Method for controlling composition of combustible gas mixture and control device thereof

An exhaust device, gas technology, applied in the direction of fuel injection device, charging system, adding non-fuel substances in fuel, etc., can solve the problems of unstable power, loss, engine speed fluctuation of internal combustion engine, etc., to reduce odor interference, simple Fuel emission value, effect of preventing fluctuations in rotation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

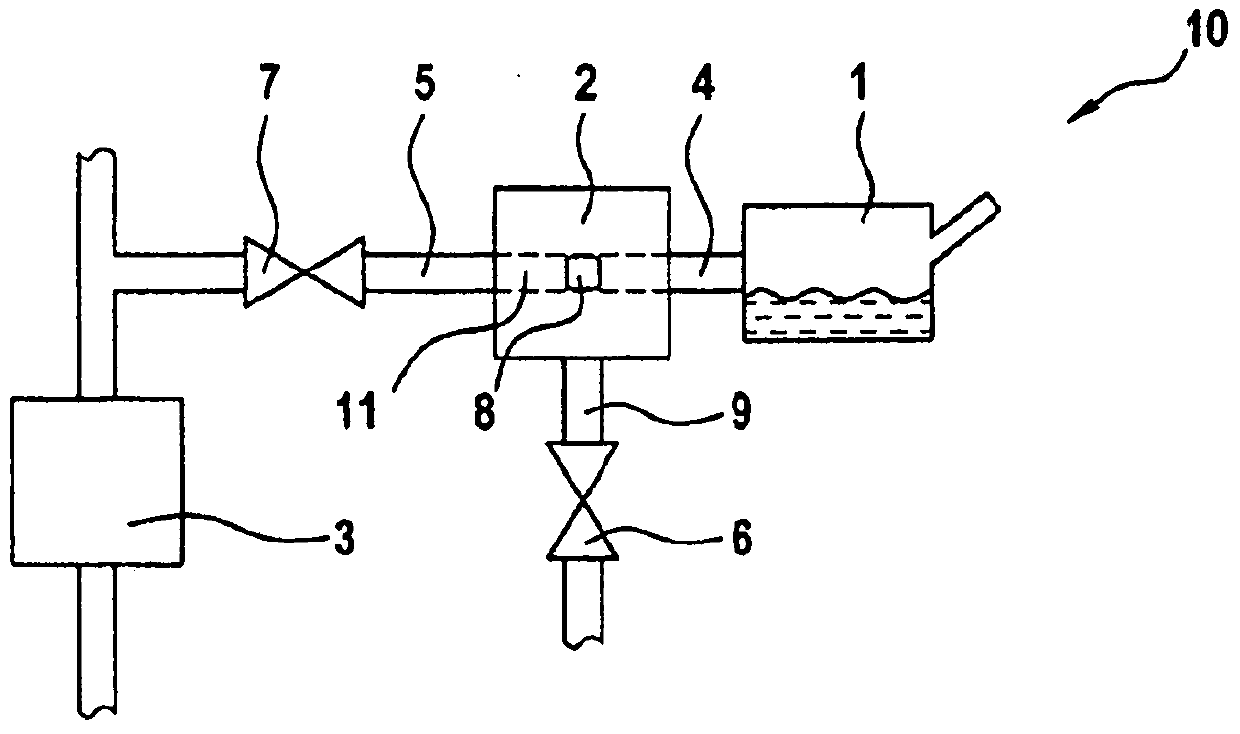

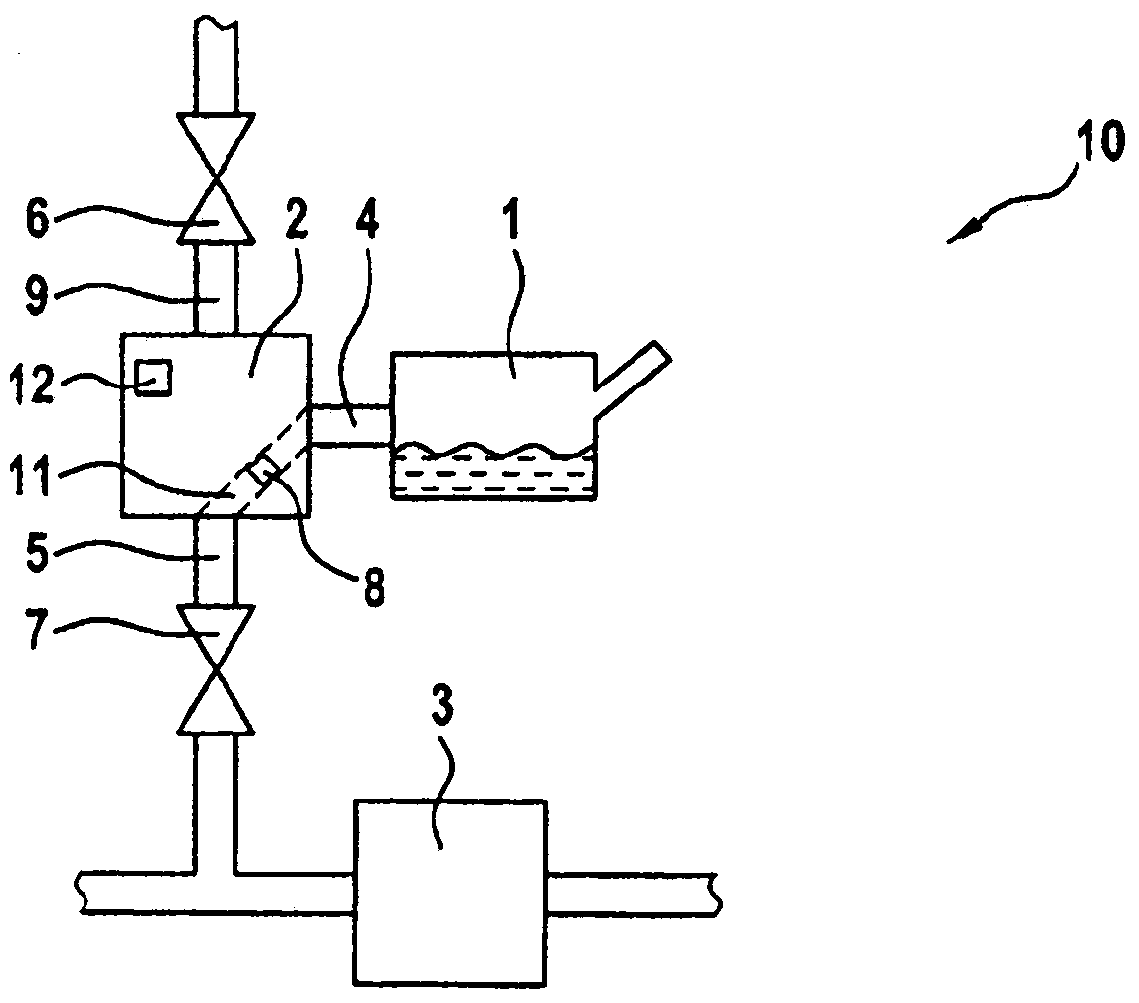

[0045] Only those aspects of the invention which are of interest here are shown in the figures, all other aspects have been left out for the sake of clarity. Furthermore, the same reference numbers refer to the same components.

[0046] figure 1 A fuel tank venting device 1 according to a first advantageous further development of the invention is shown. The fuel tank venting device 10 is introduced here between the fuel tank 1 and the internal combustion engine 3 and comprises a fuel reservoir 2 with an activated carbon bed for storing fuel, which is connected to the fuel tank 1 via a fuel line 4 . The fuel accumulator 2 is connected to the internal combustion engine 3 via a vent line 5 on the side opposite the fuel tank 1 . For this purpose, vent line 5 includes a tank vent valve 7 , by means of which the inflow of fuel from fuel tank 1 and / or fuel accumulator 2 can be regulated.

[0047] An air intake line 9 is also connected to the fuel store 2 , by means of which scaven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com