Processing technology of spicy peanuts

A processing technology, peanut technology, applied in the field of spicy peanut processing technology, can solve the problem of poor taste of the product, and achieve the effect of long shelf life, extended shelf life and attractive color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

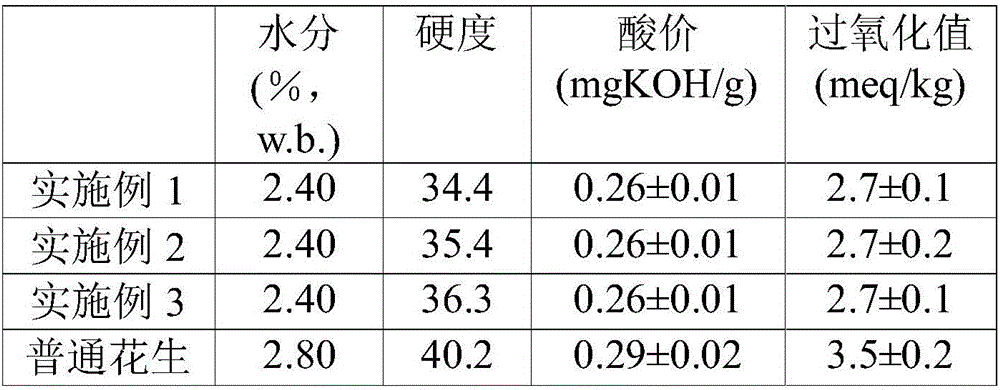

Embodiment 1

[0035] A kind of spicy peanut processing technology, selects 50kg of red-coated peanut kernels, specifically comprises the following steps:

[0036]Before soaking peanuts, select the accepted peanut raw materials, sort out moldy kernels, frozen kernels, spotted kernels, bud kernels and impurities on the conveyor belt, and put the selected peanuts into a dipping machine at 95°C for 150s; The soaked peanut kernels are sent to the peeling machine by the conveyor belt for peeling; the red-coated kernels, moldy kernels, frozen kernels, spotted kernels, bud kernels and impurities are sorted out on the conveyor belt; the peeled peanut kernels are sent to Put it into the seasoning machine, the seasoning machine adds pickling seasoning consisting of 500g of salt, 500g of monosodium glutamate, and 0.5g of stevioside. The seasoning time is 8min, and then it is sent to the pickling machine for 2.5h; Send it to the drying belt evenly through the grading belt, and dry it until the moisture ...

Embodiment 2

[0038] A kind of spicy peanut processing technology, selects 50kg of red-coated peanut kernels, specifically comprises the following steps:

[0039] Before soaking peanuts, select the accepted peanut raw materials, sort out moldy kernels, frozen kernels, spotted kernels, bud kernels and impurities on the conveyor belt, and put the selected peanuts into a dipping machine at 95°C for 160s; The soaked peanut kernels are sent to the peeling machine by the conveyor belt for peeling; the red-coated kernels, moldy kernels, frozen kernels, spotted kernels, bud kernels and impurities are sorted out on the conveyor belt; the peeled peanut kernels are sent to Put it into the seasoning machine to taste, add the pickling seasoning composed of 600g of salt, 600g of monosodium glutamate, and 0.7g of stevia into the seasoning machine, seasoning time is 9min, and then send it into the pickling machine for pickling, the time is 2.5h; The peanut kernels are evenly sent to the drying belt through...

Embodiment 3

[0041] A kind of spicy peanut processing technology, selects 50kg of red-coated peanut kernels, specifically comprises the following steps:

[0042] Before soaking the peanuts, sort the accepted peanut raw materials, pick out moldy kernels, frozen kernels, spotted kernels, bud kernels and impurities on the conveyor belt, and put the selected peanuts into the dipping machine at 95°C for 180s; The soaked peanut kernels are sent to the peeling machine by the conveyor belt for peeling; the red-coated kernels, moldy kernels, frozen kernels, spotted kernels, bud kernels and impurities are sorted out on the conveyor belt; the peeled peanut kernels are sent to Put it into the seasoning machine to taste, add salt 750g, monosodium glutamate 700g, stevioside 0.8g pickling seasoning into the seasoning machine, seasoning time is 10min, then send it into the pickling machine for pickling, time is 3h; The kernels are evenly sent to the drying belt by the grading belt, and dried until the moi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com