Patents

Literature

63results about How to "Reduce idle speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

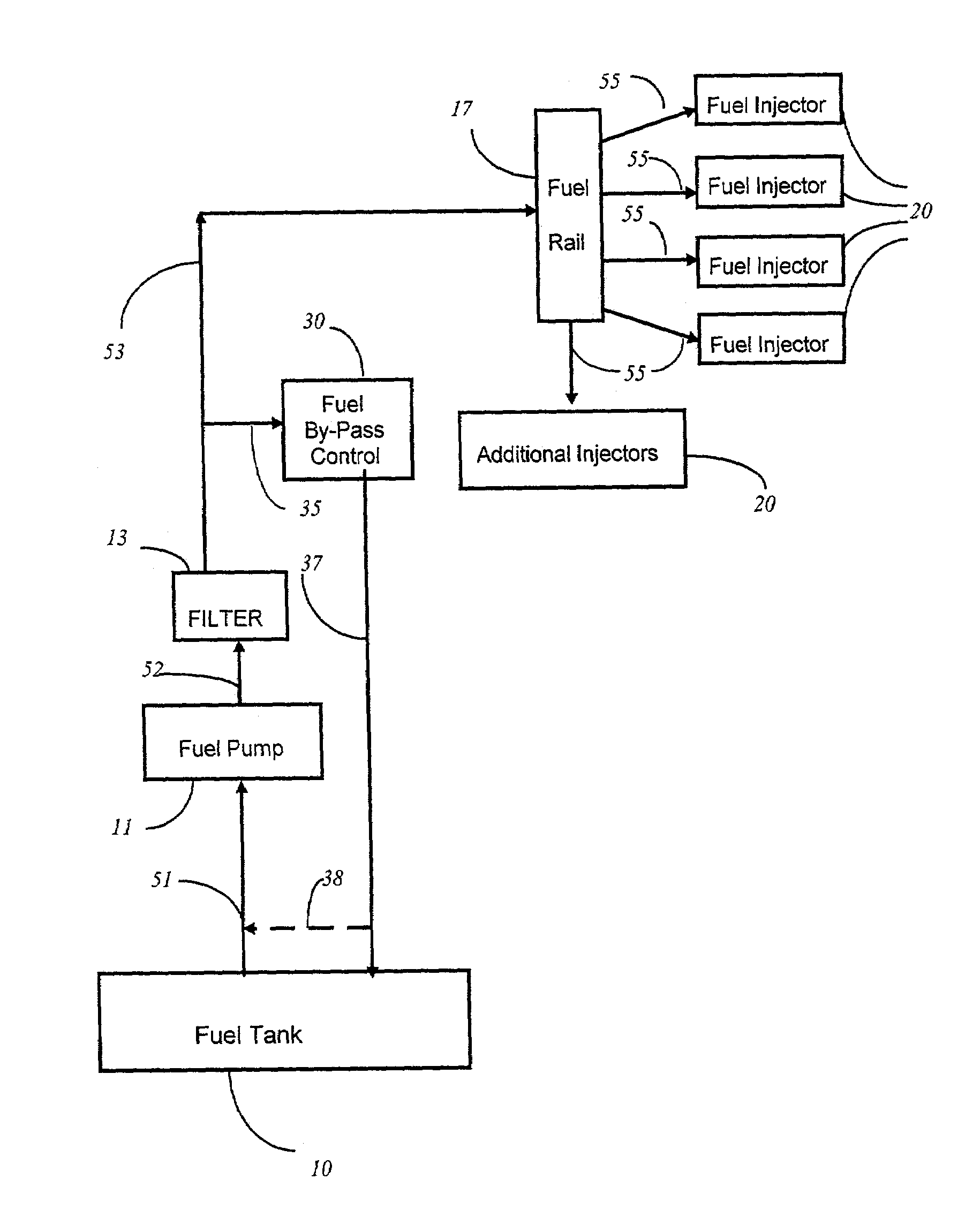

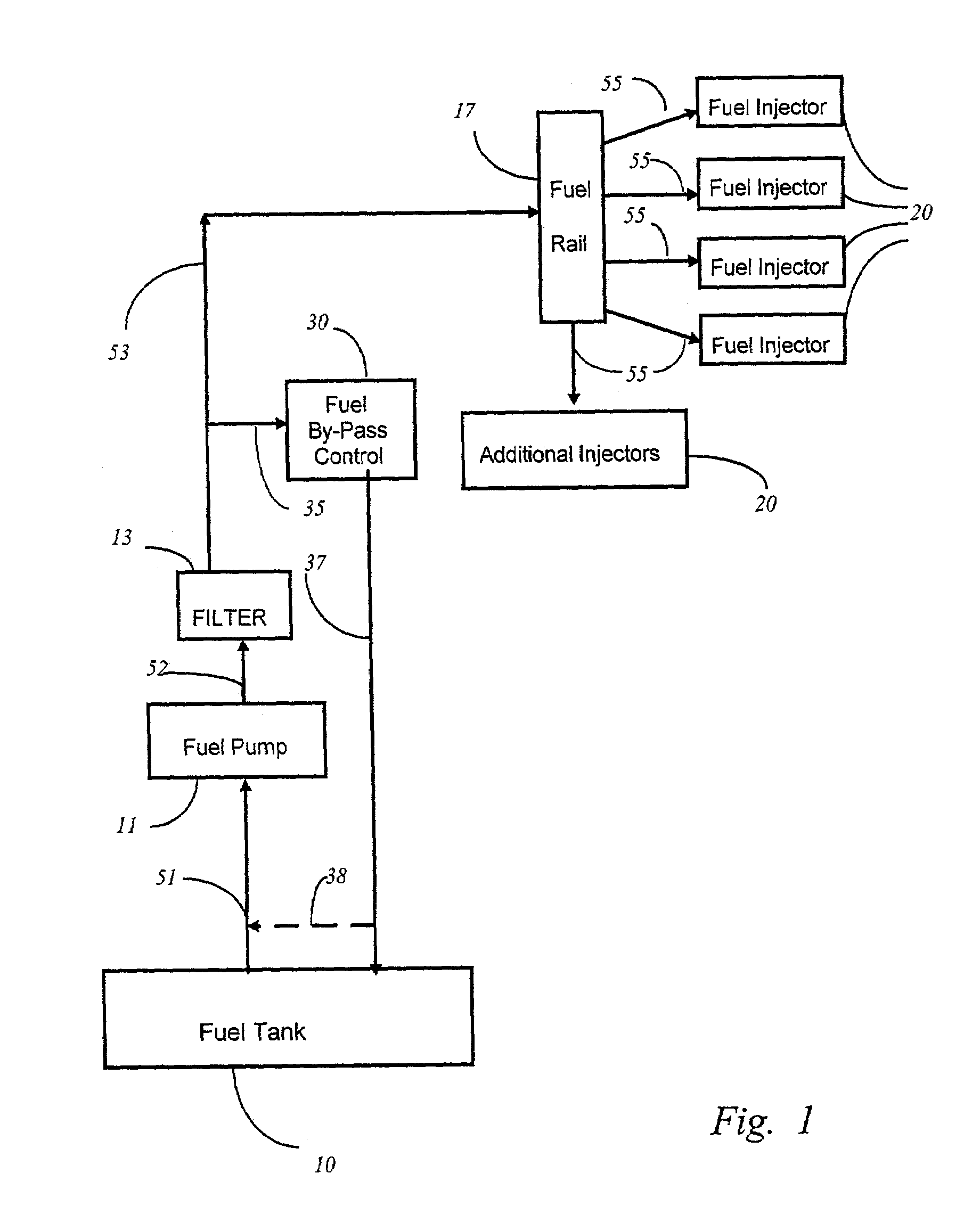

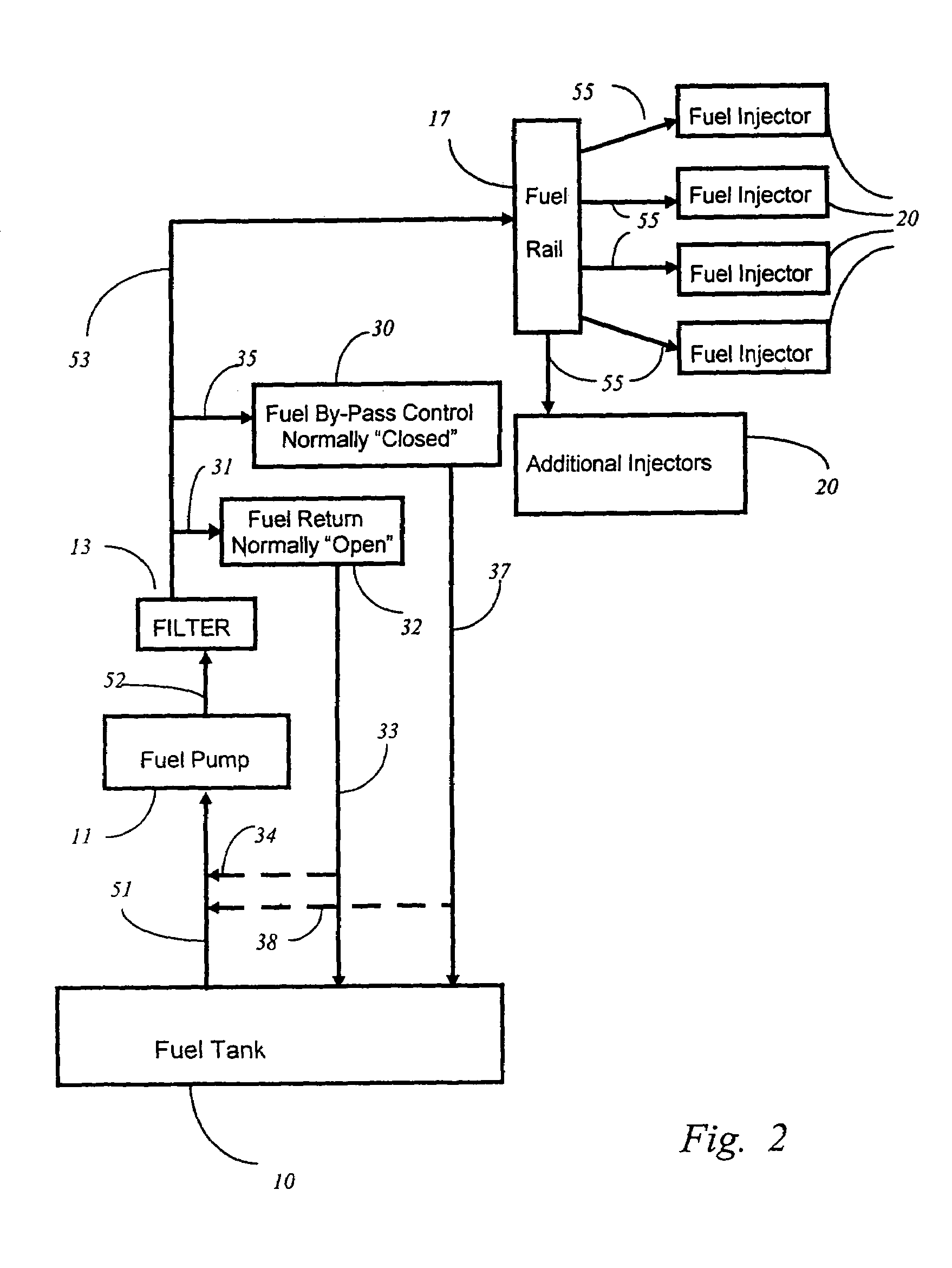

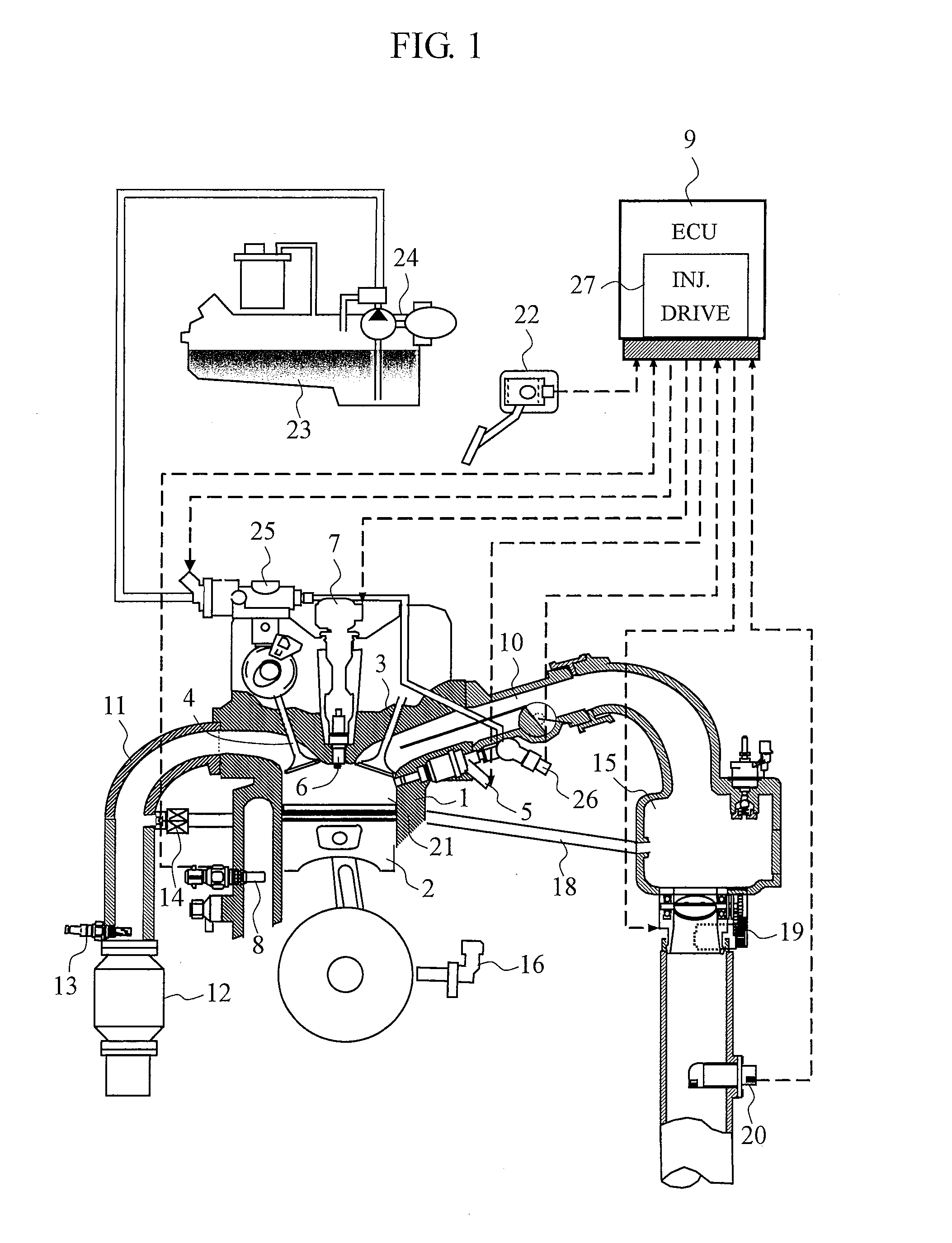

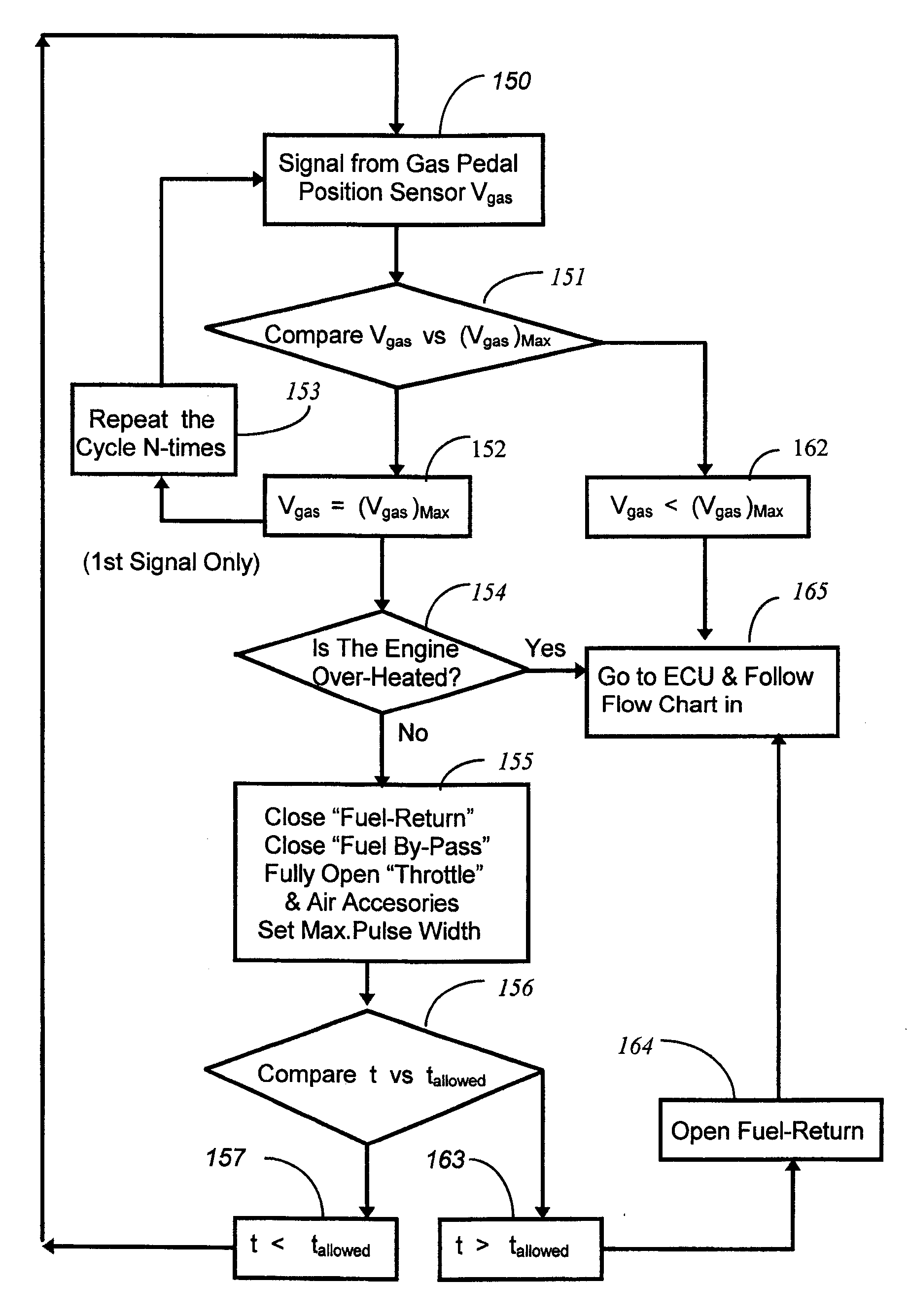

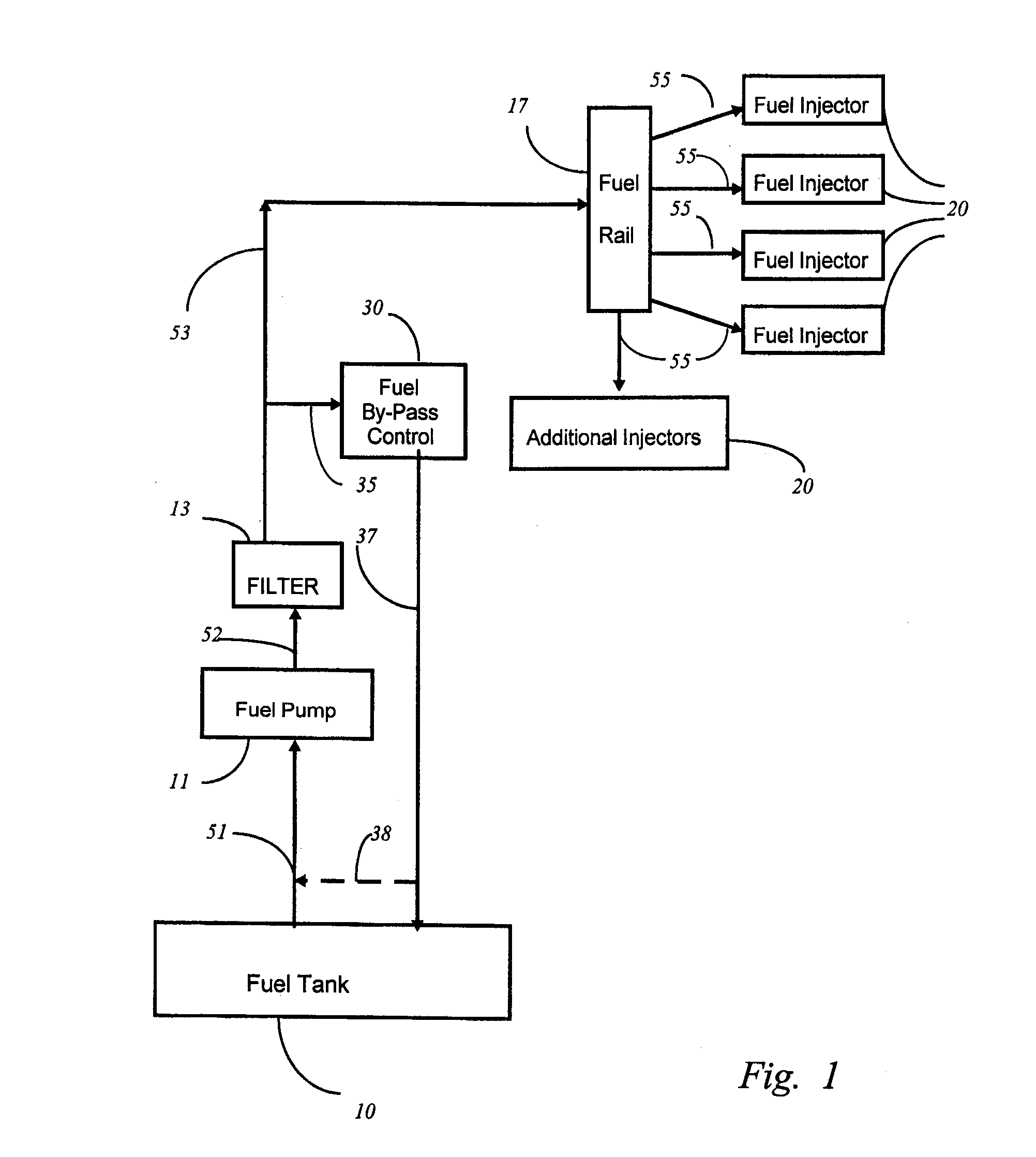

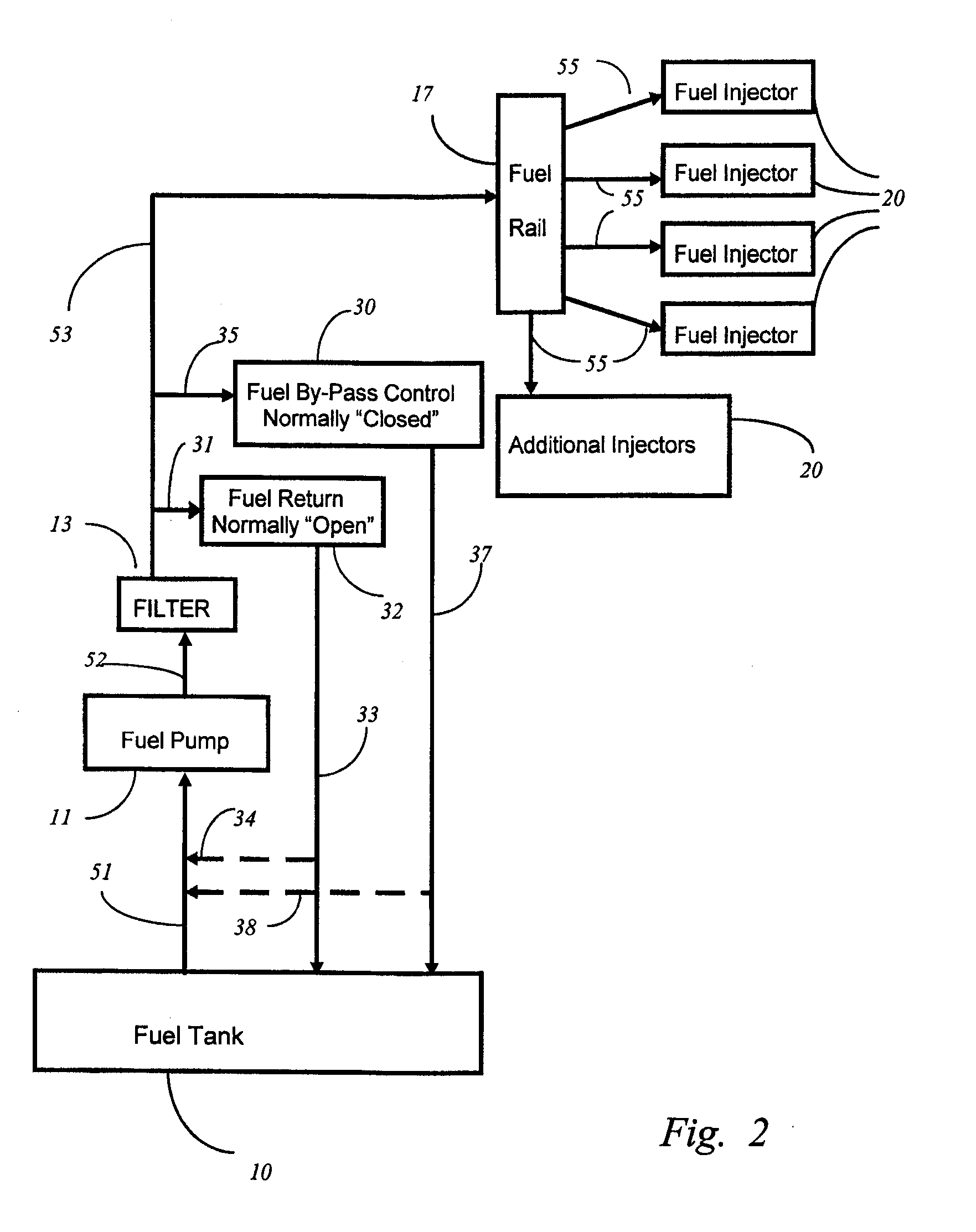

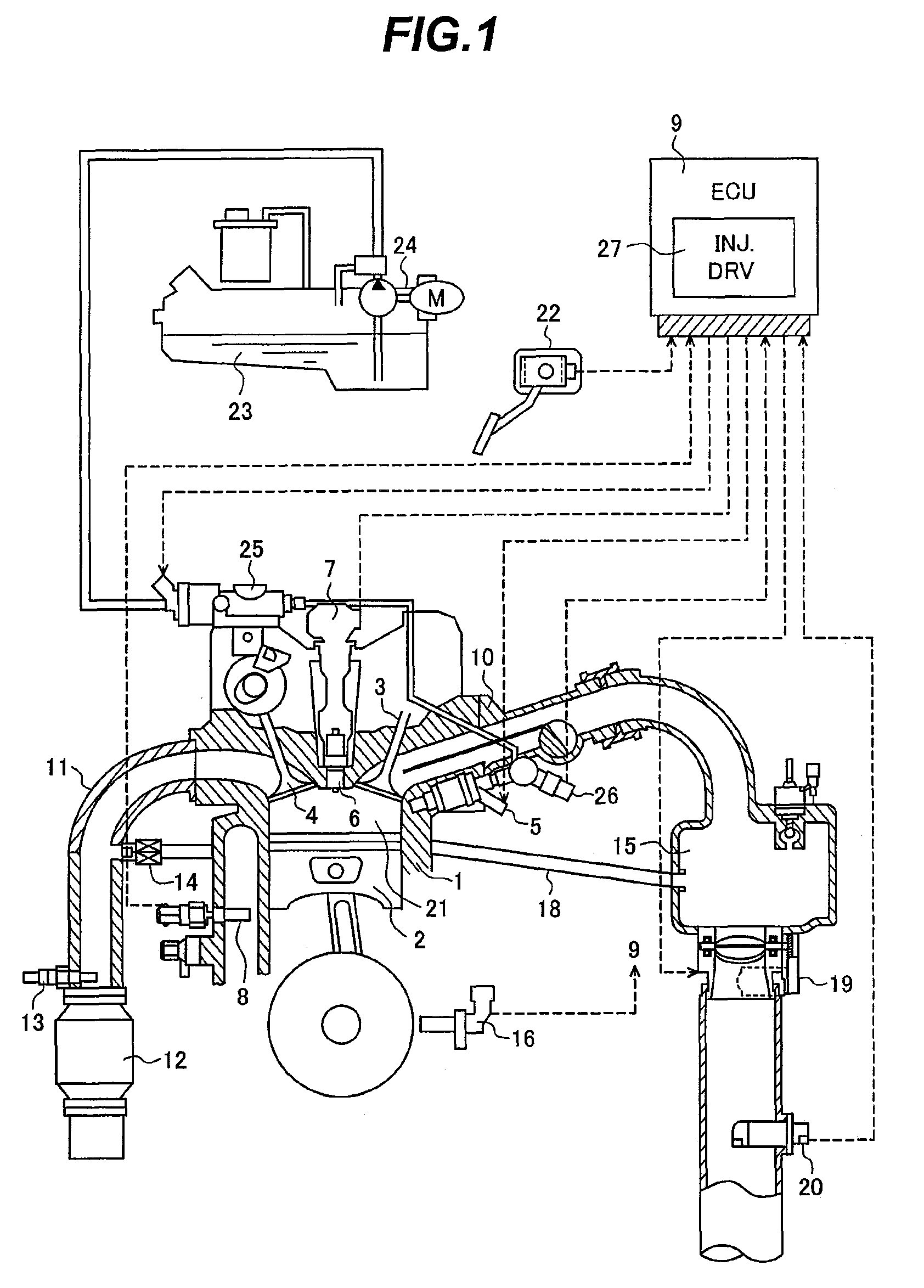

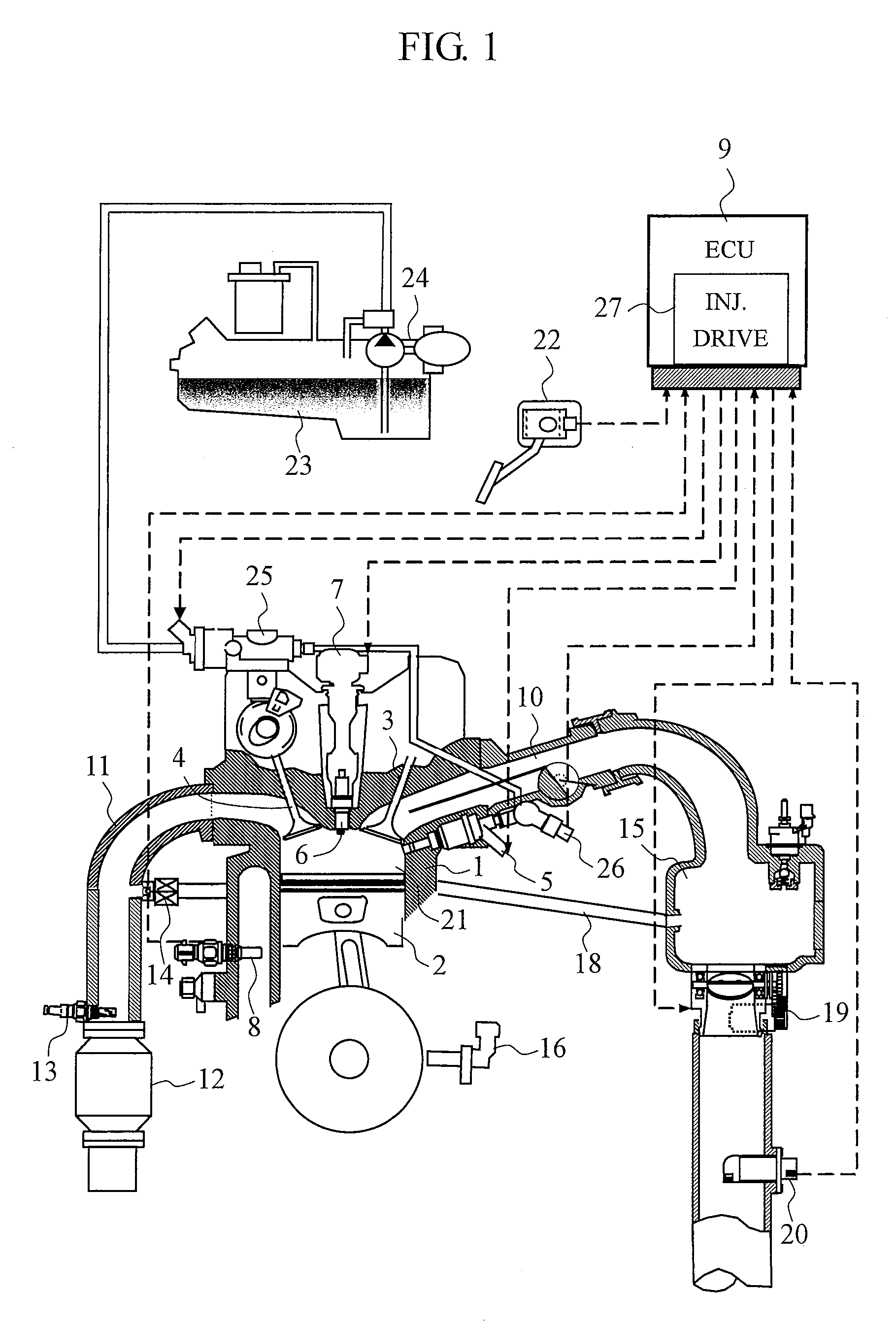

Constant-speed multi-pressure fuel injection system for improved dynamic range in internal combustion engine

ActiveUS7318414B2Avoid excess fuelAvoid pressure built-upElectrical controlLow-pressure fuel injectionExternal combustion engineFuel tank

A fuel injection system operates under a substantially constant pump speed and creates multi-pressure levels by diverting the fuel flow. Fuel pressure can be switched from one steady pressure level to another level on-demand instantly. This superimposes and overlaps typical fuel injection events in the linear operating ranges under different pressure levels, significantly increasing the fuel injection dynamic range. Lower fuel injection when idle or during city driving reduces fuel consumption per mile traveled and reduces exhaust emission that causes smog in metropolitan areas. The system delivers additional power to the engine instantly at peak load on-demand, reduces idle speed with the engine running smoothly, does not change fuel tank temperature, and may enhance the life of the fuel pump.

