Multifunctional hydraulic power station

A hydraulic power station, multi-functional technology, applied in the direction of fluid pressure actuation device, fluid pressure actuation system components, energy industry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Embodiment A kind of novel hydraulic power station

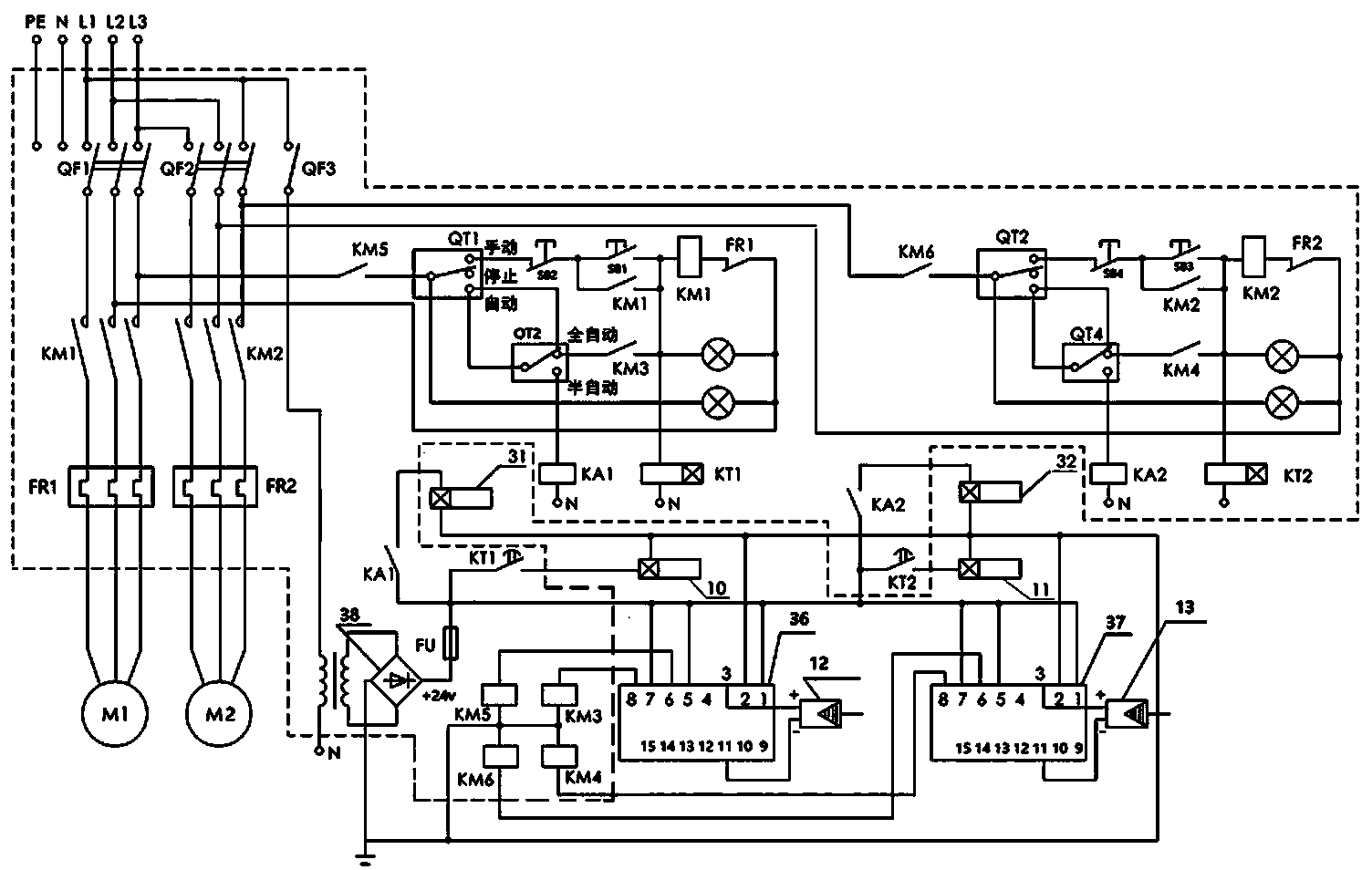

[0068] Present embodiment completes by the design of two accompanying drawings:

