Hybrid power type motor electric control silicone oil fan clutch

A hybrid power and clutch technology, applied in electromechanical devices, engine components, engine cooling, etc., can solve the problems of inability to use new energy, poor driving environment comfort, and high power consumption, so as to improve cold start characteristics and energy utilization. , Obvious effect of energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

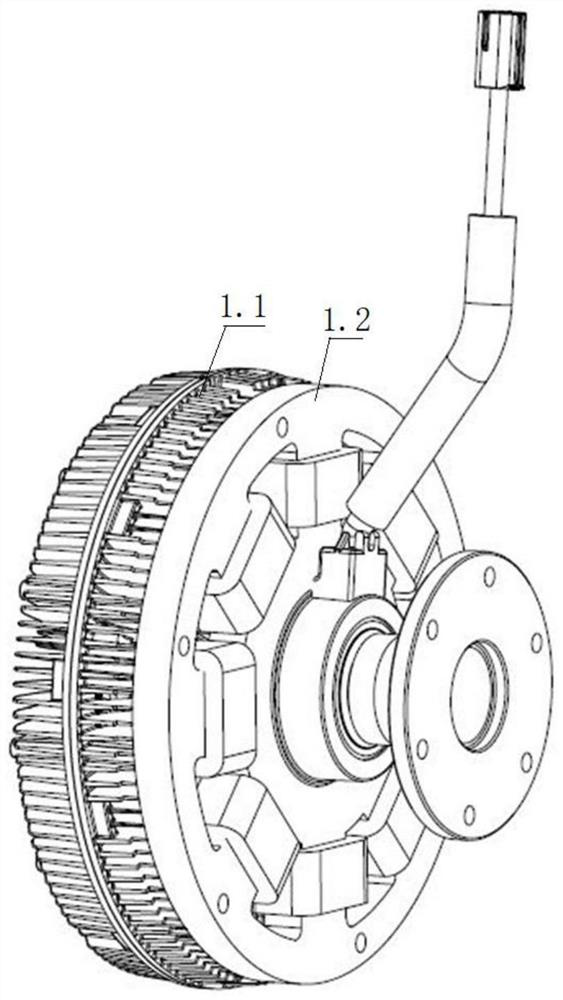

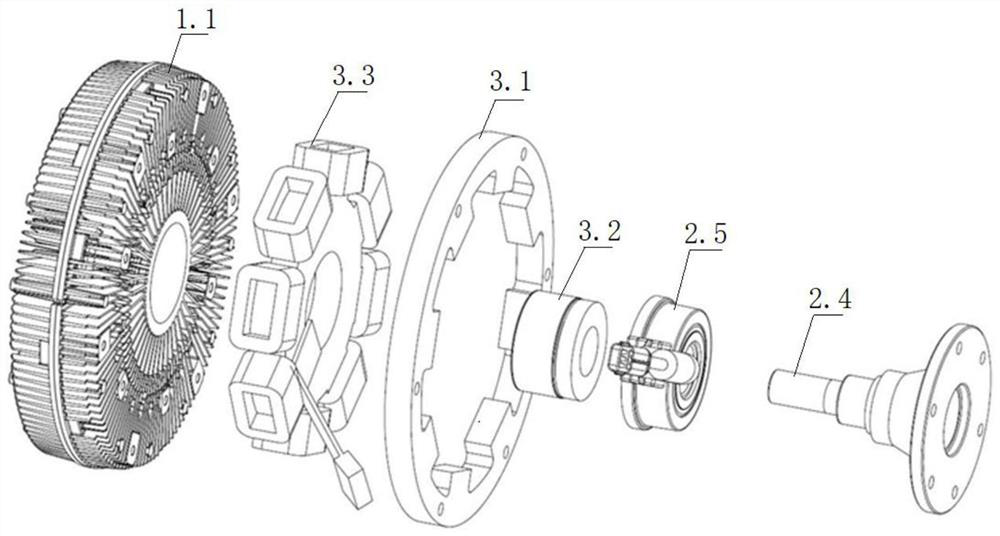

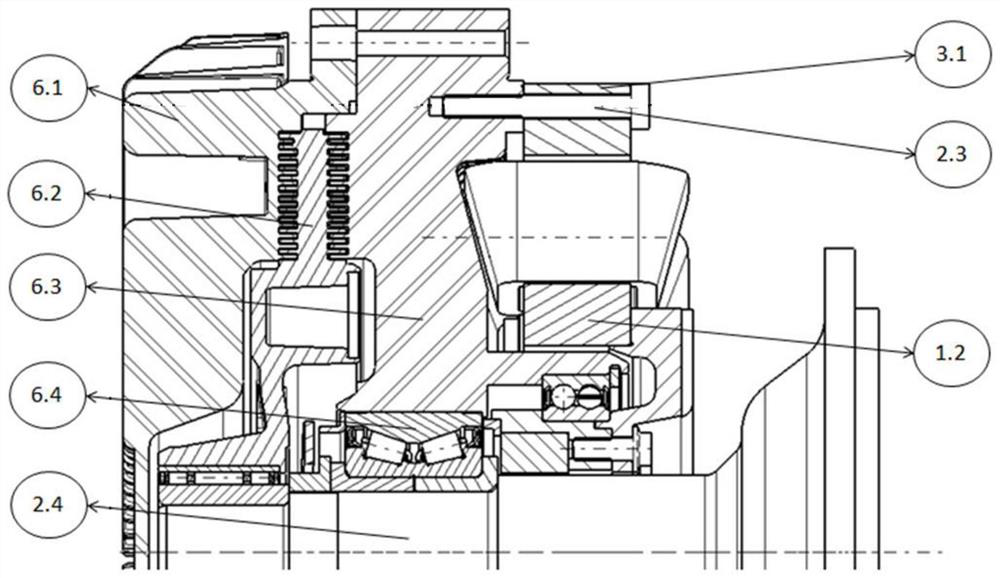

[0033] combine Figure 1-3 As shown, a hybrid electric motor electronically controlled silicone oil fan clutch of the present invention is installed in the engine compartment, with a volume of about 350mm×350mm×400mm, including a silicone oil clutch 1.1 and a brushless motor 1.2, both of which are connected by a connecting screw 2.3 fixed. Silicone oil clutch 1.1 adopts conventional electronically controlled silicon oil fan clutch (such as patent CN201910586621.5), including front cover 6.1, driving disc 6.2, rear cover 6.3, flange shaft 2.4 and solenoid 2.5, front cover 6.1 and rear cover 6.3 through bolts Fixed connection, the rear cover 6.3 is fixedly connected with the fan, the driving disc 6.2 is set between the front cover 6.1 and the rear cover 6.3, the flange shaft 2.4 passes through the rear cover 6.3 and is threadedly connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com