Owner:TMC FUEL INJECTION SYST

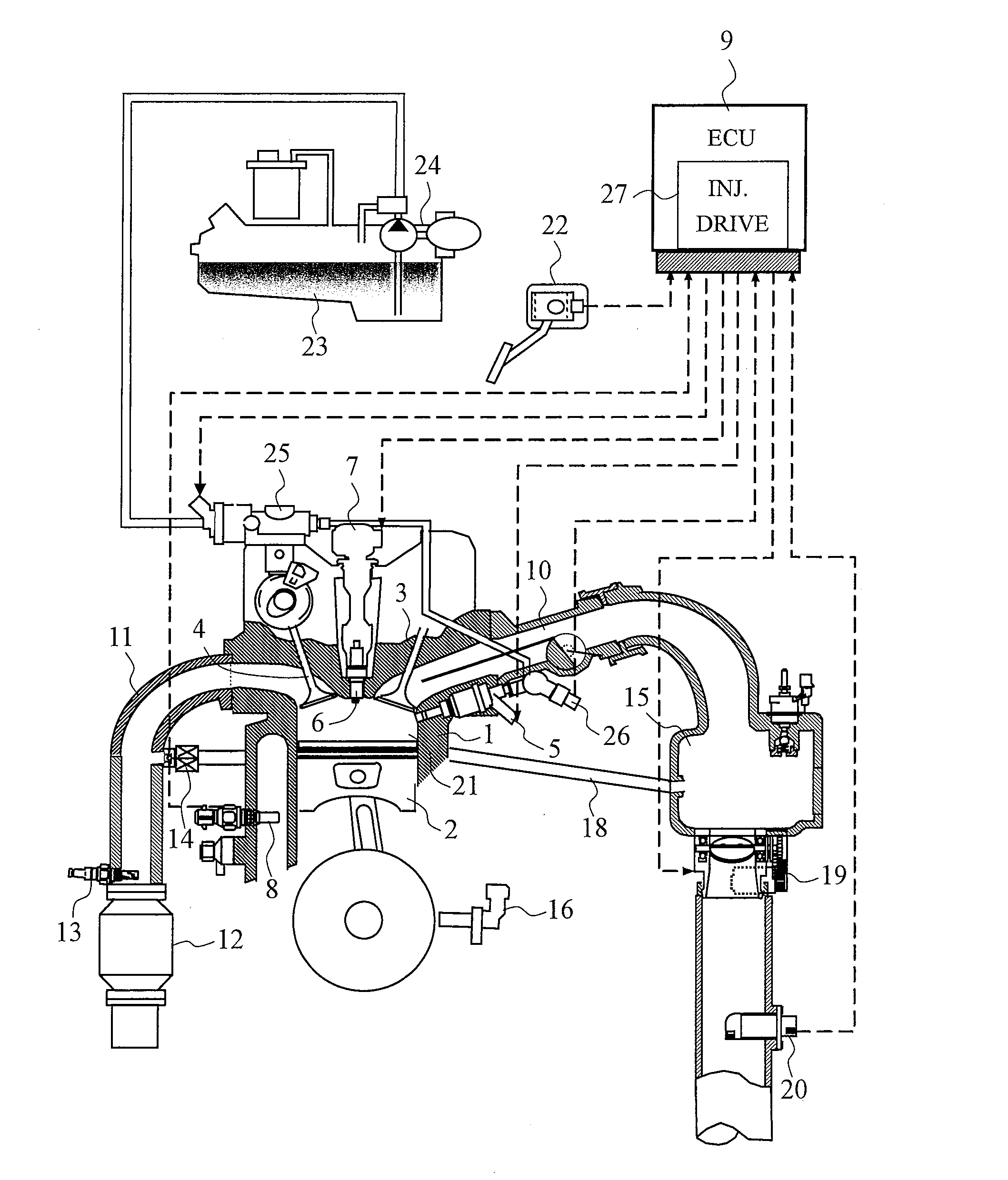

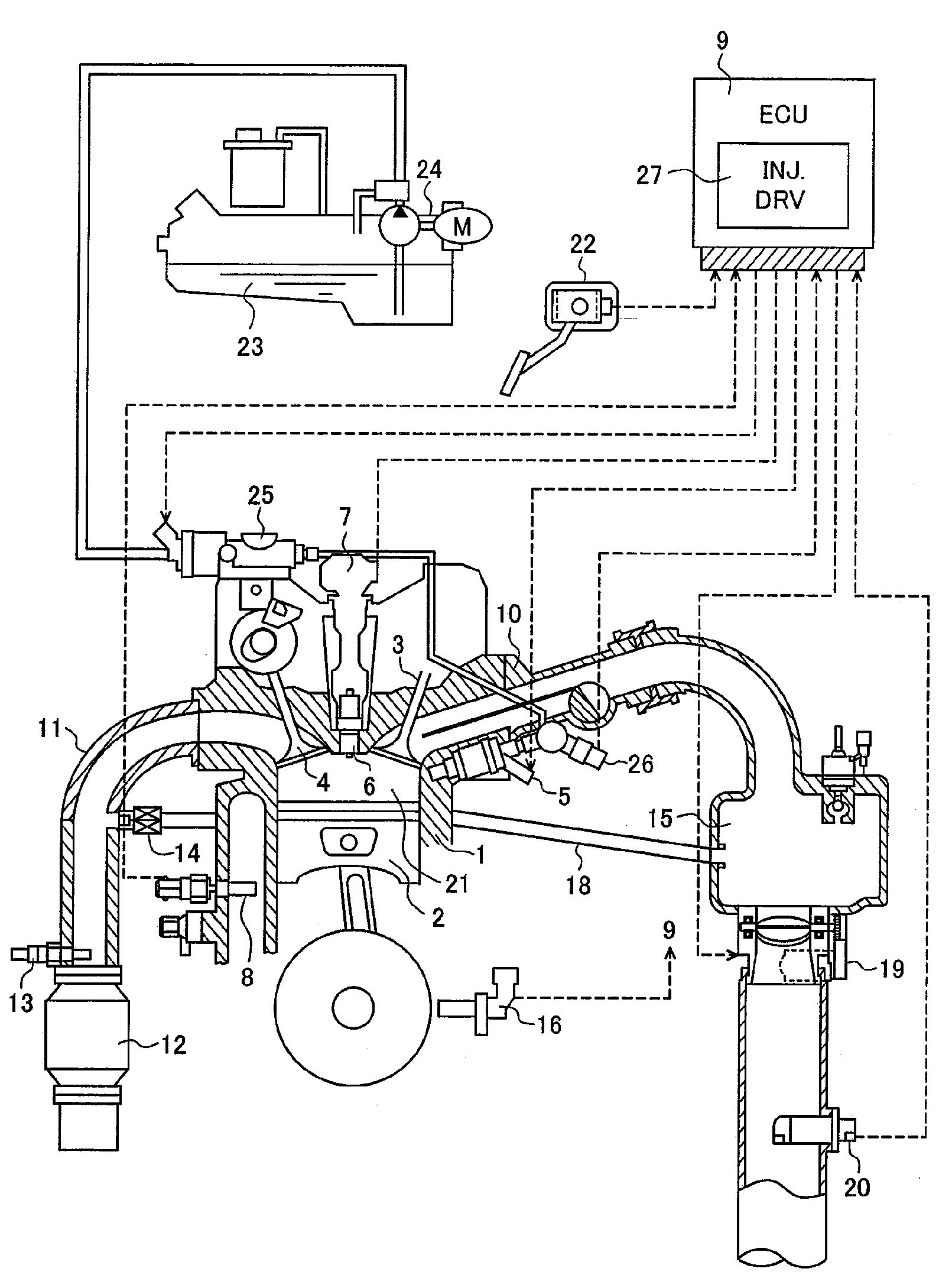

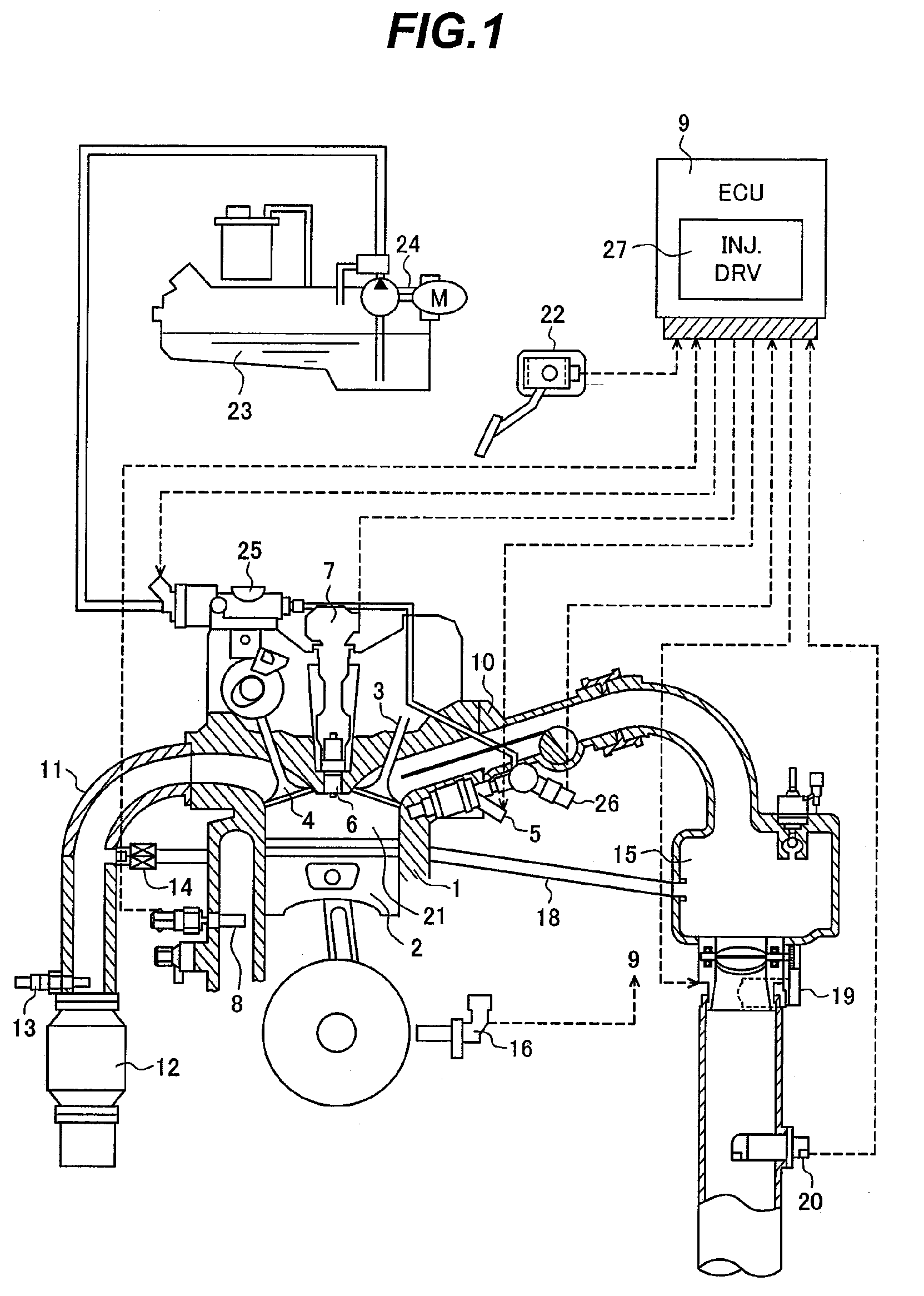

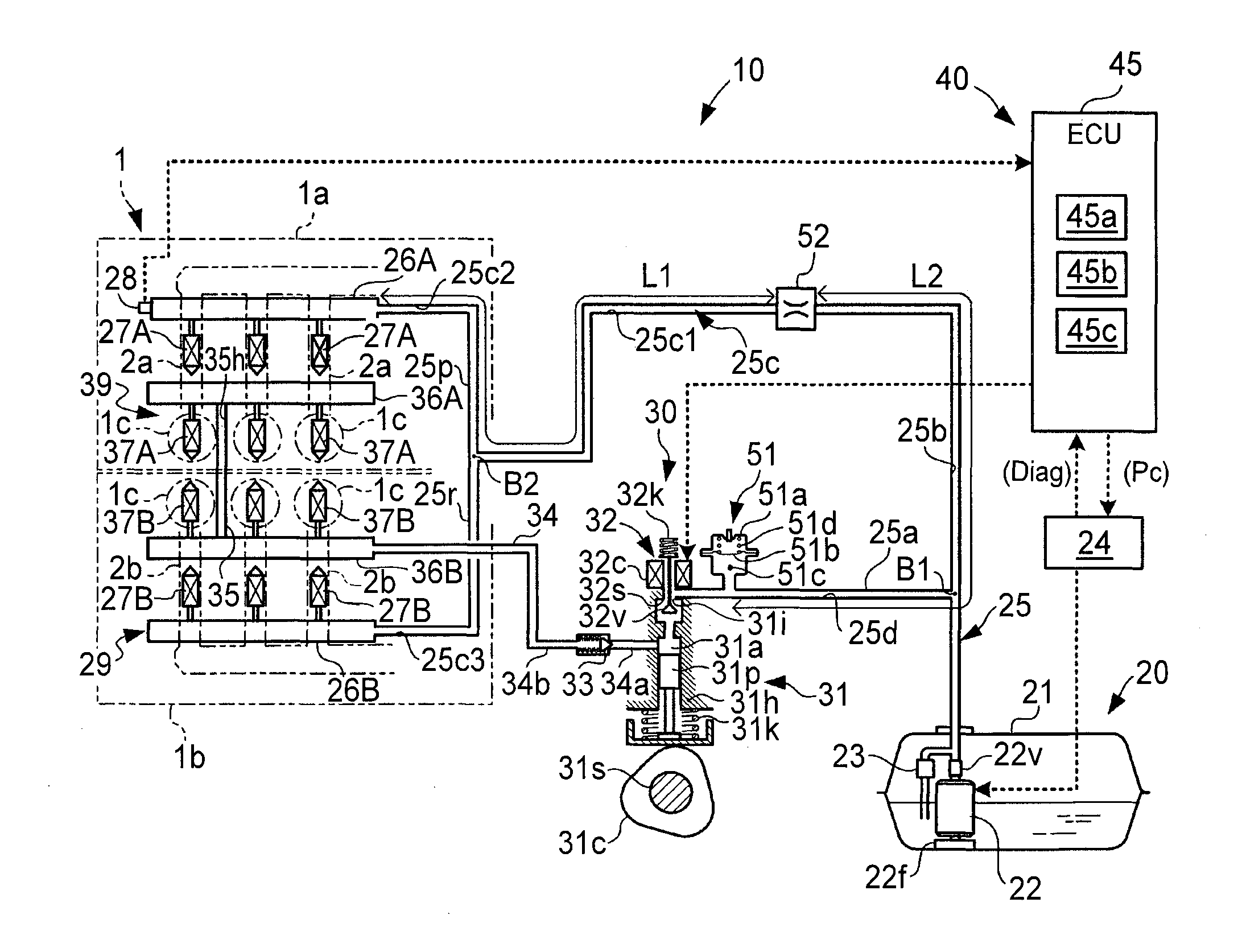

Control Apparatus for Internal Combustion Engine

ActiveUS20110100333A1Minimizing amount of fuelImprove performanceElectrical controlInternal combustion piston enginesDriving currentExternal combustion engine

A fuel injection control apparatus for an internal combustion engine which can inject a fuel injection quantity to a fuel injector with accuracy even when the fuel injection quantity is reduced than before is provided. A fuel injection control apparatus of a direct cylinder injection type of internal combustion engine, including a fuel injector which performs fuel injection by supplying a drive current to a solenoid, a fuel pressure sensor which detects fuel pressure supplied to the fuel injector, and operation state detecting means which detects the operation state of the internal combustion engine, comprises current profile changing means 100 which has multiple current profiles of the drive current and changes current profiles based on the operation state and the fuel pressure, valid pulse width calculating means 701 which calculates a valid pulse width for opening and driving the fuel injector, invalid pulse width calculating means 103 which calculates an invalid pulse width, and fuel injector control means which calculates a fuel injection pulse width based on the valid pulse width and the invalid pulse width, and controls the fuel injector based on the fuel injection pulse width, wherein the invalid pulse width calculating means 103 calculates an invalid pulse width corresponding to the current profiles to be changed before the current profiles are changed.

Owner:HITACHI ASTEMO LTD

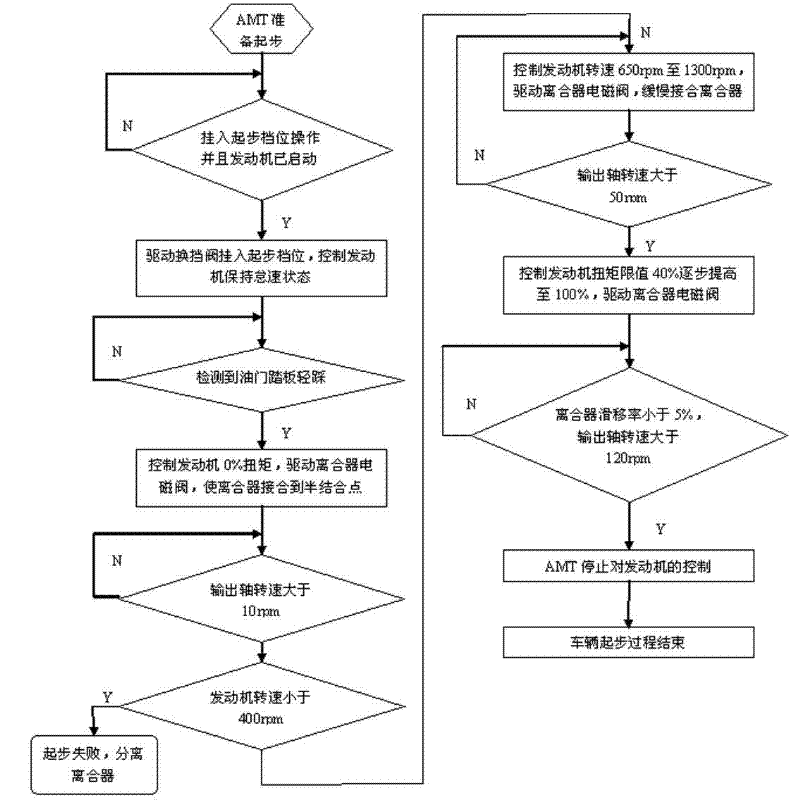

Engine idle speed control-based AMT (Automated Mechanical Transmission) vehicle start control method

The invention relates to an engine idle speed control-based AMT (Automated Mechanical Transmission) vehicle start control method, which comprises the following steps of: a, starting an engine, shifting to a start gear, controlling the engine to maintain an idle speed state by an electric control AMT, gently stamping a throttle to send out a starting signal; b, after receiving the starting signal, controlling a power source to drive a clutch to a semi-combined point; c, controlling an engine speed to be in a range of 650-1300 rpm by the electric control AMT, and detecting whether the ROTATING speed of an output shaft is more than 50 rpm or not; d, controlling the torque limit value of the engine to BE increaseD from 40% to 100% progressively by the electric control AMT and controlling the power source to drive the clutch to gradually combine, detecting whether the clutch sliding rate is less than 5% or not and whether the rotating speed of the output shaft is more than 120 rpm or not; and e, stopping controlling the engine by the electric control AMT, and ending a vehicle start process. The engine idle speed-control based AMT vehicle start control method has the beneficial effects of reducing abrasion of the clutch, increasing the comfort and economy as much as possible on the premise of maintaining dynamic property, and the like.

Owner:SINO TRUK JINAN POWER

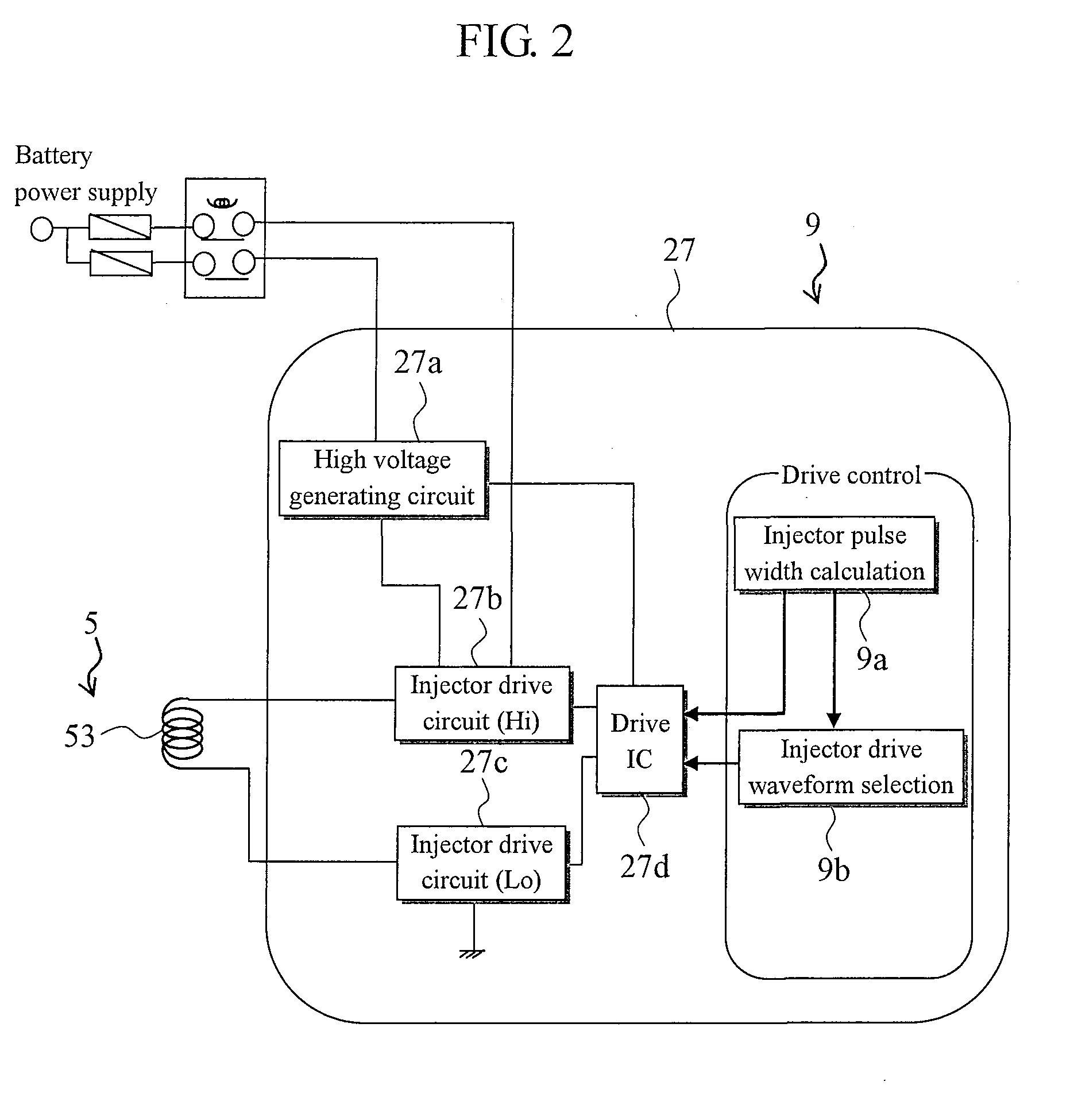

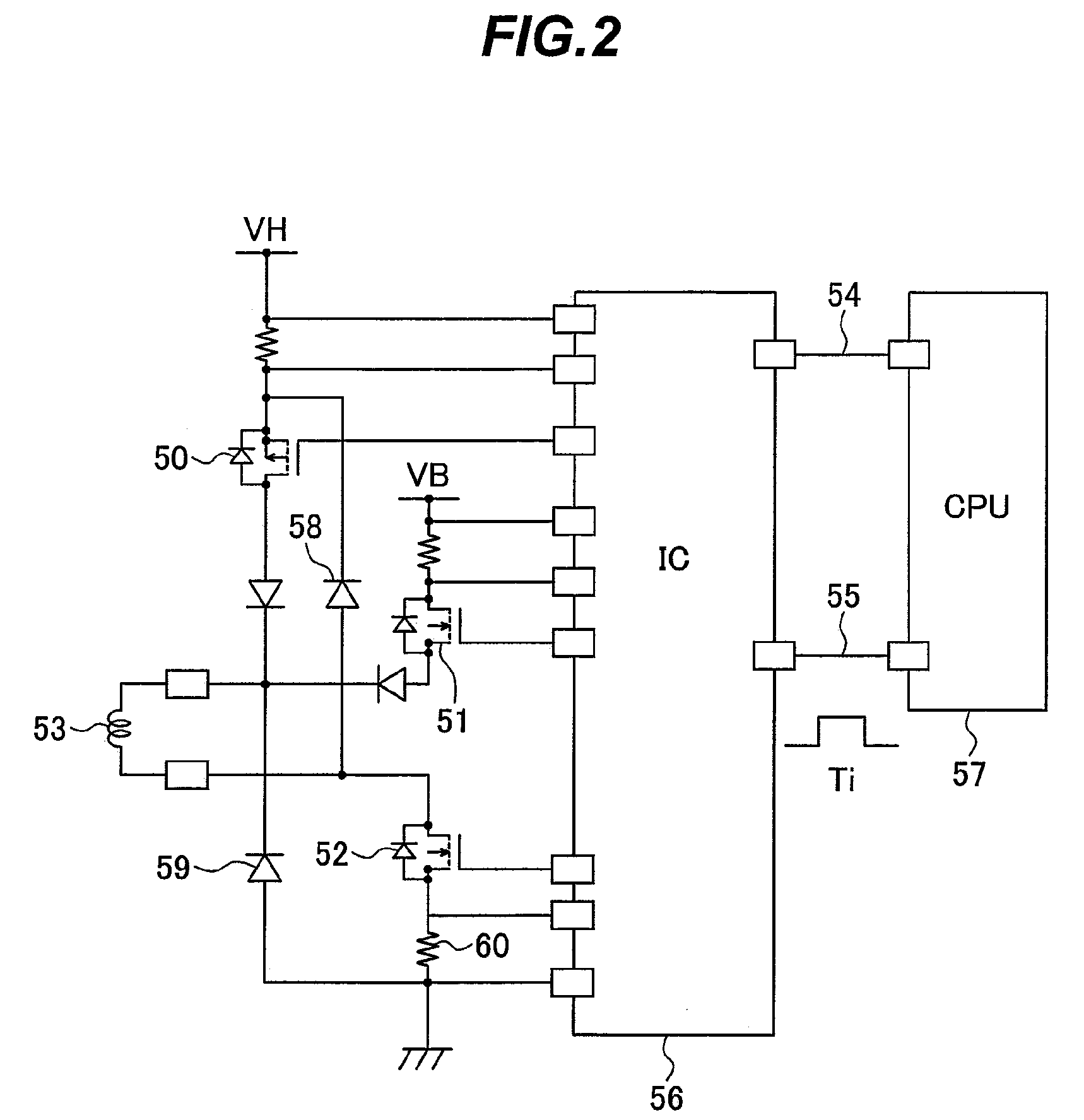

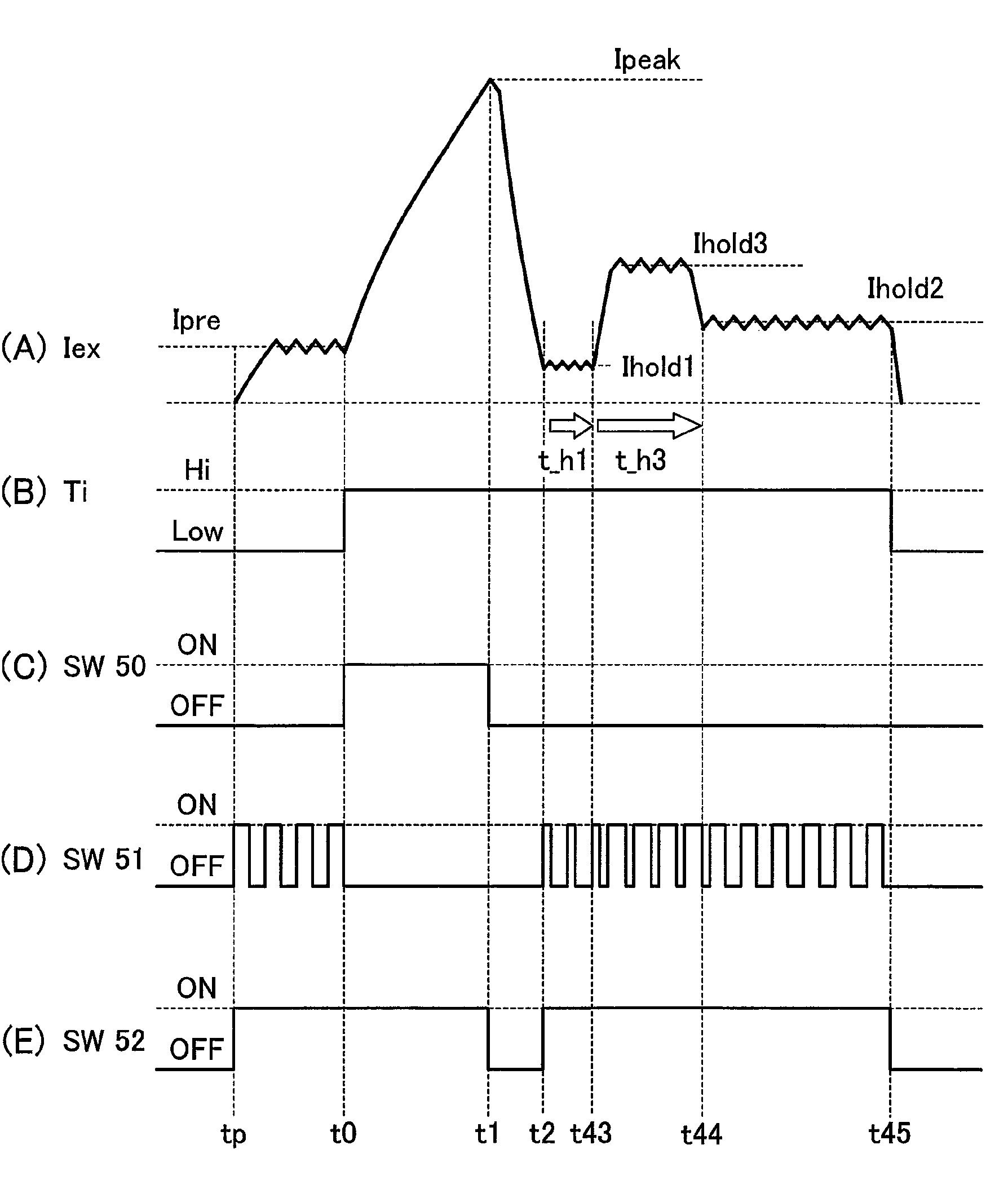

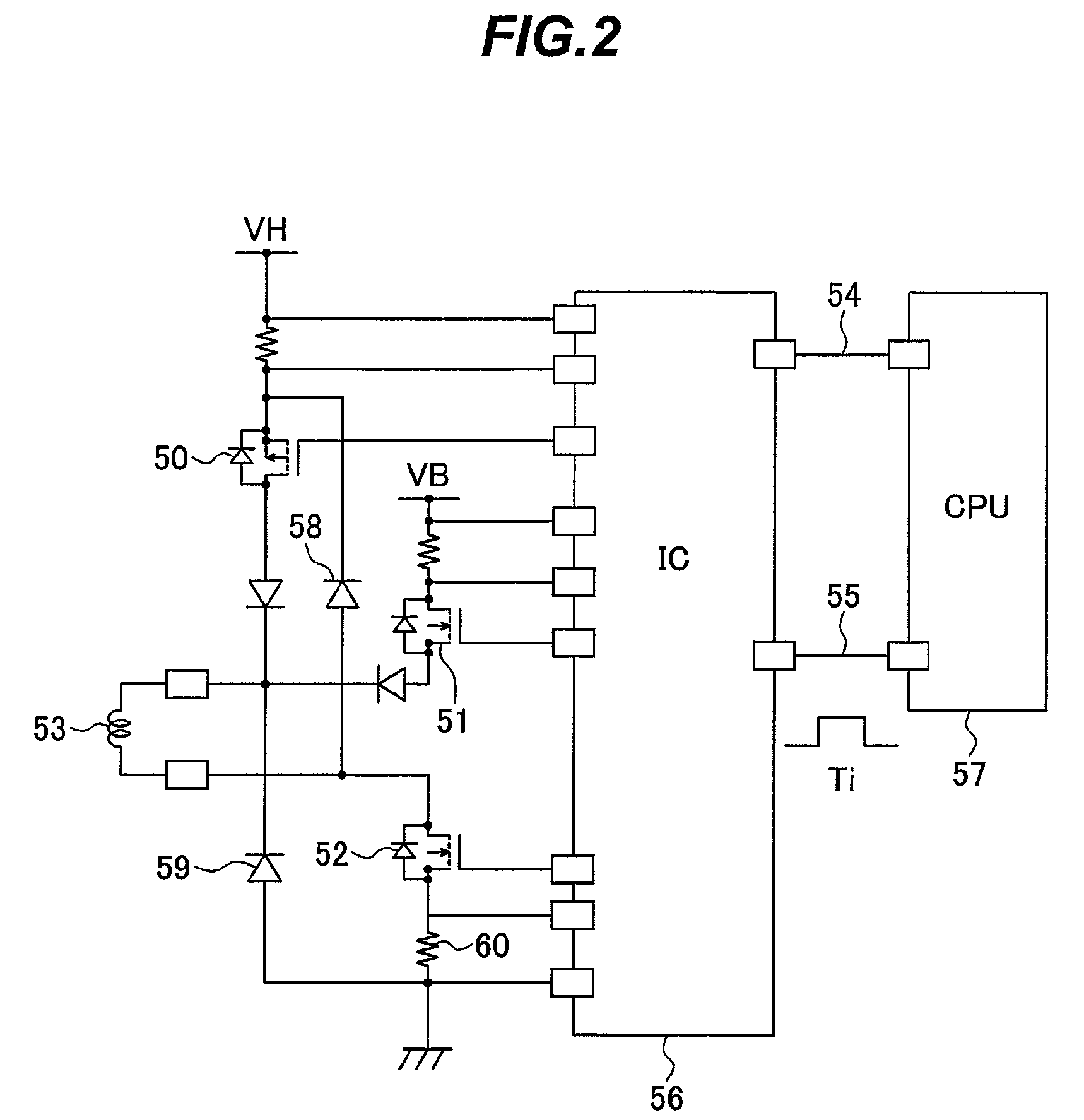

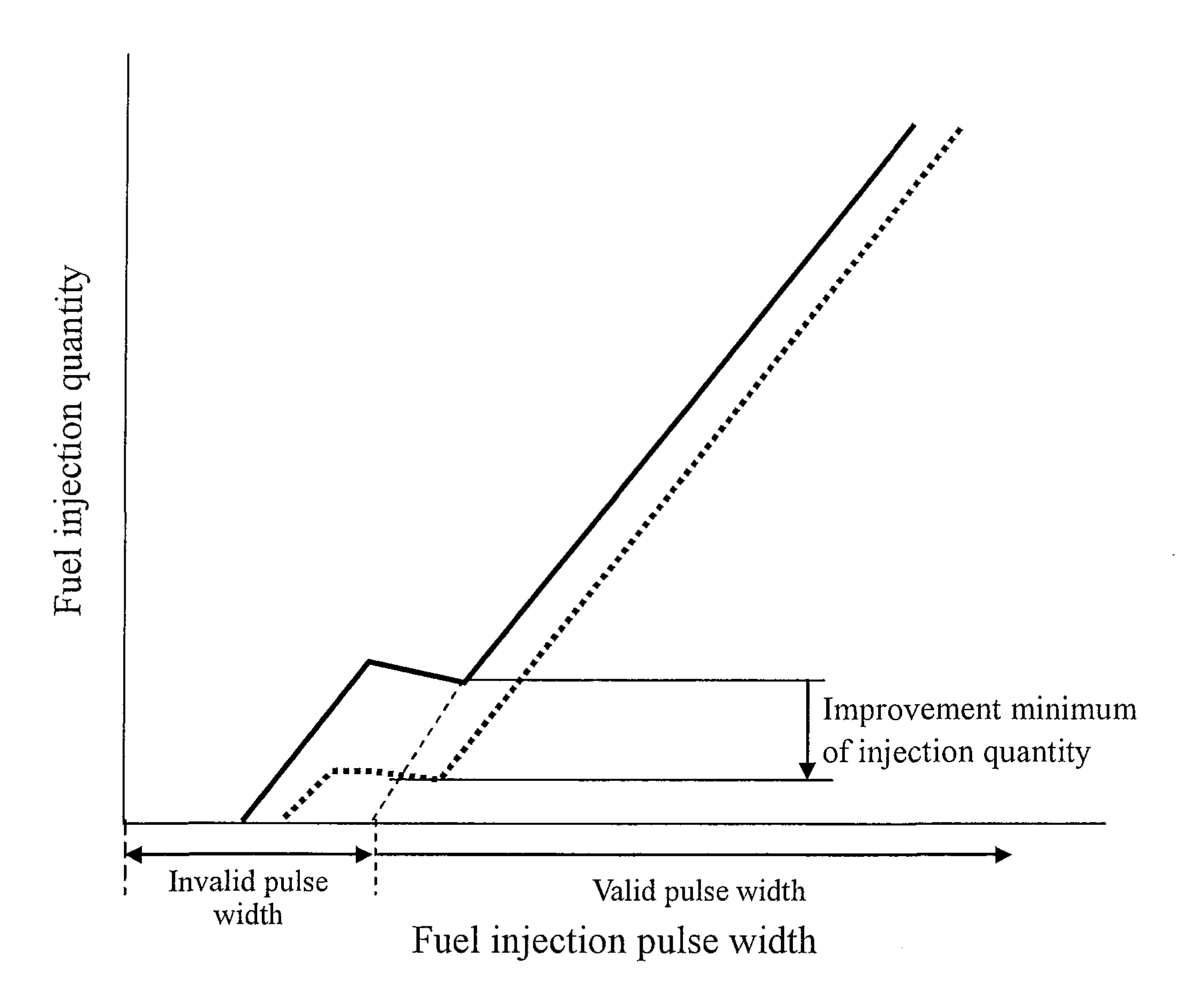

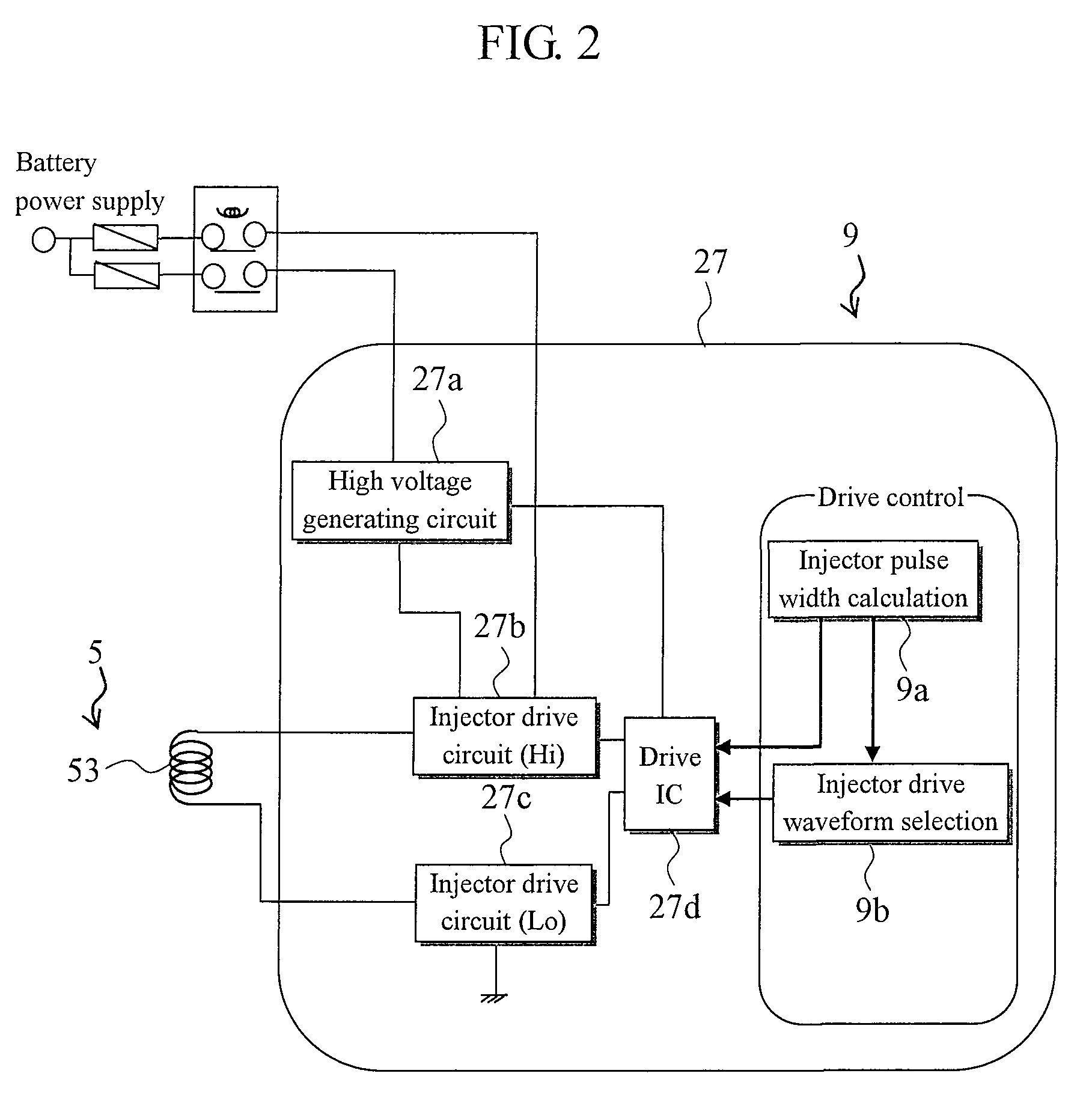

Fuel injection control apparatus

ActiveUS20090177369A1Reduce fuel consumptionImprove performanceElectrical controlDigital data processing detailsMicrocomputerLow voltage

