Electro-hydraulic control system for concrete or coal slime conveying device and method for controlling system

A technology of electro-hydraulic control system and delivery device, which is applied in the direction of fluid pressure actuation device, fluid pressure actuation system components, mechanical equipment, etc. Leakage and other problems, to achieve the effect of low manufacturing and maintenance costs, long service life and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

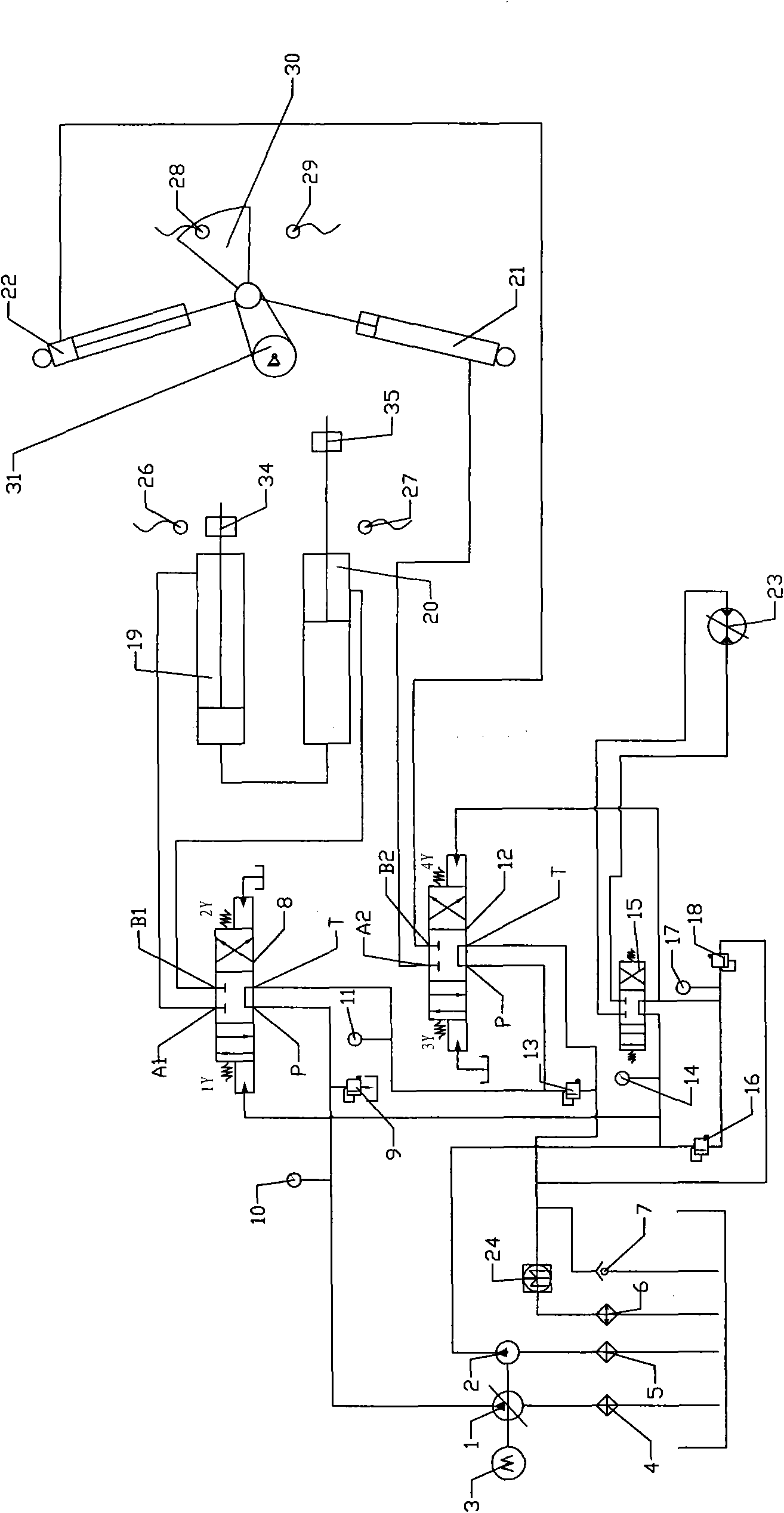

