Method of separating blast furnace gas

A blast furnace gas and separation method technology, applied in the separation method, blast furnace, hydrogen separation, etc., can solve the problems of high cost, large amount of blast furnace gas, and difficulty in removing carbon dioxide and nitrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

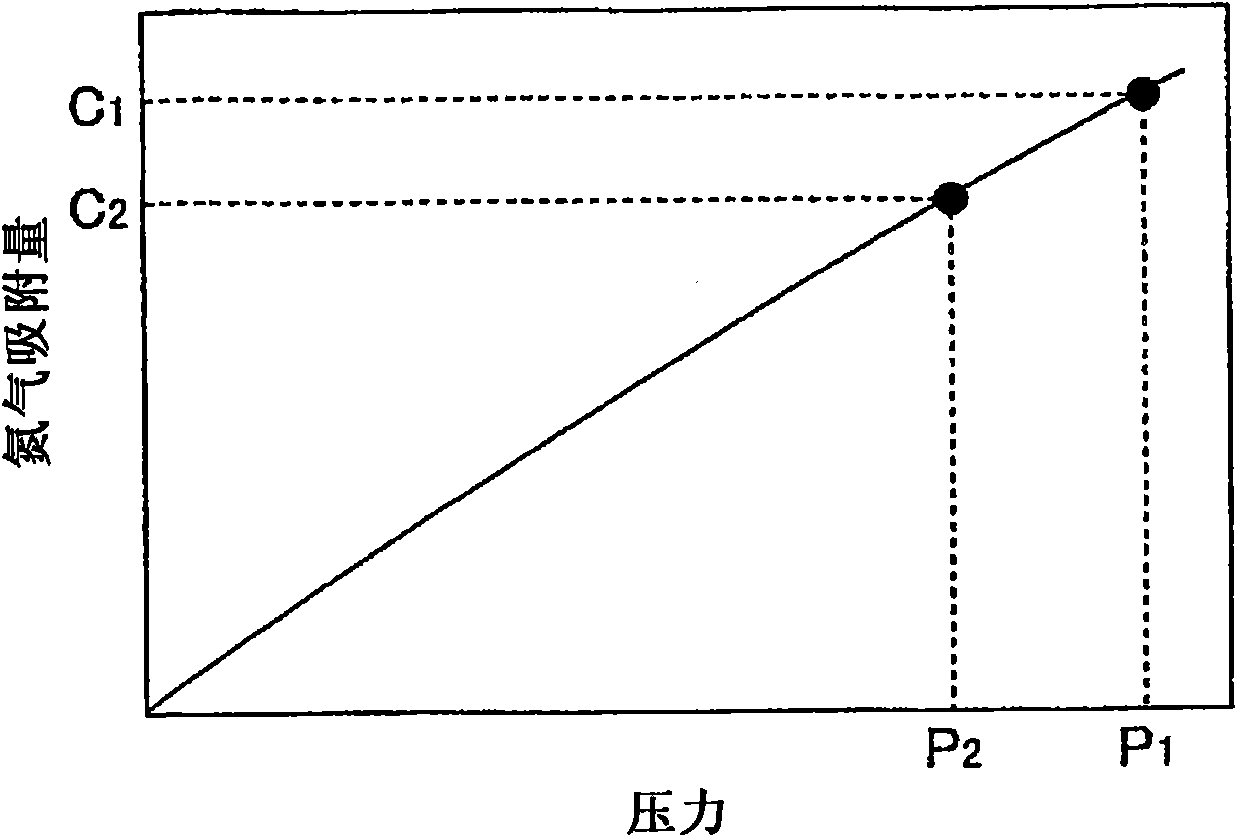

[0054] The method for separating blast furnace gas according to Embodiment 1 is characterized in that oxygen-enriched air having an oxygen concentration of 25% by volume or more is blown into the blast furnace through a tuyere provided at the lower part of the blast furnace to carry out blast furnace operation, and the blast furnace operation recovers gas from the top of the blast furnace. The exhausted blast furnace gas is separated from the recovered blast furnace gas to remove carbon dioxide and nitrogen in the gas. Hereinafter, Embodiment 1 will be specifically described.

[0055] The gas composition and calorific value when separating and removing carbon dioxide and nitrogen from blast furnace gas are explained. Shown in Table 1, for example, from containing hydrogen (hereinafter, also referred to as "H 2 ") 4.4% by volume, nitrogen (hereinafter, also referred to as "N 2 ") 49.9% by volume, carbon monoxide (hereinafter also referred to as "CO") 23.6% by volume, carbon d...