To provide a fuel injection control apparatus capable of reducing the minimum quantity of fuel injection without reducing the maximum quantity of injection.For fuel injector valve opening, a driving circuit 56 supplies an electric current from a high-voltage power supply VH to the fuel injector 53, then after valve opening, switches the high-voltage power supply VH to a low-voltage power supply LV, and retains the open state of the valve. A microcomputer 57 is adapted such that for opening the valve of the fuel injector, the microcomputer, after supplying the current from the high-voltage power supply to the injector 53, discharges the current rapidly for a decrease below a first current level Ihold1 at which the open state of the valve cannot be retained, and then controls the supply current to the injector 53 so as to supply a current of a second current level Ihold2 at which the open state of the valve can be retained.

Owner:HITACHI ASTEMO LTD

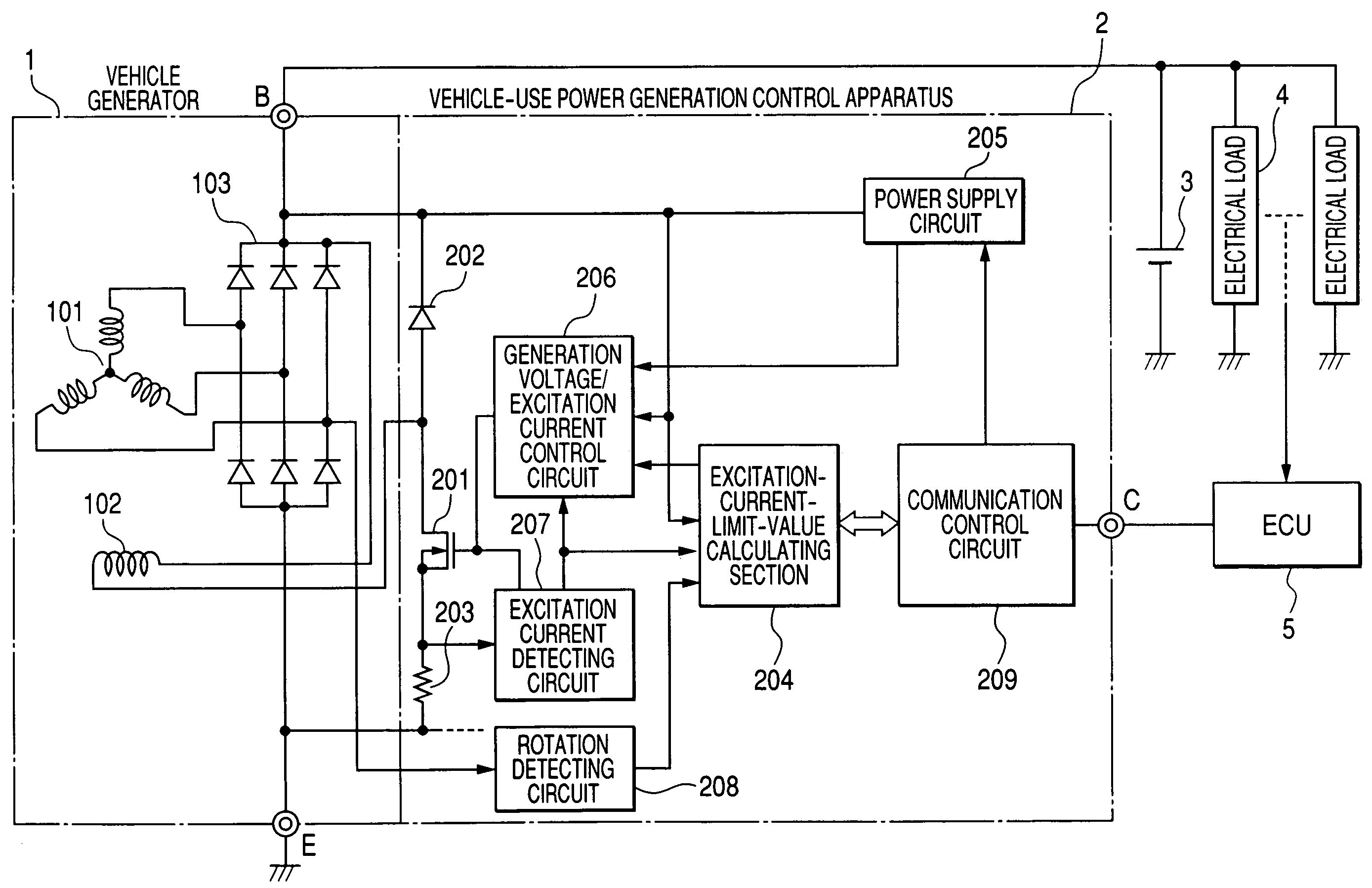

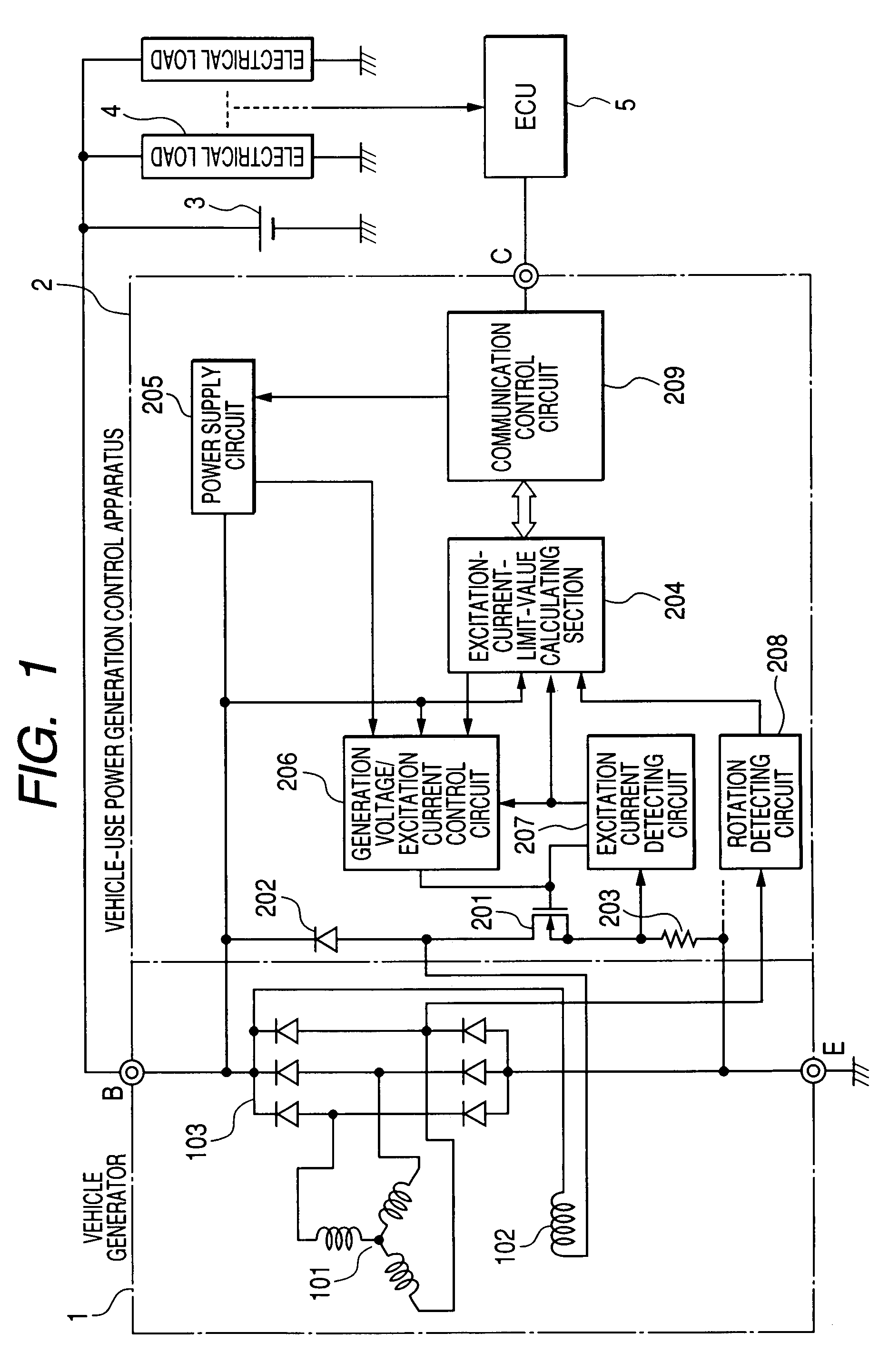

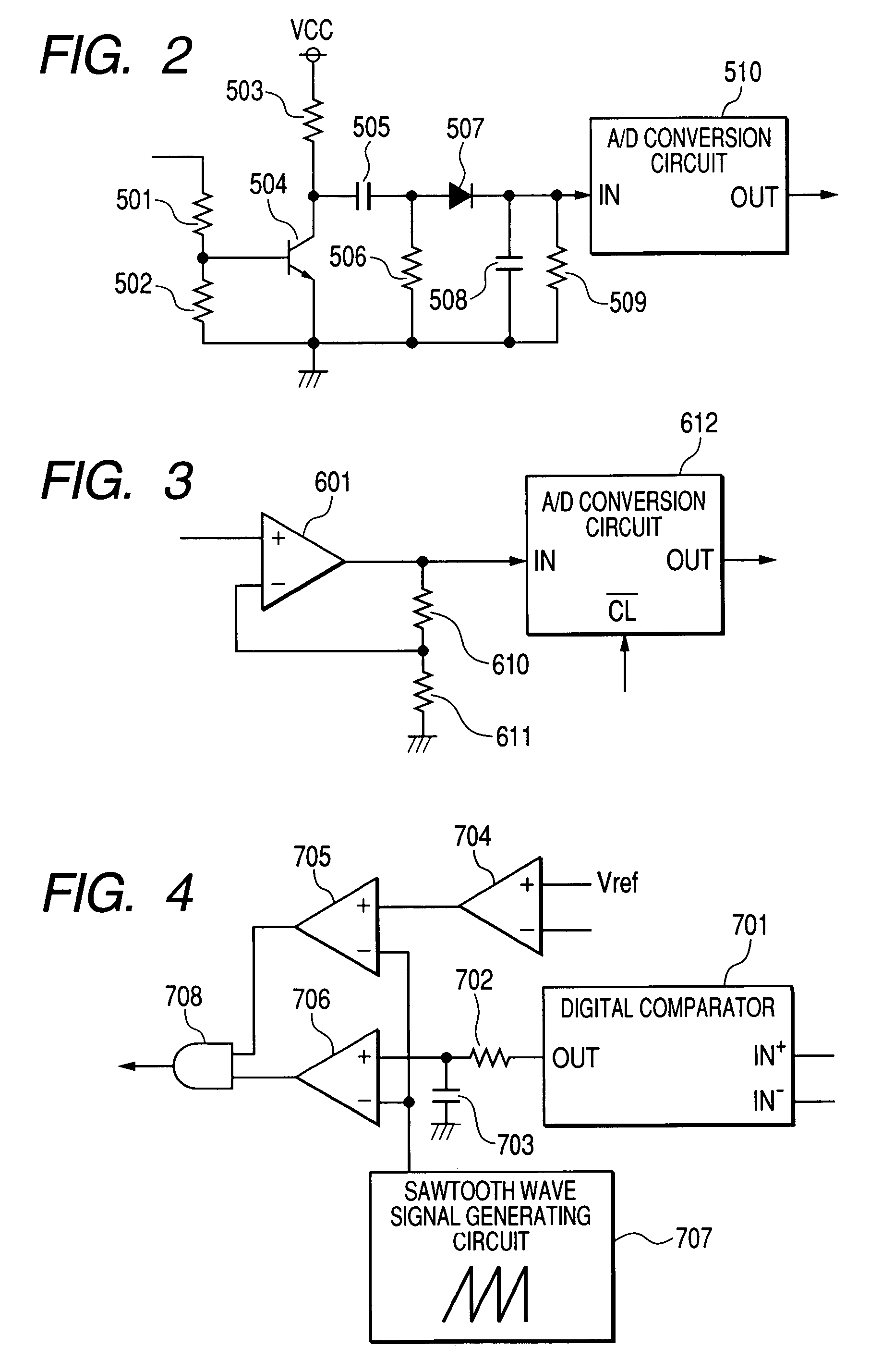

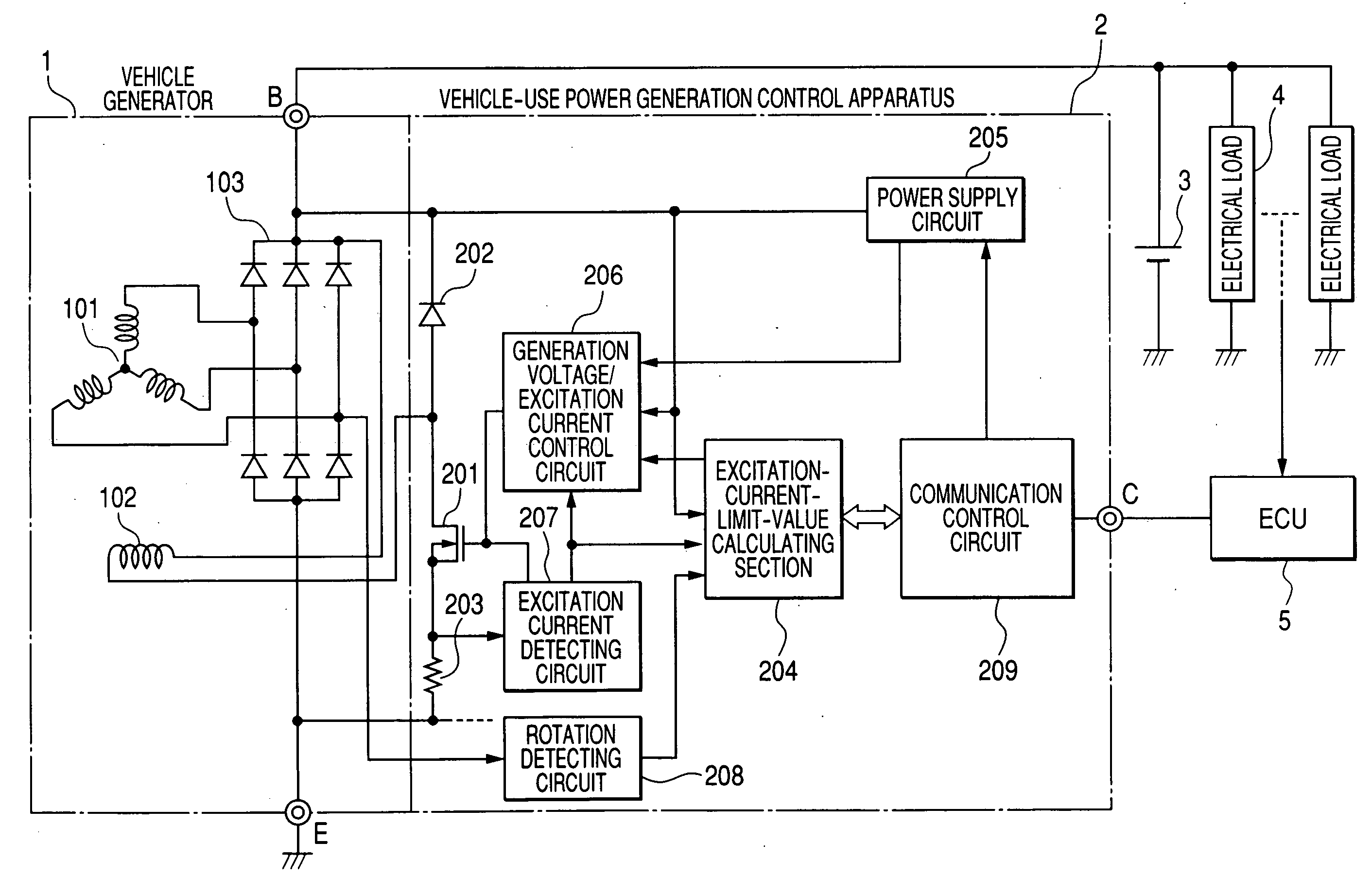

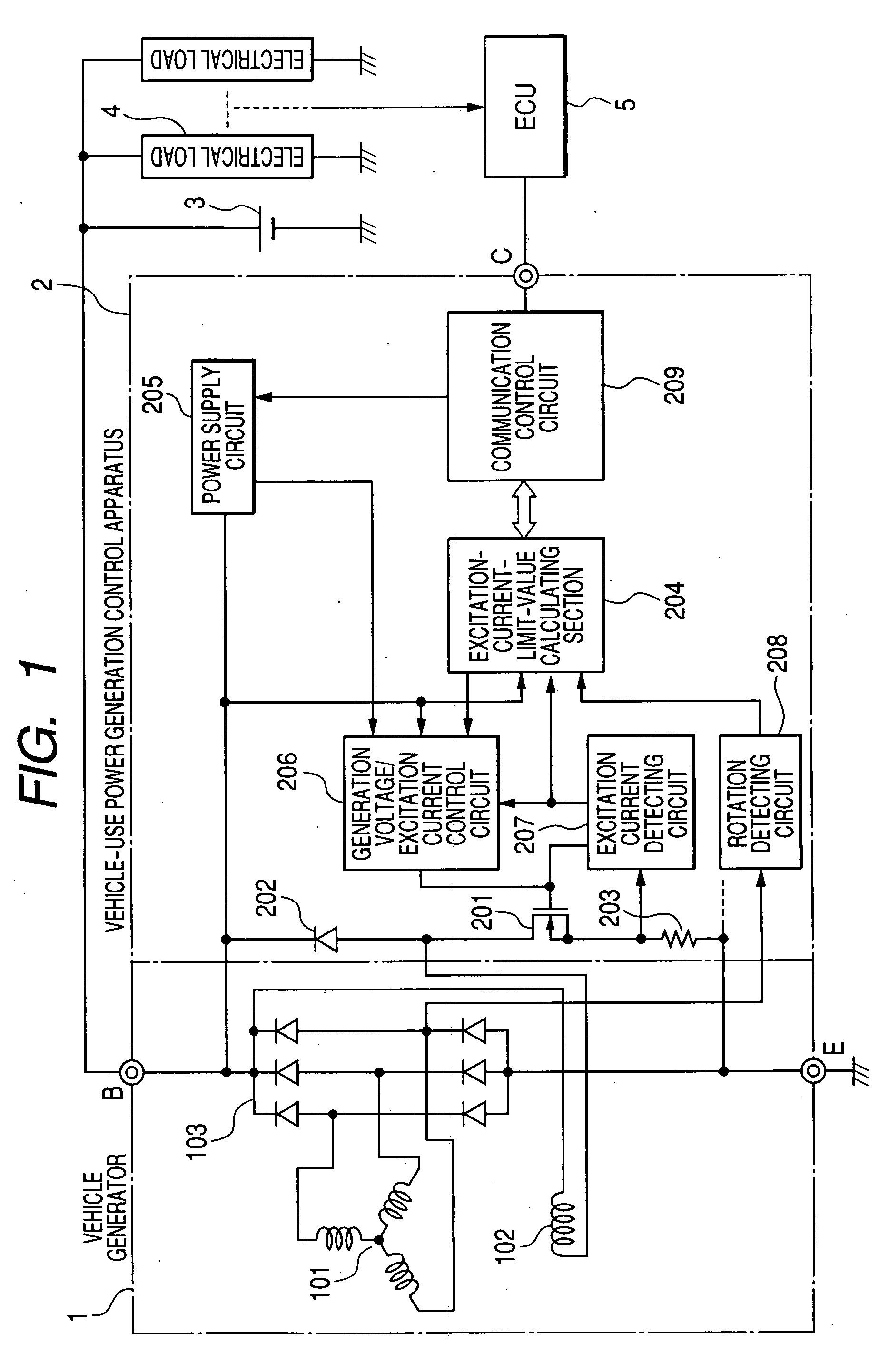

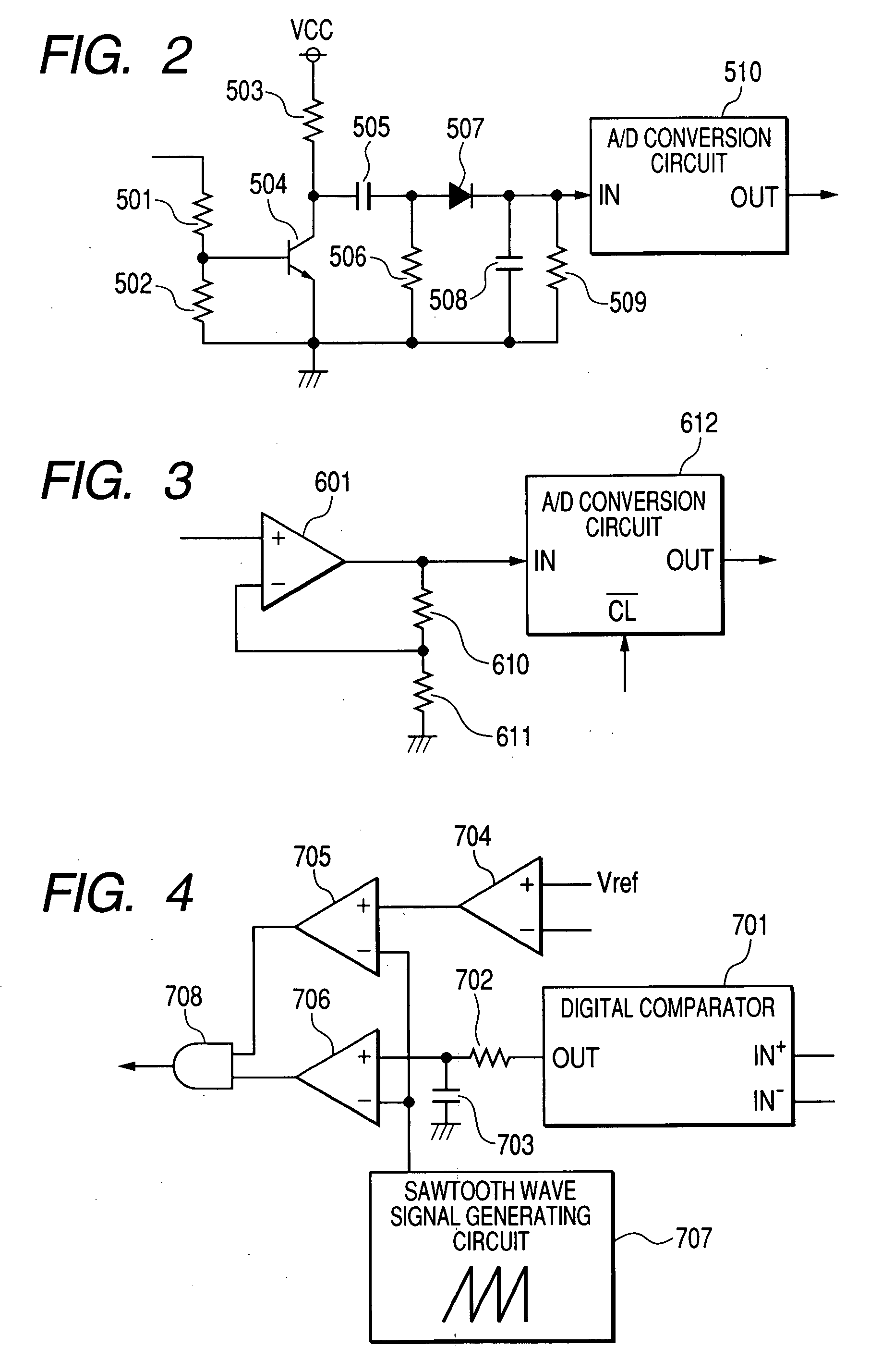

Vehicle-use power generation control apparatus

InactiveUS7528585B2Stable speedPrevent the vehicle from vibratingBatteries circuit arrangementsEmergency protective circuit arrangementsExcitation currentVoltage regulation

The vehicle-use power generation control apparatus regulates an output voltage of a vehicle generator driven by a vehicle engine at a set value by on / off controlling an excitation current flowing through an excitation winding of the vehicle generator The vehicle-use power generation control apparatus includes a rotation detecting circuit detecting a rotational speed of the vehicle generator, and an excitation current control circuit reducing, when the rotation detecting circuit detects decrease of the rotational speed, the excitation current at a rate depending on a rate of the decrease of the rotational speed detected by the rotation detecting circuit.

Owner:DENSO CORP

Vehicle-use power generation control apparatus

InactiveUS20070247119A1Reduce the impactReduce speedBatteries circuit arrangementsEmergency protective circuit arrangementsExcitation currentVoltage regulation

The vehicle-use power generation control apparatus regulates an output voltage of a vehicle generator driven by a vehicle engine at a set value by on / off controlling an excitation current flowing through an excitation winding of the vehicle generator The vehicle-use power generation control apparatus includes a rotation detecting circuit detecting a rotational speed of the vehicle generator, and an excitation current control circuit reducing, when the rotation detecting circuit detects decrease of the rotational speed, the excitation current at a rate depending on a rate of the decrease of the rotational speed detected by the rotation detecting circuit.

