Energy-saving automatic alloy bar thermal peeling machine

An alloy rod and energy-saving technology, which is applied in the field of energy-saving automatic alloy rod hot peeling machines, can solve the problems of large energy consumption of the peeling machine, and achieve the effects of improving stability, saving energy and reducing oil temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

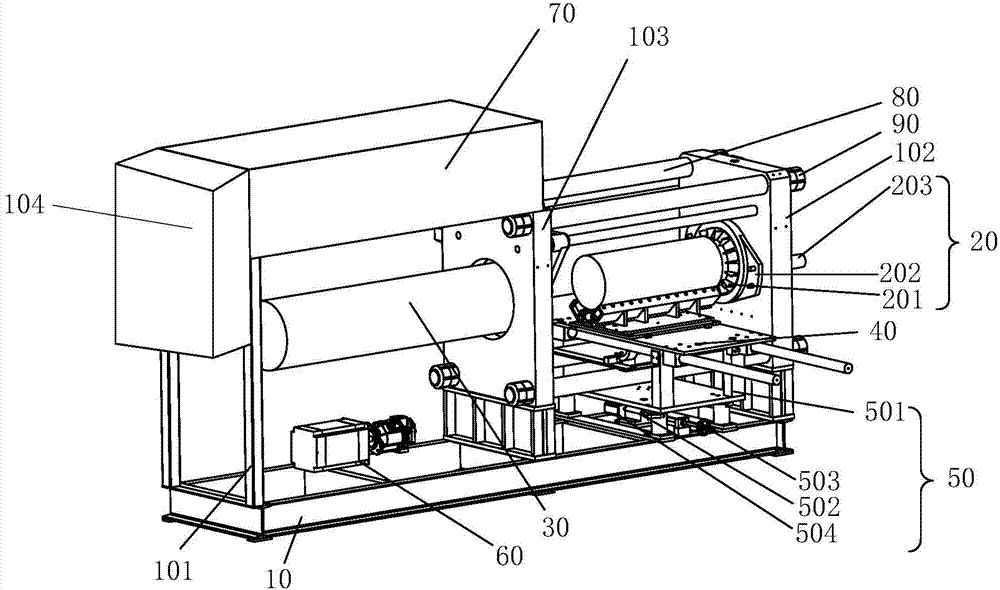

[0018] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that all the drawings of the present invention are in simplified form and use inaccurate scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

[0019] Such as figure 1 As shown, the energy-saving automatic alloy rod thermal peeling machine of the present invention includes: a base 10, a bracket 101 installed in parallel on the base 10, a front beam 102, and a rear beam 103, which are arranged on the front and rear beams 102, The peeling mechanism 20 between 103, the extruder 30 corresponding to the position of the peeling mechanism 20, the feeding mechanism 40 installed below the peeling mechanism 20, and the adjusting mechanism 50 arranged bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com