Resonant spring support structure for reciprocating compressor

A support structure and compressor technology, which is applied in the direction of liquid variable capacity machinery, mechanical equipment, machine/engine, etc., can solve the problems of difficult adjustment of the rear resonance spring and high manufacturing cost, and achieve easy setting, simple installation engineering, The effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The resonant spring support structure of the reciprocating compressor of the present invention will be described with reference to the drawings and embodiments.

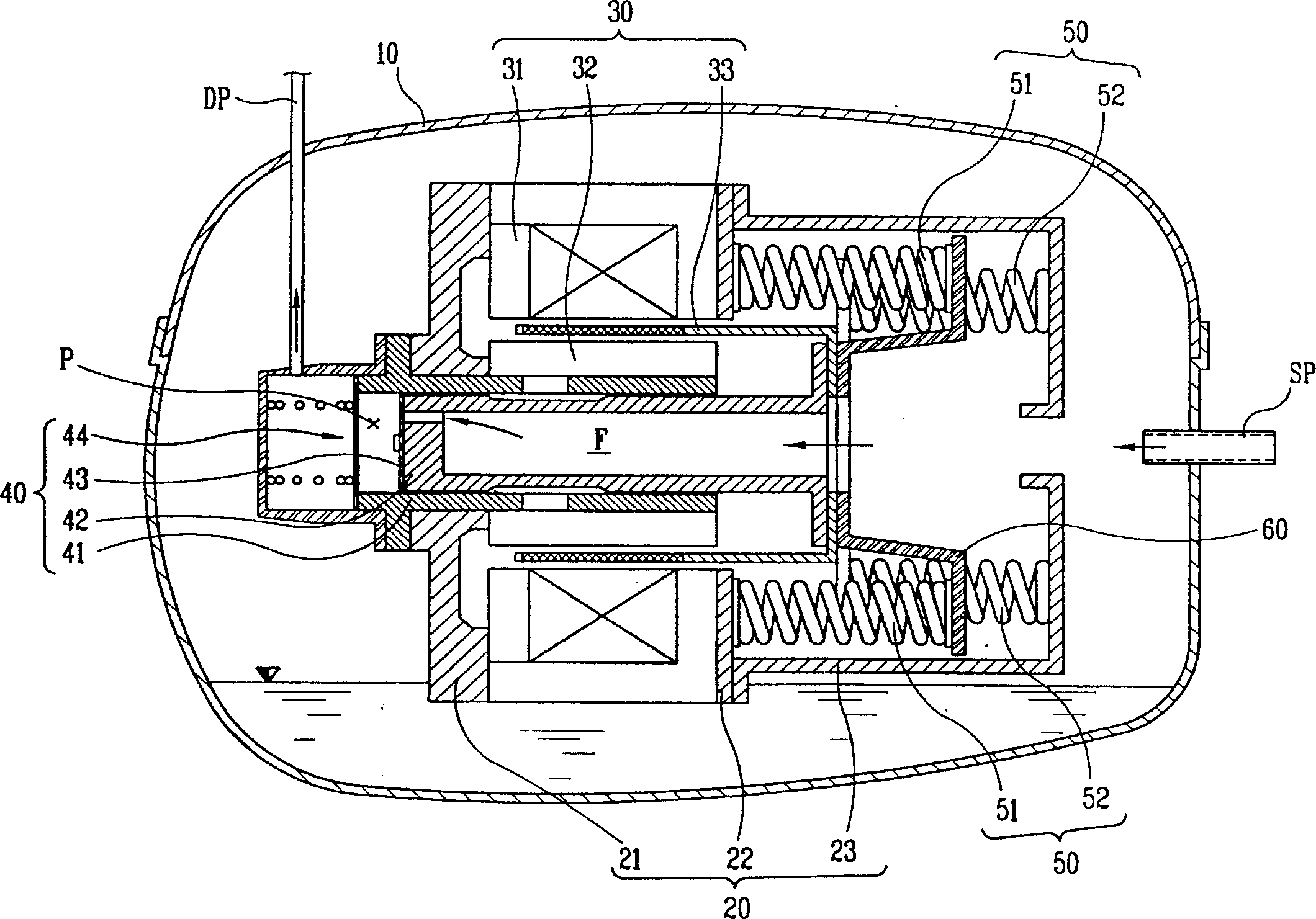

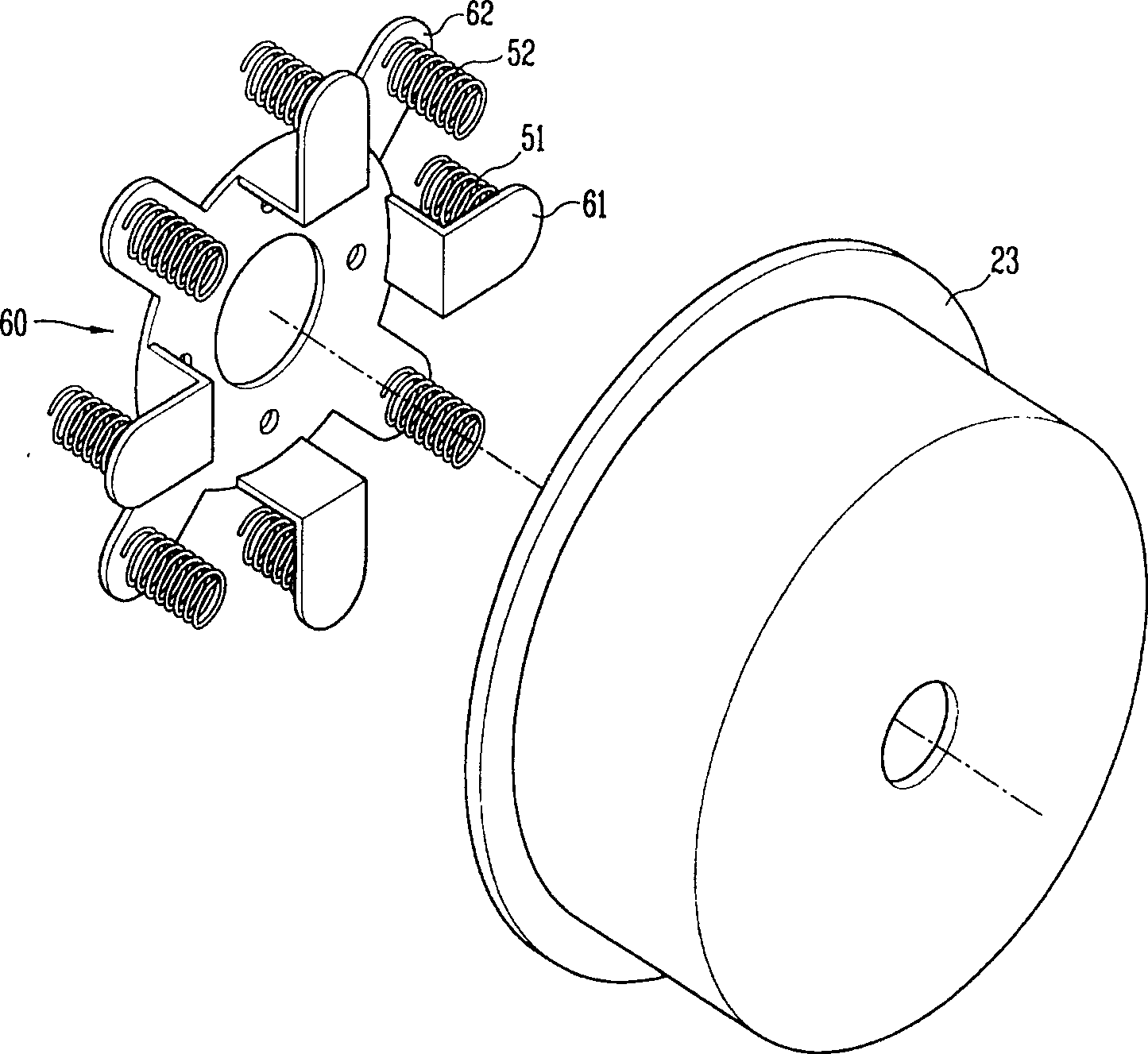

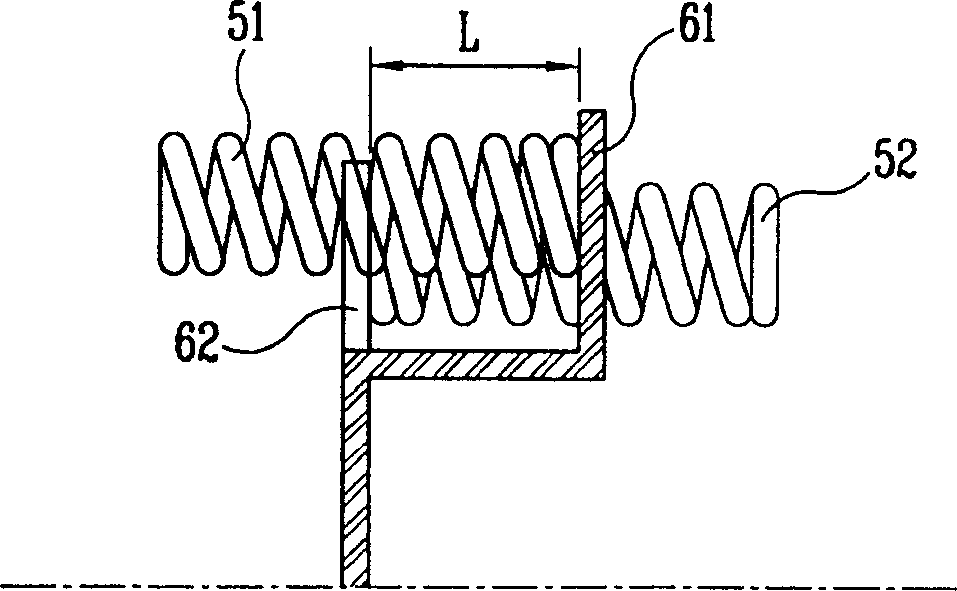

[0033] Figure 4 It is a vertical cross-sectional view of the internal structure of the reciprocating compressor provided with the resonant spring support structure according to the embodiment of the present invention. Figure 5 yes Figure 4 A perspective view of a co-resonant spring-supported structure. Figure 6 yes Figure 4 Schematic diagram of the mid-section resonant spring-supported structure. As shown in the figure, the embodiment of the present invention, that is, the reciprocating compressor includes a bracket system elastically supported inside the shell 10, a reciprocating motor 30 fixed on the bracket system and generating driving force in a straight line, supported by the bracket system The compression system 40 that inhales and compresses the fluid and is connected between the bracket syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com