Owner:DENSO CORP

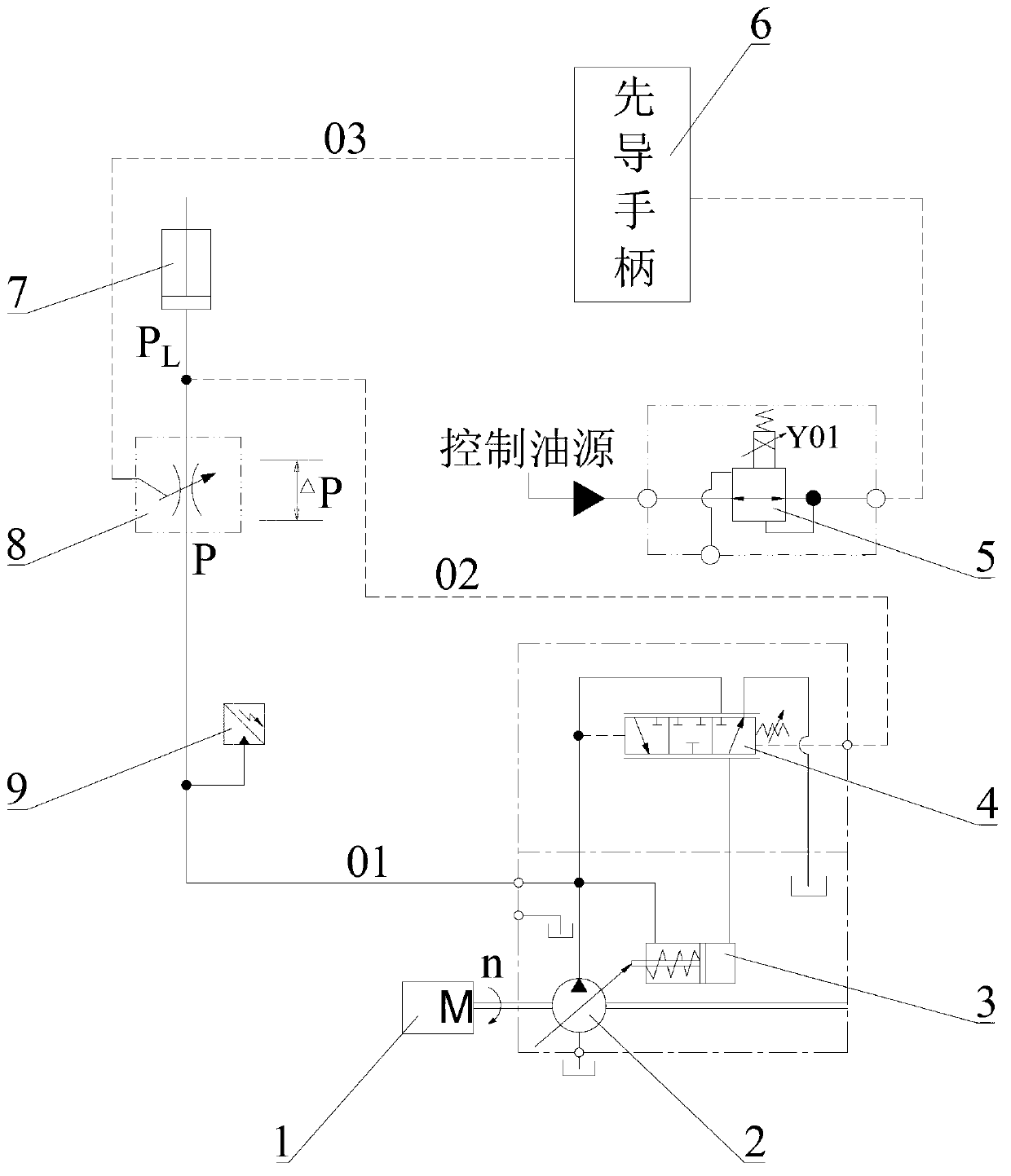

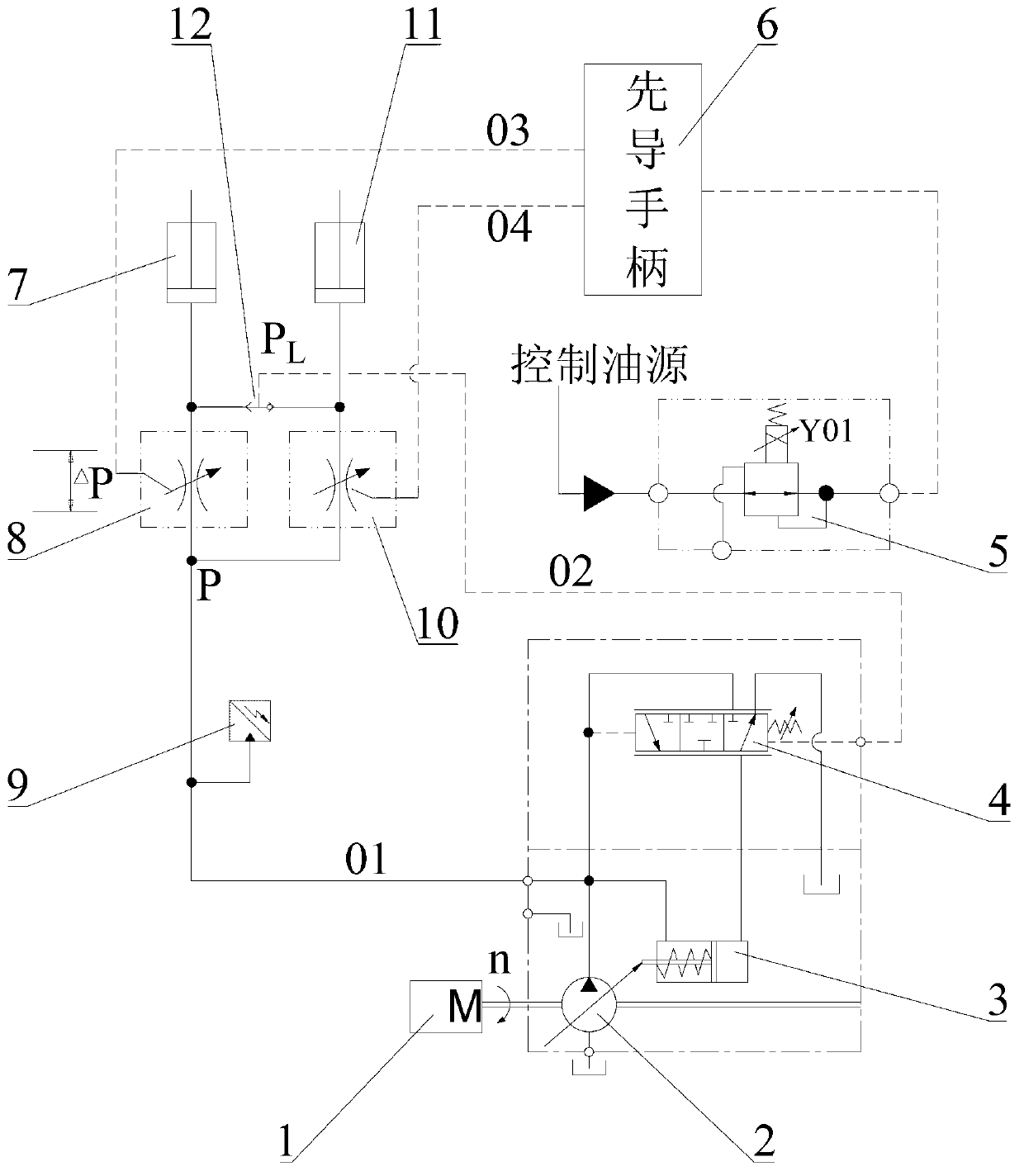

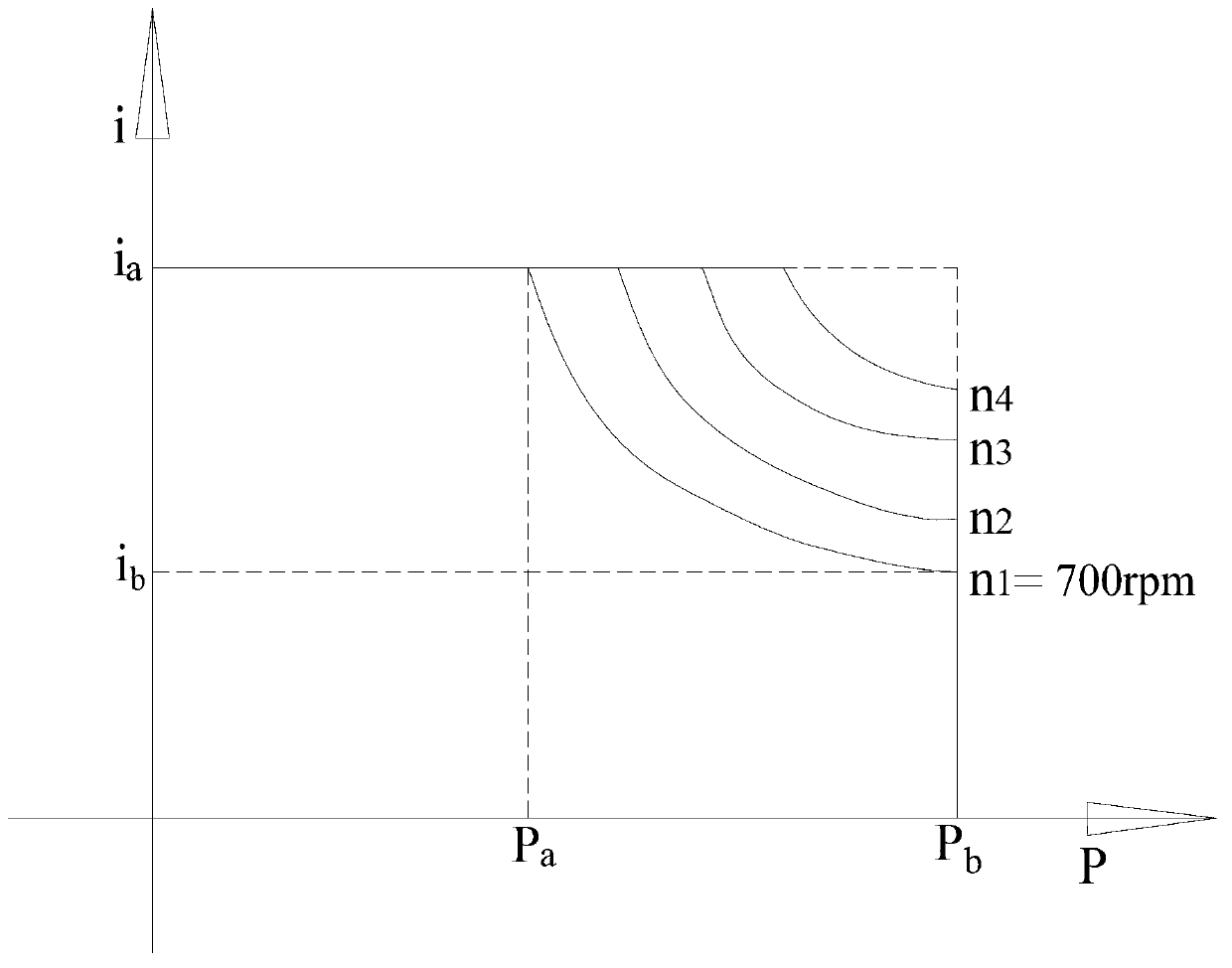

Load sensitive hydraulic system and power controller thereof as well as crane

InactiveCN102996536AIncrease powerReduce power consumptionServomotor componentsServomotorsPower controllerIdle speed

The invention discloses a load sensitive hydraulic system and a power controller thereof as well as a crane. The load sensitive hydraulic system comprises a proportional decompression valve, wherein the proportional decompression valve is arranged on an oil path between a control oil source and an oil inlet of a pilot-operated handle or is arranged on an oil path between a first oil outlet of the pilot-operated handle and a control end of a first main valve; and outlet pressure of the proportional decompression valve is preset so that when the pilot-operated handle is at the biggest opening degree, the output power of a load sensitive pump is matched with the output power of an engine. Compared with the prior art, the load sensitive hydraulic system has the advantages that the adaptability of the output power of the load sensitive pump and the output power of the engine can be improved, so that a lower engine idle speed can be selected and the power consumption is reduced; the great power can be output by an oil pump when the engine is operated at a high speed, and the energy efficiency is improved; and furthermore, the engine is effectively prevented from being stalled.

Owner:SANY HEAVY IND CO LTD (CN)

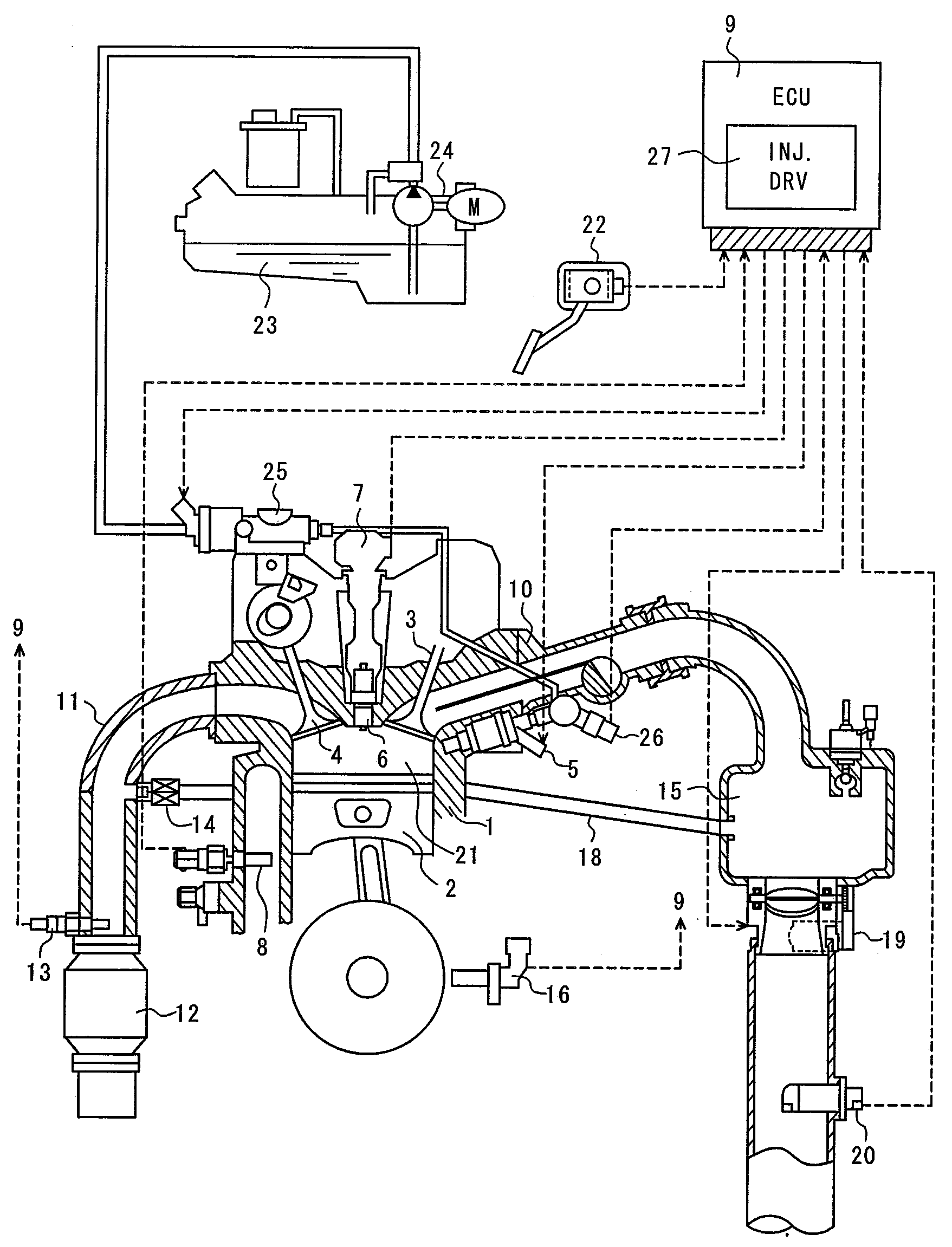

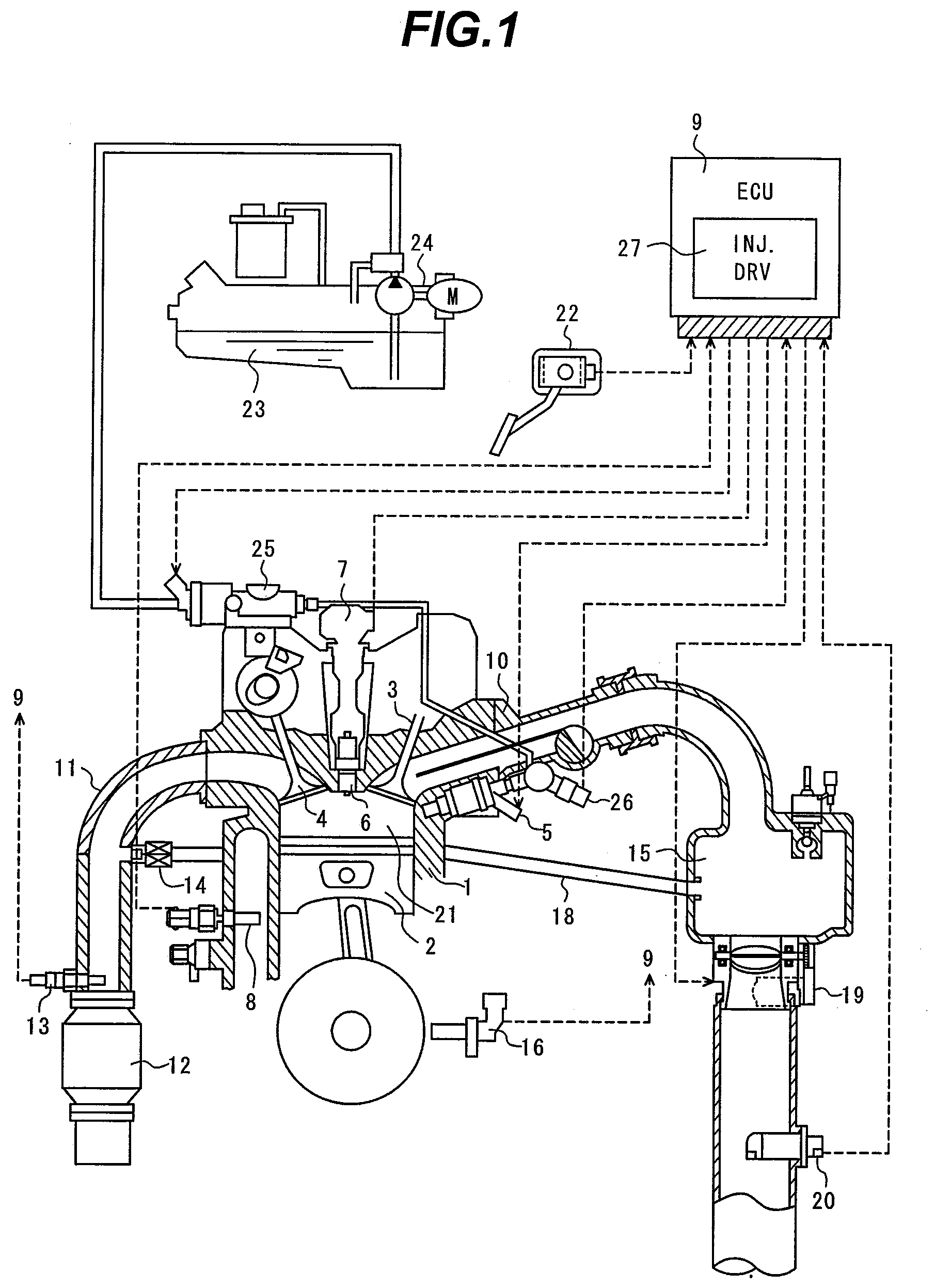

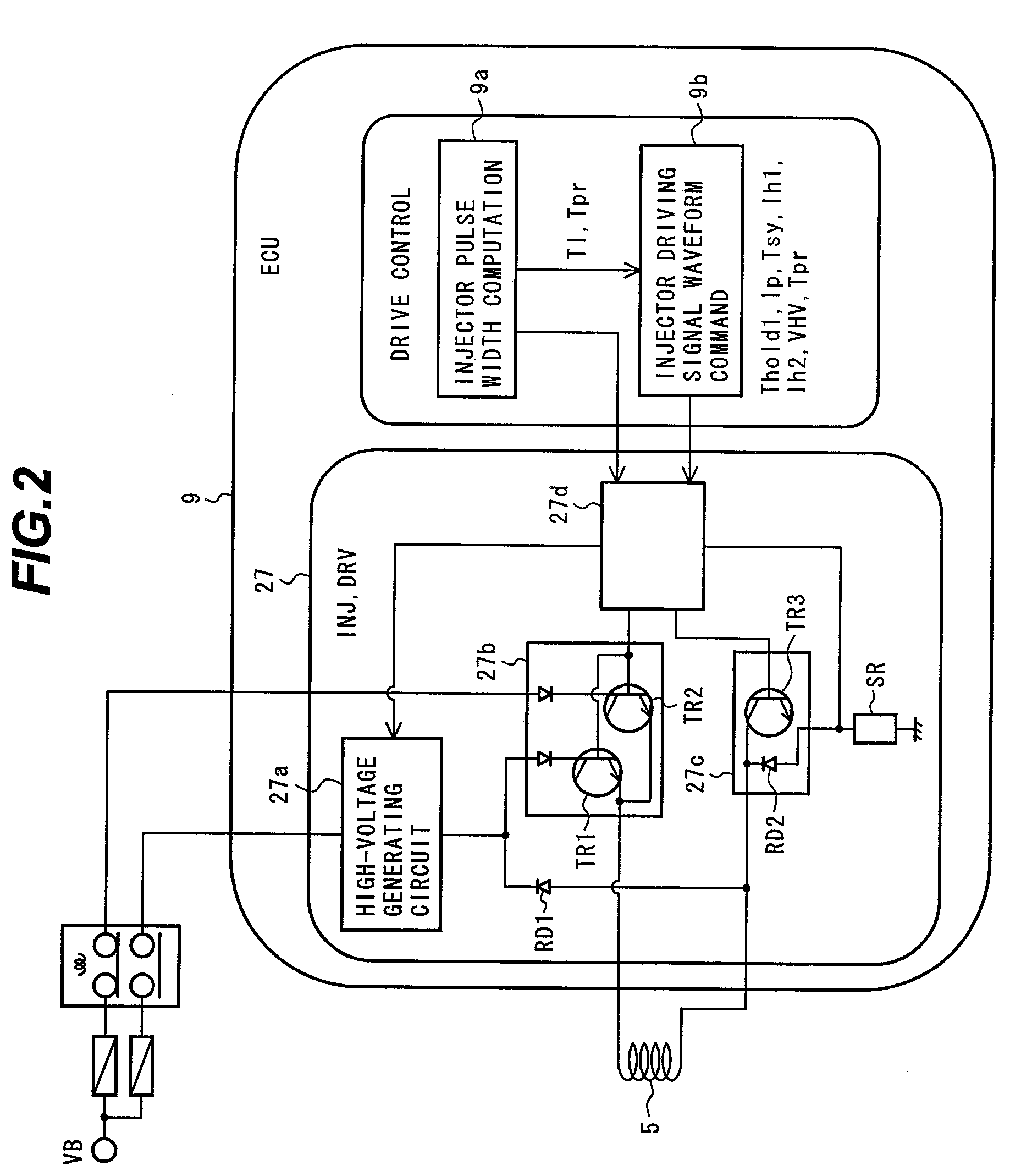

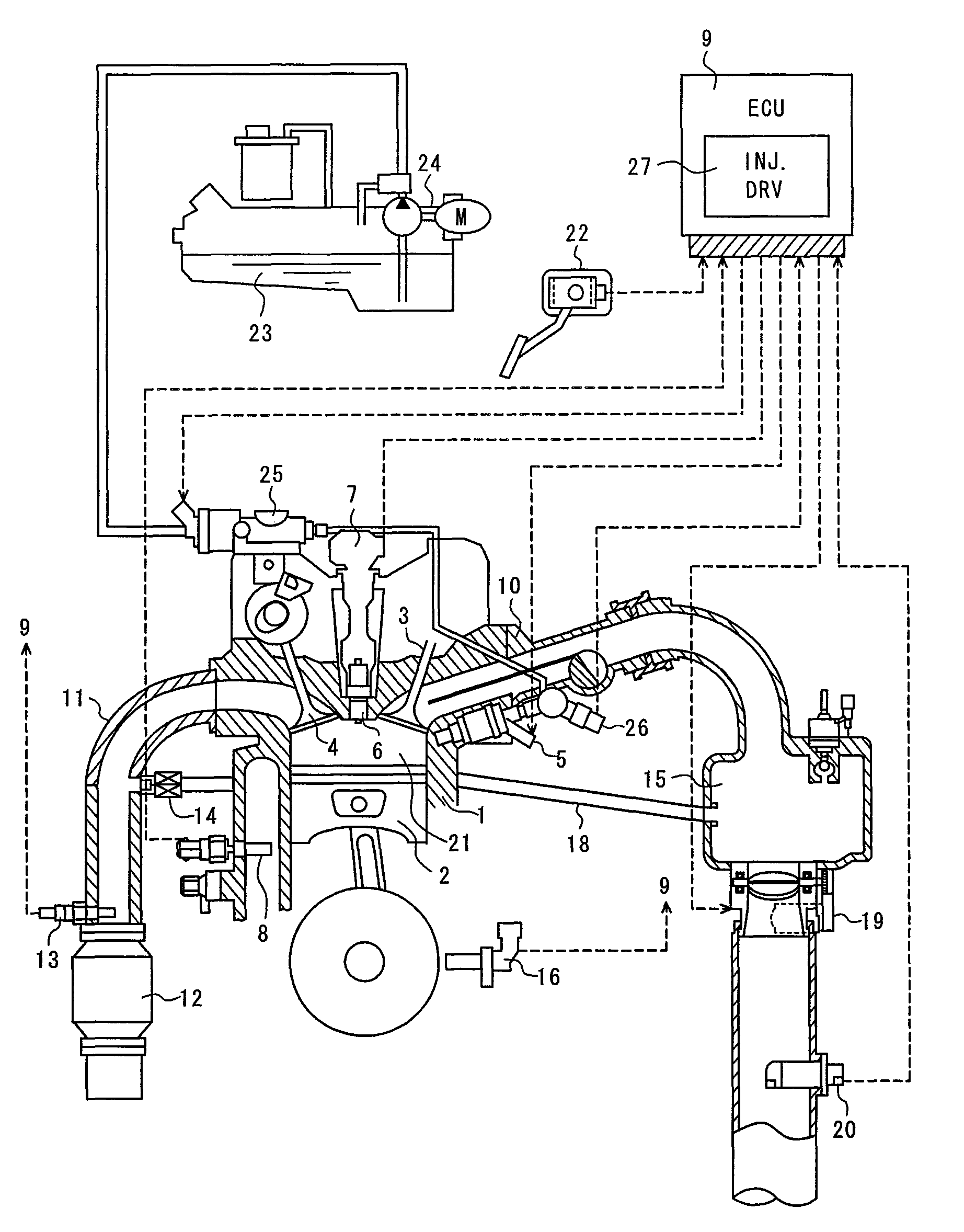

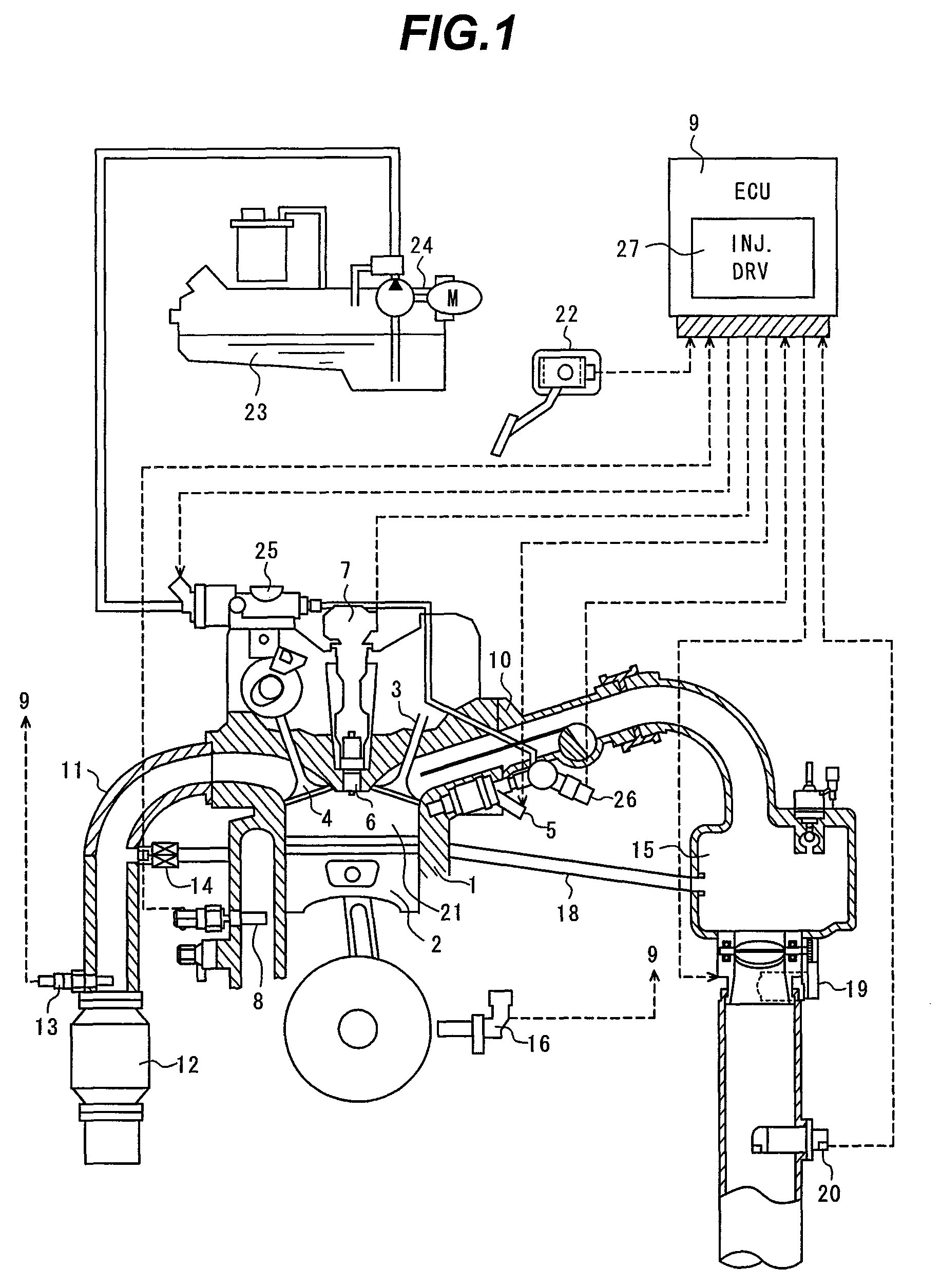

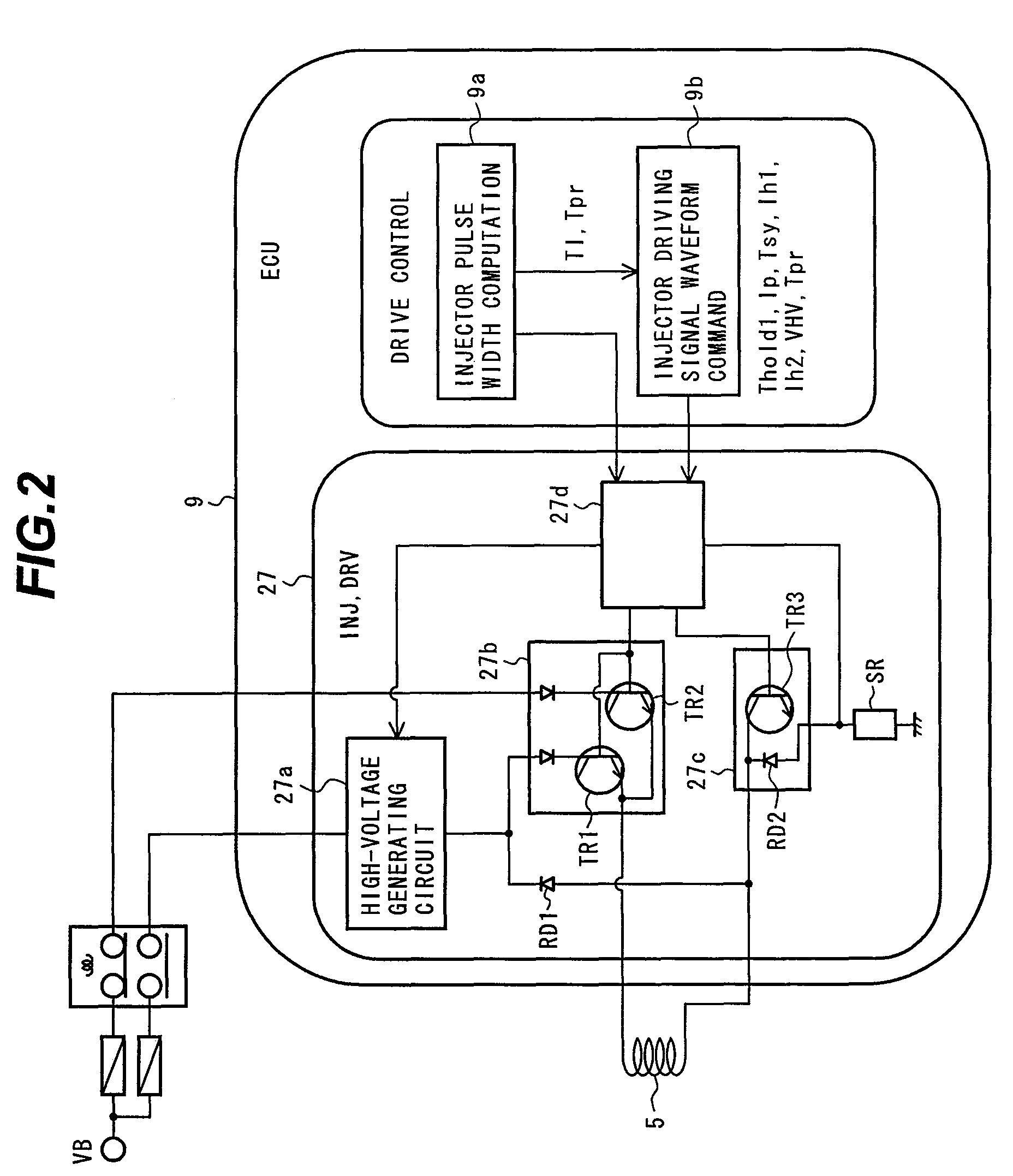

Fuel injection control apparatus for internal combustion engine

InactiveUS20090177367A1Open and close accuratelyImprove performanceElectrical controlDigital data processing detailsInjectorPulse duration

Disclosed herein is a fuel injection control apparatus for an internal combustion engine, capable of opening and closing accurately a valve of the fuel injector even when the quantity of injection required is small and a pulse duration of a driving pulse signal to the fuel injector is short.A fuel injector pulse width computing unit 9a calculates, from the operational state of the internal combustion engine and the fuel pressure detected by a fuel pressure sensor, pulse width of a pulse signal which drives the valve of the fuel injector. After an valve-opening command has turned on and a high valve-opening current for opening the fuel injector valve has been supplied from a high-voltage source to the fuel injector, a fuel injector driving signal waveform command unit 9b discharges the current and supplies from a low-voltage source a small hold current Ih2 that allows the fuel injector to maintain the valve-open state. Also, during the time from supply of the valve-opening current to an arrival at the value of the hold current Ih2, after the elapse of a previously assigned rapid-discharge starting time Tsy from the turn-on of the valve-opening command, the fuel injector driving signal waveform command unit 9b rapidly discharges the current until the hold current Ih2 has been reached.

Owner:HITACHI LTD

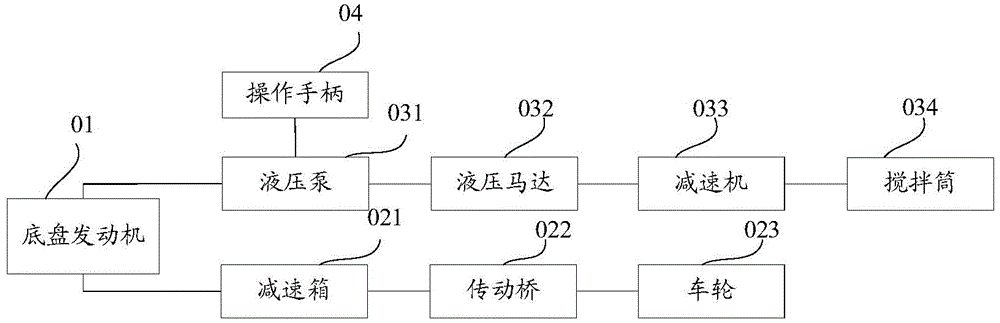

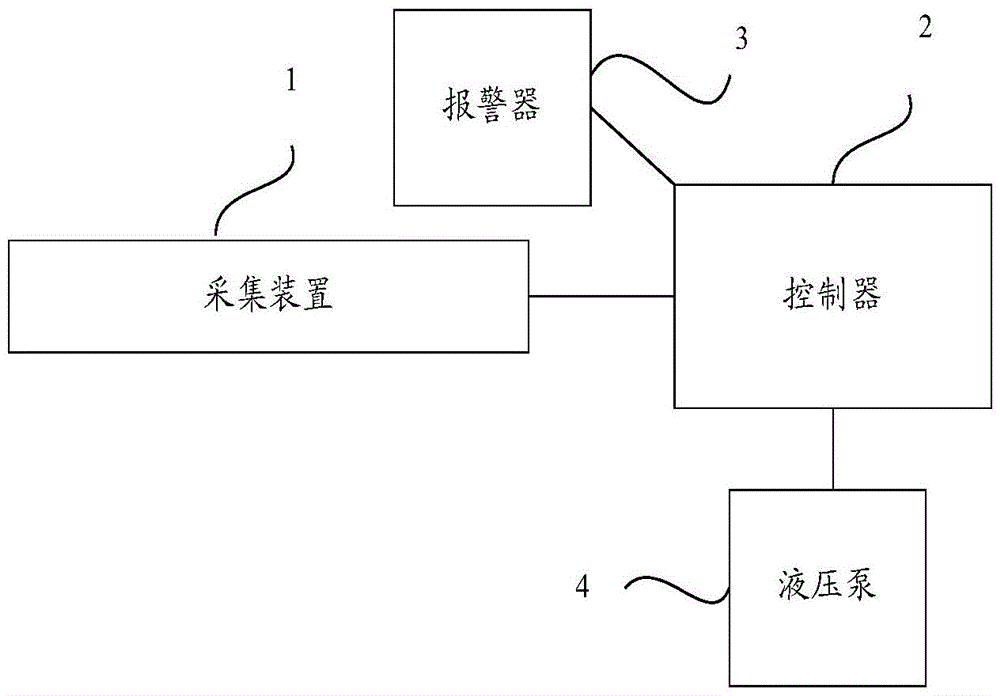

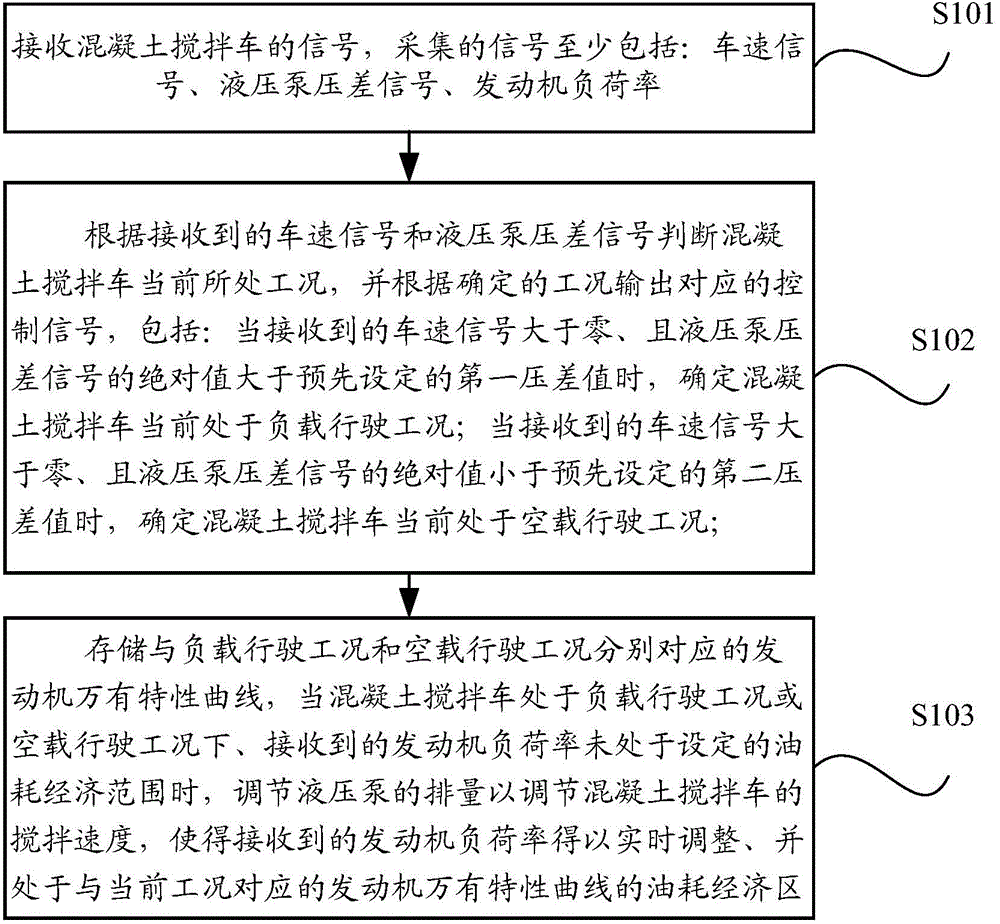

Control system, method and device of concrete mixer as well as concrete mixer

ActiveCN105480141AReduce idle speedConcrete transportationSignalling/lighting devicesEconomic regionControl system

The invention discloses a control system, method and device of a concrete mixer as well as the concrete mixer. The control system, method and device are used for improving the energy-saving performance of the concrete mixer. The control system comprises a plurality of acquisition devices and a controller, wherein the acquisition devices are used for acquiring signals of the concrete mixer; and the controller is used for judging the current working condition of the concrete mixer according to a received speed signal and a received hydraulic pump pressure difference signal and outputting a corresponding control signal according to the determined working condition, and is also used for storing engine universal characteristic curves respectively corresponding to a load running working condition and a no-load running working condition. When the concrete mixer is in the load running working condition or the no-load running working condition and the received engine load rate is not in the set oil consumption economic limit, the displacement of a hydraulic pump is adjusted so as to adjust the stirring rate of the concrete mixer, so that the received engine load rate can be adjusted in real time so as to be in an oil consumption economic region of the engine universal characteristic curve corresponding to the current working condition.