Embodiment approach 2

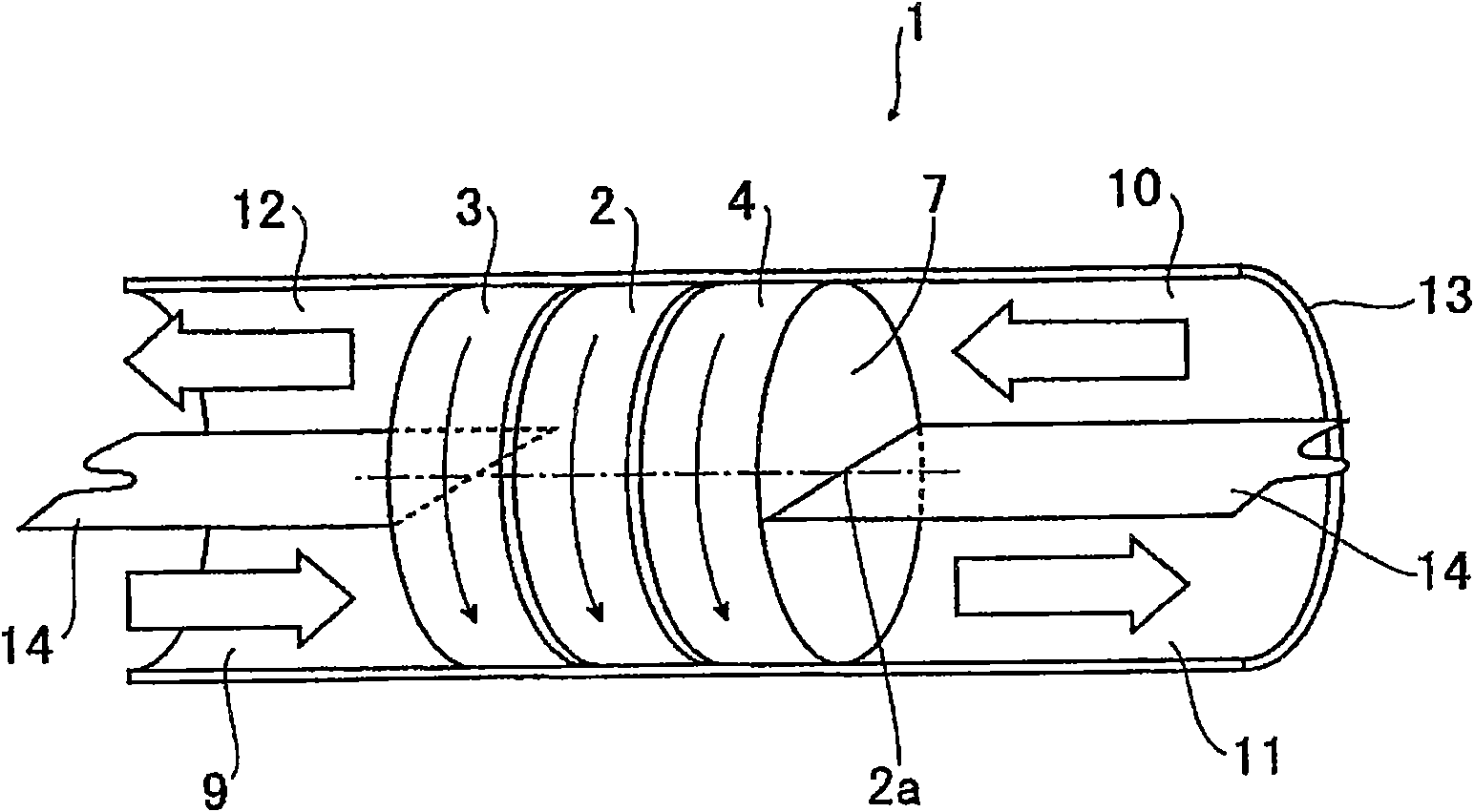

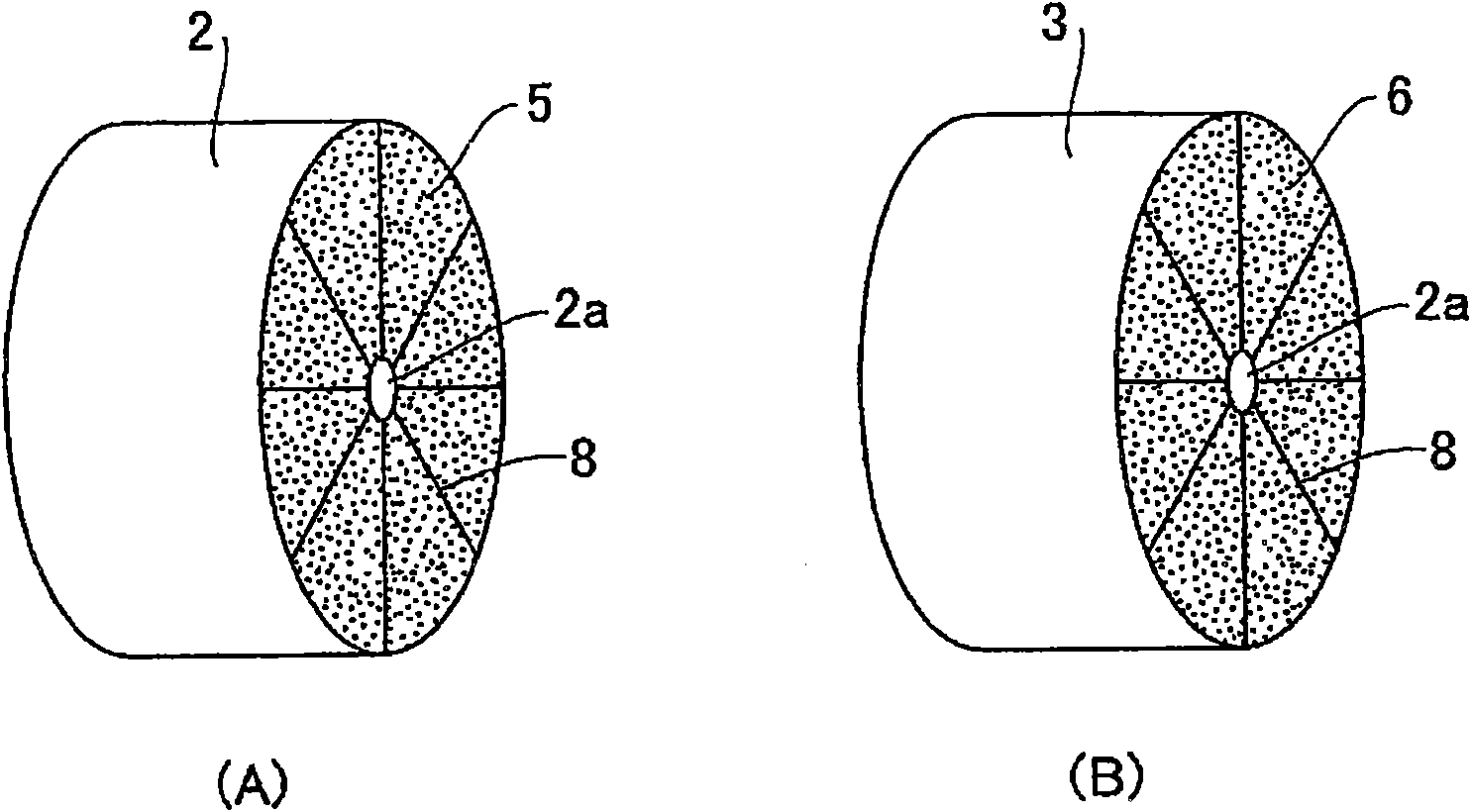

[0094] The blast furnace gas separation method according to Embodiment 2 is characterized in that CO contained in the gas is separated and removed from the blast furnace gas discharged from the top of the blast furnace. 2 and N 2 , producing a modified blast furnace gas having a higher calorific value than the blast furnace gas, and blowing the modified blast furnace gas into a blast furnace for recycling.

[0095] According to Embodiment 2, due to the removal of CO from the blast furnace gas 2 and N 2 , so the calorific value of 1060kcal / Nm can be obtained, which is more than twice that of the existing blast furnace gas 3 above (preferably 1500kcal / Nm 3 above, more preferably 2000kcal / Nm 3 above) modified blast furnace gas. When the reformed blast furnace gas is blown into the blast furnace, the reformed blast furnace gas functions as a reducing agent, thereby reducing the supply amount of the reducing agent, that is, coke or finely powdered carbon. In addition, when us...

Embodiment approach 3

[0116] The gas mixed with blast furnace gas and coke oven gas and / or converter gas is called mixed gas or M gas. Of the by-product gases produced in ironworks, blast furnace gas is extremely large compared to other by-product gases, and the reason why the blast furnace gas is gasified as a mixed gas is to effectively utilize the blast furnace gas.

[0117] Examples of gas turbine cogeneration facilities that utilize this mixed gas as fuel gas include Figure 5 shown. exist Figure 5 Among them, 101 is a gas turbine, 102 is a steam turbine, 103 is a generator, 104 is a fuel gas compressor, 105 is an air compressor, 106 is a burner, 107 is an exhaust boiler, and 108 is a transmission composed of two gears . Such as Figure 5 As shown, the combined gas turbine power generation facility is configured by arranging a gas turbine 101, a steam turbine 102, and a generator 103 on the same shaft. Gas turbine combined power generation facilities are widely used in intensive steel pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com