Electric Vehicle Electromagnetic Torque Drive System

A technology for electric vehicles and drive systems, applied in electric vehicles, battery/battery traction, electrical devices, etc., can solve the problems of increasing the manufacturing difficulty and cost of the drive system, achieve heat dissipation, improve service life, and reduce power impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

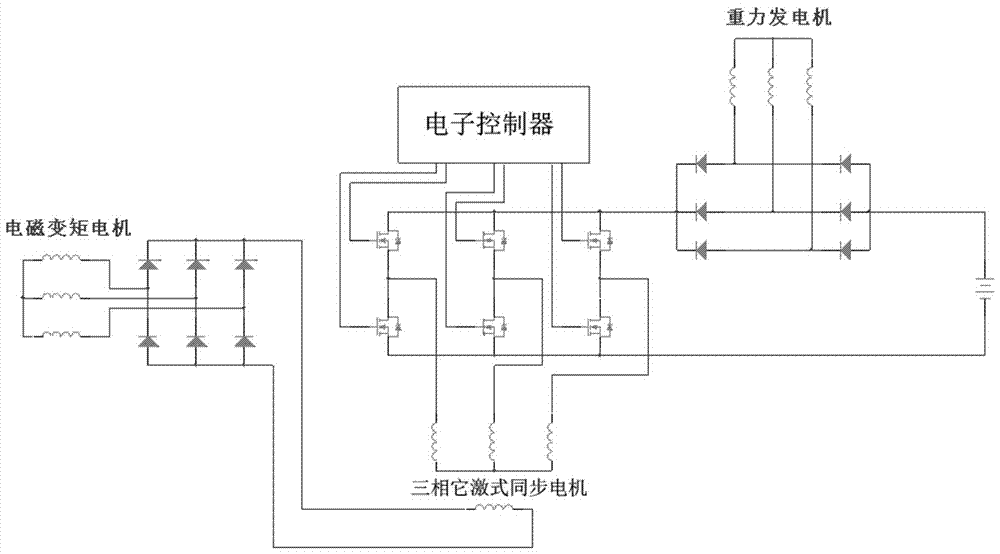

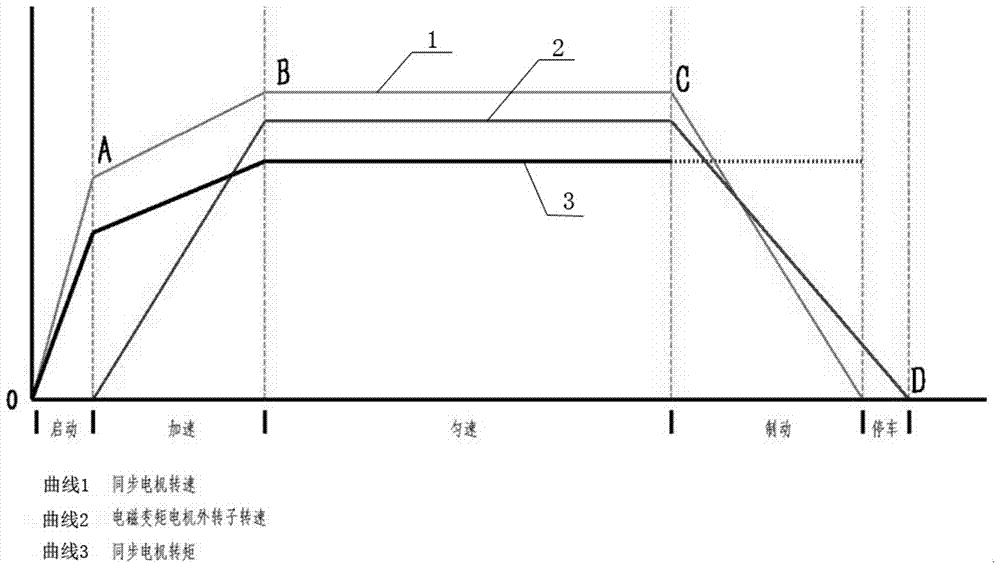

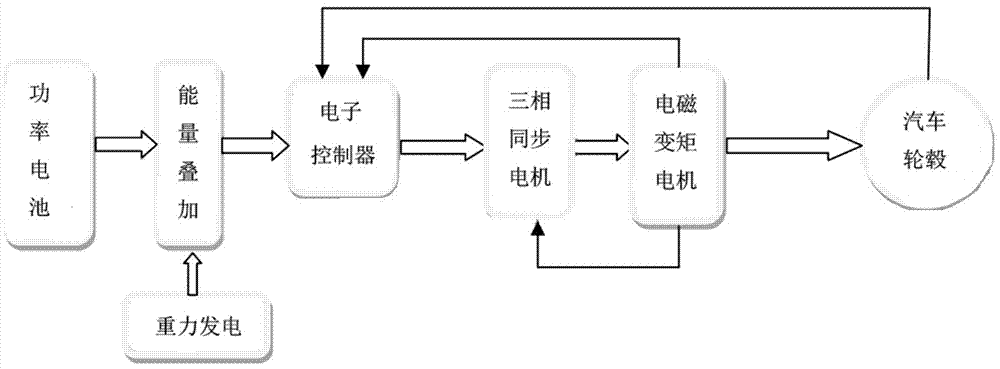

[0023]Electric vehicle electromagnetic variable torque drive system, including electromagnetic variable torque drive device, power battery, electronic controller, three-phase bridge full-control inverter circuit and three-phase rectifier circuit, electromagnetic variable torque drive device includes three-phase other excited synchronous motor It is connected with the electromagnetic variable torque motor, the rotor of the three-phase other excited synchronous motor and the inner rotor of the electromagnetic variable torque motor, the power battery is connected with the input end of the three-phase bridge full-control inverter circuit, and the three-phase bridge full-control inverter The output end of the circuit is connected to the armature winding of the three-phase other-excited synchronous motor, the three-phase bridge full-control inverter circuit is controlled by the electronic controller, and the inner rotor magnetic pole winding of the electromagnetic variable torque moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com