[0002] In order to overcome the current situation that there are no access roads and poor

traffic conditions in hilly areas and small fields, large, medium and small agricultural machines cannot enter the field, and agricultural machines are actively developing in the direction of

miniaturization. By reducing the size of agricultural machines and reducing the weight of agricultural machines The weight is used to improve the ability of agricultural machinery to enter the field, so that it can be widely used in the cultivation of various fields. The most representative one is the micro

tillage machine. For this reason, the country has also promulgated corresponding industry standards, such as JB / T 10266.1-2001 "Technical Conditions for Micro Tillers", JB / T10266.2-2001 "Test Methods for Micro Tillers", etc. The outstanding shortcomings are: 1) The

power transmission is circuitous and complicated, the

power transmission efficiency is low, the volume and weight of the whole machine are still relatively large, and its

traffic capacity needs to be improved

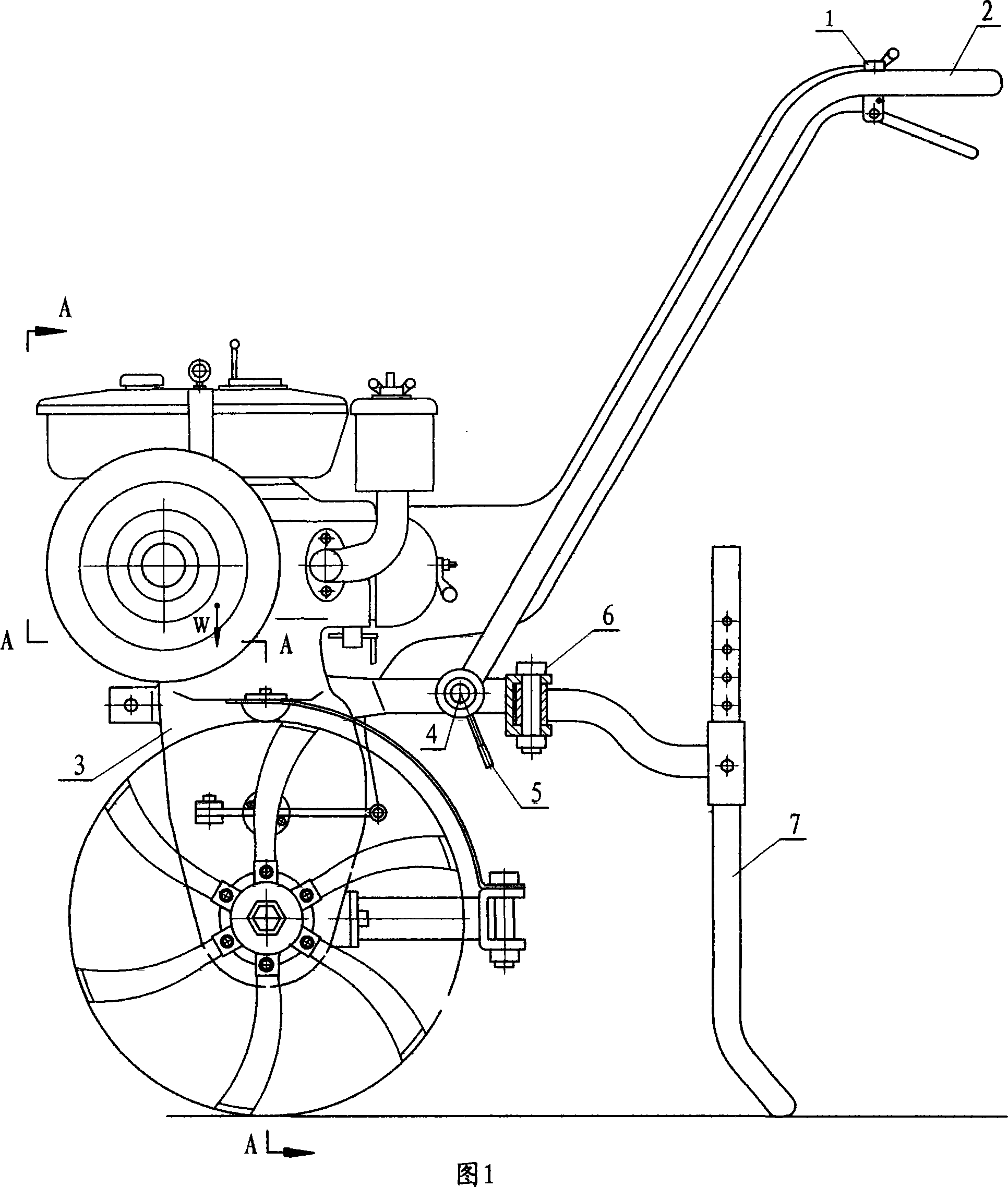

Usually, the miniature cultivator is composed of a power machine, a belt and a

pulley (or transmission shaft), a

clutch, a transmission, a rotary

tiller, an operating frame, and a resistance bar. At the upper rear of the transmission, the rotary cultivating wheel is connected to the lower front of the transmission through the rotary

tiller shaft, and the resistance bar is connected to the middle and rear of the transmission. The upper part is transmitted to the input end of the transmission—after passing through the

reduction ratio of the transmission, it is turned back forward to the output of the rotary

tiller shaft at the front and lower side—then the rotary tiller shaft drives the rotary tiller wheel to rotate, and the soil is rotary tilled downward by gravity , its clutches (including belt tension clutches, friction disc clutches, etc.) are set between the power machine and the transmission or at the input end of the transmission. The efficiency of the transmission is low, so that the micro-cultivator needs to be equipped with a higher-power power machine, and it also leads to a relatively large volume and weight of the micro-cultivator, and its

traffic capacity needs to be improved; 2) The labor intensity of the control is high

Because the plowing and walking of the micro tiller is driven by the power to rotate the front rotary tiller, and the soil is rotated downward by gravity (the weight of the whole machine), and at the same time, the rotary tiller is moved forward by the soil. The reaction force of the micro tiller is used to push the micro cultivator forward, that is, the rotation of the front rotary tiller wheel is driven by power, and self-propelled self-cultivation is realized through gravity, while the adjustment of its