Owner:ZOOMLION HEAVY IND CO LTD

Constant-speed multi-pressure fuel injection system for improved dynamic range in internal combustion engine

InactiveUS20080173280A1Improve dynamic rangeMinimizes pressure fluctuationElectrical controlDigital data processing detailsInternal combustion engineLinearity

A fuel injection system operates under a predetermined substantially constant pump speed and creates multi-pressure levels by diverting the fuel flow. Fuel pressure can be switched from one steady pressure level to another level on-demand instantly. This superimposes and overlaps typical fuel injection events in the linear operating ranges under different pressure levels, significantly increasing the fuel injection dynamic range. The dynamic range is further increased when another predetermined constant pump speed is assigned. Thus, the system saves fuel and reduces exhaust emission in city driving when gas pedal is released including idle. The same system can instantly deliver additional fuel on-demand for extra power beyond engine rating producing a sport-car-like performance.

Owner:TMC

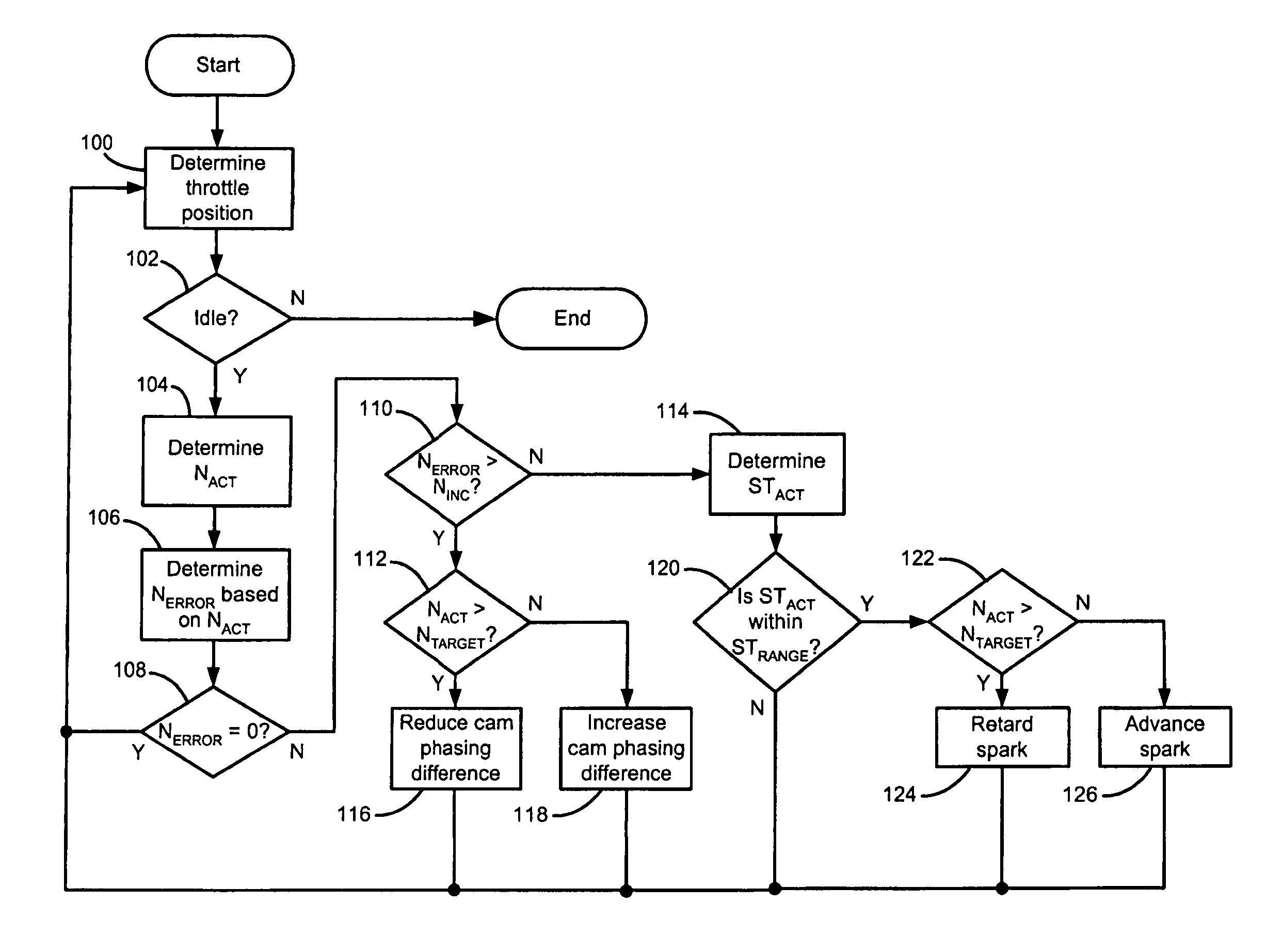

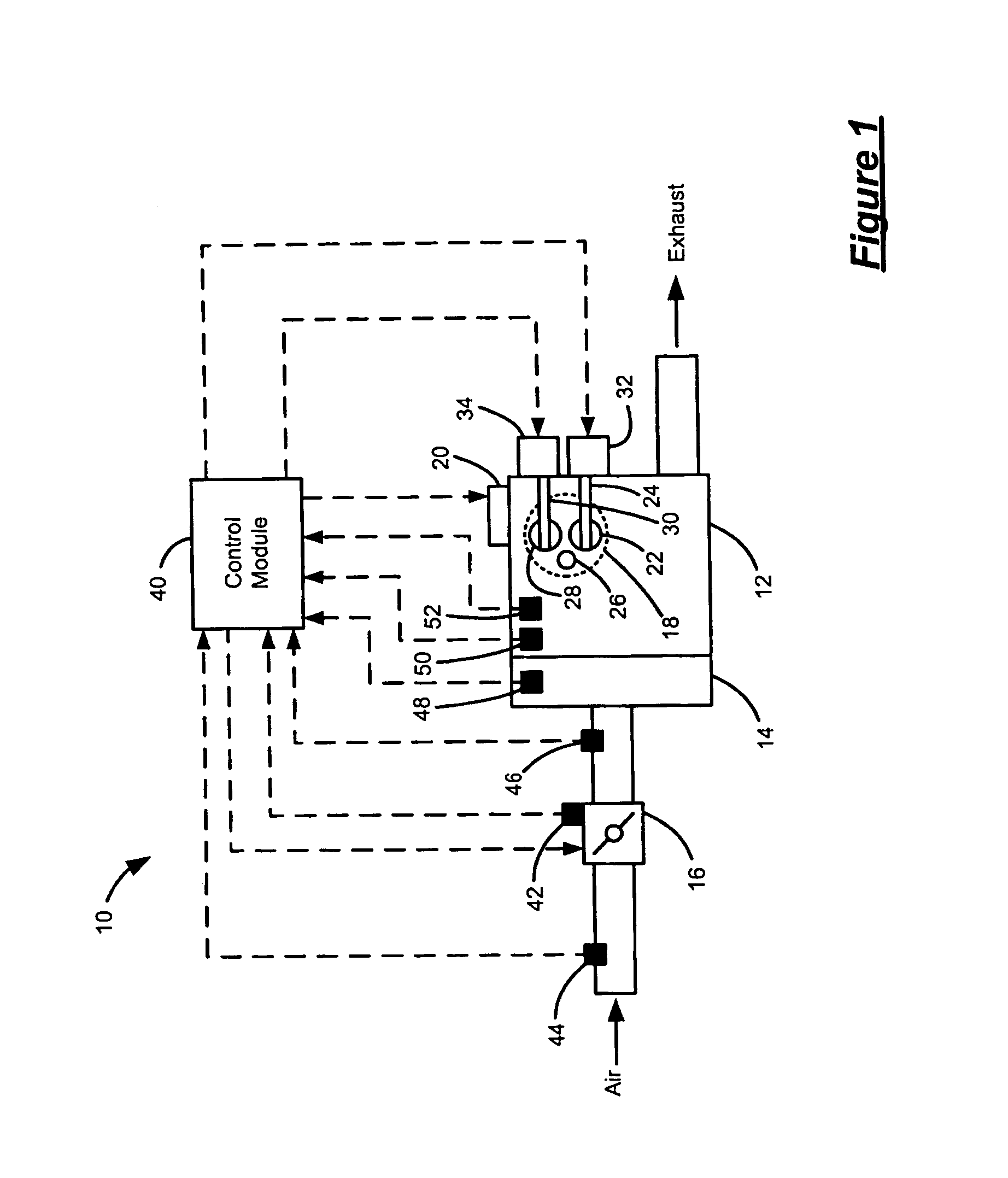

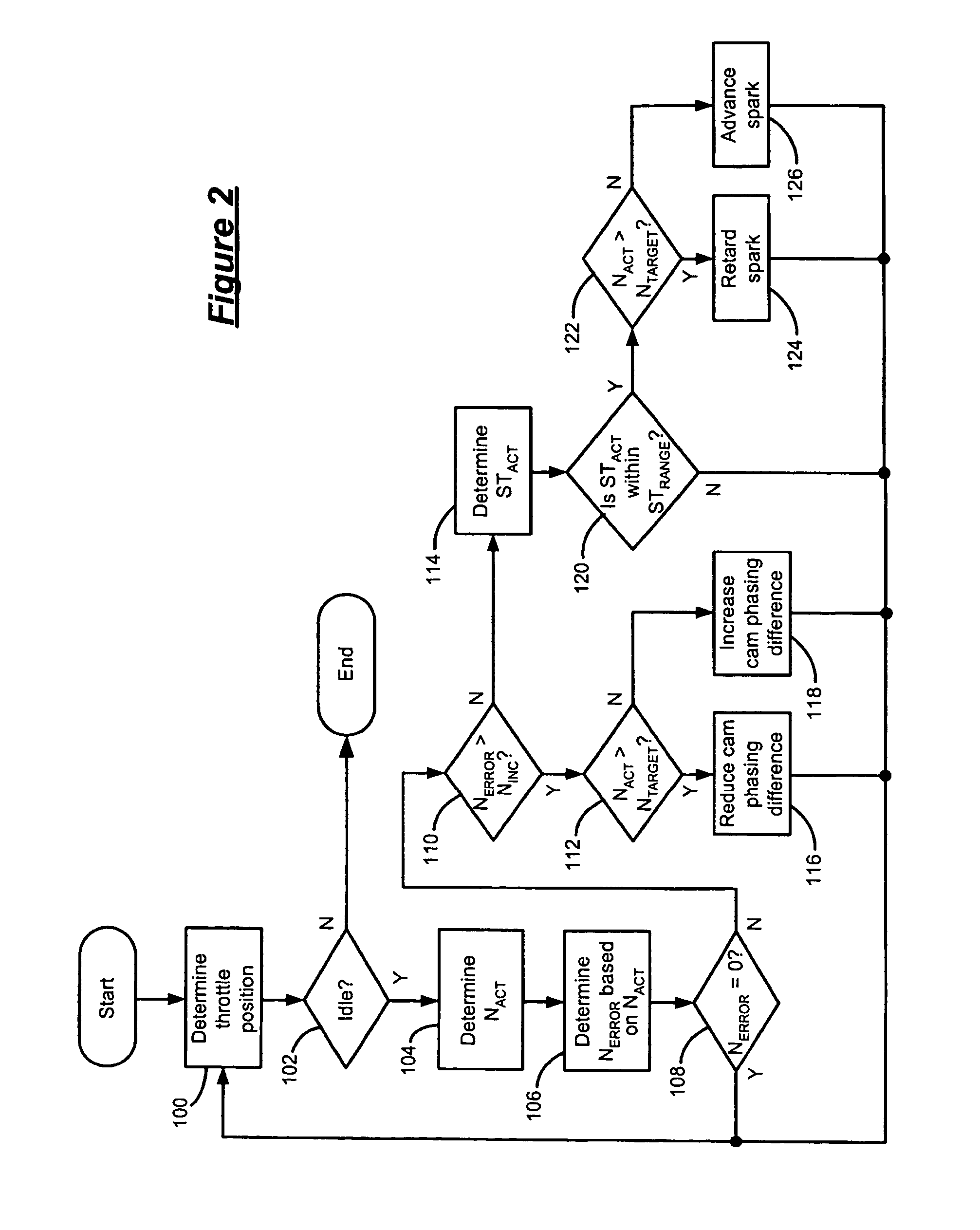

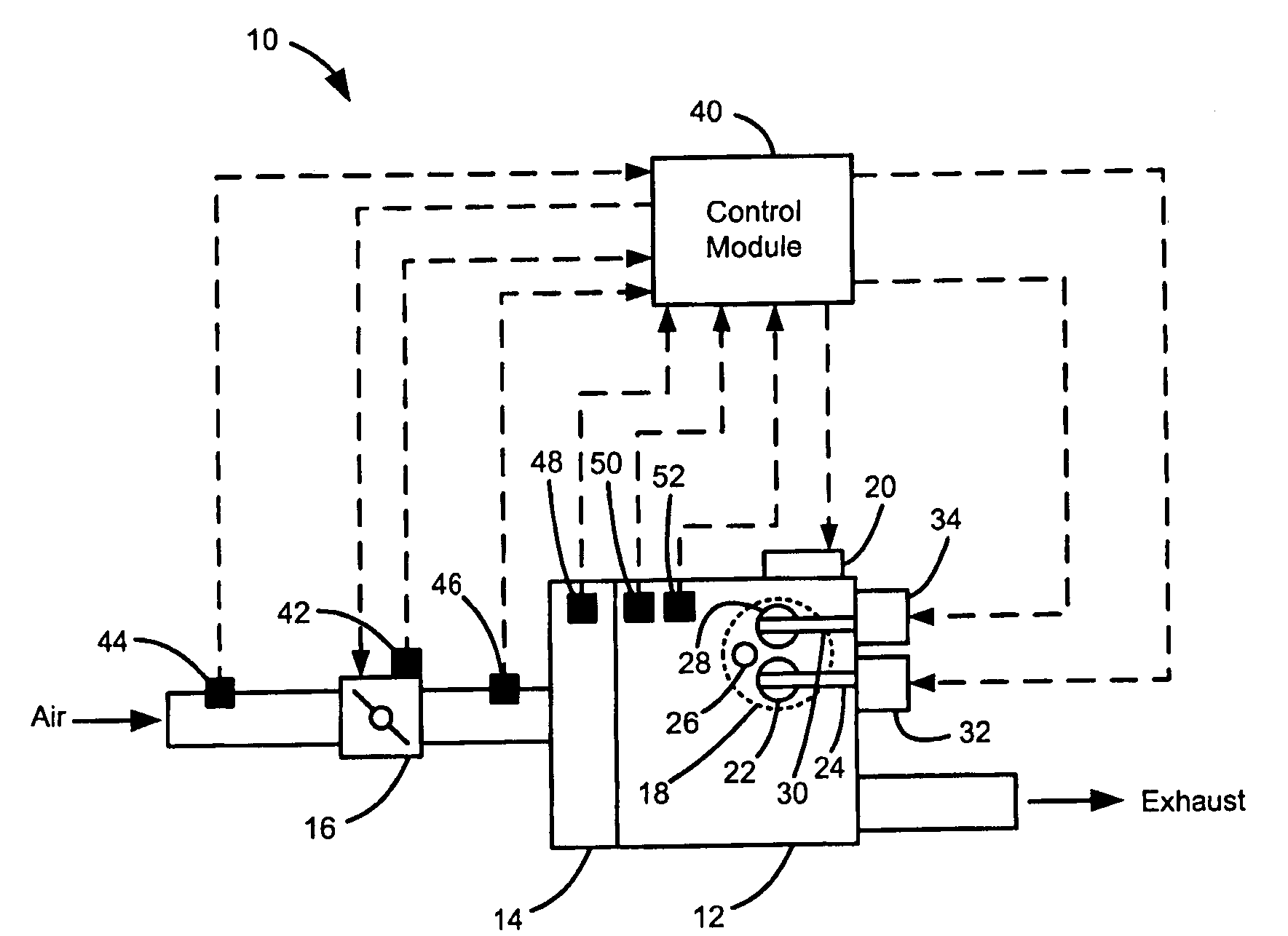

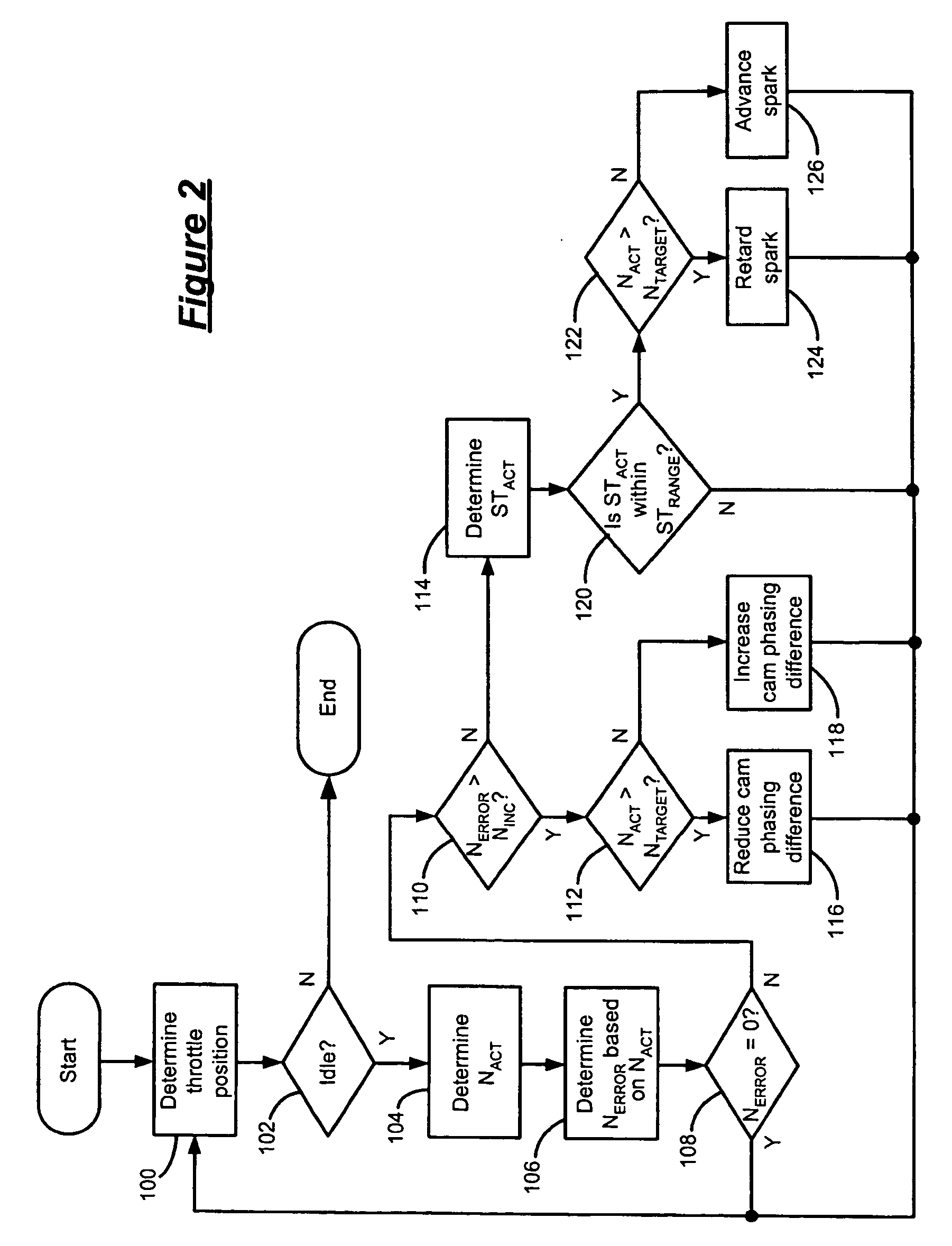

Engine idle control system

InactiveUS7021281B2Reduce idle speedValve arrangementsElectrical controlIdle speed controlControl signal

An internal combustion engine idle speed control system includes a first valve control mechanism that adjusts a first operating parameter of a first cylinder valve. A control module determines an idle speed error and generates a first control signal to the first valve control mechanism to adjust the first operating parameter. The first control signal is based on the idle speed error.

Owner:GM GLOBAL TECH OPERATIONS LLC

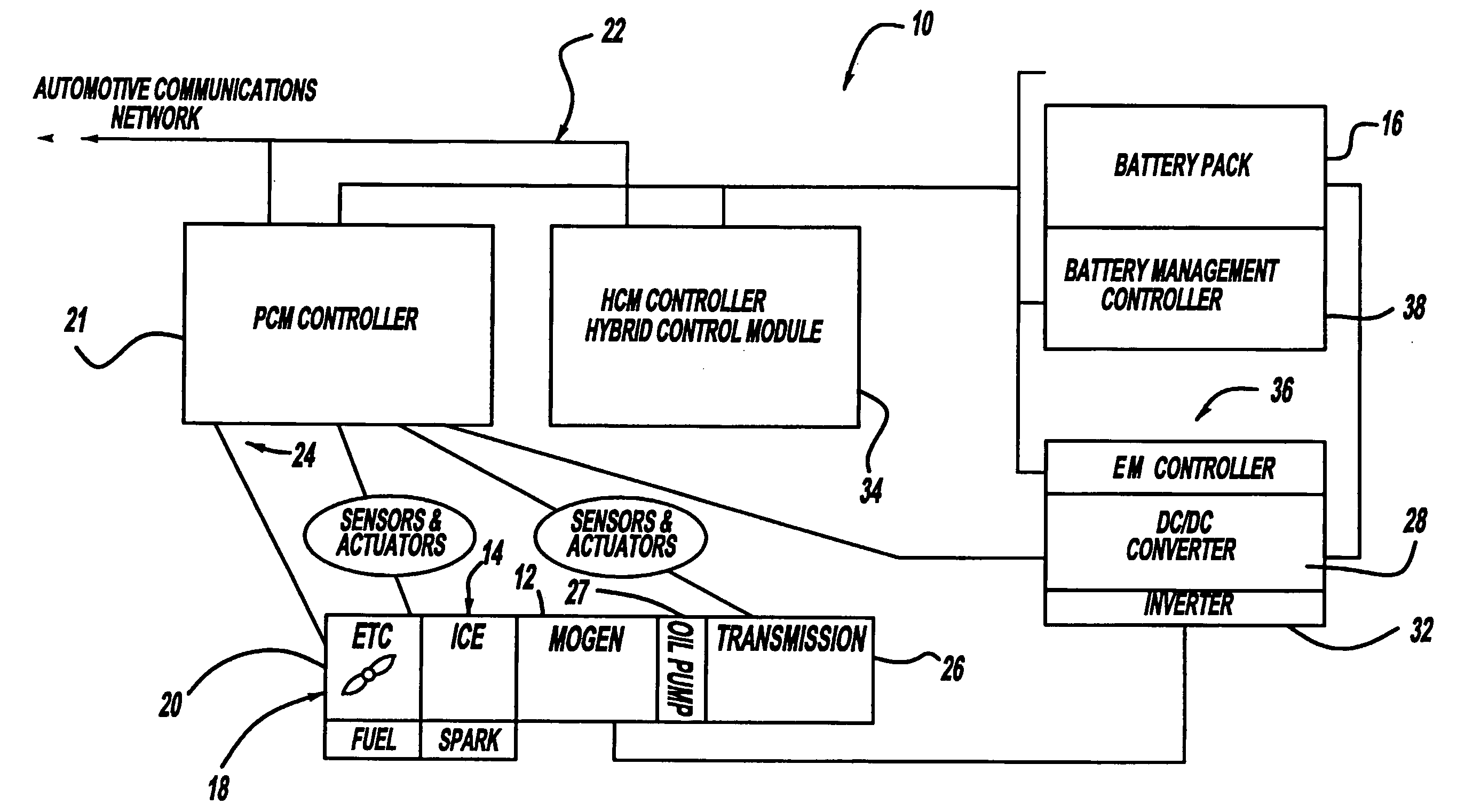

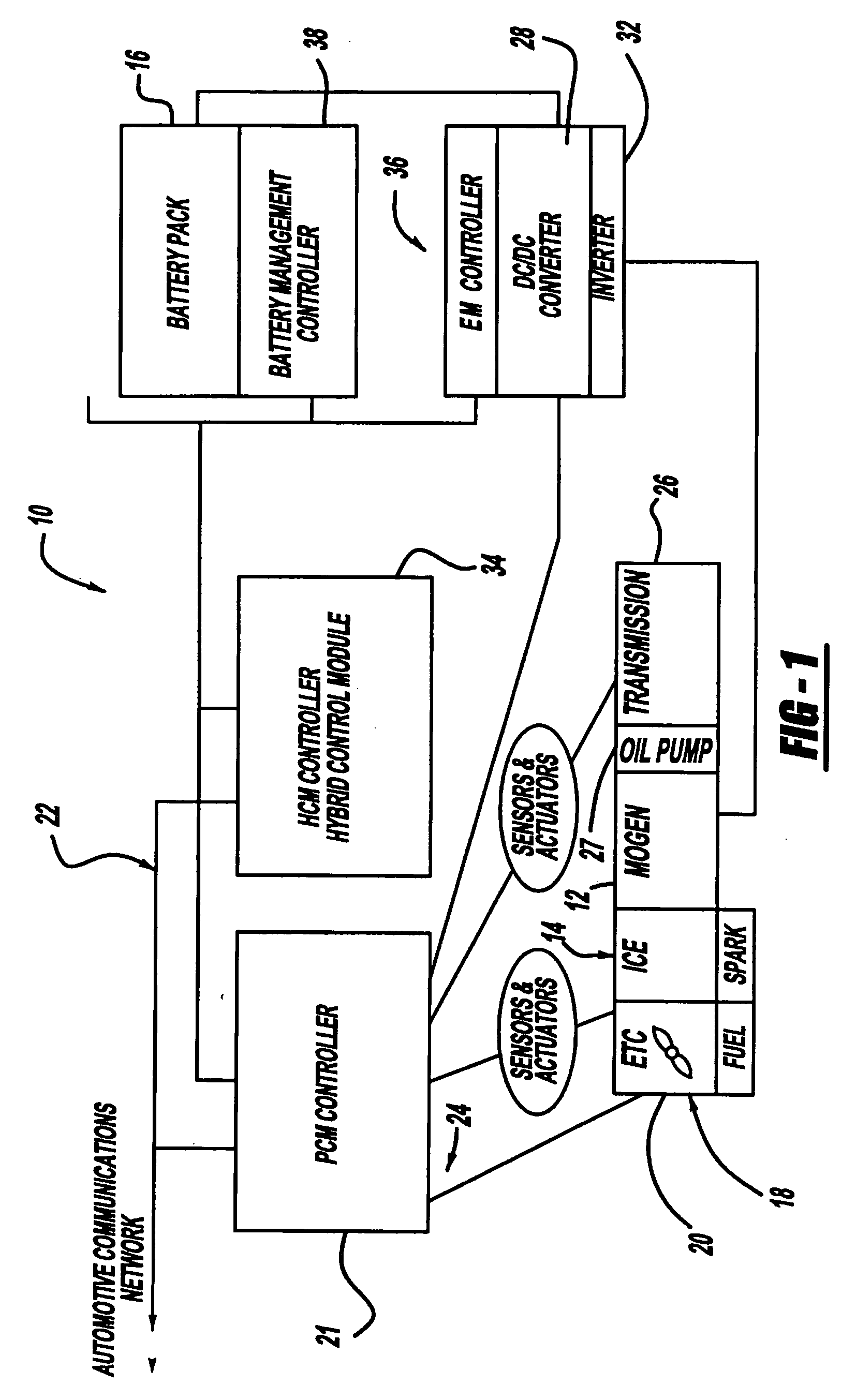

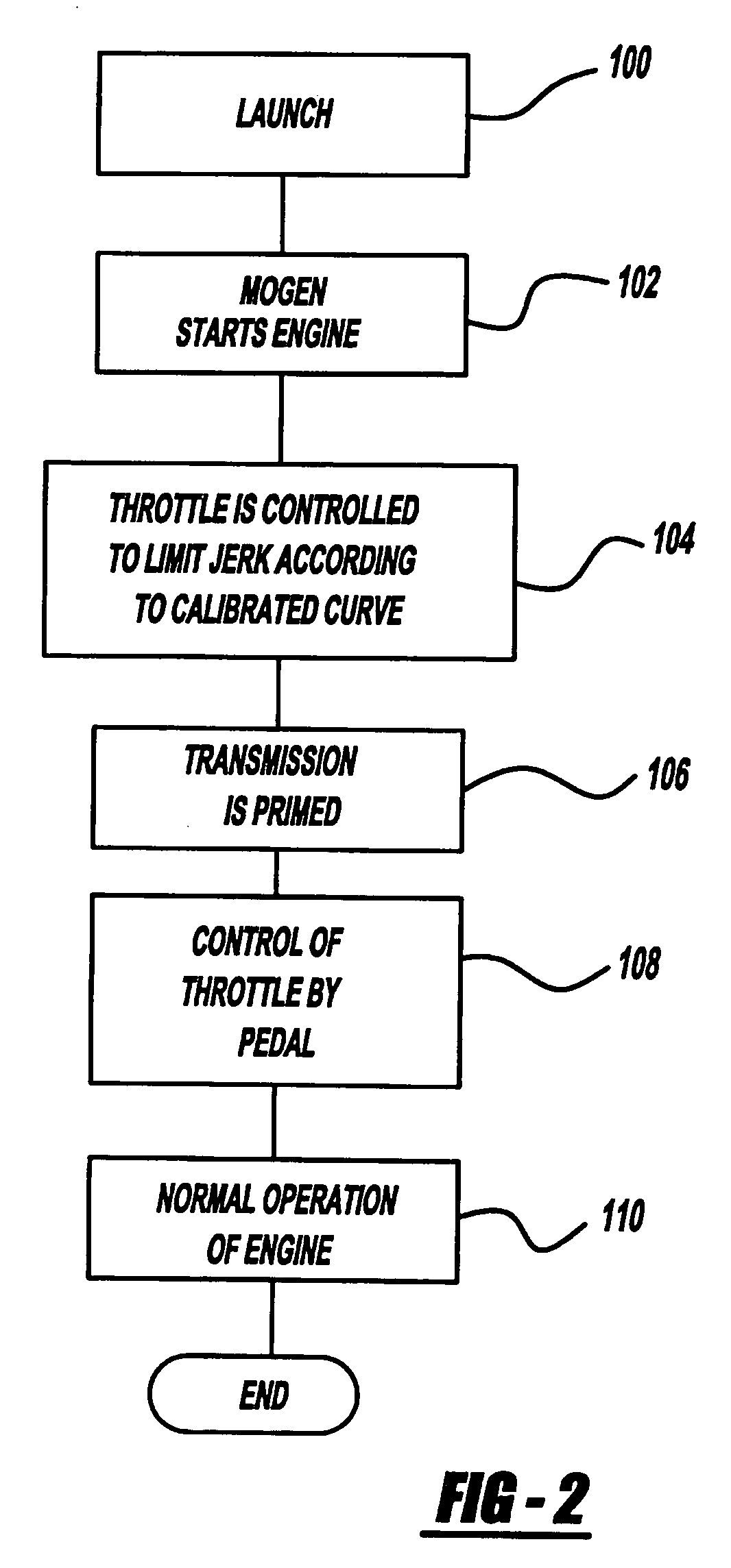

Hybrid transmission launch algorithm

ActiveUS20050261817A1Increase transmission pump capacityImprove system responseDigital data processing detailsElectric propulsion mountingElectronic throttleExternal combustion engine

A launch system for a hybrid vehicle includes a pump, an electronic throttle, a sensor, and a hybrid control module. The pump is driven by an internal combustion engine and provides pressurized fluid to a transmission. The electronic throttle selectively adjusts airflow to the internal combustion engine and current to an electric motor. The sensor detects when a brake pedal has been released. The hybrid control module increases pressure of the pressurized fluid and limits torque transfer from at least one of the internal combustion engine and the electric motor when the sensor detects that the brake pedal has been released until a predetermined condition has been met. The hybrid control module increases pressure of the pressurized fluid with the pump by increasing the revolutions of the internal combustion engine and limits torque to the transmission by retarding the responsiveness of the electronic throttle.

Owner:GM GLOBAL TECH OPERATIONS LLC

Fuel injection control apparatus

ActiveUS7789073B2Improve performanceReduce idle speedElectrical controlDigital data processing detailsMicrocomputerDriver circuit

A fuel injection control apparatus is capable of reducing a minimum quantity of fuel injection without reducing a maximum quantity of injection. To open a fuel injector valve, a driving circuit supplies an electric current from a high-voltage power supply to the fuel injector. Then, after valve opening, the high-voltage power supply is switched to a low-voltage power supply, and an open state of the valve is retained. For opening the valve of the fuel injector, a microcomputer, after supplying current from the high-voltage power supply to the injector, discharges the current rapidly for a decrease below a first current level at which the open state of the valve cannot be retained. The microcomputer then controls the supply current to the injector so as to supply a current at a second current level at which the open state of the valve can be retained.

Owner:HITACHI ASTEMO LTD

Engine idle control system

InactiveUS20060011166A1Reduce idle speed errorReduce idle speedValve arrangementsElectrical controlIdle speed controlControl system

An internal combustion engine idle speed control system includes a first valve control mechanism that adjusts a first operating parameter of a first cylinder valve. A control module determines an idle speed error and generates a first control signal to the first valve control mechanism to adjust the first operating parameter. The first control signal is based on the idle speed error.

