Load sensitive hydraulic system and power controller thereof as well as crane

A power controller and load-sensitive technology, applied in mechanical equipment, fluid pressure actuators, servo motors, etc., can solve problems such as low output power, increased output power, and increased maximum power of oil pumps, so as to improve energy efficiency, Facilitate automatic control and reduce power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

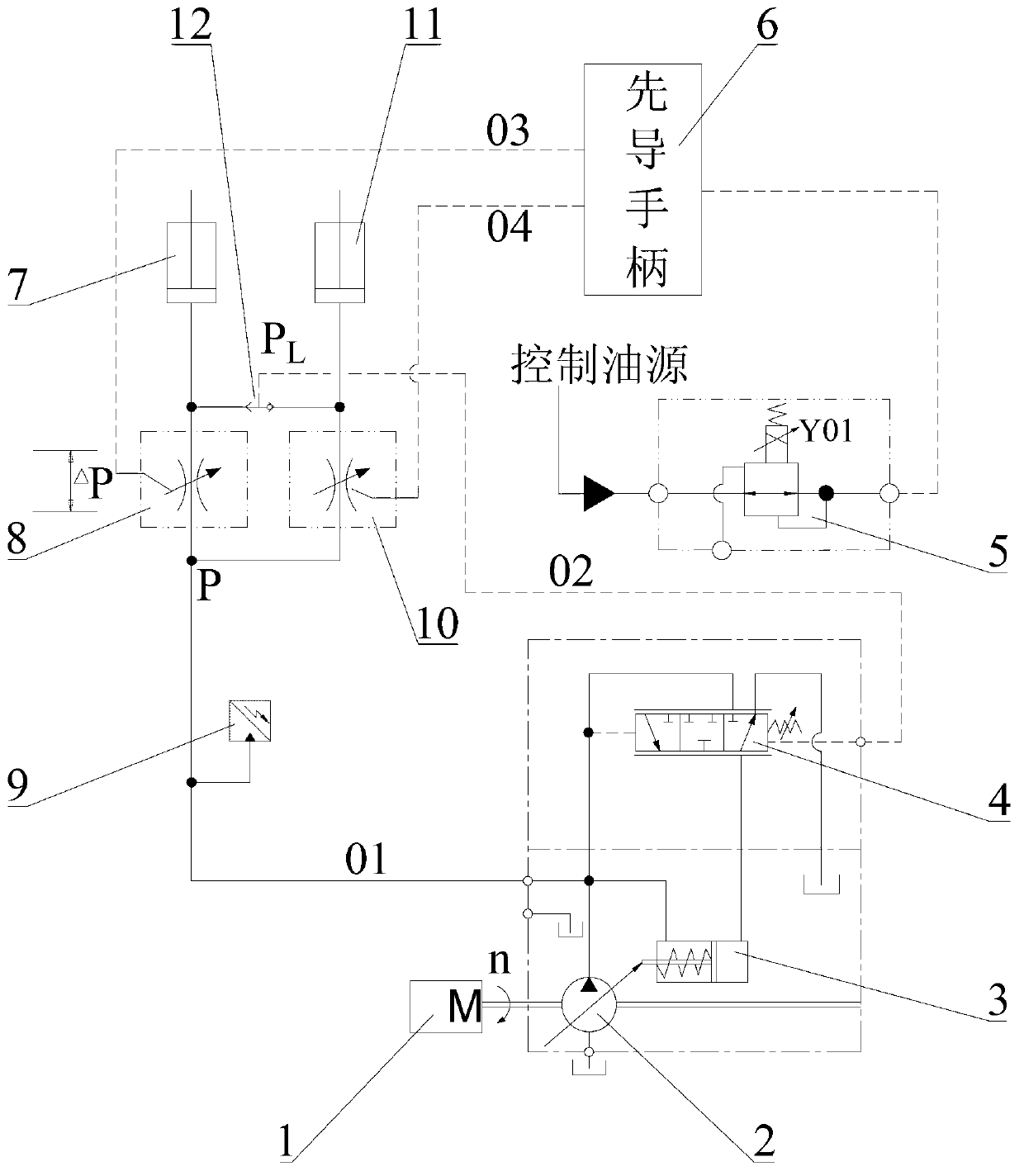

[0059] In the second embodiment, the shuttle valve 12 is used to select the oil pressure of the second oil port of the first main valve 8 and the second oil port of the second main valve 10. In other embodiments of the load-sensing hydraulic system, it can also be used Other forms, as long as the function can be realized.

[0060] On the basis of the second embodiment, more loads can be added; correspondingly, the pilot handle 6 can have more oil outlets, and the oil pressure of multiple loads with higher oil pressure can be fed back to the sensitive cavity through the feedback oil circuit 01 In this way, the function of the present invention can also be realized. In addition, this method (including the second embodiment) can realize compound actions under a single pump, and can meet energy-saving requirements.

[0061] In the embodiments of the various load-sensing hydraulic systems described above, the first actuator 7 may be a hydraulic cylinder or a hydraulic motor, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com