tillage state (rotary tillage downward or forward walking) And the control is realized by the operator's force to hold the operation frame to increase or decrease the resistance of the rear resistance bar (when the micro cultivator walks forward, the soil reacts backward to the rear resistance bar). When the forward reaction force of the rotary

tilling wheel is slightly greater than the backward resistance of the soil to the resistance bar, the micro cultivator will move forward and rotate downward at the same time to realize self-propelled self-cultivation; When the reaction force is greater than the backward resistance of the soil to the resistance bar, the micro tiller will move forward or move forward, resulting in missing tillage; and when the reaction force of the soil to the rotary tiller wheel is less than or equal to When the resistance of the resistance bar is backward, the miniature cultivator stops and digs the soil downward in situ; that is, the combination of the forward reaction force of the soil to the rotary tiller wheel and the backward resistance of the soil to the resistance bar (force ) controls the tillage state of the miniature cultivator, but the soil condition of the soil (such as

hardness,

viscosity,

humidity, degree of

desertification,

salinity, etc.) The reaction force of the resistance bar and the resistance bar changes randomly, which causes the micro tiller to suddenly move forward in actual work, or suddenly stop, or suddenly deep, or suddenly shallow, or forward and leaking, or Digging pits in situ requires the operator to use greater strength to hold the operating frame, and increase or decrease the resistance of the rear resistance bar by pressing down, lifting up, or swinging left and right, so as to control the plowing and walking of the micro cultivator. The labor intensity of its manipulation is too large; meanwhile, the control structure of its miniature tiller is controlled by a rear resistance bar (static

single point) and a row of rotary tiller wheels (dynamic multi-point) surface), its control method has been inverted to "control the surface with points", and its vibration and swing are strong, which further aggravates the difficulty of controlling the micro cultivator, and requires the operator to use more force to hold the operation frame. Only by increasing or decreasing the resistance of the rear resistance bar can the plowing and walking of the micro cultivator be controlled, and the labor intensity of the control is too high

Login to View More

Login to View More  Login to View More

Login to View More