Saw blade matrix pressure quenching device and quenching process thereof

A saw blade and matrix technology, applied in the field of new processing technology and auxiliary devices, can solve problems such as flatness not meeting technical requirements, difficult to meet technical requirements, saw blade matrix fracturing, etc., to reduce the influence of tissue stress and uniformity And the effect of good consistency and elimination of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

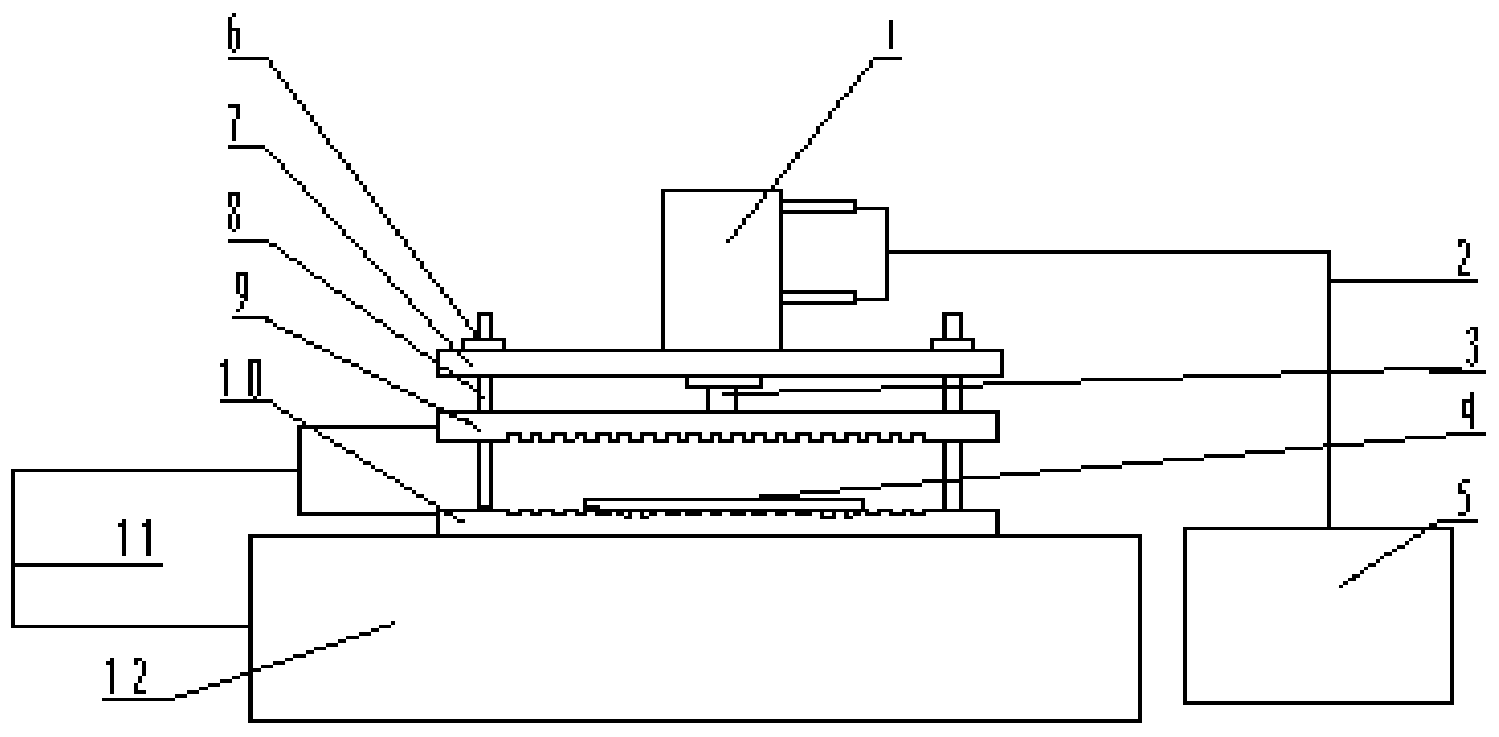

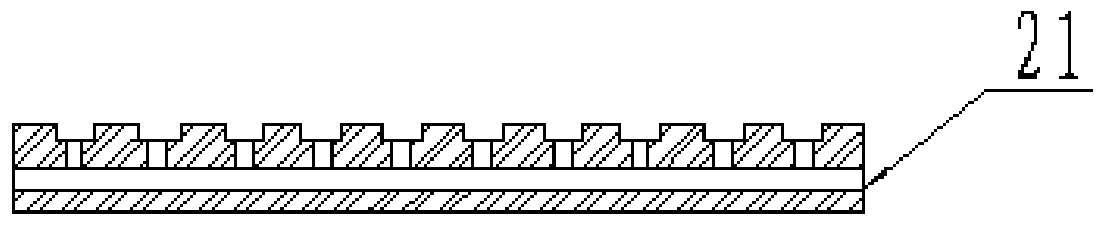

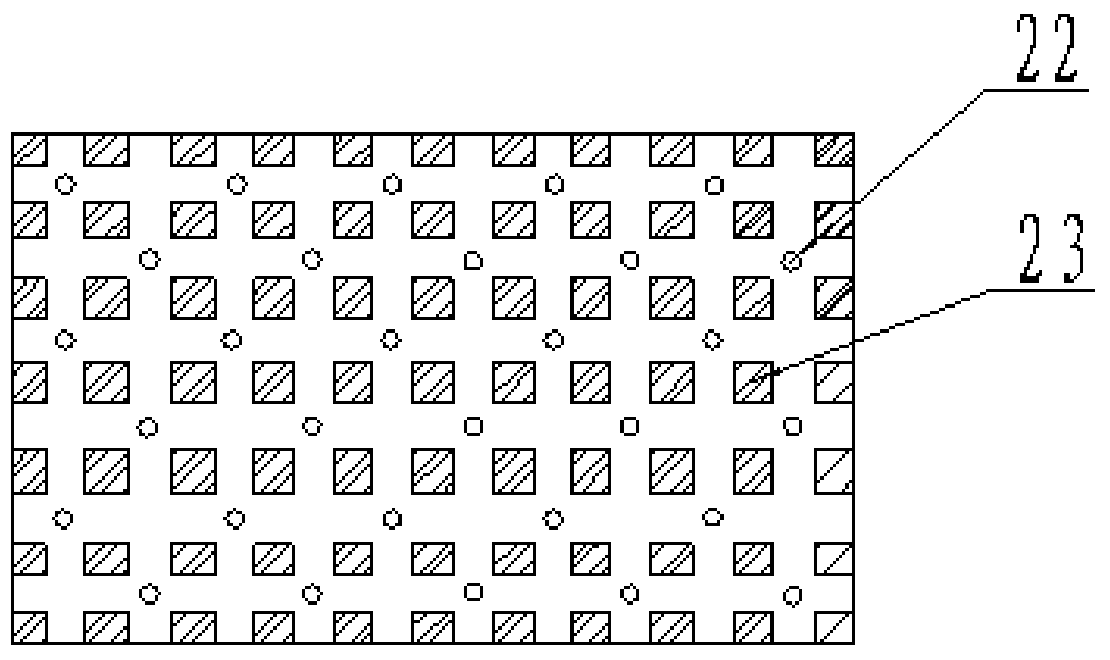

[0033] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 .

[0034] The saw blade substrate press quenching device of the present invention includes a hydraulic cylinder 1, a hydraulic control circuit system 2, a hydraulic cylinder and an upper platen connection device 3, a saw blade substrate (that is, a workpiece) 4, a hydraulic oil tank 5, an upper fixing frame 7, a guide Column 8, upper platen 9, lower platen 10, quenching oil control circuit system 11 and quenching oil tank 12; hydraulic cylinder 1 is installed on upper fixed frame 7, said hydraulic cylinder 1, upper fixed frame 7, upper platen 9, lower platen 10 and the quenching oil tank 12 are sequentially adjacent from top to bottom, the lower platen 10 is fixed above the quenching oil tank 12, and the four cylindrical guide pillars 8 are four cylindrical guide pillars an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com