Vacuum multi-purpose furnace

A multi-purpose furnace and vacuum technology, applied in coating, quenching device, metal material coating process, etc., can solve problems such as inability to feed materials, poor continuity and automation, and low heat treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

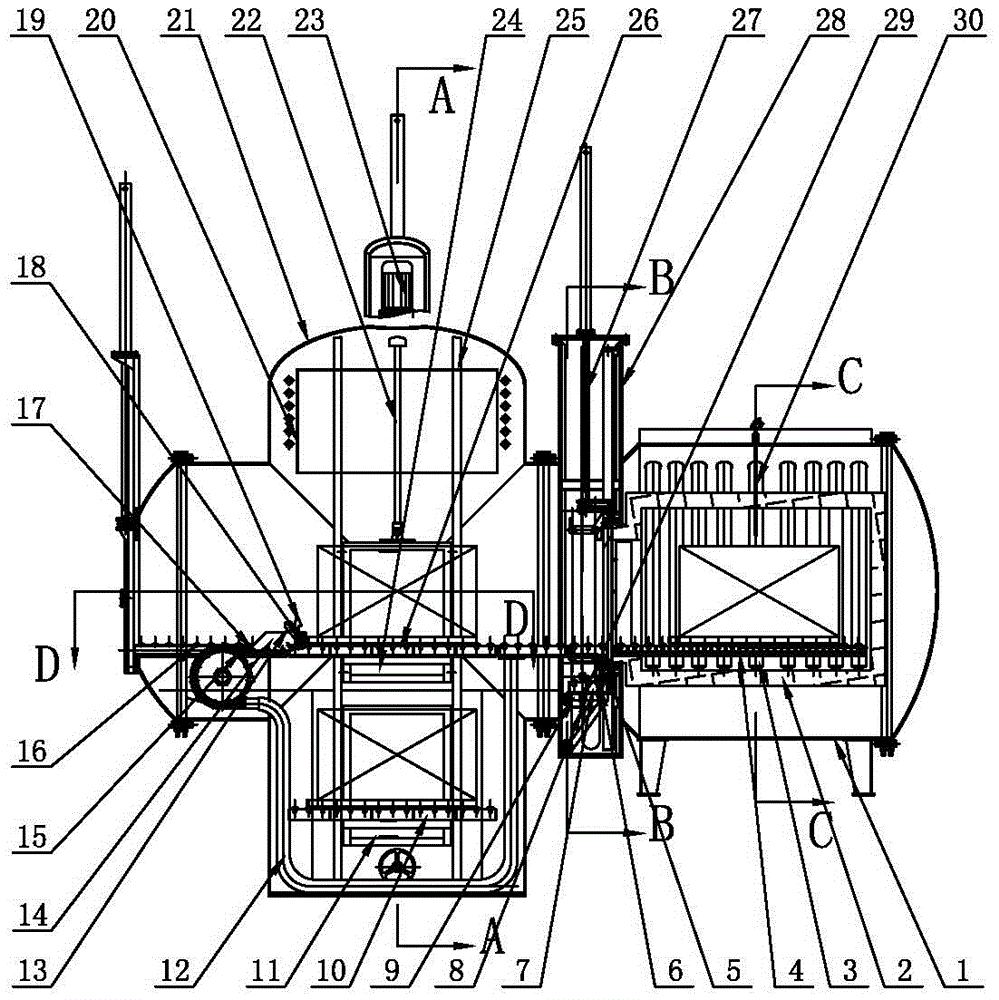

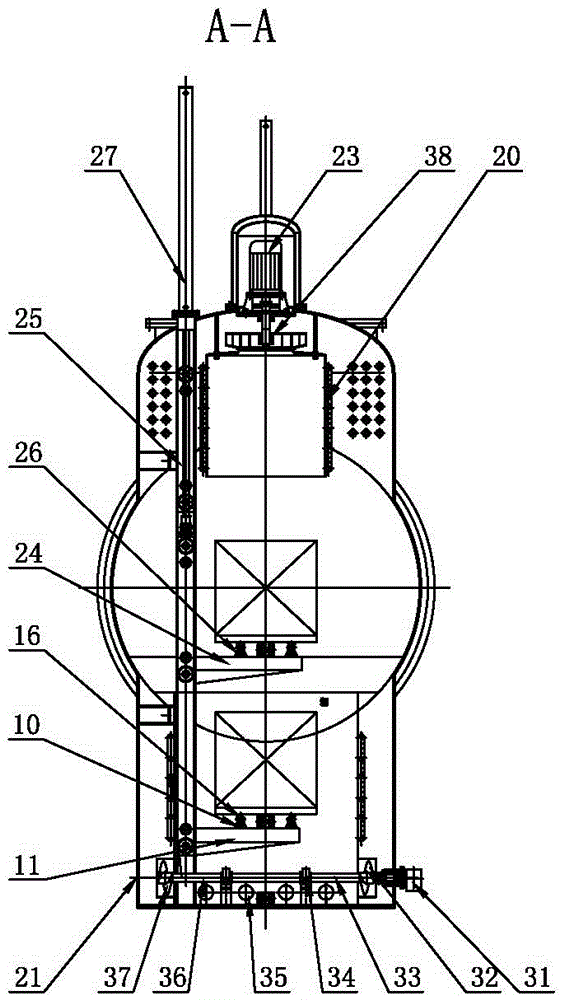

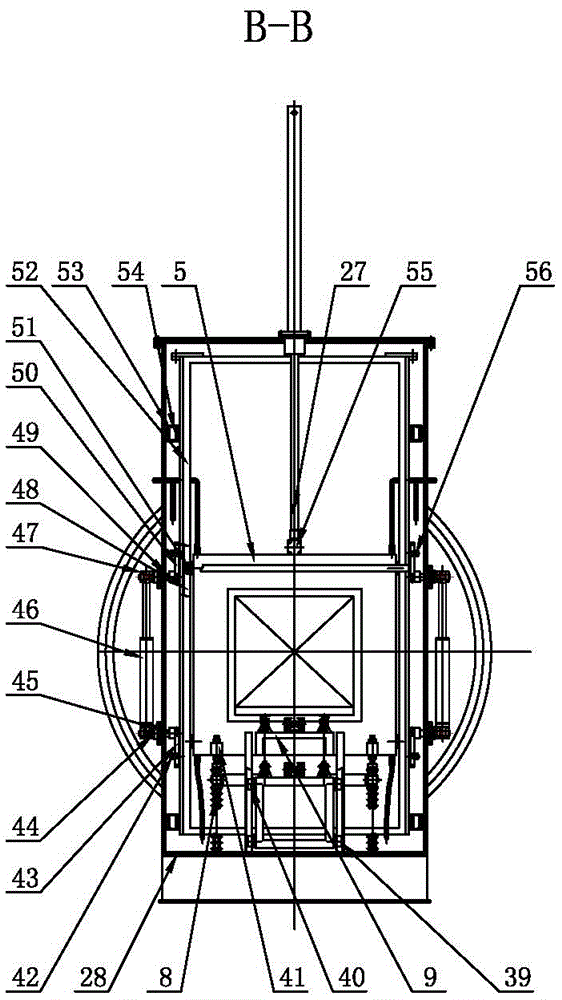

[0026] The following will be described in detail in conjunction with specific implementation methods.

[0027] like Figure 1 to Figure 10A vacuum multipurpose furnace shown includes a quenching furnace shell 21, an inner furnace shell 28 and a carburizing furnace shell 1. The quenching furnace shell 21 is connected to the carburizing furnace shell 1 through the inner furnace shell 28, and the opening of the quenching furnace shell 21 An outer furnace door is provided, and both the quenching furnace shell 21 and the carburizing furnace shell 1 are provided with an inlet and outlet rail 4, and the quenching furnace shell 21 is provided with a wind guide hood 20, a push-pull feeder and a lifting platform for feeding and discharging materials, push-pull The feeder and the lifting platform are in a cross shape. The push-pull feeder includes a second motor 31 and a first chain box 12. The second motor 31 is connected to a sprocket 70 in transmission, and the sprocket 70 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com