Owner:GM GLOBAL TECH OPERATIONS LLC

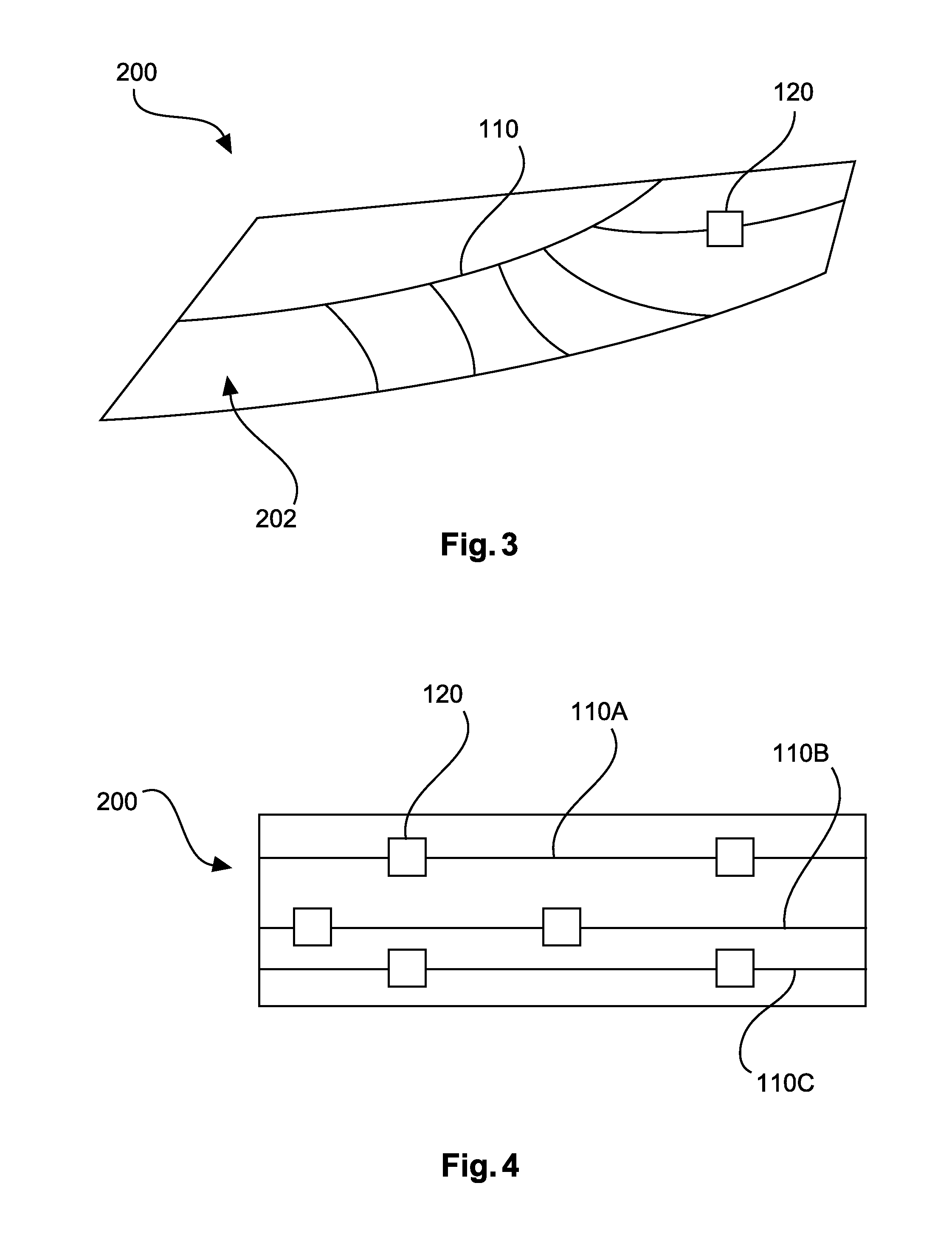

Structural Health Monitoring System for a Material and Production Method

ActiveUS20150071324A1Enable detectionReduce weightVolume/mass flow by thermal effectsAerodynamic testingCarbon nanotubeEngineering

A structural health monitoring system includes a signal transmission element and a sensor unit. The sensor unit is designed to feed a first signal into the signal transmission element and to read out a second signal from the signal transmission element. The signal transmission element has carbon nanotubes.

Owner:AIRBUS DEFENCE & SPACE

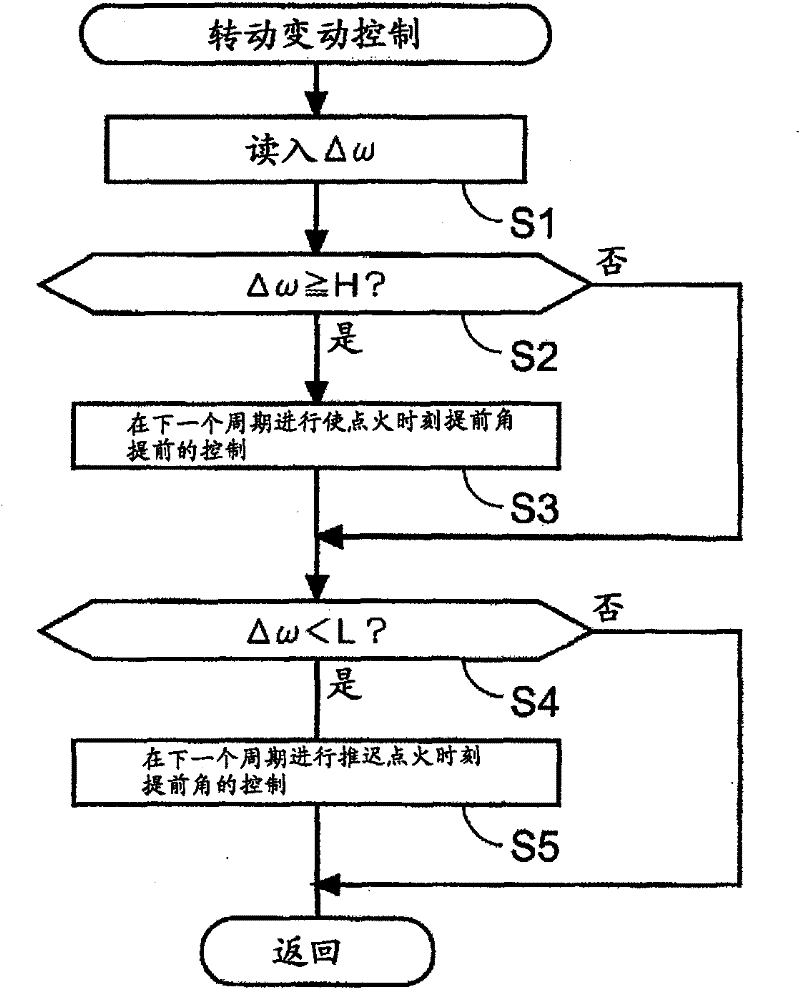

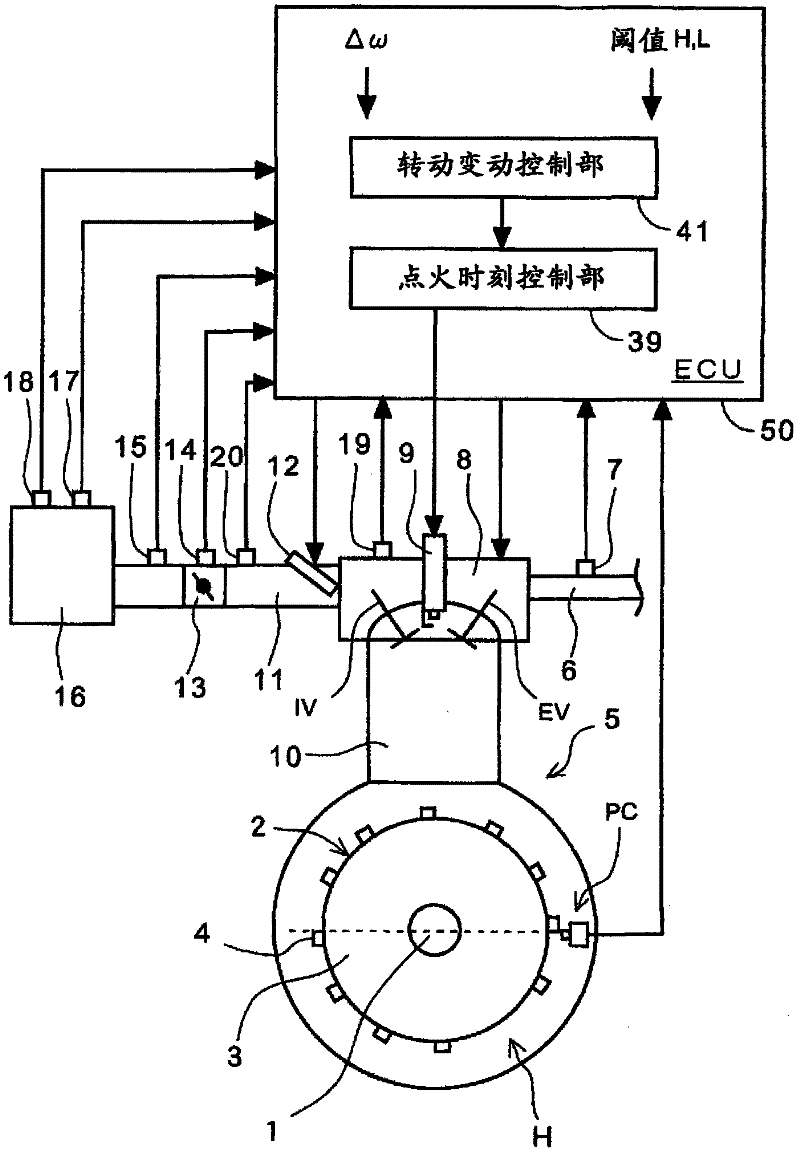

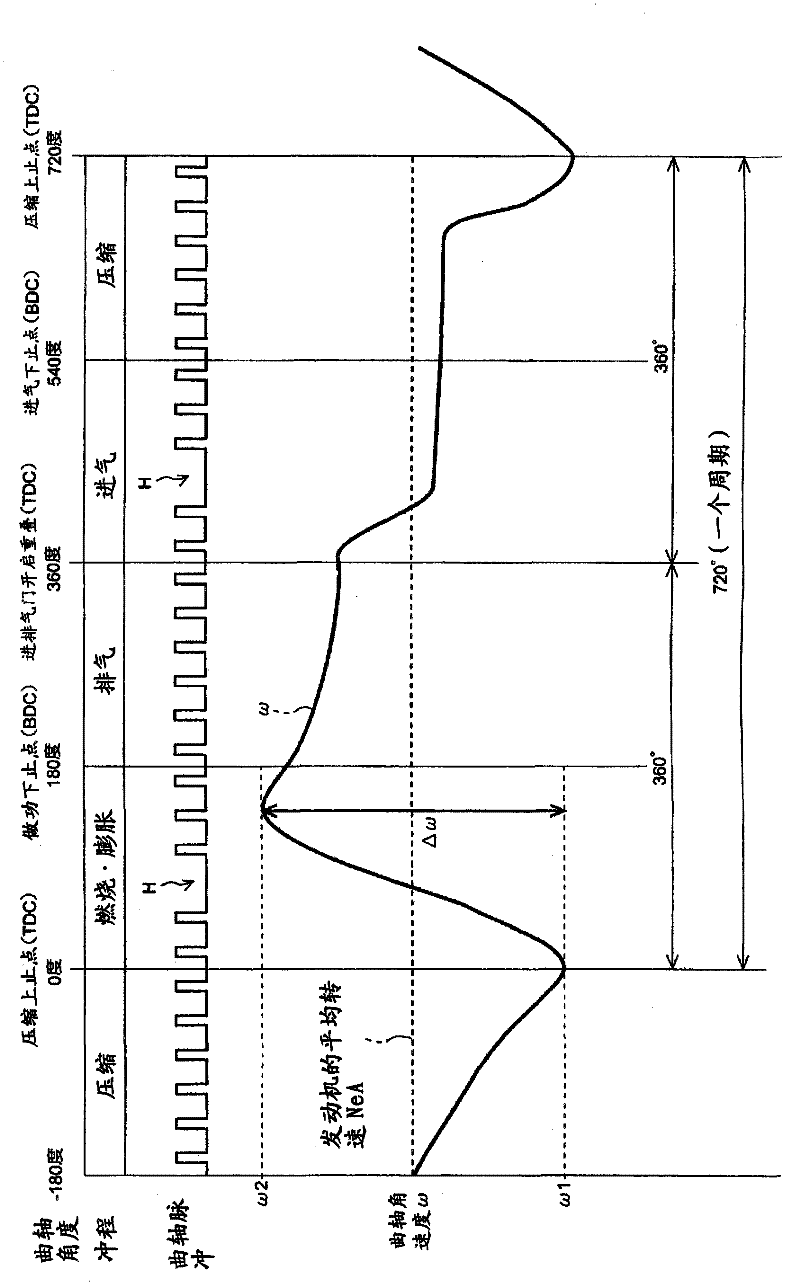

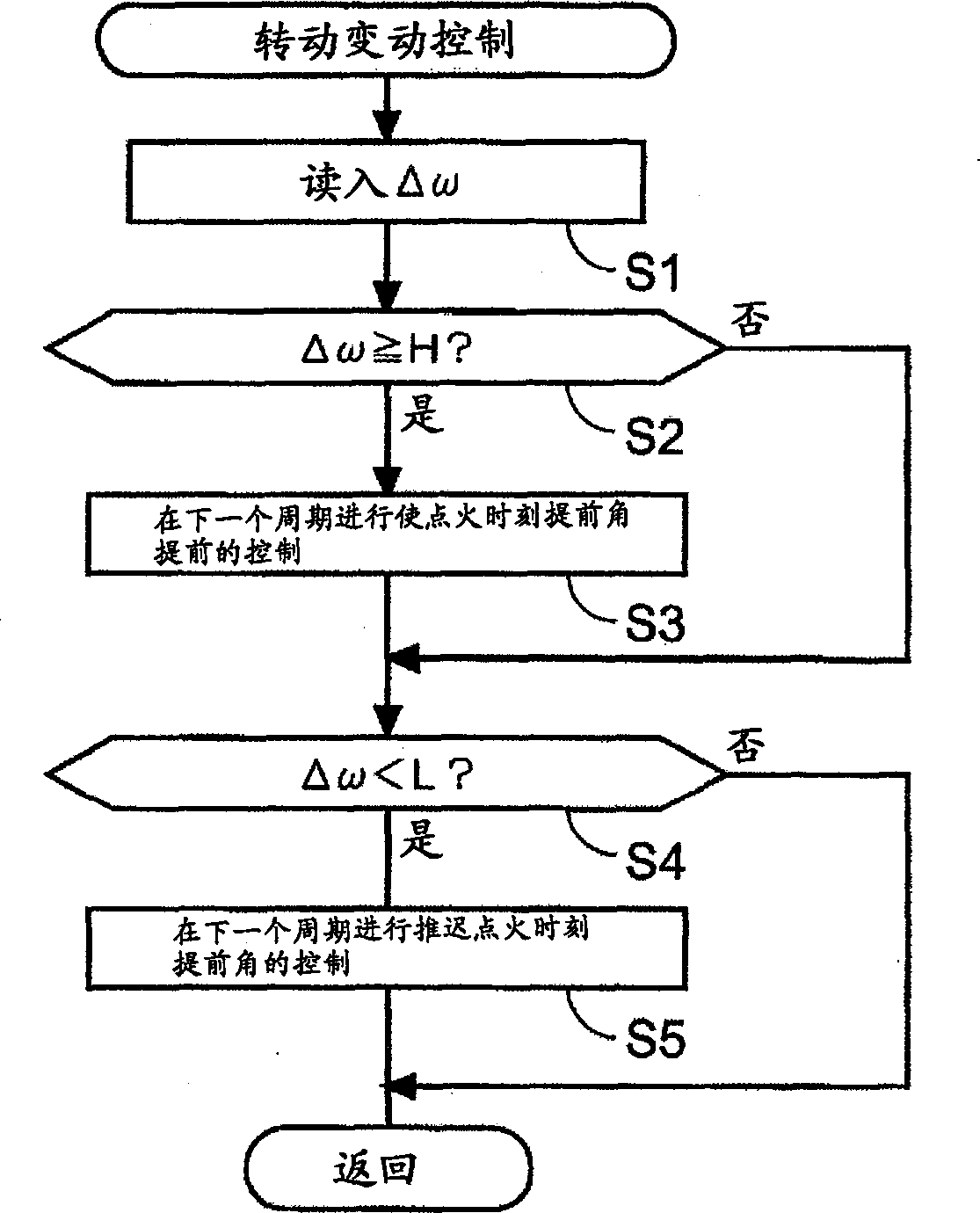

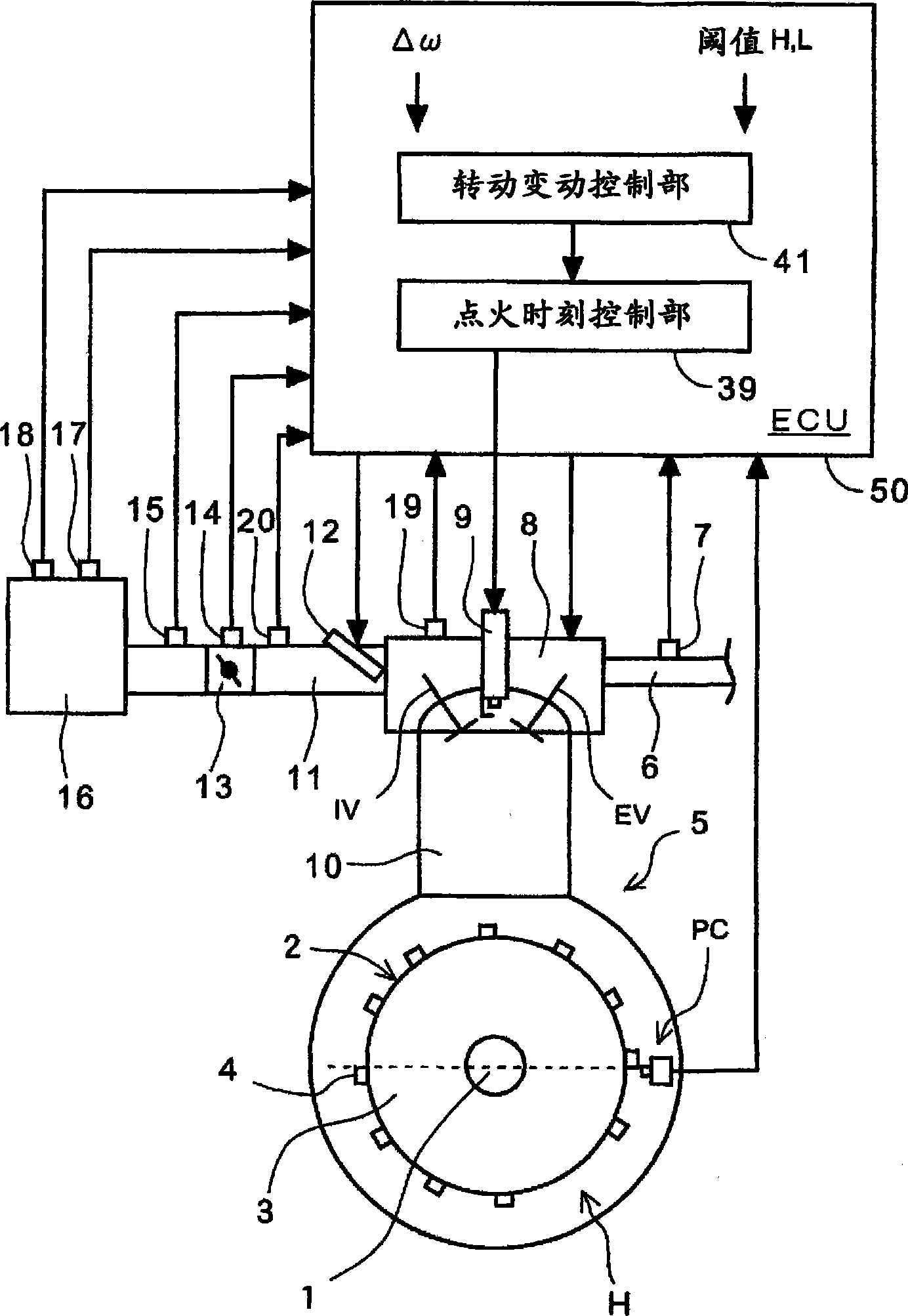

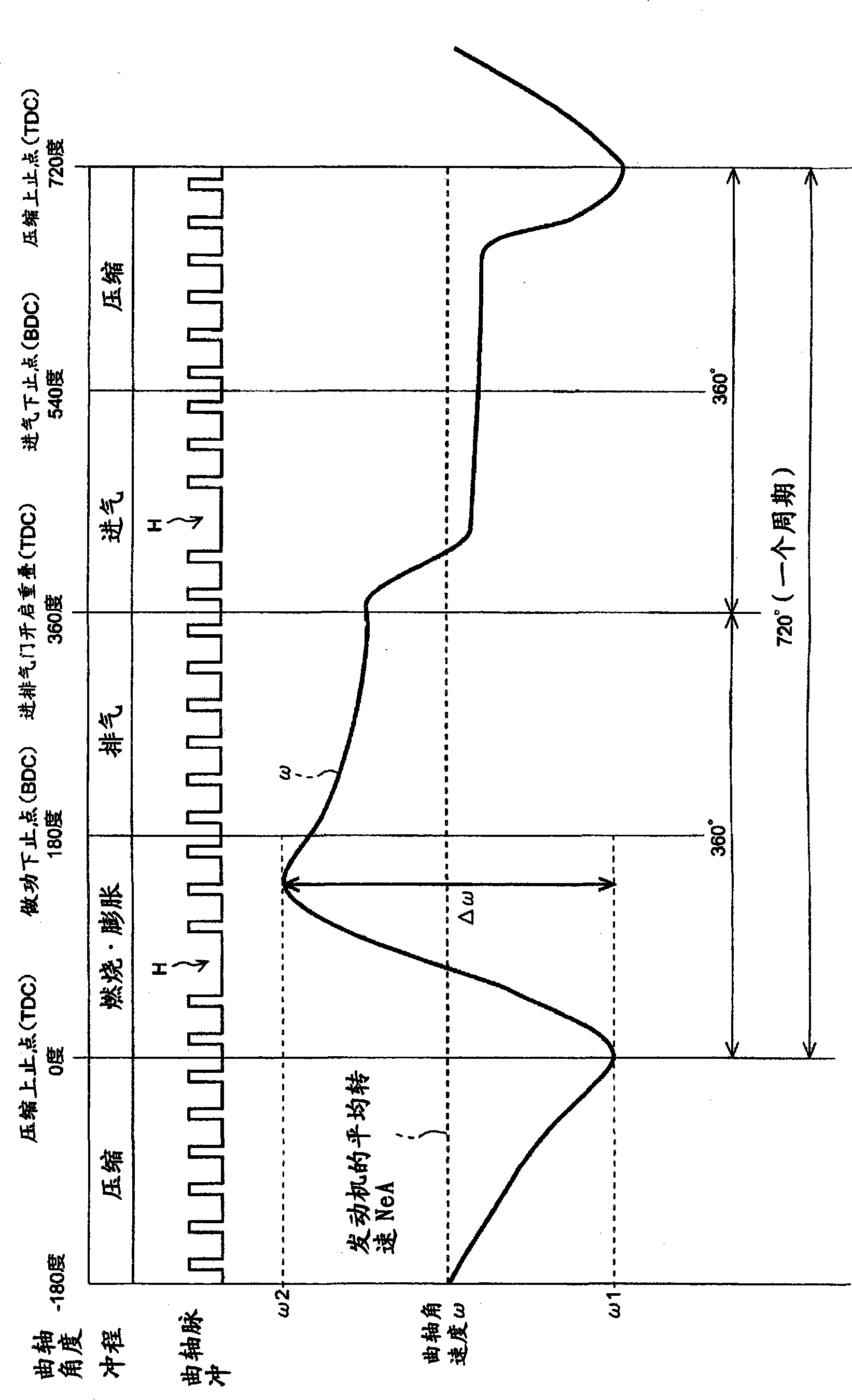

Engine control device

ActiveCN102418644AReduce idle speedEx situ inferred loadInternal combustion piston enginesIgnition automatic controlLower thresholdEngineering

The invention provides an engine control device which can eliminate the unstable working phenomenon of the engine caused by the period changes of idling rotate speed. A bent axle angular speed change amount obtaining part (36) detects the bent axle angular speed change amount (delta w) representing the engine load. According to the judgment result which is bigger than an upper threshold set in a threshold setting part (40) or is smaller than a lower threshold set in the threshold setting part (40), an engine load judging mechanism (37) reduces or increases the advance angular value in a next period, so according to the change rules of each period, he angular speed change amount (delta w) in the next period is in an allowable range determined by the threshold (H) and (L). The engine load can also be indicated by the indicating average effective pressure (IMEP).

Owner:HONDA MOTOR CO LTD

Control apparatus for internal combustion engine

ActiveUS8280613B2Minimizing amount of fuelImprove performanceElectrical controlInternal combustion piston enginesDriving currentExternal combustion engine

A fuel injection control apparatus for an internal combustion engine which can inject a fuel injection quantity to a fuel injector with accuracy even when the fuel injection quantity is reduced than before is provided. A fuel injection control apparatus of a direct cylinder injection type of internal combustion engine, including a fuel injector which performs fuel injection by supplying a drive current to a solenoid, a fuel pressure sensor which detects fuel pressure supplied to the fuel injector, and operation state detecting means which detects the operation state of the internal combustion engine, comprises current profile changing means 100 which has multiple current profiles of the drive current and changes current profiles based on the operation state and the fuel pressure, valid pulse width calculating means 701 which calculates a valid pulse width for opening and driving the fuel injector, invalid pulse width calculating means 103 which calculates an invalid pulse width, and fuel injector control means which calculates a fuel injection pulse width based on the valid pulse width and the invalid pulse width, and controls the fuel injector based on the fuel injection pulse width, wherein the invalid pulse width calculating means 103 calculates an invalid pulse width corresponding to the current profiles to be changed before the current profiles are changed.

Owner:HITACHI ASTEMO LTD

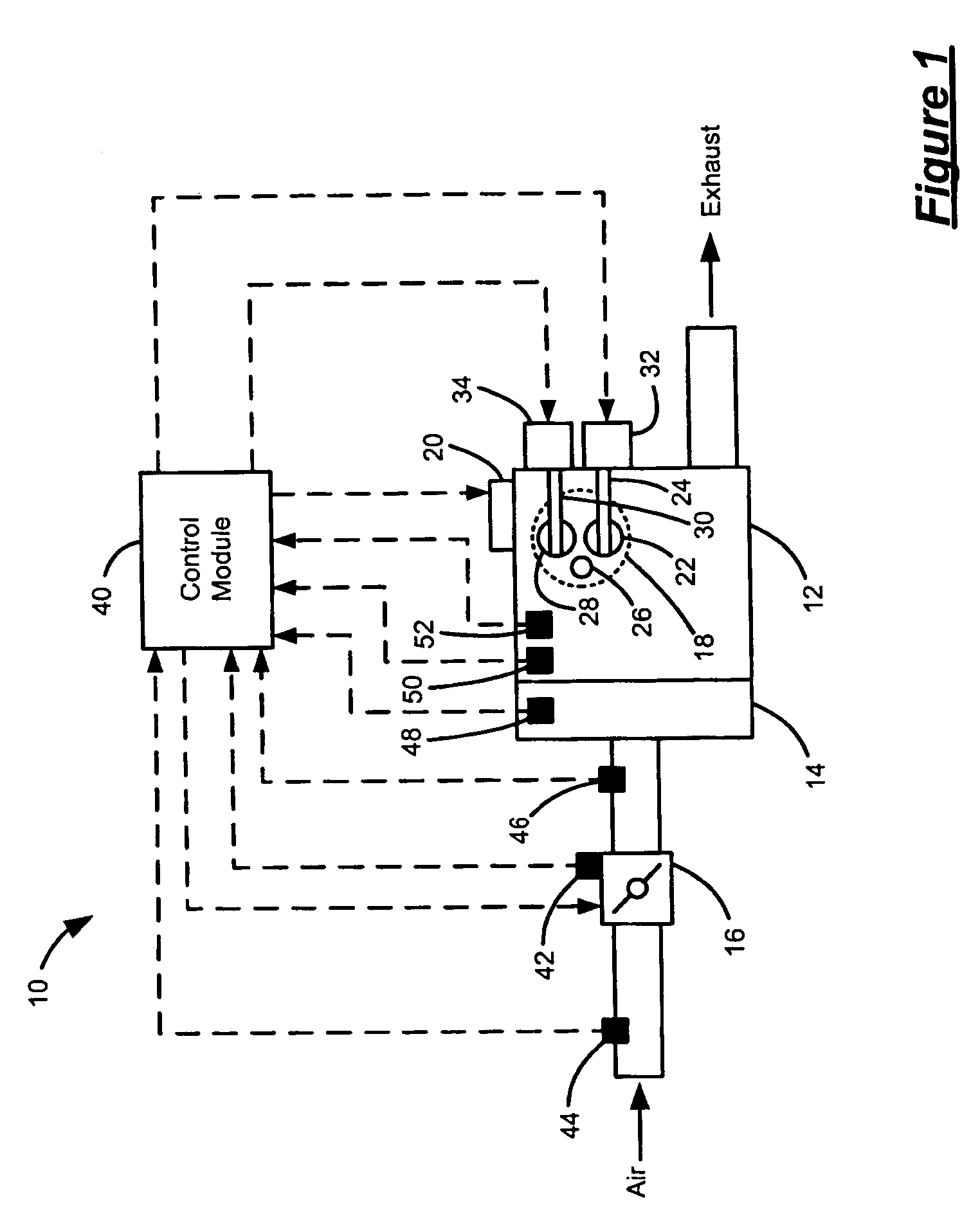

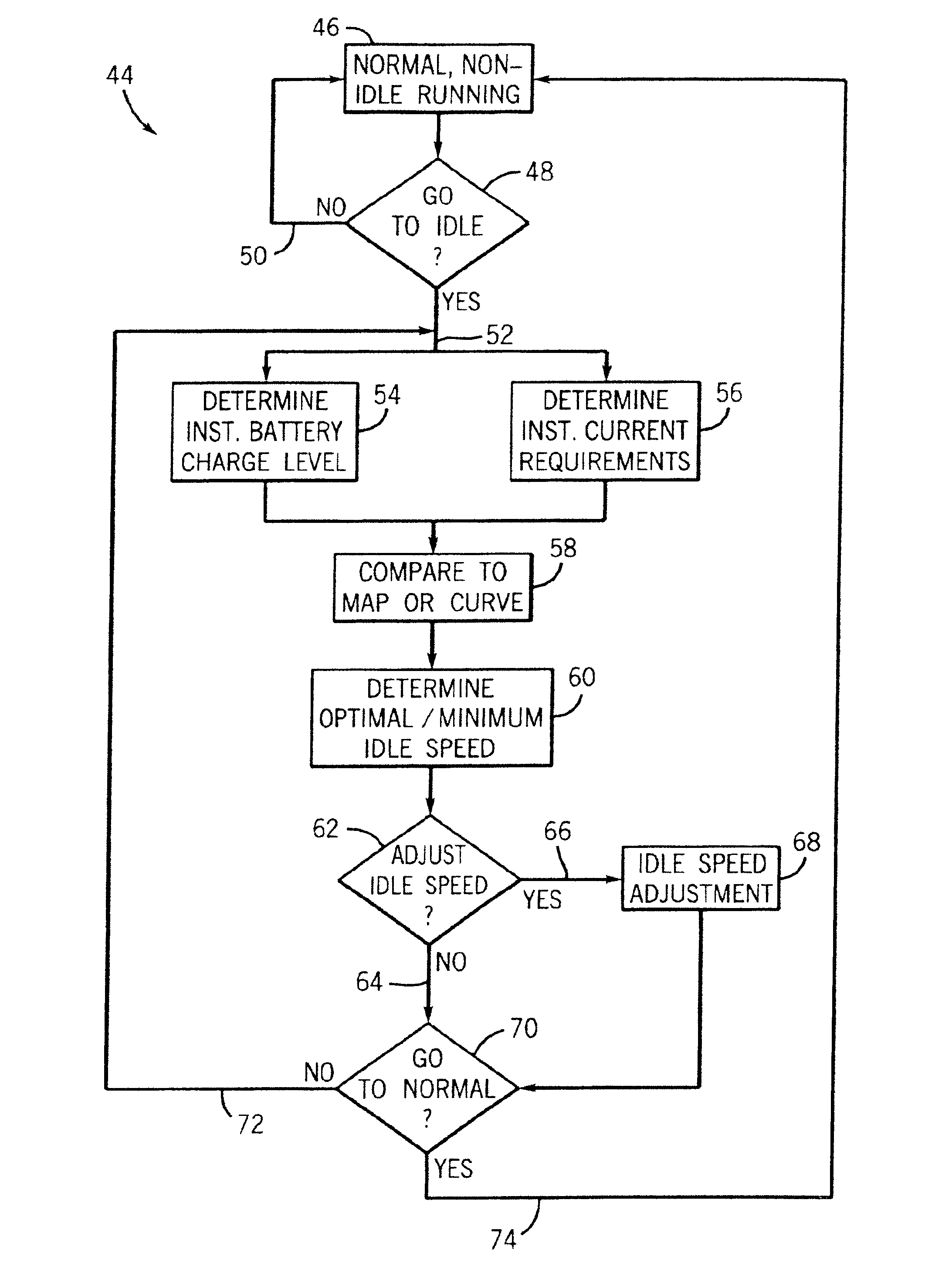

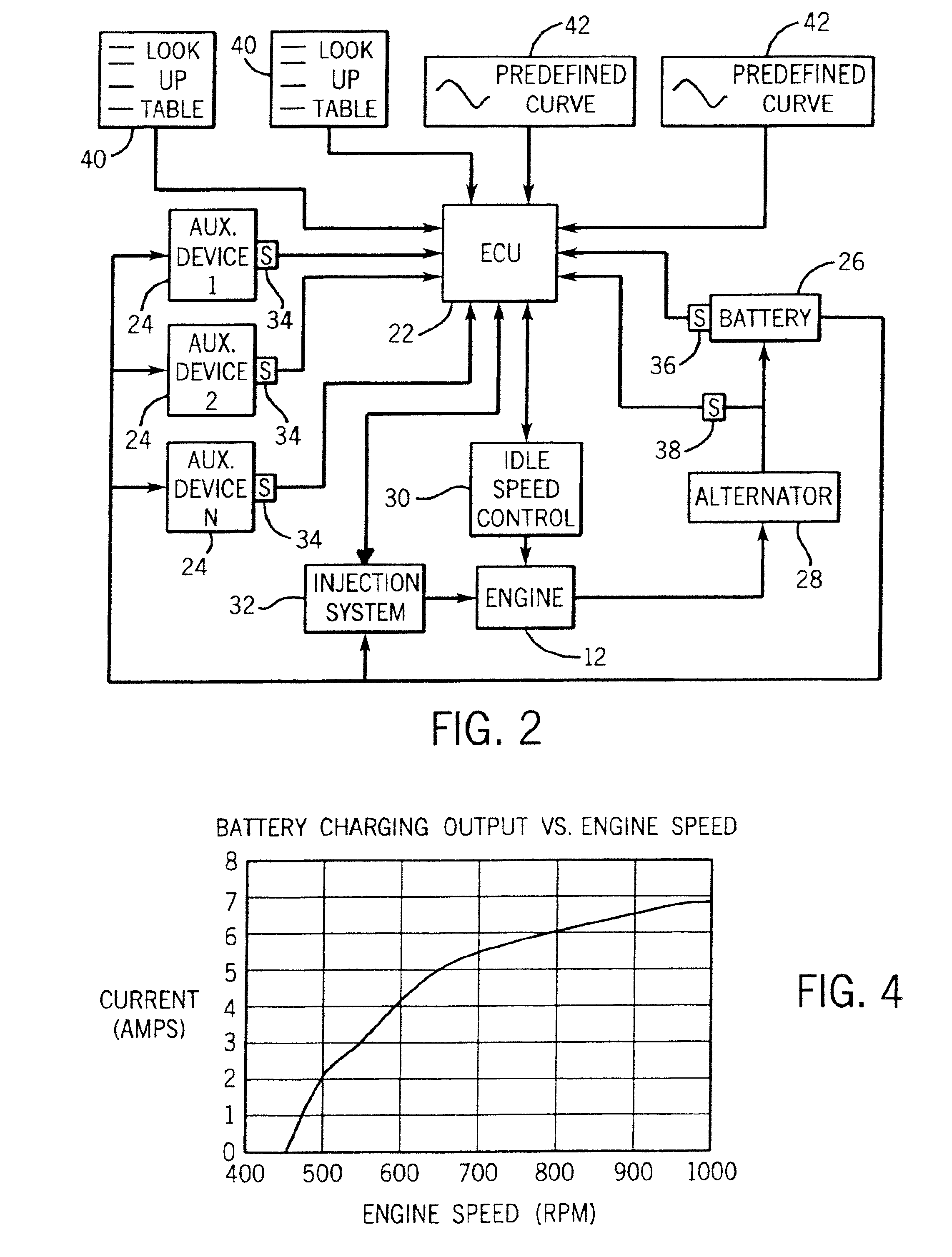

Adaptive idle speed control for a direct injected internal combustion engine

InactiveUS6883495B1Reduce idle speedTrollingElectrical controlPropulsion power plantsIdle speed controlSelf adaptive

The present invention provides a system and method of adaptively setting the idle speed of an internal combustion engine based on instantaneous power requirements of the engine. By adaptively setting engine idle speed based on instantaneous power requirements of the engine as well as the power requirements of any auxiliary devices, the noise and exhaust emissions of the engine may be reduced as well as improving fuel consumption efficiency. The engine's electronic control unit (ECU) is designed to regulate an idle speed controller based on current feedback received from sensors operationally connected to the engine as well as the various auxiliary devices. The ECU regulates the idle speed control such that the engine electronics are sufficiently energized to run the engine, but the engine idle speed is also set to a level that takes into account the instantaneous power requirements of the various system components and / or devices.

