Axial flow rotor blade

An axial flow wind and wind wheel technology, which is applied to the components of pumping devices for elastic fluids, non-variable displacement pumps, machines/engines, etc., can solve the problems of high aerodynamic noise and low-energy fluid accumulation of the wind wheel, To achieve the effect of reducing the weight of the rotor and the motor load, inhibiting growth, reducing the cost of the rotor and the power of the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

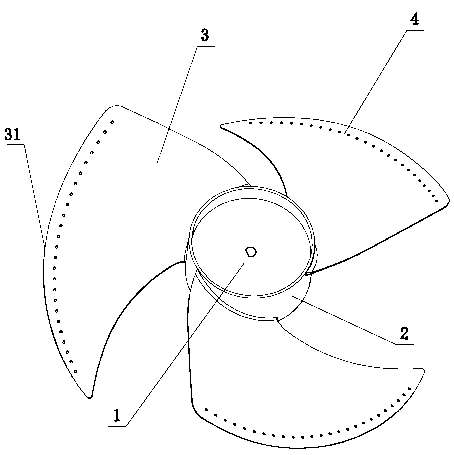

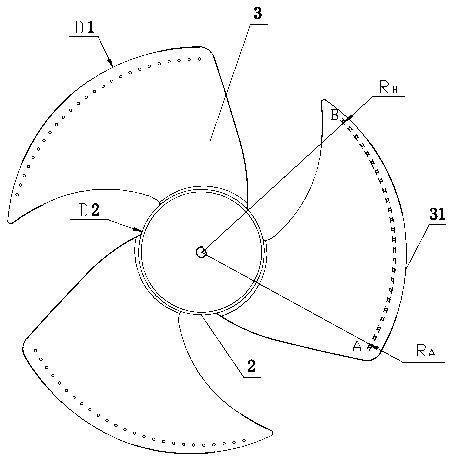

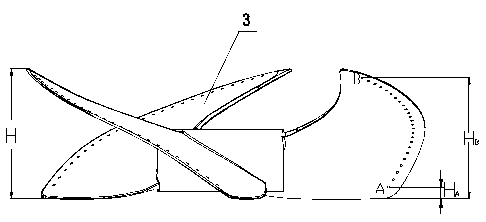

[0023] In each figure, 1 is the axial flow wind wheel, 2 is the hub, 3 is the blade, 31 is the outer edge of the blade, 4 is the through hole in the hole-shaped area, D 1 is the outer diameter of the axial flow rotor, D 2 is the hub diameter, R m is blade height, R A is the radius of the position A where the hole patterning area starts near the outer edge of the blade, R B is the radius of the position B at the end of the hole-shaped area near the outer edge of the blade, H is the height of the rotor, H A is the height of position A where the hole-shaped area near the outer edge of the blade is located, H B is the height of position B at the end of the hole-shaped area near the outer edge of the blade, c 1 、c 2 、c 3 ,... c n-1 is the distance between two adjacent through-holes in the hole-shaped area of the blade, d 1 、d 2 、d 3 ,... d n is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com