Internal circulation oil cylinder having built in logic valve

A logic valve and internal circulation technology, applied in the field of hydraulic cylinders, can solve the problems of reducing oil quality, consuming pressure oil energy, affecting hydraulic systems, etc., achieving the effects of compact structure, faster cylinder travel, and avoiding oil temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

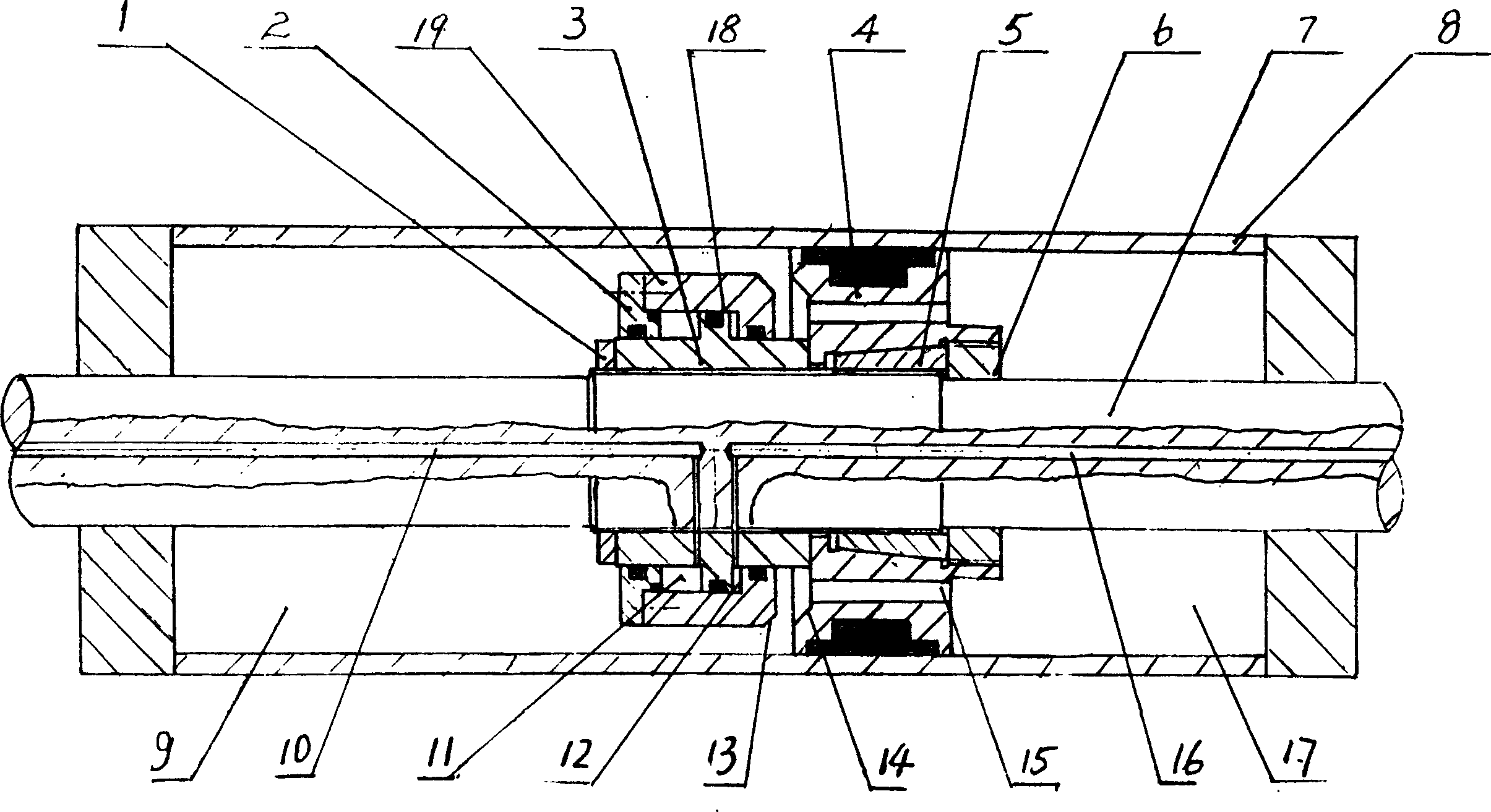

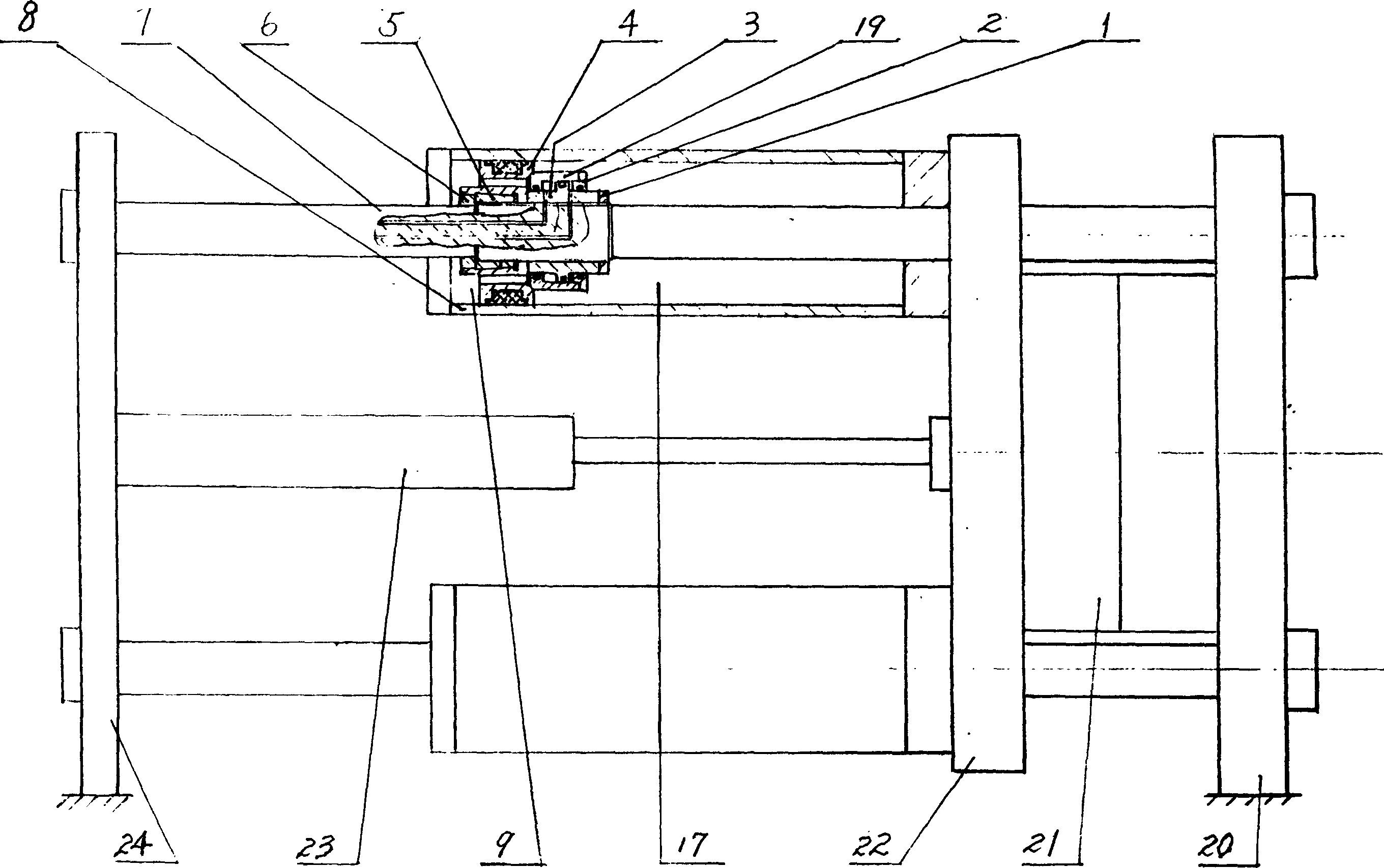

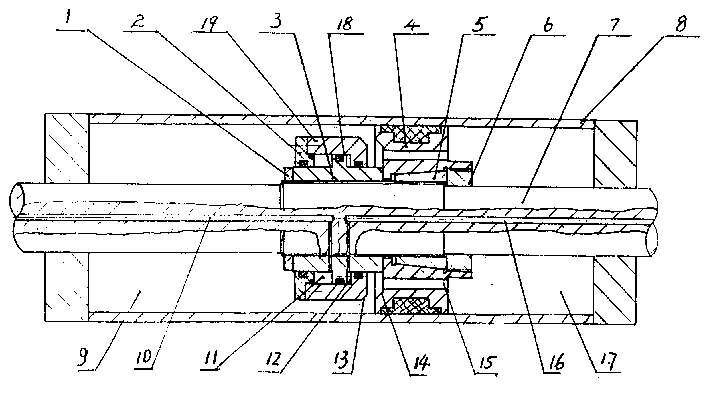

[0010] Such as figure 1 As shown, the present invention is made up of piston rod, oil cylinder, piston and logic valve, and piston 4 has axial channel 15, and piston 4 is fastened on piston rod 7 with taper sleeve 5 and self-locking nut 6, and in oil cylinder 8, is enclosed by piston 4 is divided into two oil chambers, oil chamber 9 and oil chamber 7, and the two oil chambers can communicate through the axial passage 15. The logic valve installed on the side of the piston 4 and fastened to the piston rod 7 is composed of the valve cover 2, the valve The seat 3 and the valve sleeve 19 are composed of the valve seat 3, which is threadedly connected to the piston rod 7, and positioned by the piston 4, and the nut 1 is locked, and the valve cover 2 is tightly connected with the valve sleeve 19 and moves with the valve seat 3 to form a logic The control oil chamber of the valve, the control oil chamber is divided into two control oil chambers by the pillow block 18 set on the valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com