Owner:BRP US

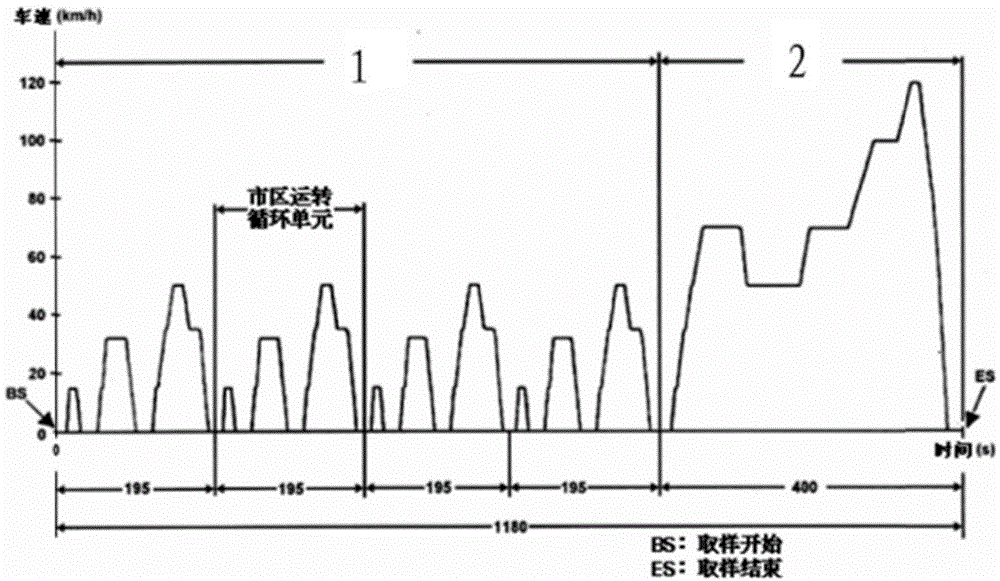

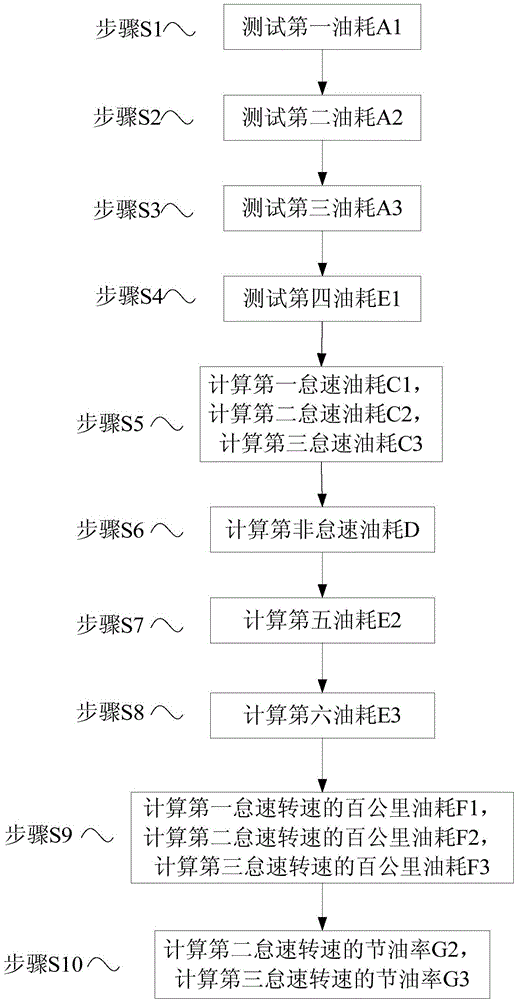

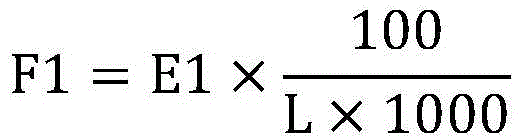

Idling fuel saving rate calculation method

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

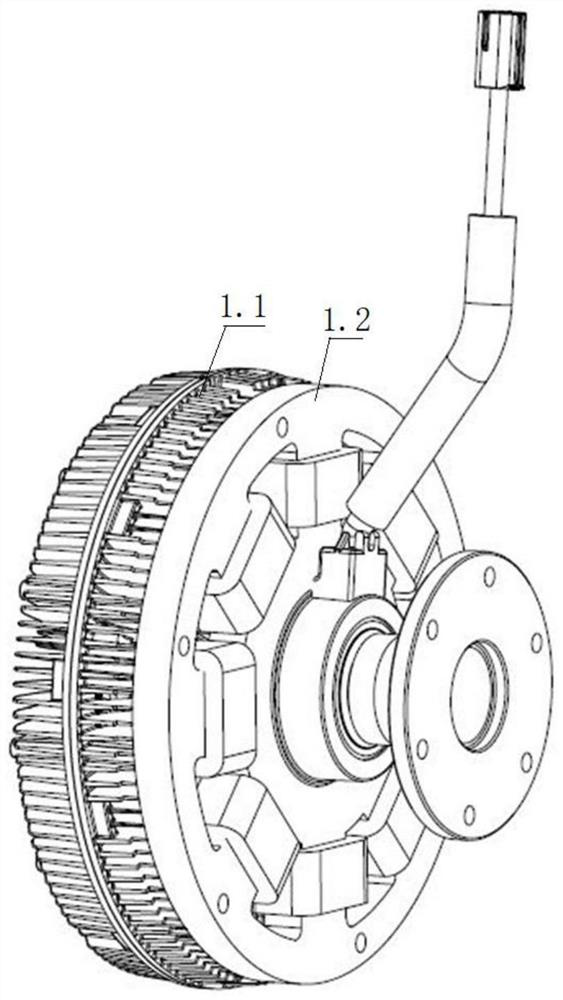

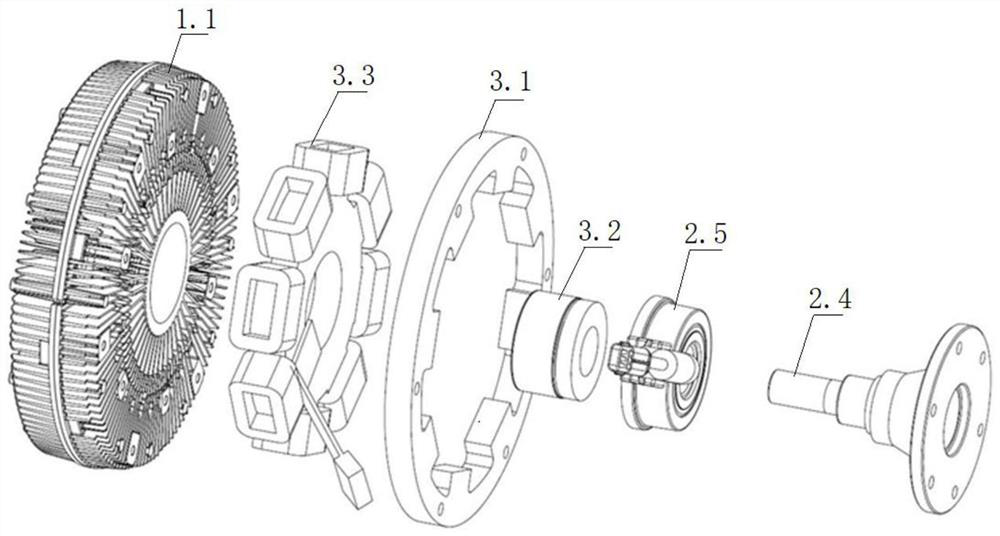

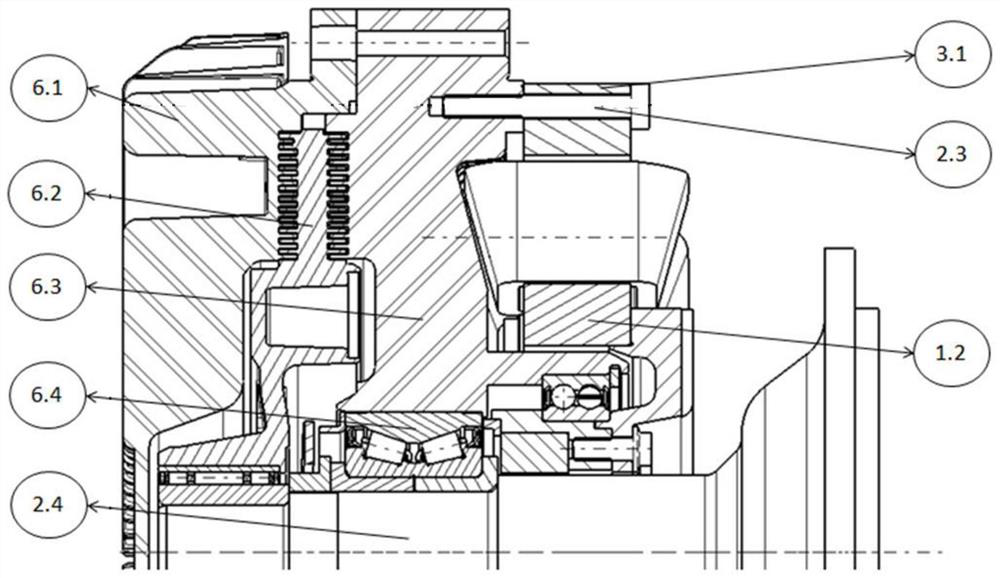

Hybrid power type motor electric control silicone oil fan clutch

ActiveCN112145278ASimple structureTo achieve comprehensive utilizationAssociation with control/drive circuitsCoolant flow controlBrushless motorsNew energy

The invention relates to a hybrid power type motor electric control silicone oil fan clutch. The hybrid power type motor electric control silicone oil fan clutch comprises a front cover, a driving disc, a rear cover, a flange shaft, a solenoid and a brushless motor, the rear cover is fixedly connected with a fan, the front cover is fixedly connected with the rear cover, the driving disc is arranged between the front cover and the rear cover, the flange shaft penetrates through the rear cover to be in threaded connection with the driving disc, the flange shaft is connected with an engine crankshaft or a belt pulley, the solenoid is arranged on the flange shaft and connected with an ECU, the brushless motor comprises a stator part and a rotor part, the rotor part is fixedly connected with the rear cover, and the stator part is fixed with an engine cylinder body. According to the hybrid power type motor electric control silicone oil fan clutch, the structure of a traditional electric control silicone oil fan is optimized, the brushless motor is introduced, the brushless motor and the traditional silicone oil fan are combined, the effect that the electric control silicone oil fan can comprehensively utilize electric energy, diesel oil, natural gas and other new energy is achieved, and the energy utilization rate is increased.

Owner:DONGFENG BEHR THERMAL SYST

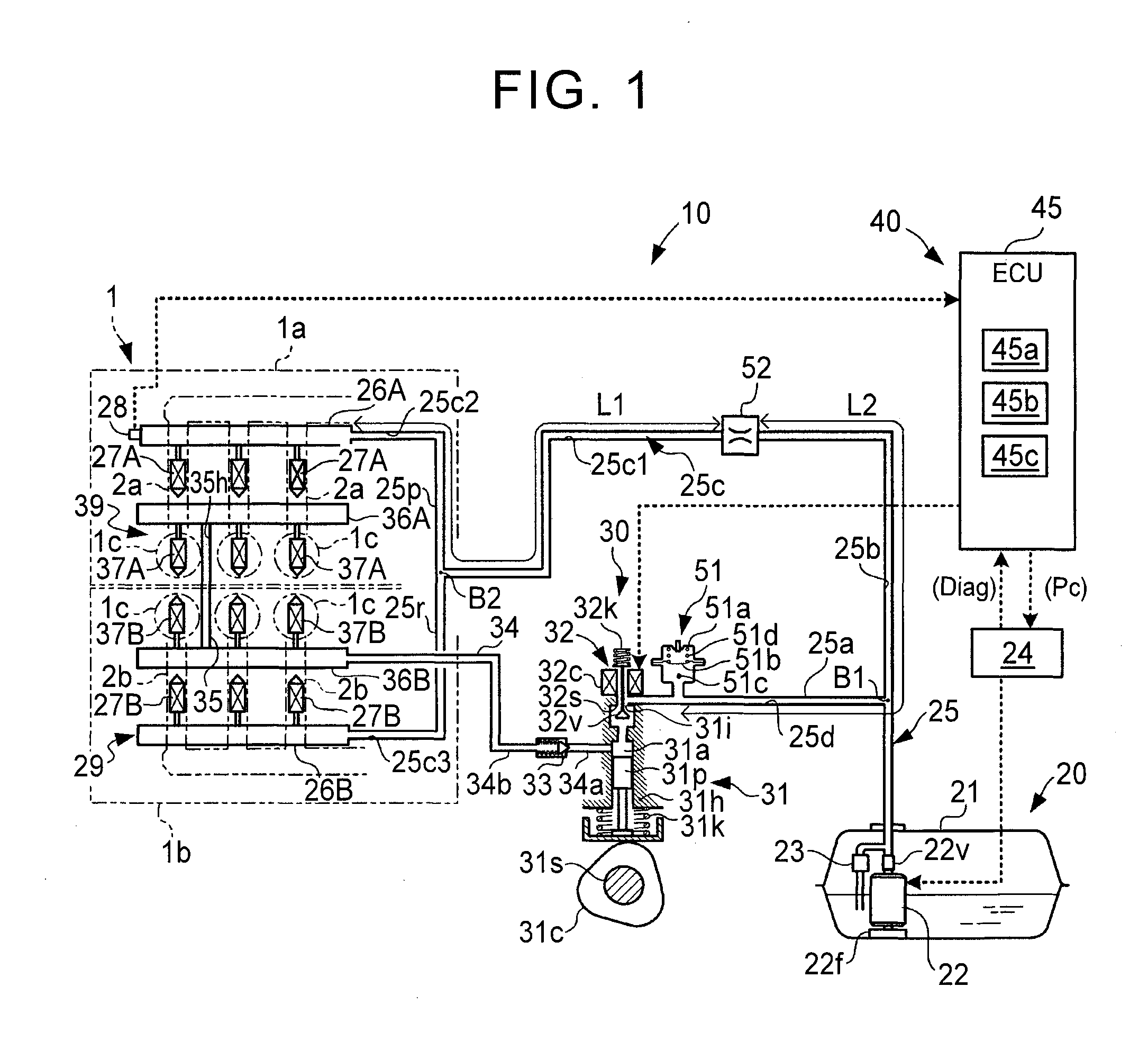

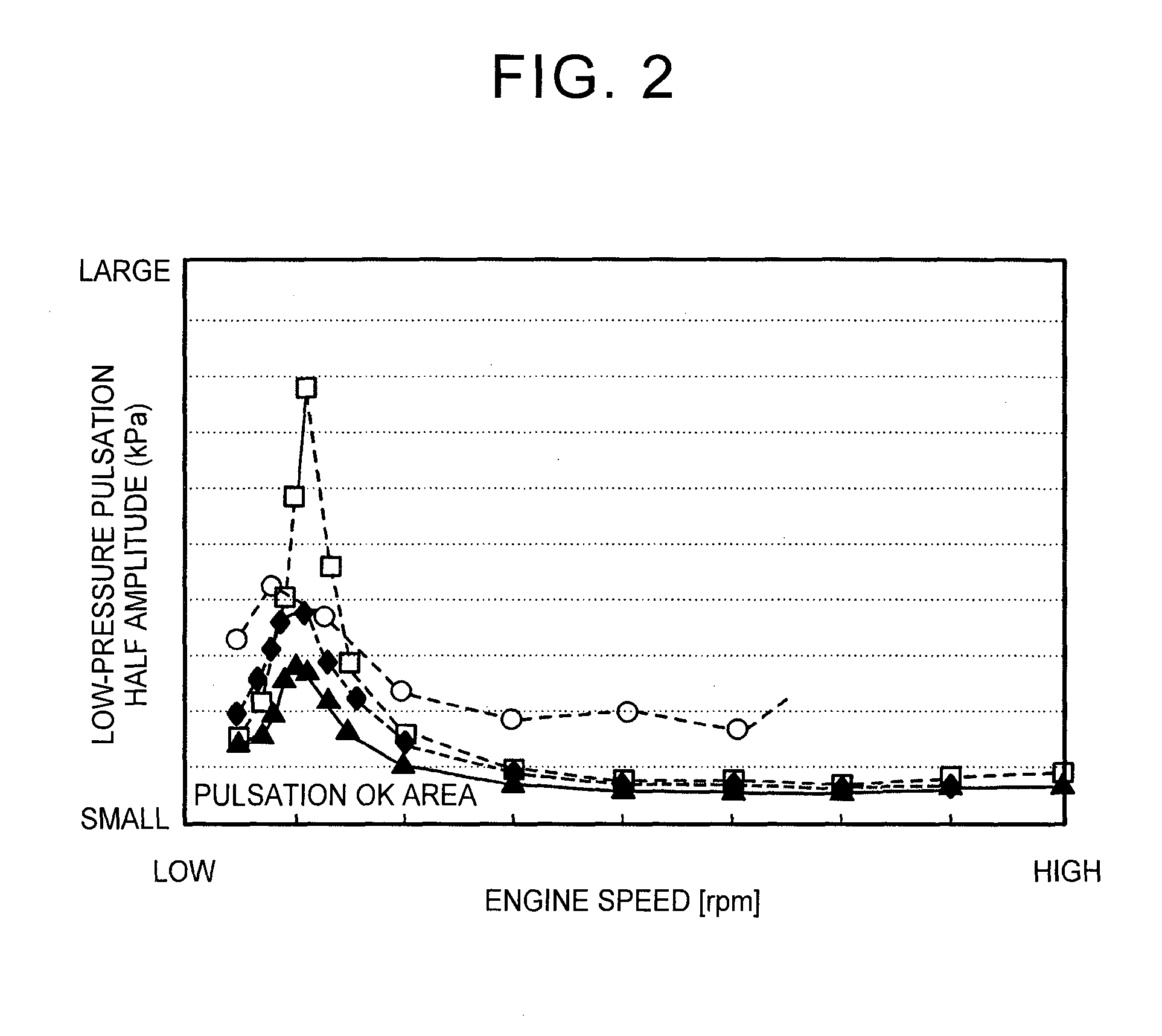

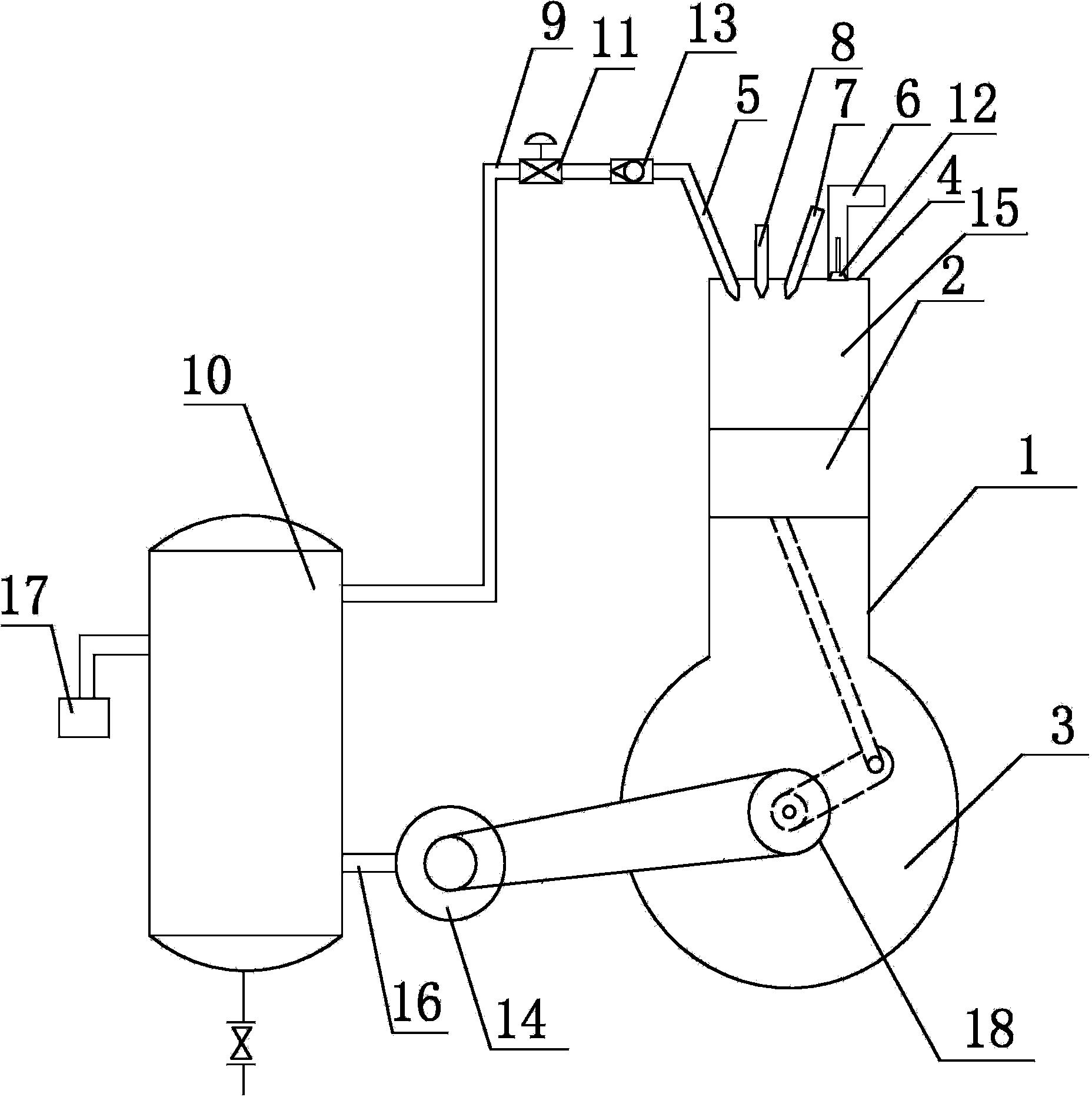

Fuel supply apparatus for internal combustion engine

InactiveUS20160090955A1Suppress pulsationReduce pulsationLow-pressure fuel injectionMachines/enginesExternal combustion engineInternal combustion engine

A fuel supply apparatus for an internal combustion engine includes a low-pressure fuel injection mechanism, a high-pressure fuel injection mechanism, a low-pressure fuel pump, a high-pressure fuel pump, a first pulsation damping element, and an orifice. The first pulsation damping element is provided in a passage, located on. the high-pressure fuel pump-side, in a “fuel pipe interposed between the high-pressure fuel pump and the low-pressure fuel injection mechanism. The orifice is provided in the passage, located on the low-pressure fuel injection mechanism-side relative to the first pulsation damping element, in the fuel pipe.

Owner:TOYOTA JIDOSHA KK

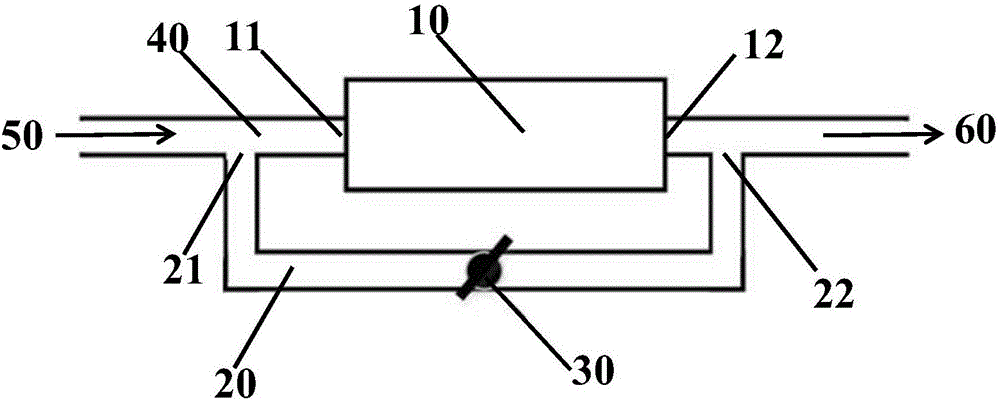

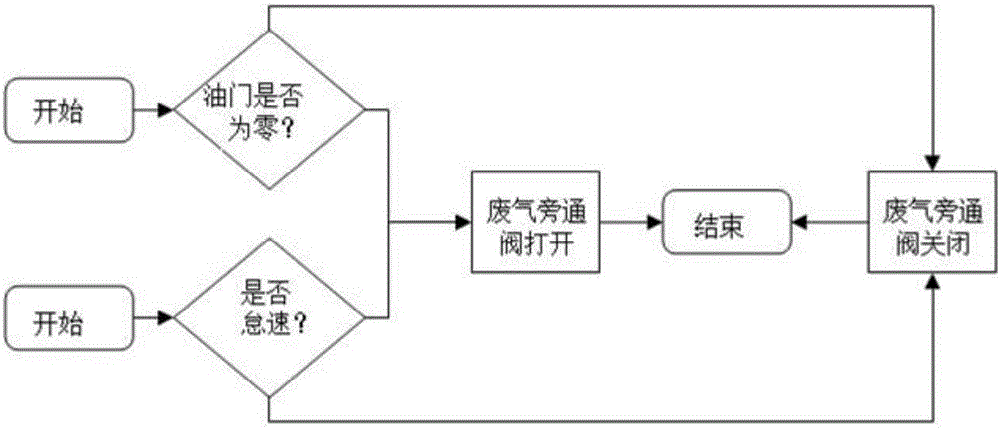

Exhaust postprocessing device and method used for engine

InactiveCN106593600ADynamic influenceReduce idle speedInternal combustion piston enginesExhaust apparatusBypass valveElectronic control unit

The invention provides an exhaust postprocessing device and method used for an engine. The exhaust postprocessing device comprises a postprocessing part used for conducting postprocessing on exhaust of the engine and arranged in an exhaust pipeline, a bypass branch and a bypass valve, wherein an inlet and an outlet of the bypass branch communicate to the exhaust pipeline located at the inlet end and the outlet end of the postprocessing part correspondingly; and the bypass valve is arranged in the bypass branch and used for enabling exhausted gas from the engine to wholly or at least partially bypass the postprocessing part according to commands of an electronic control unit of the engine.

Owner:WEICHAI POWER CO LTD

Fuel injection control apparatus for internal combustion engine

InactiveUS7778765B2Improve performanceReduce idle speedElectrical controlDigital data processing detailsInstruction unitStart time

A fuel injection control apparatus includes a computing unit that calculates a pulse width for a pulse signal which drives the valve of a fuel injector, based on the operational state of the internal combustion engine and fuel pressure detected by a fuel pressure sensor. After a valve-opening command has turned on and a high valve-opening current has been supplied to open the fuel injector valve, a fuel injector driving signal waveform command unit discharges the current and supplies a small hold current Ih2 to maintain the injector's valve-open state. After the elapse of a predetermined rapid-discharge starting time from the turn-on of the valve-opening command, the fuel injector driving signal waveform command unit rapidly discharges the current until the hold current Ih2 has been reached.

Owner:HITACHI LTD

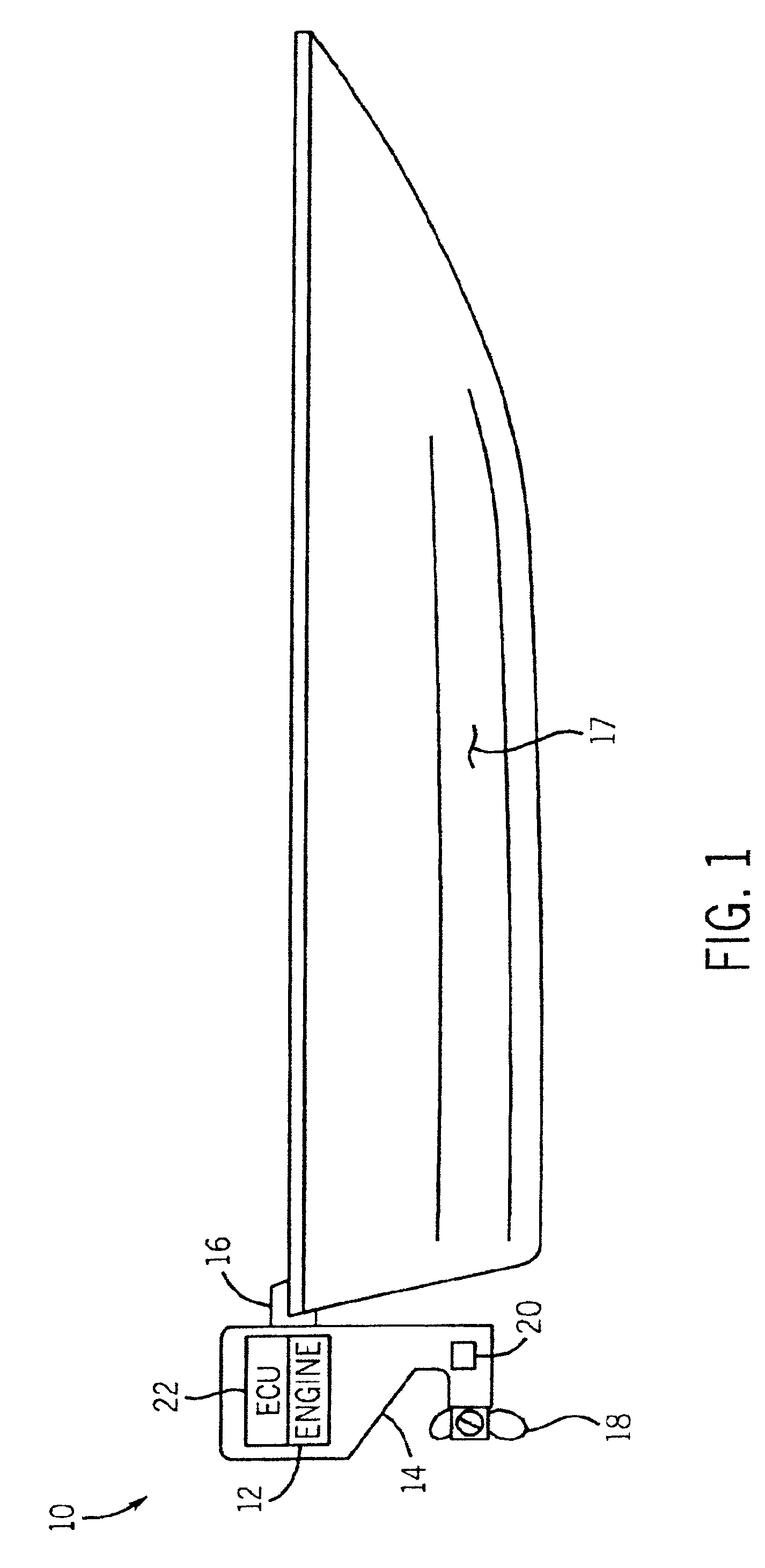

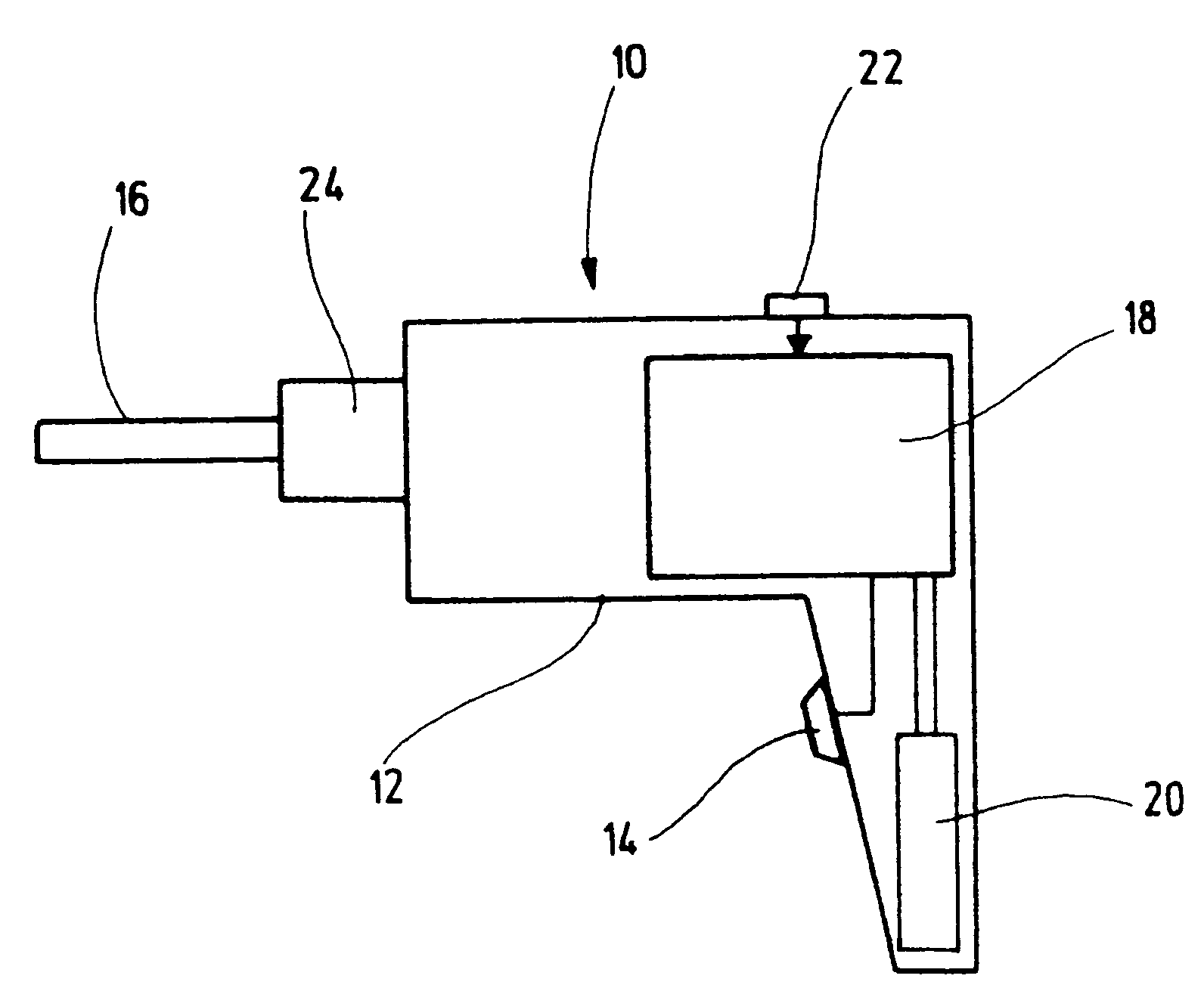

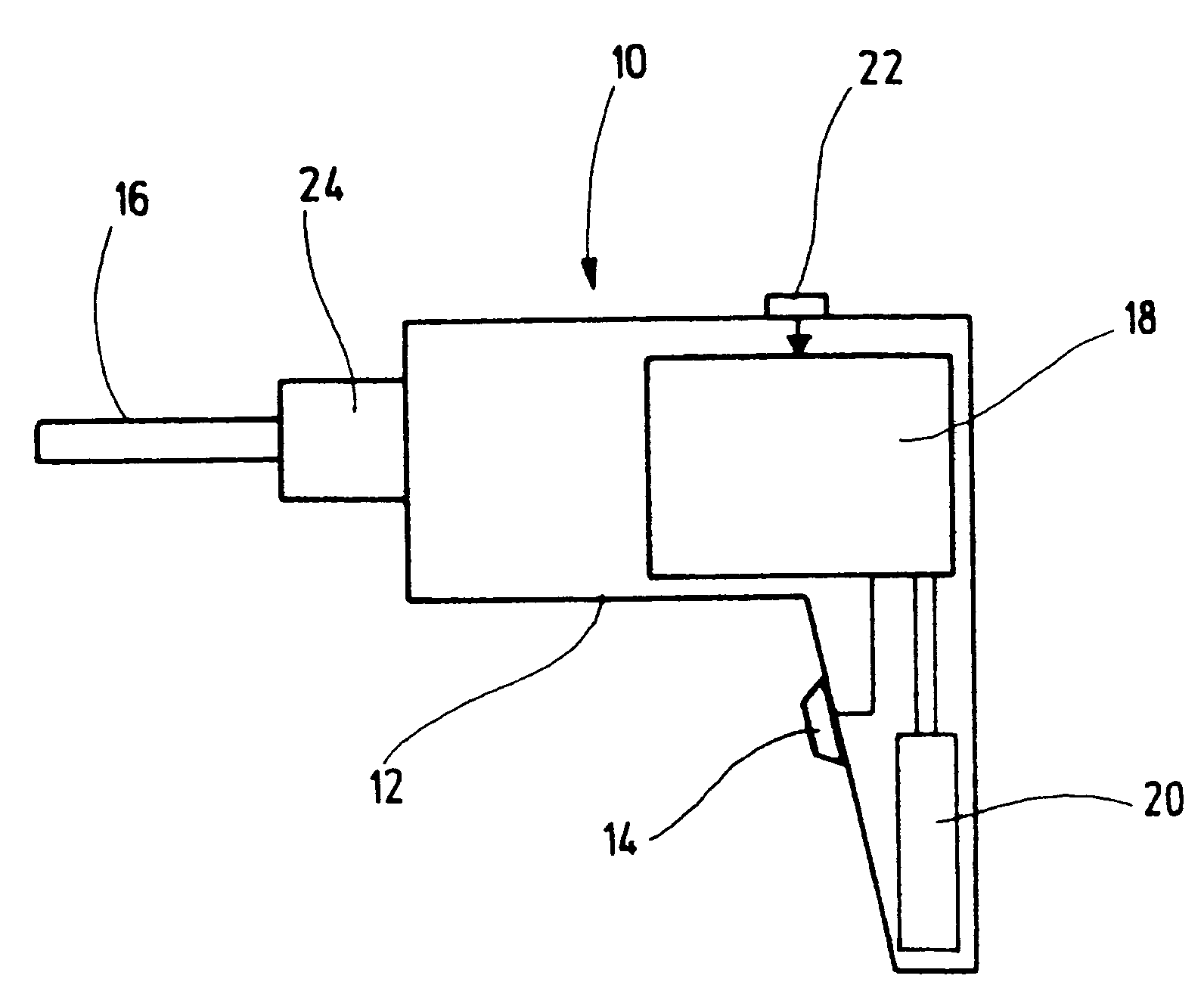

Rechargeable battery-operated hand machine tool

InactiveUS7395875B2Easy dischargeIncrease dynamicsDrilling rodsConstructionsRechargeable cellHand held

The invention is based on a rechargeable battery-operated hand machine tool (10) having an electric drive motor (18) accommodated in a housing (12) and powered by a rechargeable battery (20), which motor is used to drive a tool (16), and having an actuating means (14) for switching the drive motor (18) on and off.A mechanism (22) is provided, which is capable of reducing the discharging of the battery (20) during operation.

