Pushbutton switch

A switch and cover technology, applied in the field of push switches, can solve the problems of increased manufacturing cost, large frictional resistance, and unsmooth pressing touch, etc., and achieve the effect of simplifying the structure, reducing frictional resistance, and reducing operating noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

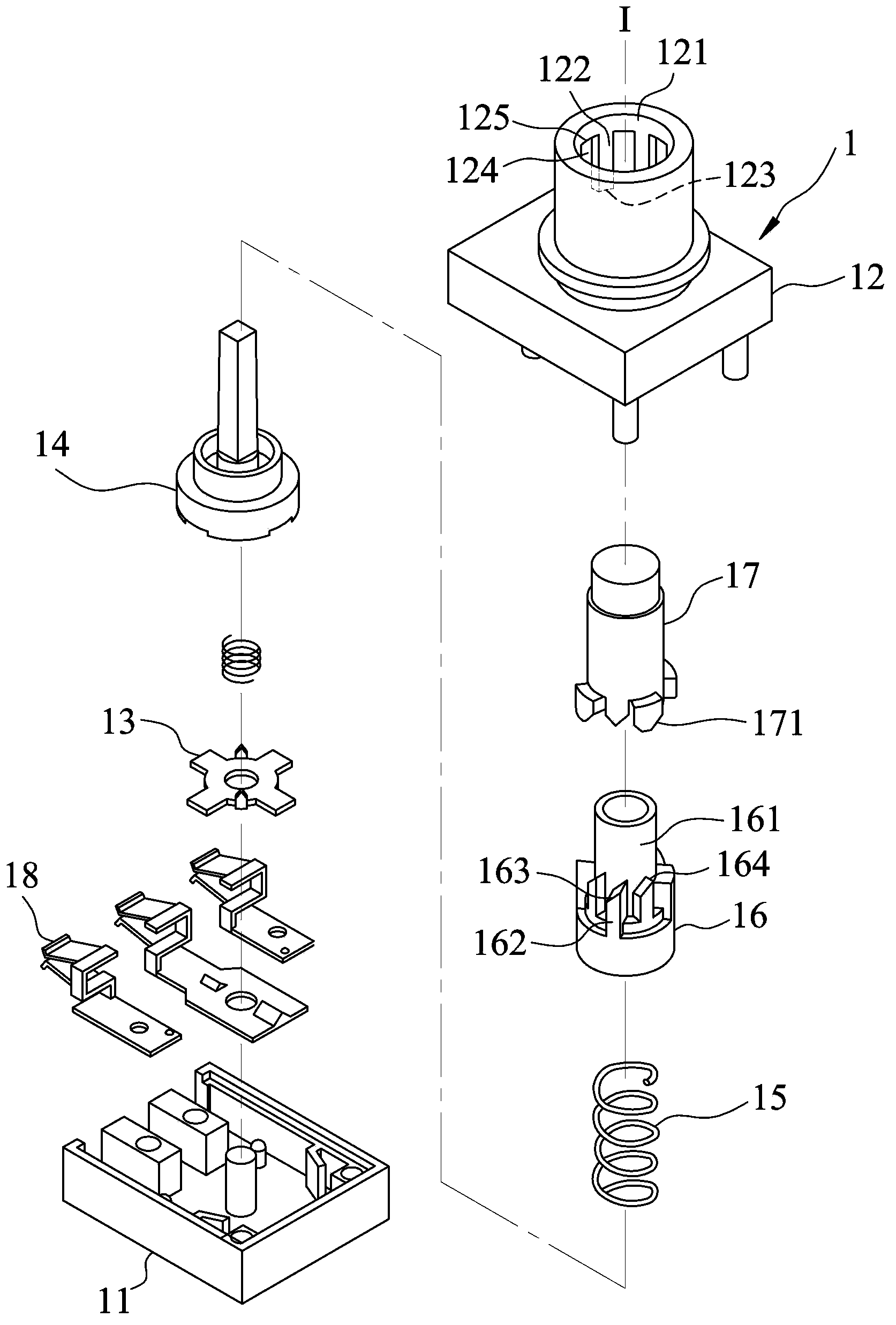

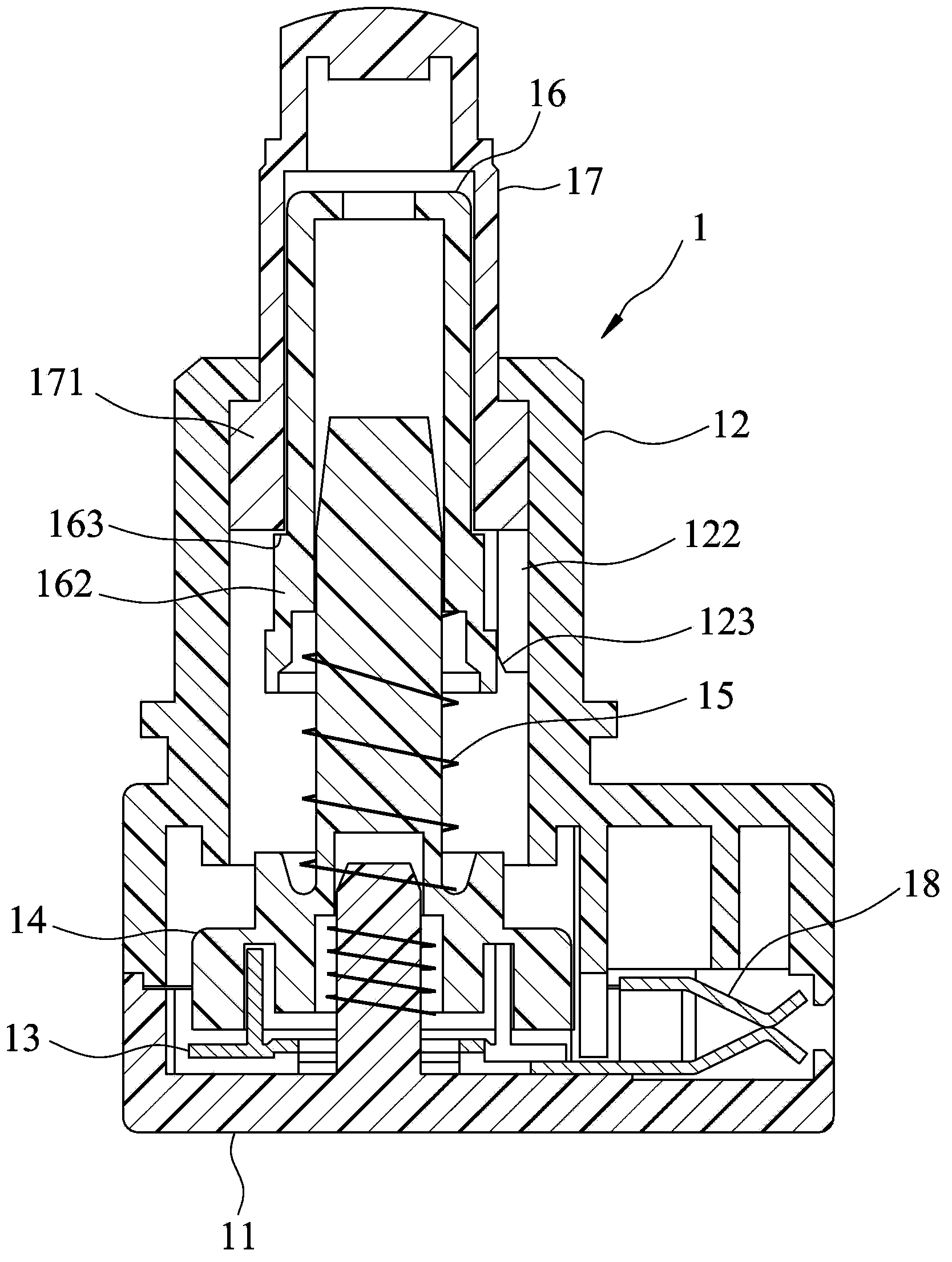

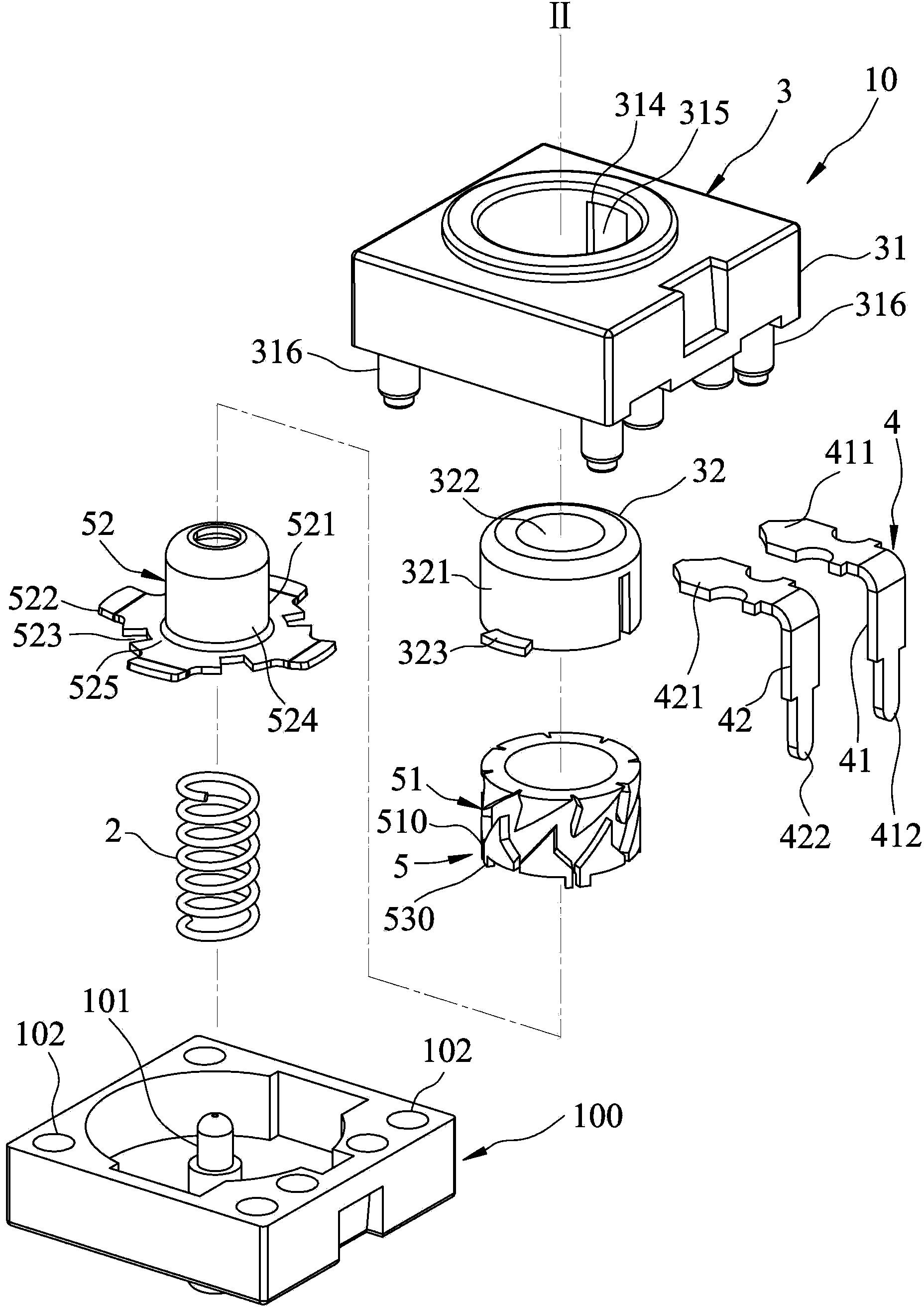

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0036] refer to image 3 , Figure 4 and Figure 6 , a preferred embodiment of the push switch 10 of the present invention is suitable for being installed on a base 100, and includes an elastic element 2 arranged on the base 100, and a cover unit 3 correspondingly engaged with the base 100 , an electrical connection unit 4 positioned between the cover unit 3 and the base 100 , and a movable mechanism 5 installed between the elastic element 2 and the cover unit 3 .

[0037] The elastic element 2 is arranged on the base 100 along an axis II. In this embodiment, the elastic element 2 is a spring, and the base 100 is an independent element designed to be correspondingly combined with the housing unit 3, and has an upward protrusion along the axis II for the The elastic element 2 is sleeved and positioned on the pillar 101 , and a plurality of installa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com