Limit load adjustment method of all hydraulic bulldozer and apparatus thereof

A technology for extreme loads and bulldozers, which is applied to earth movers/shovels, construction, etc. It can solve problems such as pump and motor leakage, engine output power drop, transmission system load increase, and signal lag, etc., to improve system response speed , Adjustment quality improvement, and the effect of improving control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

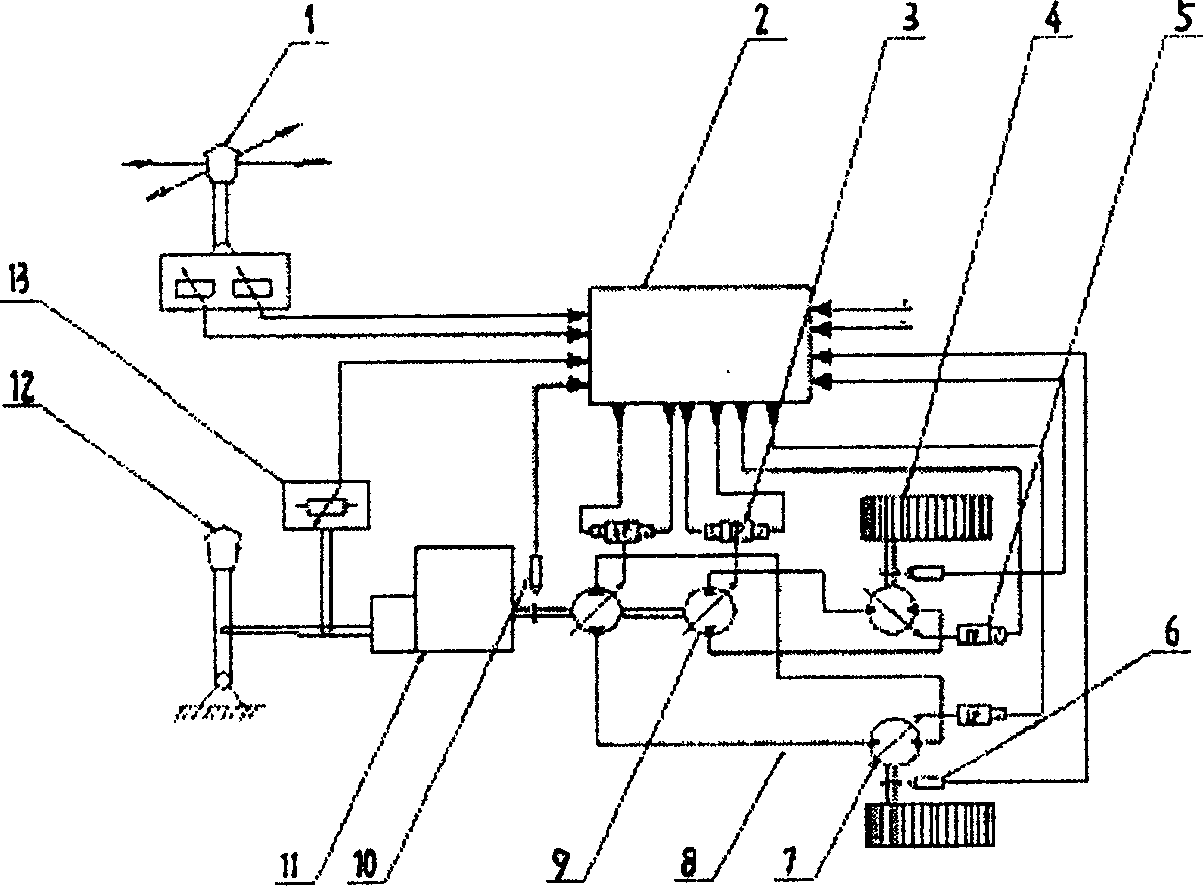

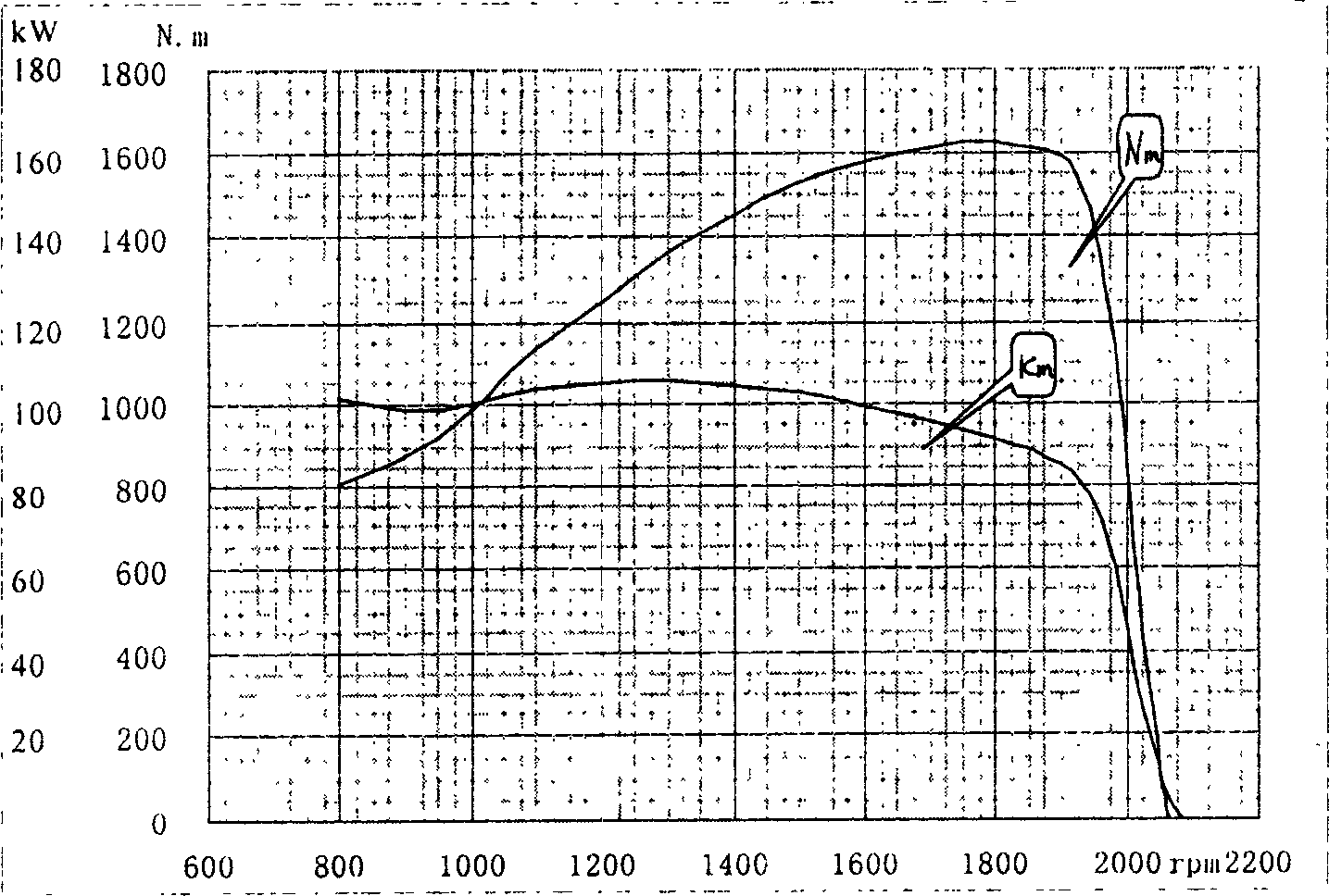

