High-efficient intake and exhaust system of internal combustion engine

An internal combustion engine, high-efficiency technology, applied in the charging system, mechanical equipment, engine components, etc., can solve the problems of unreasonable internal combustion engine ratio and valve mechanism, incomplete combustion, and high fuel consumption, achieve low idle speed, and save fuel costs. , the effect of reducing production and use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

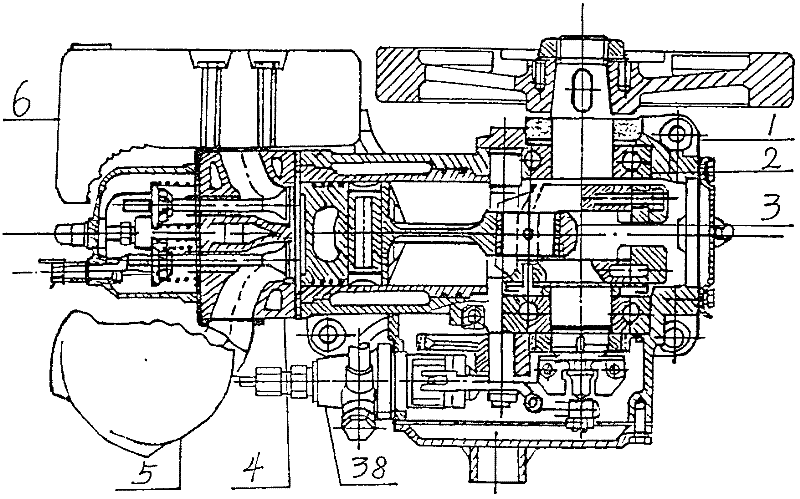

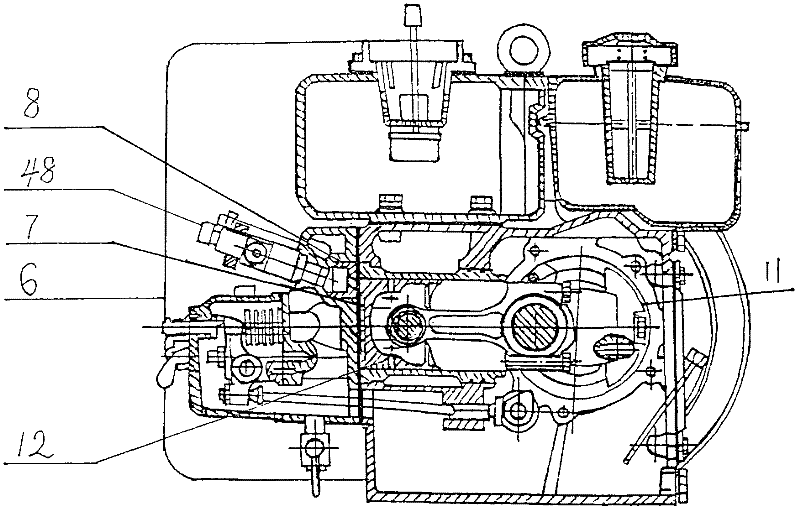

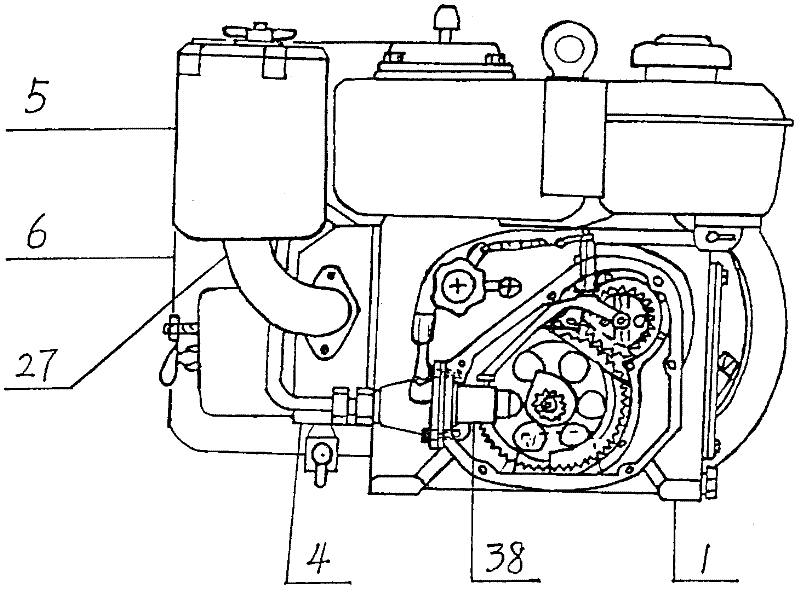

[0029] Such as Figure 1-4 As shown, the present invention is a high-efficiency internal combustion engine intake and exhaust system, including a camshaft assembly, an air filter assembly, and a muffler assembly. When the valve is closed, it is 10-38° after the bottom dead center, when the exhaust valve is opened, it is 25-45° before the bottom dead center, and when the exhaust valve is closed, it is 2-10° after the top dead center.

[0030] A high-efficiency internal combustion engine intake and exhaust system, the cam 33 of the valve train is an eccentric cam 33 . Cam 33 open line 35, close line 36, depth line 37 are straight line or arc.

[0031] The filter element 28 of the air filter 5 is provided with a folding groove 29 which forms an angle β with the axis. The air filter 5 is provided with a heat insulating layer 30 or made of a heat insulating material 30 on the air intake pipe 27 or the air intake pipe pad 30 or the casing 26 . The upper side of the casing 26 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com