flows into the liquid level regulating furnace 101. As the amount of molten iron gradually increases, the connecting pipe 109 is also filled with molten iron, and the liquid level gradually rises to the bottom of the gasification furnace 201.

[0117] After filling the molten iron to a predetermined amount, part of the slag carried by the molten iron floats up to the top of the molten iron bath 301 of the liquid level regulating furnace 10...

Embodiment 3

[0141] The inner height of the liquid level regulating furnace 101 is 6000mm, and the inner diameter is 3500mm. The inner height of the gasifier 201 is 9000m, and the average inner diameter is 4000mm. The inner diameter of the connecting pipe 109 is 600mm. The port of the connection part of the liquid level regulating furnace 101 is 300 mm high, 1000 mm wide, and 3000 mm in axis length.

[0142] 143 tons of pre-melted molten iron, with a carbon content of 3-5wt%, is heated into the liquid level regulating furnace 101, and filled into the connecting pipe 109, reaching the level of the bottom surface of the gasifier 201. The height h1 of the molten iron liquid level in the liquid level regulating furnace 101 is 2100mm.

[0143] Adjust the pressure P1 in the pressurization chamber 102 where the liquid level regulating furnace 101 is located to an absolute pressure of 0.28MPa, while maintaining the pressure P2 of the free space 303 of the gasifier at an absolute pressure of 0.13MP...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com