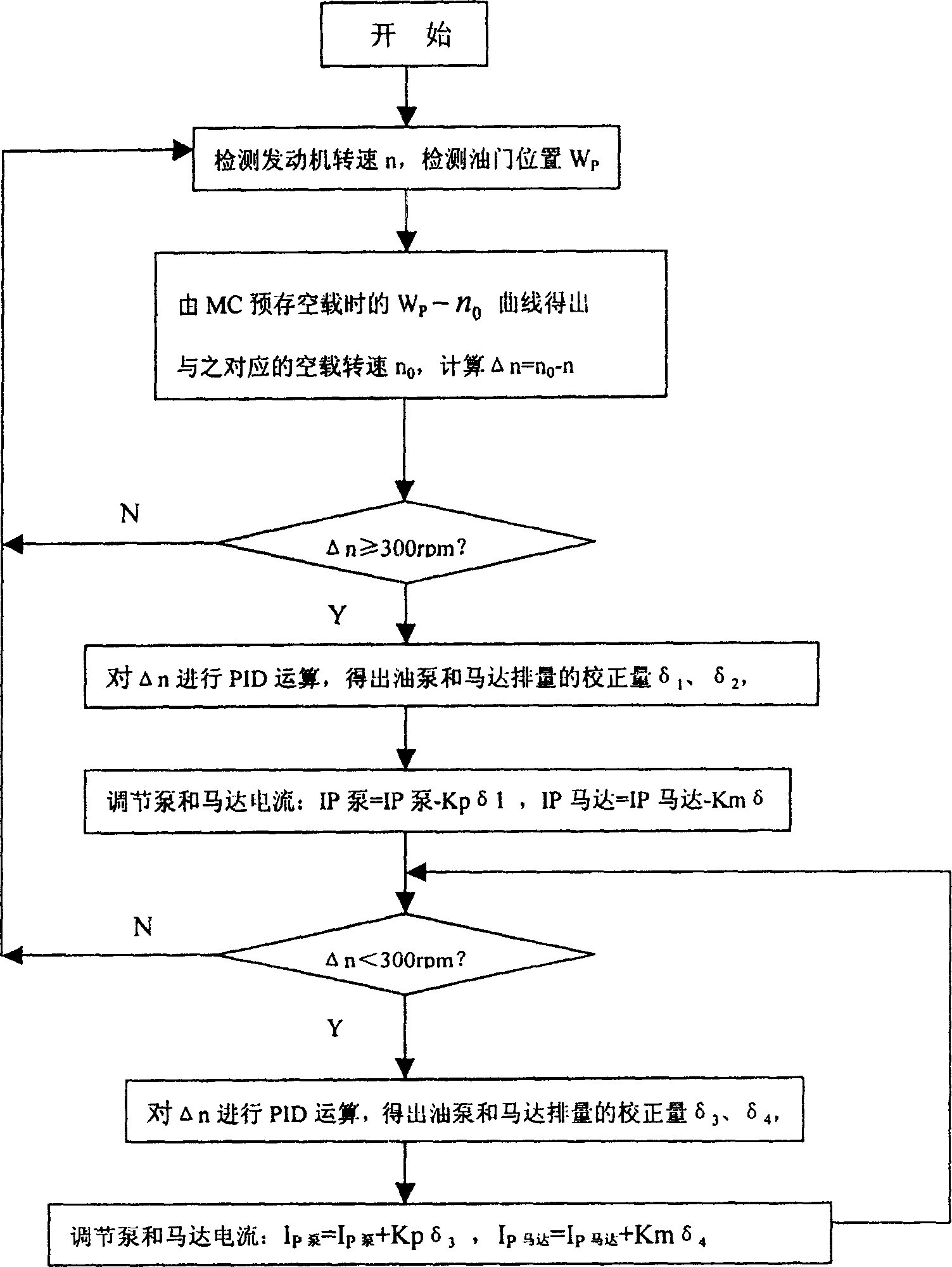

[0009] The present invention is conceived according to the problems existing in the prior art. It connects the accelerator position sensor connected to the throttle joystick, the engine speed sensor connected to the engine, the motor speed sensor connected to the travel motor and the motor electric proportional valve to the MC microcontroller, and the engine is rigidly connected to the variable oil pump , the variable oil pump is connected to the MC micro-controller through the electric proportional valve, and then the MC micro-controller calculates the actual speed of the engine and motor under the working condition and the set speed under the corresponding throttle opening according to the electric signal transmitted by the throttle position sensor and the speed sensor The difference value, after data processing and PID calculation, adjusts the variable oil pump electric proportional valve and motor electric proportional valve current to keep the engine speed at a constant va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com