Owner:ROBERT BOSCH GMBH

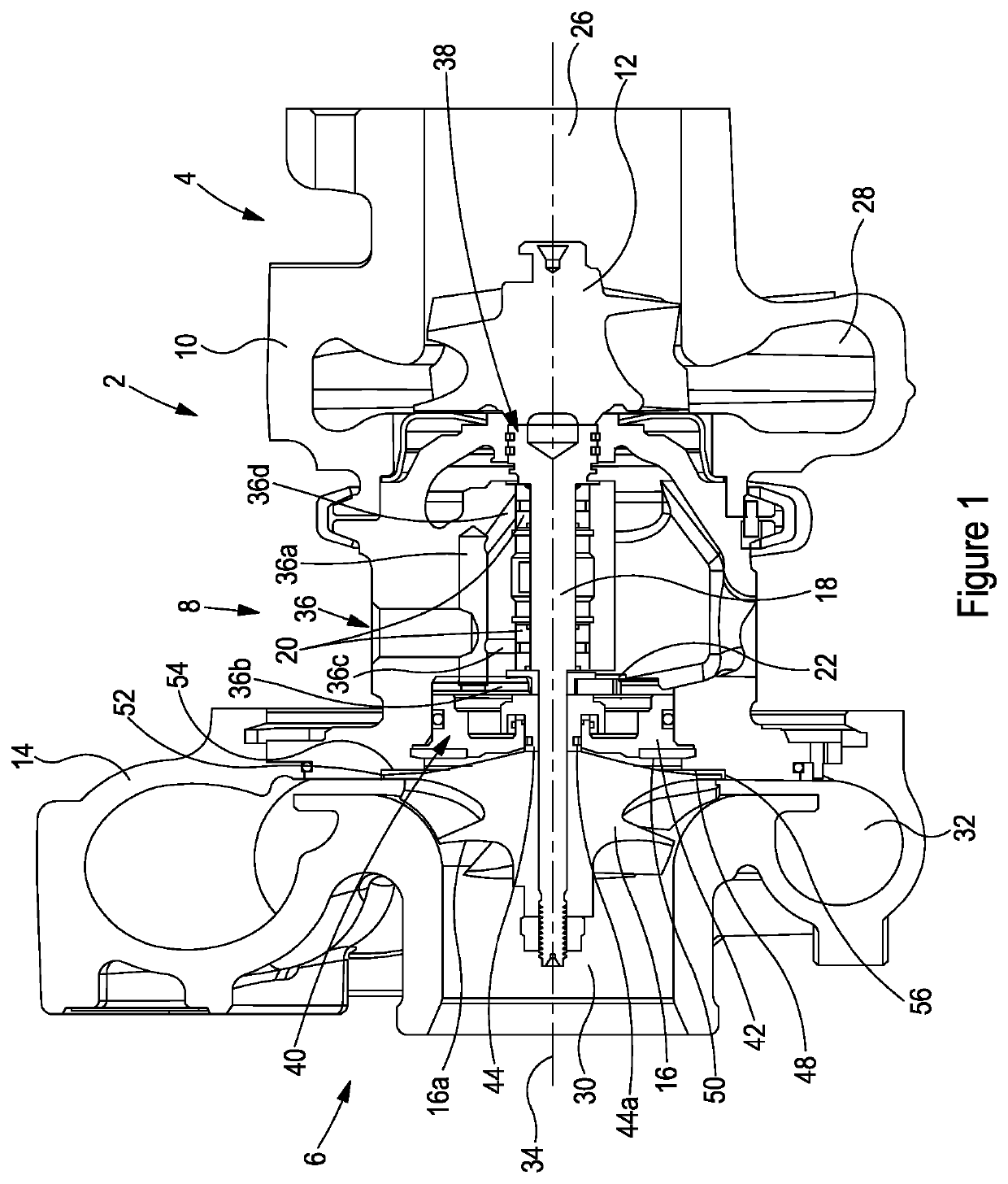

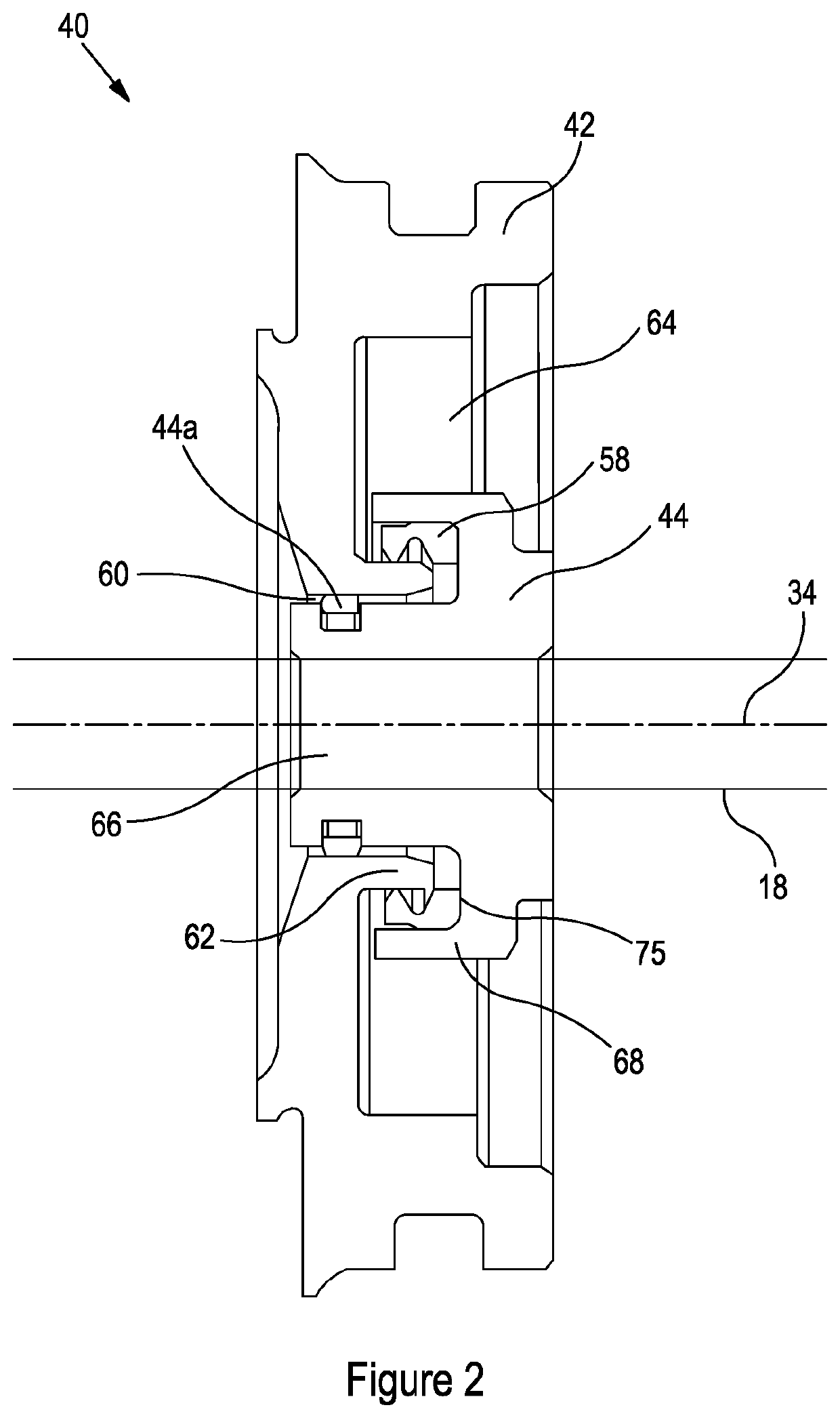

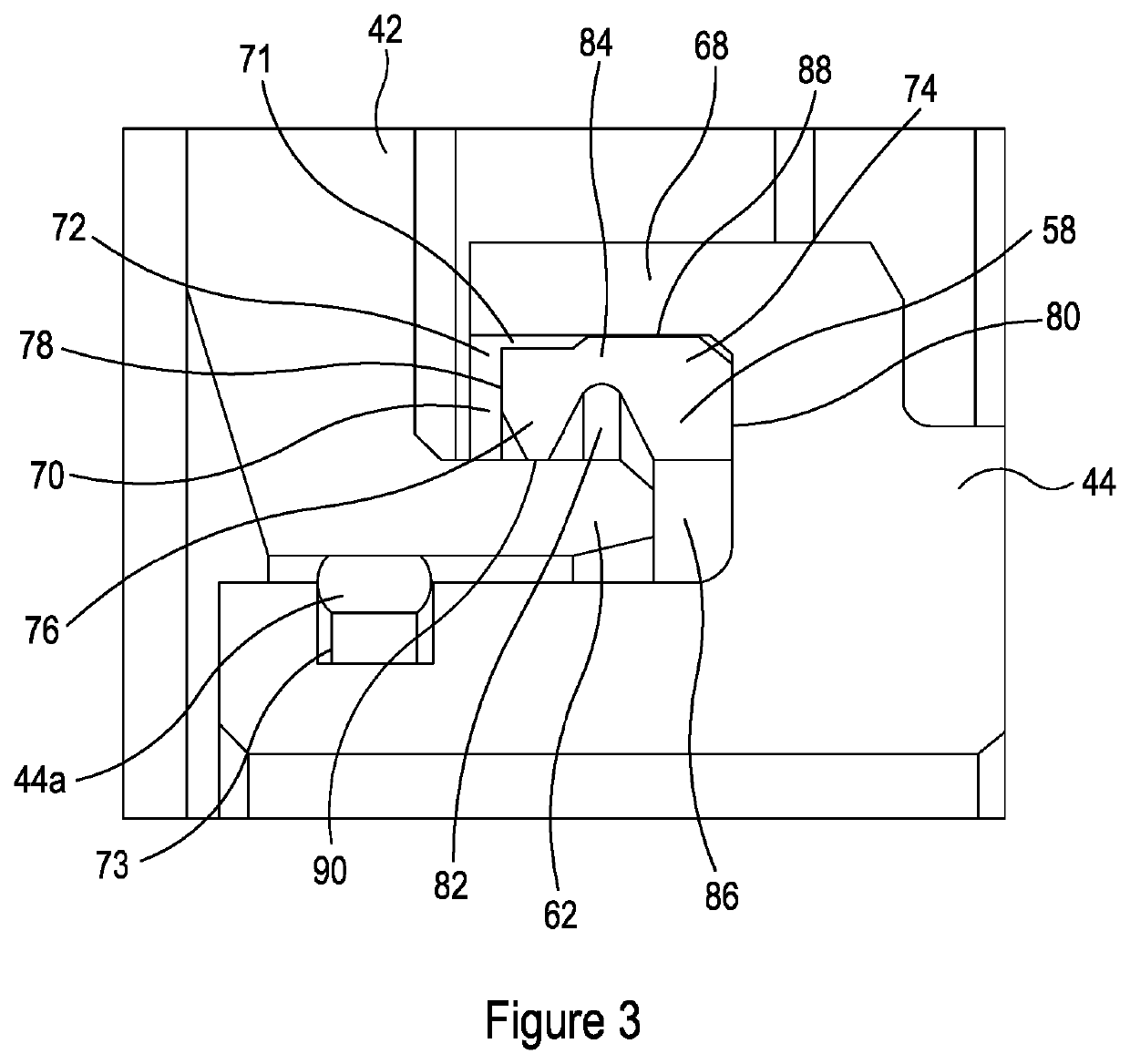

Seal assembly

A seal assembly for use in a turbomachine, the seal assembly comprising an oil seal plate; a rotatable component which defines a central axis and is received in a central aperture of the oil seal plate; and an annular seal which comprises a base and a sealing portion, the base being held by the rotatable component; wherein the sealing portion is configured to form a seal with the oil seal plate when the rotatable component and annular seal are rotating below a predetermined rotational speed; and wherein the sealing portion is configured to move radially outwards with respect to the central axis such that the sealing portion loses contact with the oil seal plate when the rotatable component and annular seal are rotating above the predetermined rotational speed.

Owner:CUMMINS LTD WEST YORKSHIRE

High-efficient intake and exhaust system of internal combustion engine

InactiveCN102505975AIncrease motivationSolution to short lifeCombustion-air/fuel-air treatmentValve drivesLow noiseCombustion

The invention discloses a high-efficient intake and exhaust system of an internal combustion engine, wherein a cam of a gas distribution mechanism is an eccentric cam, and a profile of the eccentric cam consists of a base line, an opening profile, a closed profile and a deep-stroke line. The high-efficient intake and exhaust system disclosed by the invention has the advantages of suitability for large, intermediate and small cylinders, a single cylinder and multiple cylinders, a water-air-cooled engine, increased power due to natural air suction (preferably boosted intermediate cold) and full combustion, low oil consumption, low exhaust reaching the Europe emission standard 1-4, low noise, low vibration, low idle speed, low cost, long service life, good startability and reliability, and reduced oil consumption and emission compared with the same model of the internal combustion engine, and is an upgrade product that the energy is saved by 20 percent and the emission is reduced by 50 percent; and the internal combustion engine with performances exceeding the advanced level of the world and various matched powers are obtained.

Owner:周亮俊

Engine control device

ActiveCN102418644BReduce fuel consumptionReduce exhaustInternal combustion piston enginesIgnition automatic controlState variationInstability

Owner:HONDA MOTOR CO LTD

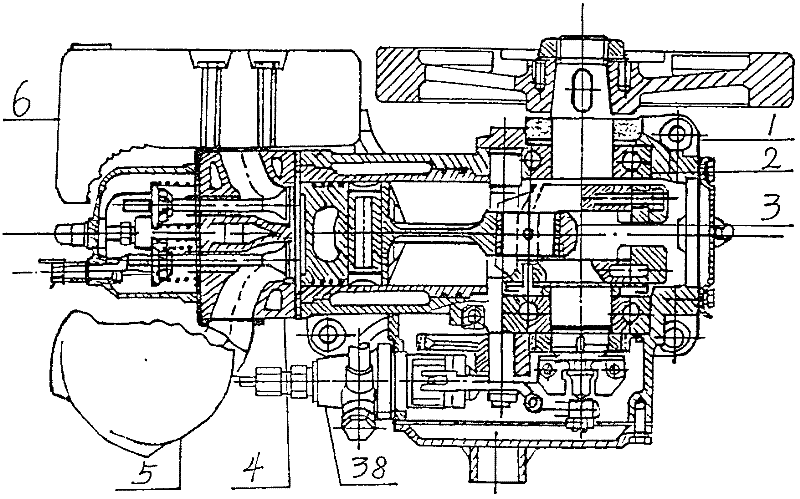

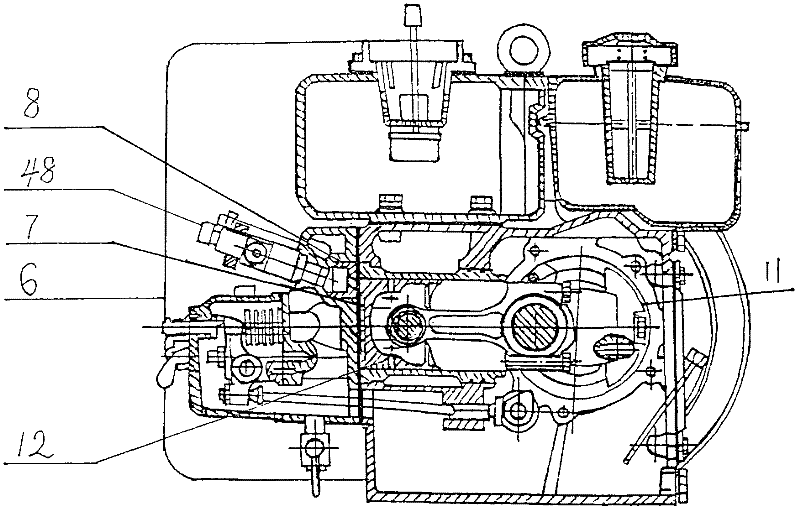

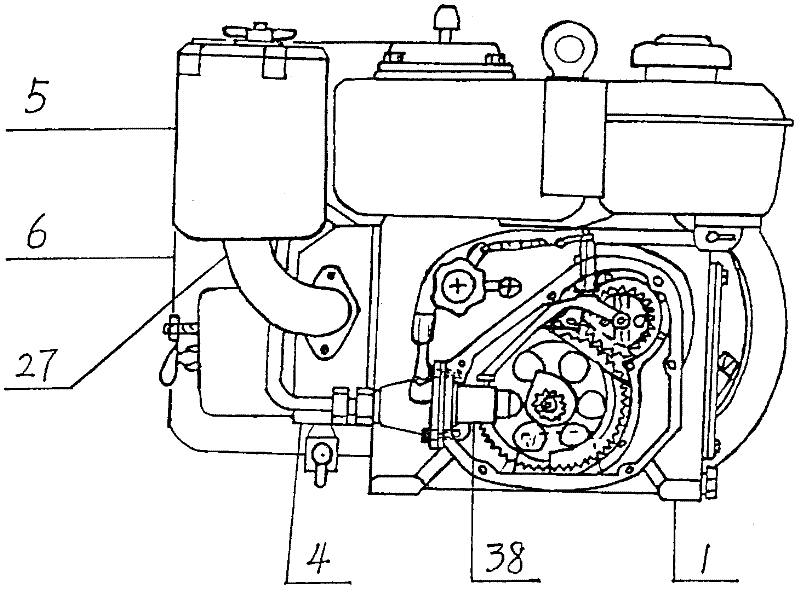

Two-stroke internal combustion engine

ActiveCN103696848AReduce idle speedReduce idling fuel consumptionCombustion enginesAutomatic controlExhaust valve

The invention discloses a two-stroke internal combustion engine. The two-stroke internal combustion engine comprises a shell, wherein the shell is internally provided with a piston and a crankshaft box; the crankshaft box comprises a rotating shaft; the rotating shaft is connected with a rotary compressor; the rotary compressor comprises an electromagnetic clutch and a compressed air outlet; the compressed air outlet is connected with a compressed air storage tank; the top of the shell is provided with an end cover; the end cover is provided with a compressed air nozzle, an exhaust port, a fuel injector and an ignition device; the compressed air nozzle is connected with the compressed air storage tank through a communicating pipe; the communicating pipe is provided with a compressed air automatic control valve; the exhaust port is provided with an exhaust valve; the internal combustion engine carries out air suction, acting and air exhaust processes in sequence. According to the two-stroke internal combustion engine provided by the invention, air suction and air exhaust are carried out independently, and the emission and fuel consumption are reduced.

Owner:郭志辉

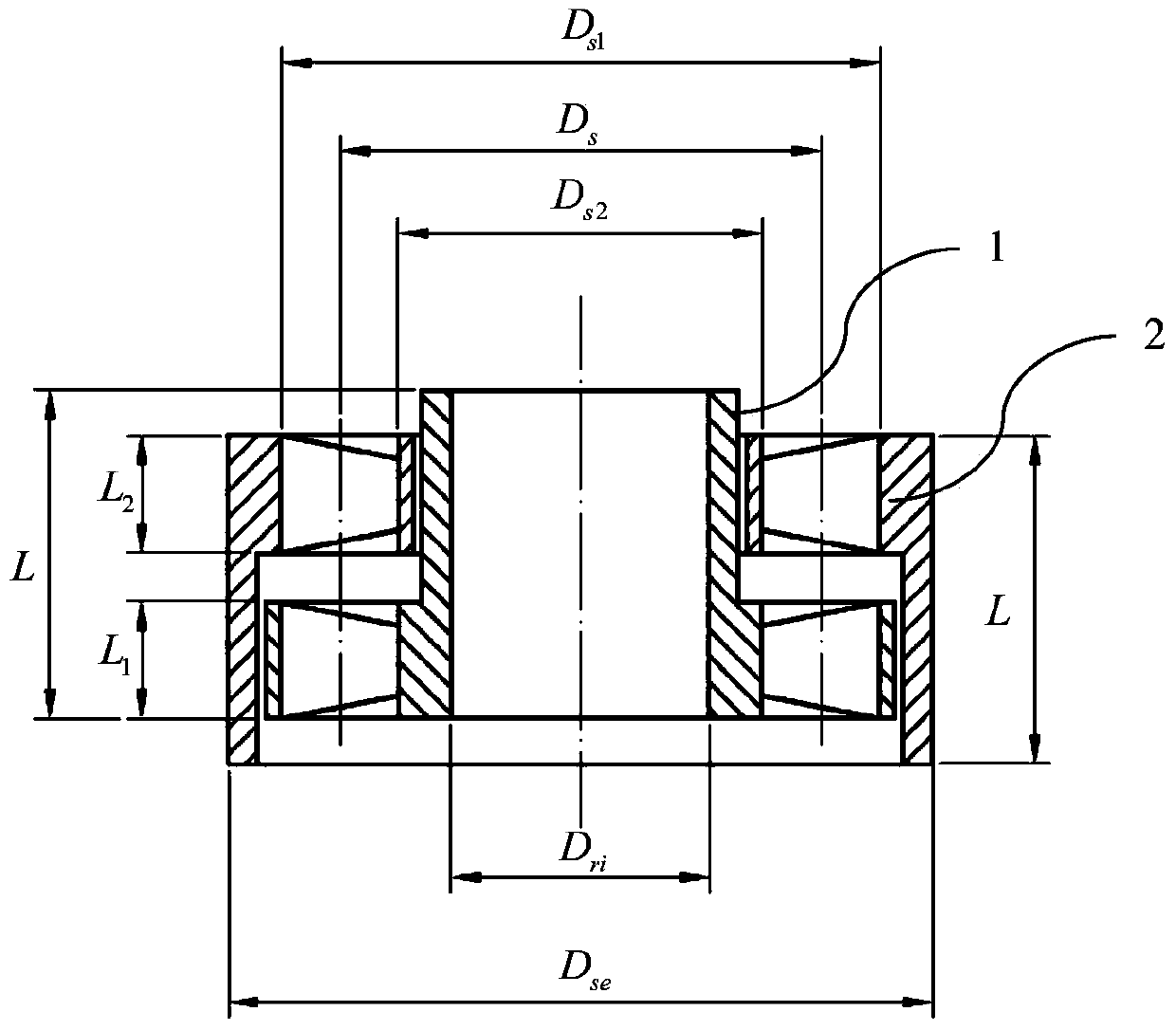

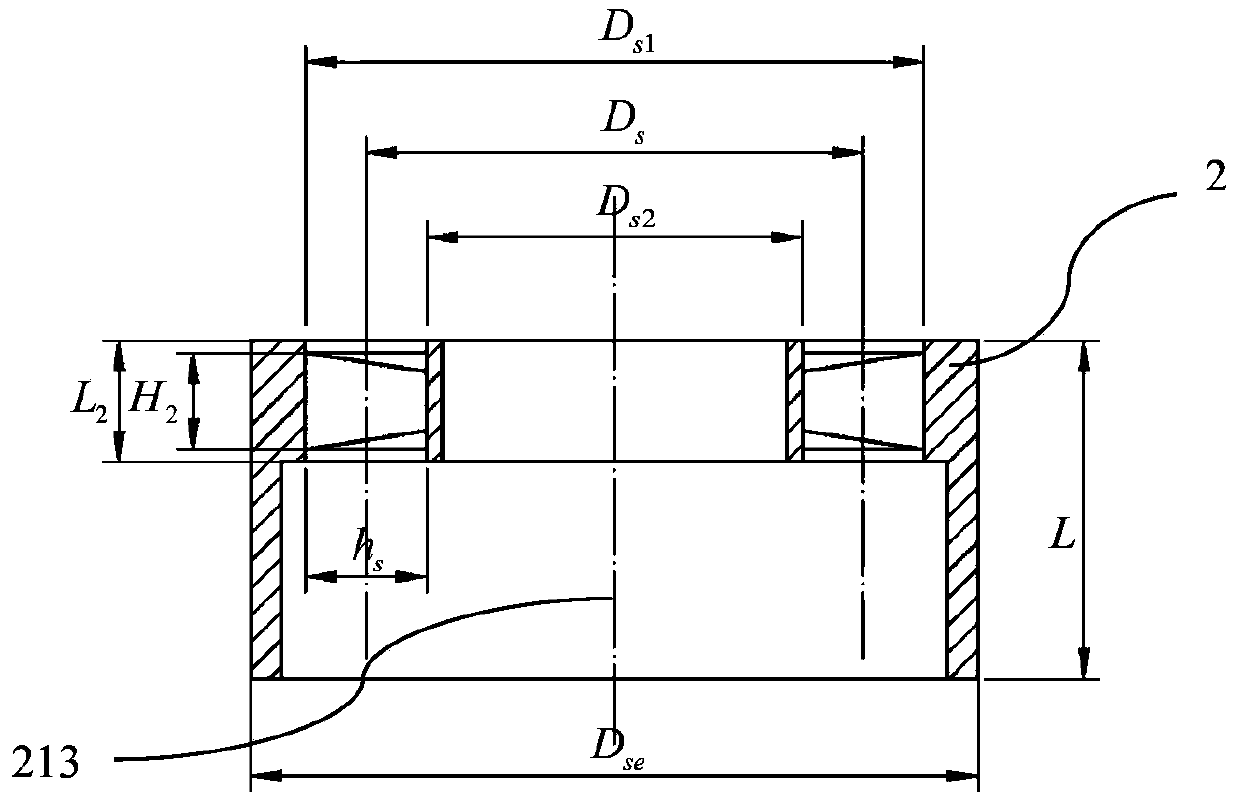

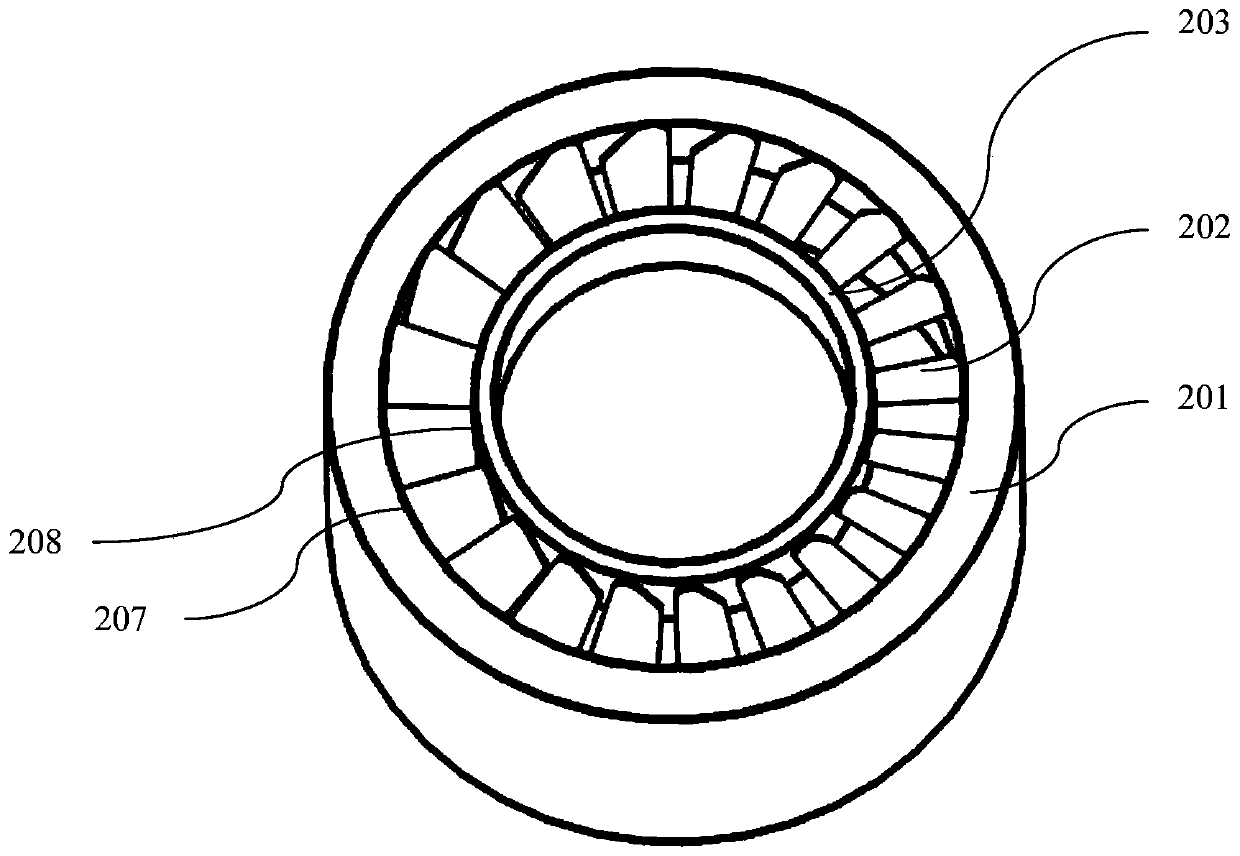

Point-projection wedge-shaped blade brake-stage stator and rotor assembly

InactiveCN104047795AReduce hydraulic lossHigh braking torqueHydro energy generationBorehole drivesBrake torquePoint projection

The invention provides a point-projection wedge-shaped blade brake-stage stator and rotor assembly. Stator blades and rotor blades are in a wedge shape with the width gradually increasing from top to bottom and from blade bottom to blade top. The multiple stator blades are circumferentially arranged between the outer wall of a stator leaf crown and the inner wall of a stator body in an inclined mode. The multiple rotor blades are circumferentially arranged between the outer wall of a rotor body and the inner wall of a rotor leaf crown in an inclined mode. The stator blades and the rotor blades are the same in inclining angle and inclining direction. Both the stator blades and the rotor blades are formed through point projection. The point-projection wedge-shaped blade brake-stage stator and rotor assembly is small in hydraulic loss and large in braking torque; after a certain number of point-projection wedge-shaped blade brake-stage stators and rotors and a certain number of turbine-stage stators and rotors are assembled together, working time of a turbine drill can be obviously prolonged, overload capacity of the turbine drill can be obviously improved, stability can be obviously improved when the turbine drill works at a low rotating speed, and the footage during turbine drilling can be obviously increased.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Nano-diamond lubricating oil for taxis and buses

The invention discloses nano-diamond lubricating oil for taxis and buses. The nano-diamond lubricating oil is characterized by being prepared according to the following method: performing dispersing:adding 0.3-0.5g of nano-diamond into each liter of dispersing agent OP-10, performing heating to 60-80DEG C, carrying out strong shearing and stirring for 10-18min, and conducting standing; performingemulsifying, taking out the supernatant, adding the supernatant into 150N base oil according to a ratio of 1:1.4-1.6, performing mixing, then stirring the substances strongly, and performing standingto obtain an emulsified composition; adding 2-2.5% by mass of the emulsified composition into base lubricating oil, conducting strong shearing and stirring, and performing standing; and adding 0.4-0.6% by mass of a pour point depressant into the mixture obtained in step (3), conducting strong shearing and stirring, and performing standing to obtain the product. The problems that taxies and busesare prone to breaking down and air conditioners cannot be used in summer are solved, the engine service life is prolonged, tail gas emission is reduced, and fuel oil or fuel gas is saved.

Owner:李家诚

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com