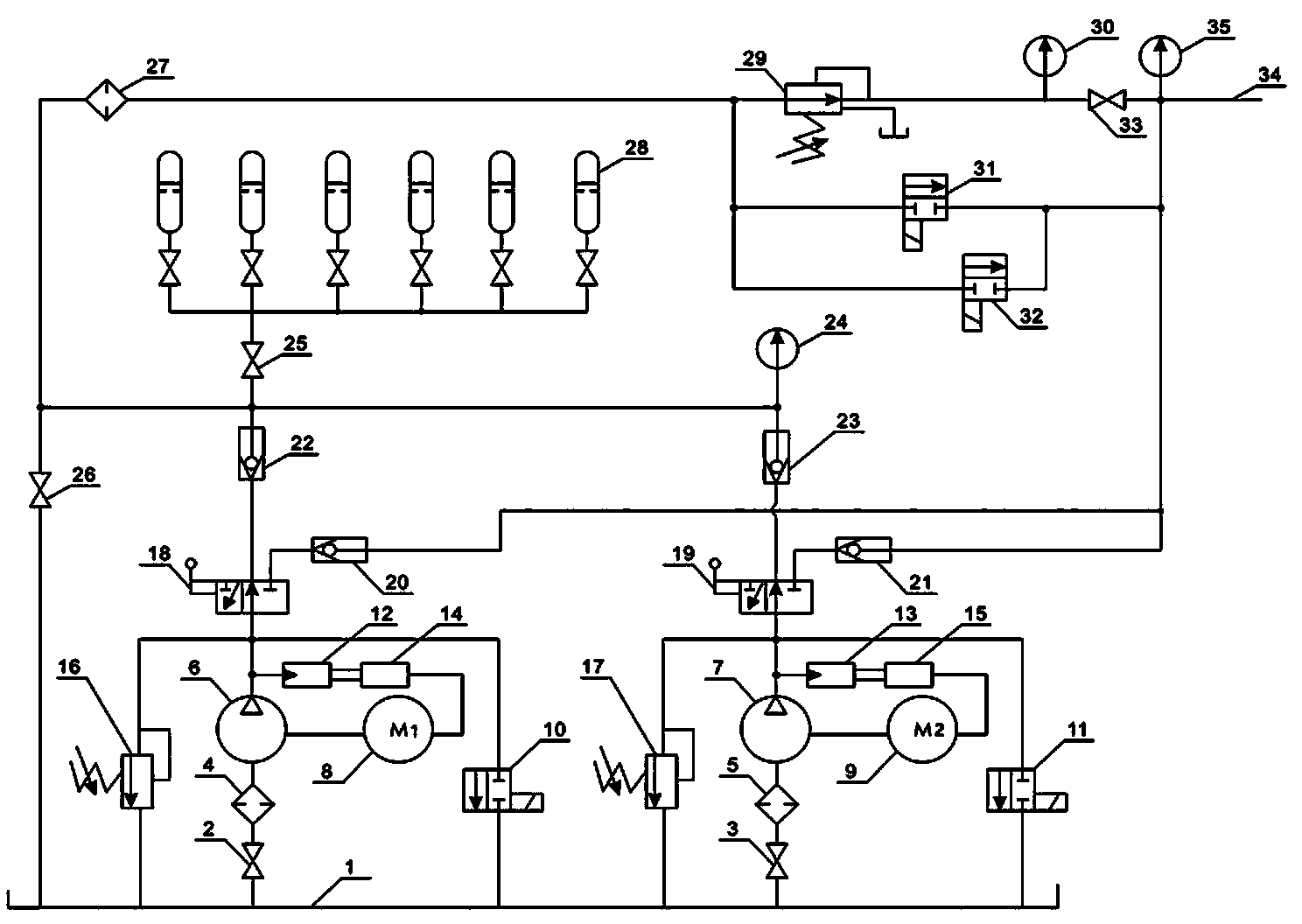

[0069] figure 1 Shows the structure and hydraulic working principle of the hydraulic power station of this embodiment

[0070] Such as figure 1 shown : 1 is oil tank, 2 and 3 are low-pressure ball valves, 4 and 5 are low-pressure filters, 6 and 7 are plunger pumps, 8 is motor M1 (explosion-proof), 9 is motor M2 (explosion-proof), 10 and 11 are normally open Solenoid valves, 12 and 13 are electronic pressure transmitters, 14 and 15 are explosion-proof electric control boxes, 16 and 17 are overflow valves, 18 and 19 are manual reversing valves, 20, 21, 22, 23 are check valves ,, 25, 26 and 33 are cut-off valves, 27 is a high-pressure filter, 28 is an accumulator, 29 is a manual decompression and pressure relief valve, 31 and 32 are normally closed solenoid valves, 24, 30 and 35 are Pressure gauge, 34 is high-pressure oil output ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com