Injection drive apparatus for injection molding machine

a technology of injection molding machine and drive apparatus, which is applied in the direction of auxillary shaping apparatus, manufacturing tools, food shaping, etc., can solve the problems of large energy consumption of driving, and achieve the effect of reducing the load of the motor and increasing the yield rate of injection molding products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

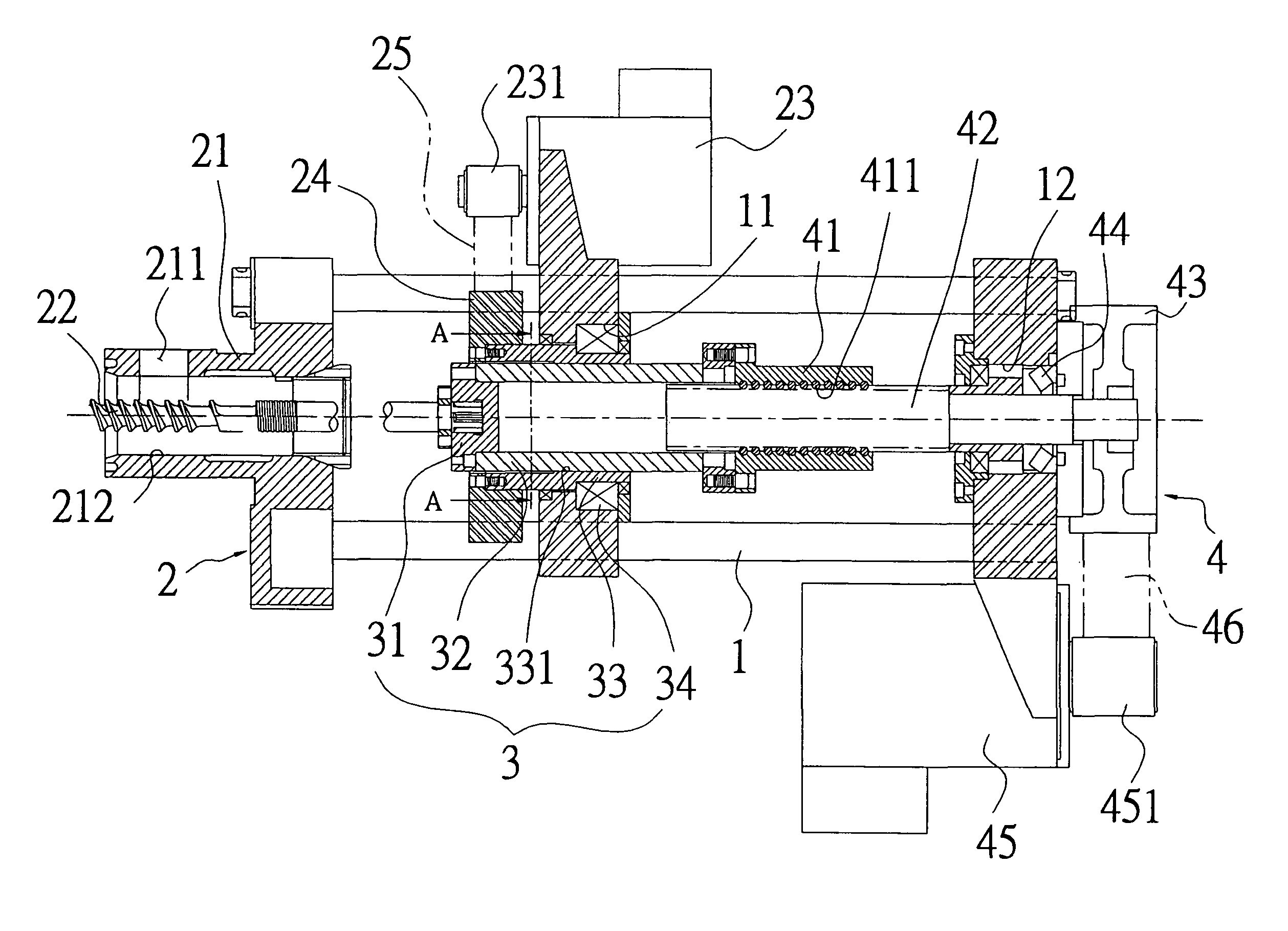

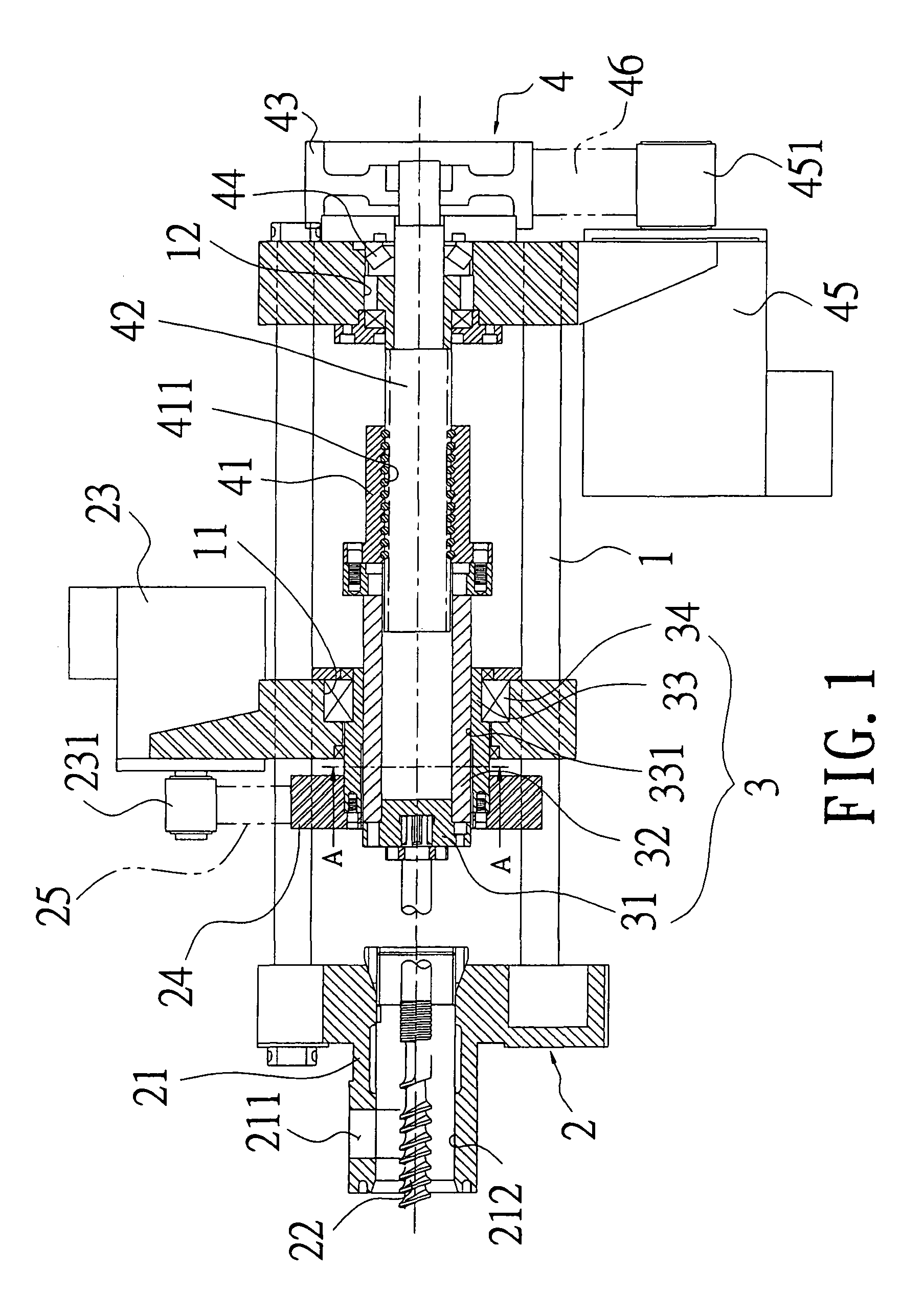

[0024]Refer to FIG. 1, an injection drive apparatus for an injection molding machine according to the present invention includes a machine platform 1 and a material feeding mechanism 2, a slide mechanism 3 and an injection mechanism 4 all arranged at the machine platform 1.