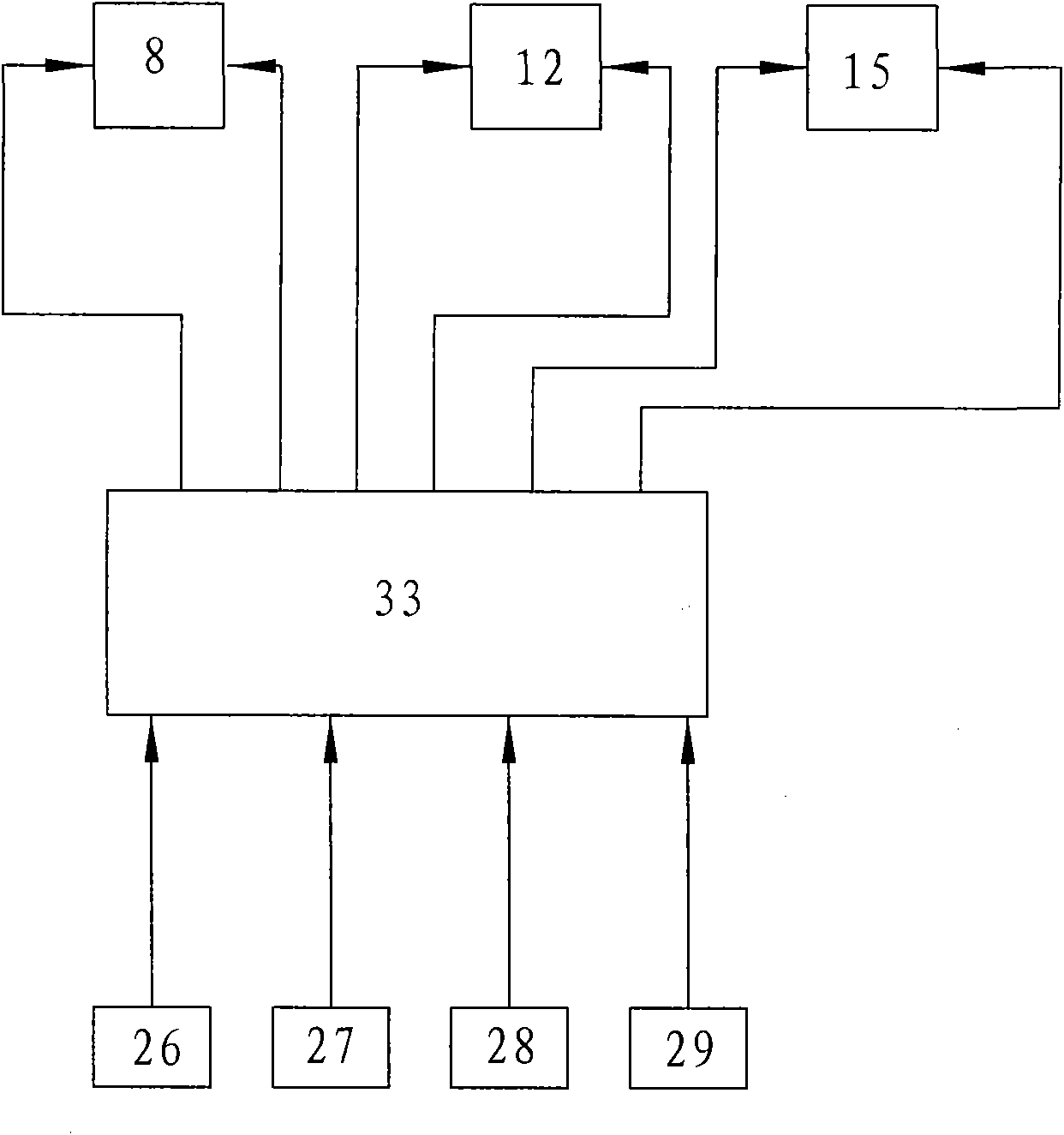

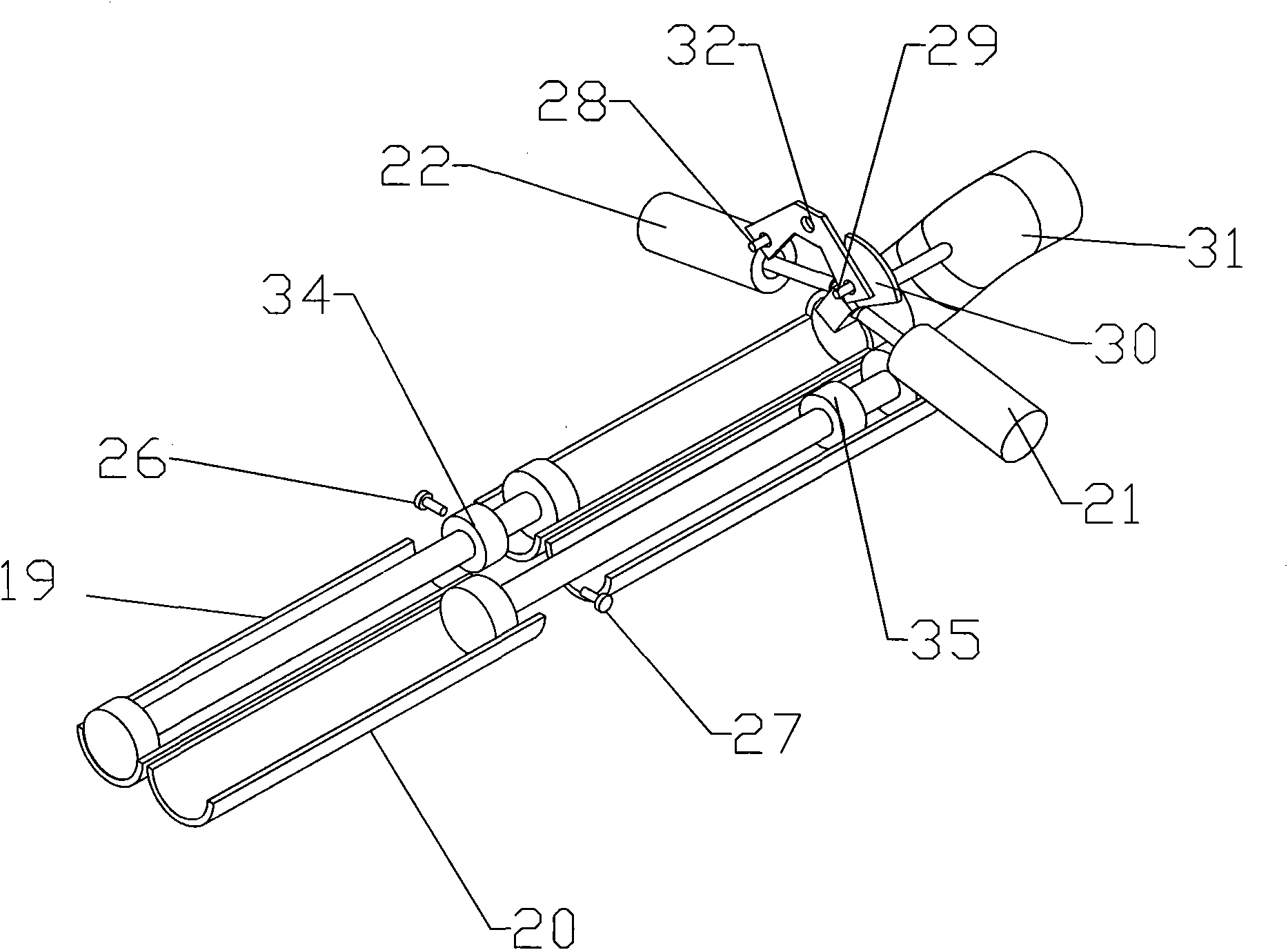

[0020] Such as Figure 1~2 As shown, an electro-hydraulic control system applied to a concrete or coal slime conveying device and a method for controlling the system include a main hydraulic pump 1, an auxiliary hydraulic pump 2, and a power device that drives the main hydraulic pump 1 and the auxiliary hydraulic pump 2 to work 3. The unloading overflow valve 9 for setting the pumping pressure, the unloading overflow valve 13 for setting the swing pressure, the first pumping cylinder 19 and the second pumping cylinder 20 for pushing concrete, It is used to connect to the swing S pipe 31 of the discharge port of the aforementioned two pumping cylinders, and is used to drive the swing cylinders 21 and 22 of the swing S pipe 31 to swing; the swing S pipe 31 is provided with a fan-shaped block 30 that can swing with it , the delivery device is provided with the first and second sensors 28 and 29 for detecting the position of the swing S pipe 31, the third and fourth sensors 26 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com