Method for preparing soybean protein isolate with high solubility without soybean smell

A technology of soybean protein isolate and bean flavor, which is applied in the protein composition of vegetable seeds, plant protein processing, protein food ingredients, etc., and can solve the problems of low addition of soybean protein isolate, restrictions on the application of soybean protein isolate, and beverage precipitation, etc. , to achieve the effect of ensuring the stability of the solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

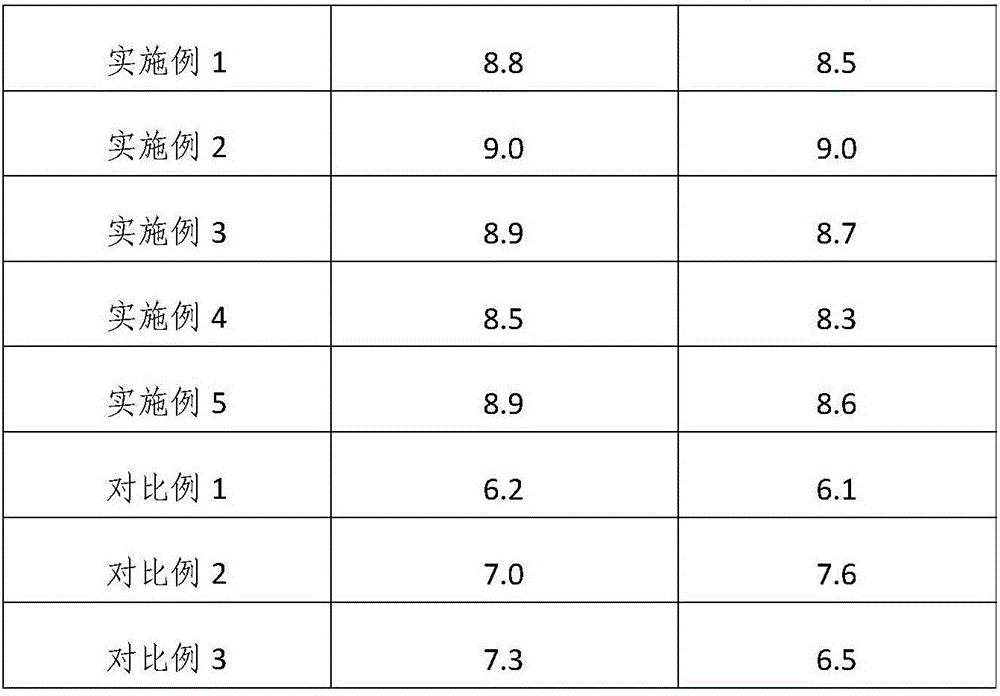

Examples

Embodiment 1

[0037] A method for preparing soybean protein isolate that improves solubility and eliminates beany smell, the specific steps are as follows:

[0038] (1) One-time extraction: mix low-temperature defatted soybean meal and water at a ratio of 1:12, water temperature is 20°C, adjust pH value to 6.5 with liquid NaOH, add 2.0‰ sodium isoVC, stir and extract at low speed for 60min, stirring speed 60-70r / min;

[0039] (2) Primary centrifugal separation: after the primary extraction is completed, the extract is centrifuged with a horizontal screw discharge centrifuge, the solid phase 1 enters the secondary extraction process, and the liquid phase 1 enters the acid precipitation process;

[0040] (3) Secondary extraction: add water 5 times the weight of the raw material to the solid phase 1 for secondary extraction, the water temperature is 20°C, the extraction is stirred at a low speed for 5 minutes, and the stirring speed is 60-70r / min;

[0041] (4) Secondary centrifugation: After...

Embodiment 2

[0051] A method for preparing soybean protein isolate that improves solubility and eliminates beany smell, the specific steps are as follows:

[0052] (1) Primary extraction: mix low-temperature defatted soybean meal with water at a ratio of 1:16, water temperature is 20°C, adjust pH value to 6.5 with liquid NaOH, add 2.0‰ of L-cysteine, stir and extract at low speed for 30-60min, Stirring speed 60-70r / min;

[0053] (2) Primary centrifugal separation: after the primary extraction is completed, the extract is centrifuged with a horizontal screw discharge centrifuge, the solid phase 1 is used for other purposes, and the liquid phase 1 enters the acid precipitation process;

[0054] (3) Acid precipitation: the liquid phase enters the acid precipitation tank, adds hydrochloric acid to adjust the pH to 4.4, and settles for 5 minutes;

[0055] (4) Separation of curd: the acid precipitation liquid is centrifuged with a horizontal screw discharge centrifuge, the solid phase 3 is reco...

Embodiment 3

[0063] A kind of soya protein isolate preparation method that improves dissolubility, eliminates bean flavor described in embodiment 1, difference is:

[0064] Step (1) The amount of sodium isoVC added is 5.0‰ of the weight of low-temperature defatted soybean meal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com