[0025]The material feeding mechanism 2 consists of a material feeder 21 connected and fixed with the machine platform 1, a material inlet 211 disposed over the material feeder 21 and a material feeding hole 212 arranged at a center of the material feeder 21. The material feeding hole 212 is connected with the material inlet 211 and a material feeding screw 22 is inserted through the material feeding hole 212. Moreover, the machine platform 1 is disposed with a material-feeding motor 23 and a conveyor belt 25 is arranged between a drive shaft 231 of the material-feeding motor 23 and a disc 24.

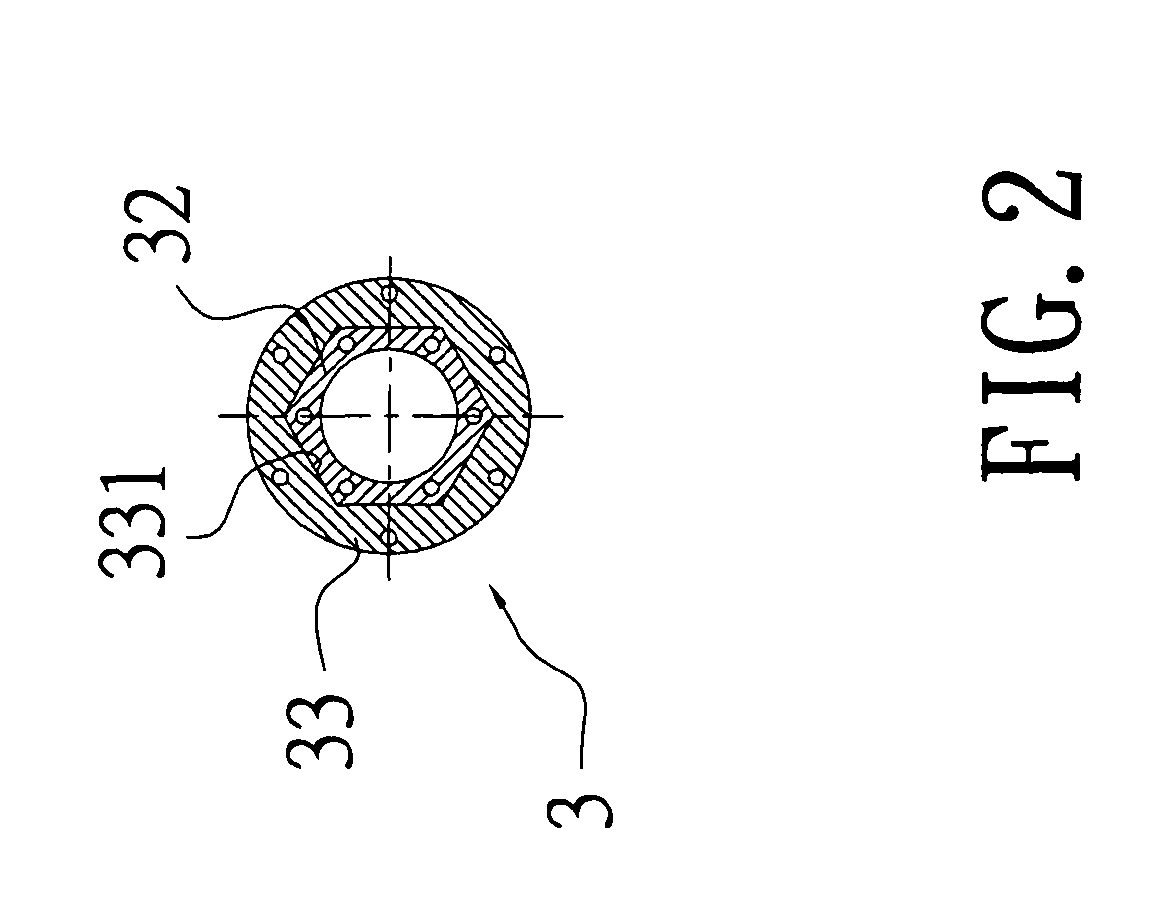

[0026]Also referring to FIG. 2, the slide mechanism 3 includes a sliding slave member 31 connected and assembled with a rear...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shape | aaaaa | aaaaa |

| yield rate | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com