Sealing structure of grate cooler

A technology of sealing structure and grate cooler, which is applied in the field of cement machinery and equipment, can solve the problems of device loss, large friction area, and easy loss, and achieve the effects of good sealing, avoiding friction loss, and avoiding blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

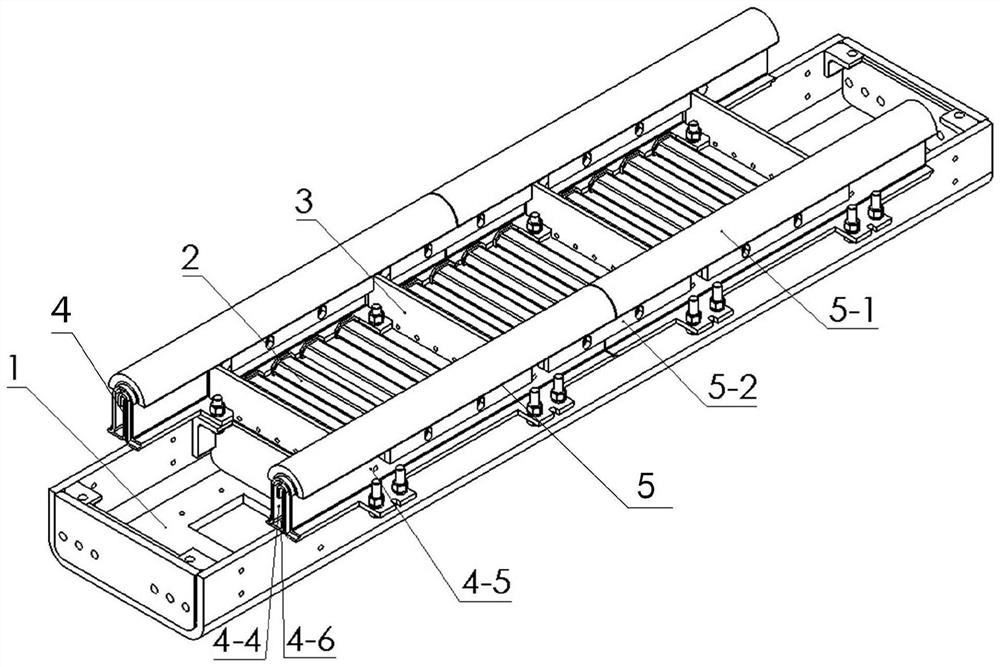

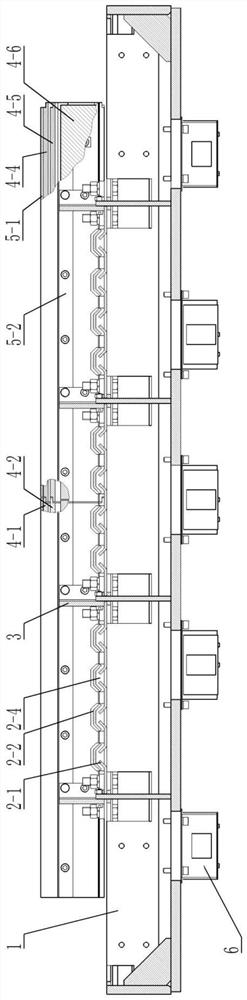

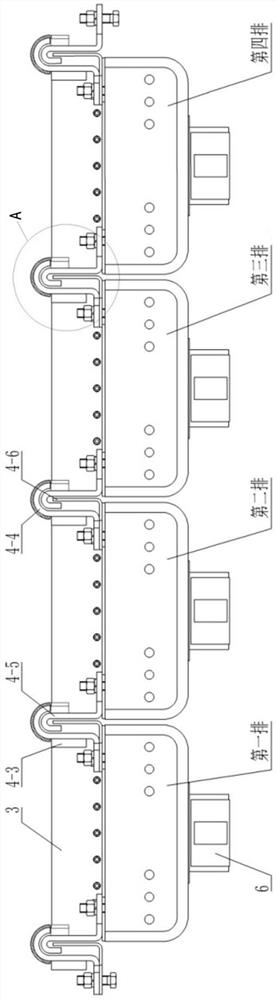

[0047] like Figure 1 to Figure 12 As shown, the sealing structure of a grate cooler of the present invention greatly reduces the contact friction area between the device and the hot clinker through the optimization of the structure, reduces the reverse friction to the concave sealing plate, and greatly reduces the friction At the same time, it also improves the sealing performance of the equipment.

[0048] The invention can arbitrarily increase the width and length of the equipment according to the needs. Increasing the number of sealing modules horizontally means increasing the width of the equipment, and increasing the number of sealing modules in each row vertically means increasing the length of the equipment. Each sealing module includes a segment beam 1, a grate plate 2, a baffle plate 3, a relative sliding mechanism 4, an anti-wear and leak-proof system 5 and a ventilation valve 6, wherein the segment beam 1 includes a baffle plate 1-1, a ventilation port 1 -2 and an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com