A kind of nano-fuel additive and preparation method thereof

An additive and fuel technology, applied in the field of materials, can solve the problem of not seeing nano silver and its alloys, and achieve the effects of ensuring dissolution stability, promoting combustion, and good catalytic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

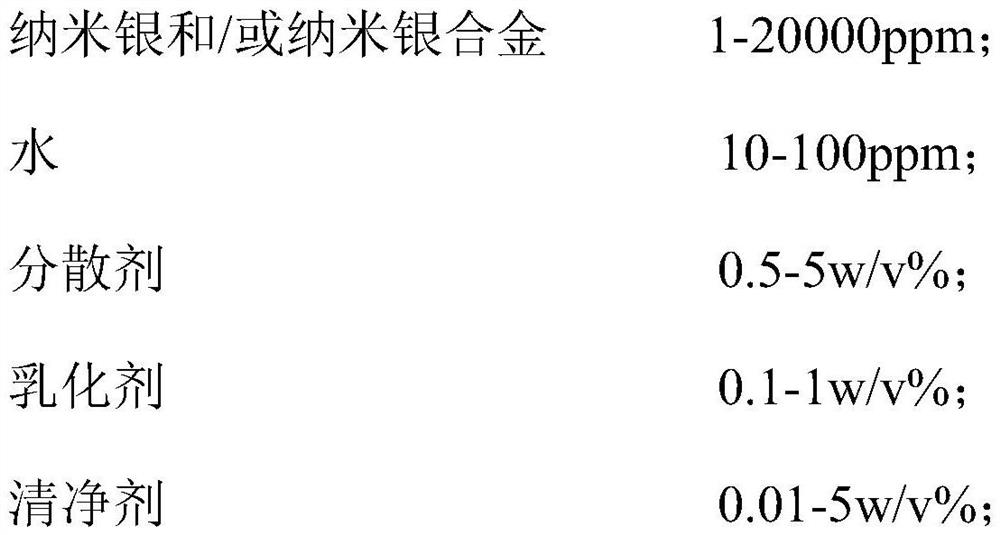

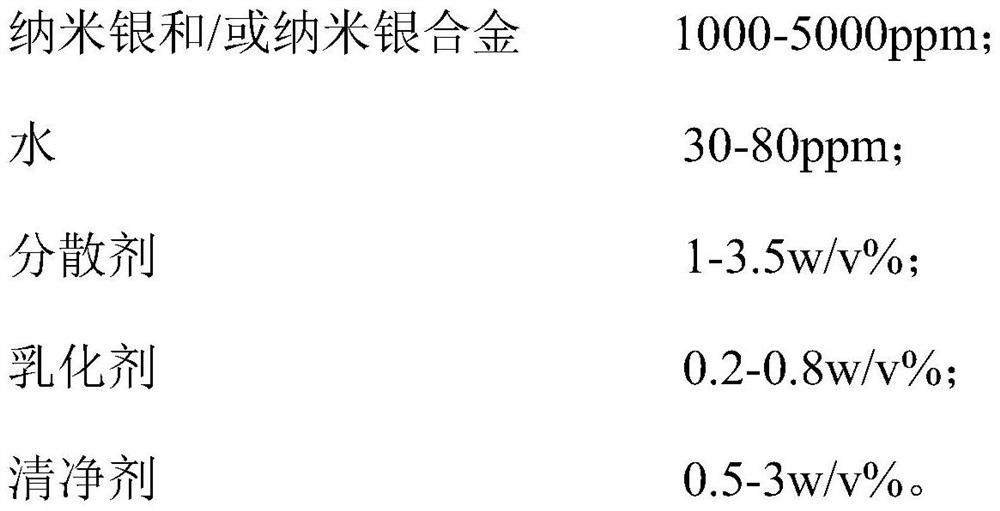

Method used

Image

Examples

Embodiment 1

[0047] 1. Preparation of nano-fuel additives

[0048] (1) Measure 100L of ethanol, add it to the reaction kettle, and heat it in a water bath to 60°C to condense and reflux;

[0049] (2) Weigh 4kg Span60 into the reactor, stir to dissolve; weigh 1kg of sodium dodecylbenzenesulfonate, add to the reactor, stir to dissolve;

[0050] (3) Take by weighing 3.4kg silver nitrate, dissolve in 5L deionized water, obtain an aqueous solution, slowly add the aqueous solution in the reaction kettle, stir and mix evenly;

[0051] (4) Take by weighing 1kg sodium dodecylbenzenesulfonate, dissolve in 5L deionized water, then add 1kg sodium borohydride, stir and dissolve to obtain reducing agent solution;

[0052] (5) Slowly drop the reducing agent solution described in step (4) into the reaction kettle through a peristaltic pump, and after the dropwise addition, continue to stir and react for 60 minutes;

[0053] (6) Stand still, cool to room temperature, pour out the supernatant, separate th...

Embodiment 2

[0063] 1. Preparation of nano-fuel additives

[0064] (1) Measure 90L of ethanol, add it to the reaction kettle, and heat it in a water bath to 70°C to condense and reflux;

[0065] (2) Take by weighing 4kg oleic acid and add it to the reaction kettle, stir and dissolve; take by weighing 1kg sodium lauryl sulfate, add it to the reaction kettle, stir and dissolve;

[0066] (3) Take by weighing 1.56kg silver sulfate, be dissolved in 2.5L deionized water, obtain aqueous solution, slowly add described aqueous solution in reactor, stir and mix; Take by weighing 1.45kg nickel nitrate, be dissolved in 2.5L deionized water, To obtain an aqueous solution, slowly add the aqueous solution into the reaction kettle, stir and mix evenly;

[0067] (4) Take by weighing 1kg sodium dodecylbenzenesulfonate, dissolve it in 5L deionized water, then add 1kg vitamin C, stir and dissolve to obtain a reducing agent solution;

[0068] (5) Slowly drop the reducing agent solution described in step (4) ...

Embodiment 3

[0077] 1. Preparation of nano-fuel additives

[0078] (1) Measure 95L of ethanol, add it to the reaction kettle, and heat it in a water bath to 55°C to condense and reflux;

[0079] (2) Take 4kg of lecithin and add it to the reactor, stir and dissolve; weigh 1kg of sodium polyacrylate PAA, add it to the reactor, stir and dissolve;

[0080] (3) Take by weighing 1.7kg silver nitrate, be dissolved in 2.5L deionized water, obtain aqueous solution, slowly add described aqueous solution in the reactor, stir and mix evenly; Take by weighing 500g copper sulfate, be dissolved in 2.5L deionized water, obtain Aqueous solution, slowly adding the aqueous solution into the reaction kettle, stirring and mixing evenly;

[0081] (4) Weigh 1kg of PAA, dissolve it in 5L of deionized water, then add 135g of hydrazine hydrate, stir and dissolve to obtain a reducing agent solution;

[0082] (5) Slowly drop the reducing agent solution described in step (4) into the reaction kettle through a perist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com