A push-card assembly structure for a horizontal relay

A technology of assembling structure and pushing card, applied in relays, electromagnetic relays, detailed information of electromagnetic relays, etc., can solve the problems of too much plastic dander, too frequent contact matching, long contact matching time, etc., to achieve reliable support effect and reduce contact Fit opportunity and contact fit time, and the effect of reducing the contact friction area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

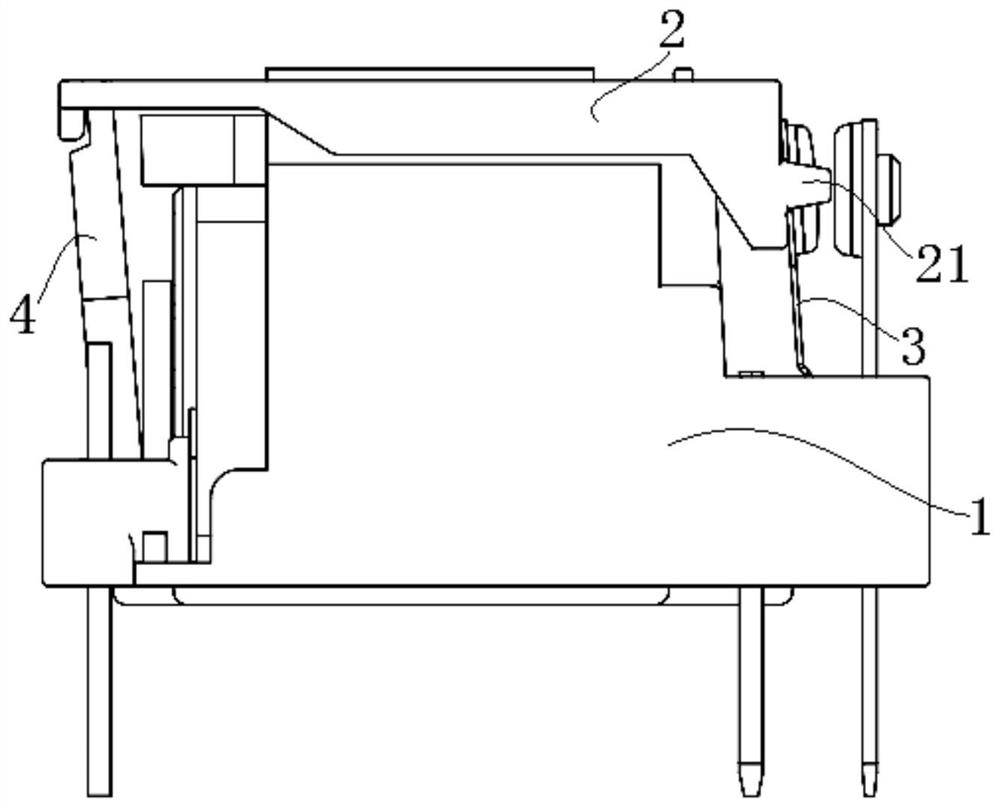

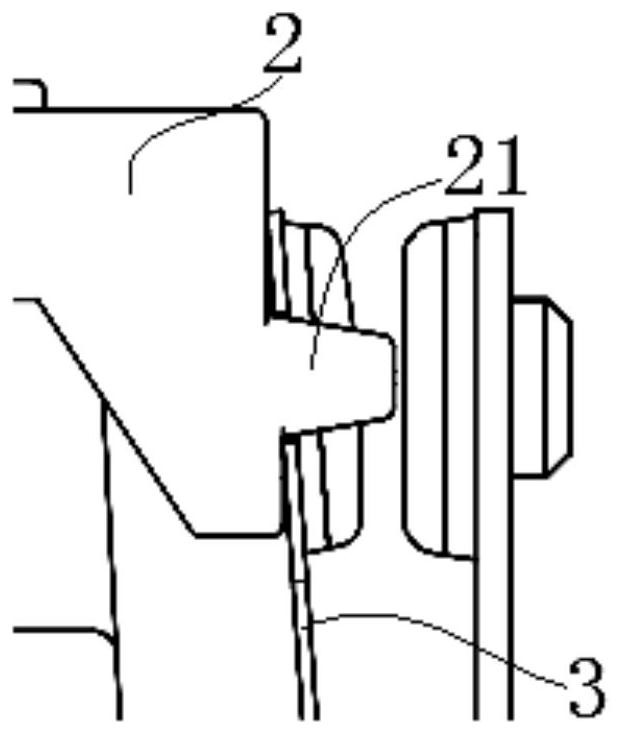

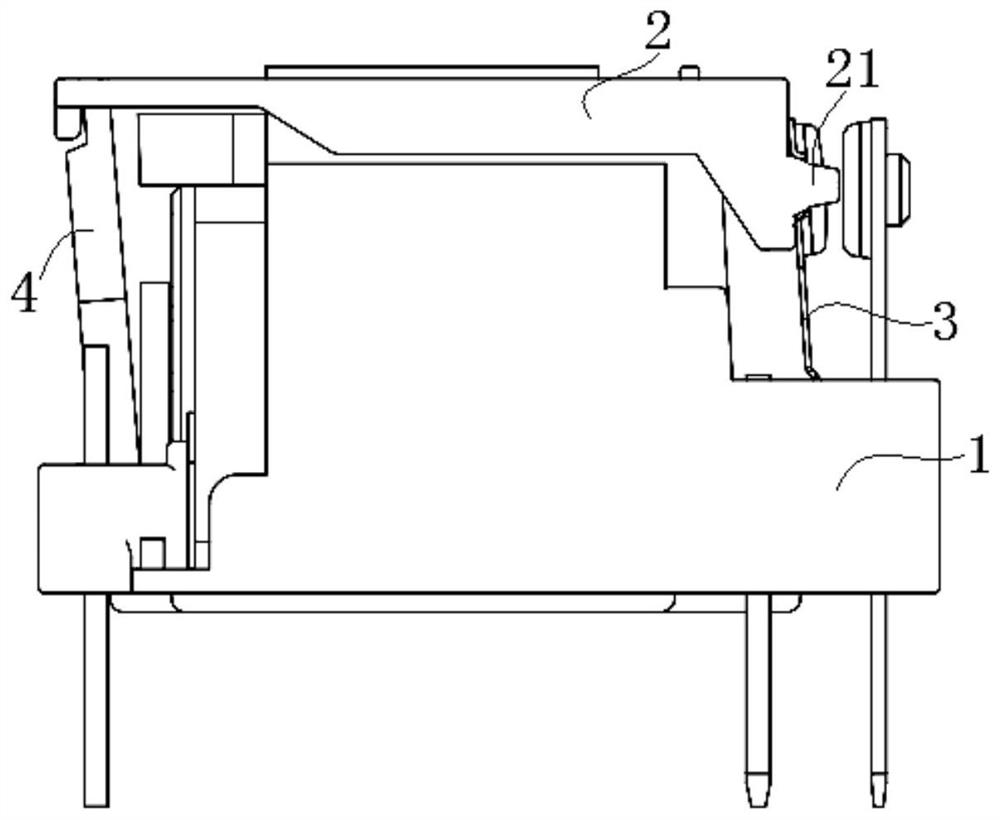

[0030] see image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 As shown, the present invention is a push card assembly structure of a horizontal magnetic circuit relay, which includes a base 1 , a push card 2 and a moving reed 3 .

[0031] Specifically, based on the structural particularity of the horizontal magnetic circuit relay, the coil frame is mounted on the base 1 horizontally, and both sides of the base 1 in the width direction have enclosure plates 11 that protrude upward from both sides of the coil frame in the diameter direction. The base 1 may be an integrally formed structure with the coil frame, or may be a separate assembly structure.

[0032] Corresponding to the length directions of both ends of the coil former, the base 1 at one end of the coil former is equipped with a movable spring plate 3 , and the base 1 at the other end is equipped with an armature 4 . There are concave and notch-shaped moving spring in...

Embodiment 2

[0043] The present invention is a push card assembly structure of a horizontal magnetic circuit relay, which includes a base, a push card and a moving reed.

[0044] Specifically, based on the structural particularity of the horizontal magnetic circuit relay, the coil frame is horizontally assembled on the base, and both sides in the width direction of the base have enclosure plates that protrude upward from both sides of the coil frame in the diameter direction. The base may be an integrally formed structure with the coil frame, or may be a separate assembly structure.

[0045] Corresponding to the length directions of both ends of the coil frame, the base at one end of the coil frame is equipped with a movable spring plate, and the base at the other end is equipped with an armature. There are concave and notch-shaped moving spring insertion holes on the vertical sides of the upper width direction of the upper part of the moving reed, and each moving spring insertion hole has...

Embodiment 3

[0056] The present invention is a push card assembly structure of a horizontal magnetic circuit relay, which includes a base, a push card and a moving reed.

[0057] Specifically, based on the structural particularity of the horizontal magnetic circuit relay, the coil frame is horizontally assembled on the base, and both sides in the width direction of the base have enclosure plates that protrude upward from both sides of the coil frame in the diameter direction. The base may be an integrally formed structure with the coil frame, or may be a separate assembly structure.

[0058] Corresponding to the length directions of both ends of the coil frame, the base at one end of the coil frame is equipped with a movable spring plate, and the base at the other end is equipped with an armature. There are concave and notch-shaped moving spring insertion holes on the vertical sides of the upper width direction of the upper part of the moving reed, and each moving spring insertion hole has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com