An agricultural soil plowing repair system

A remediation system and ploughing technology, applied in the field of agricultural soil ploughing and remediation systems, can solve the problems of reducing soil ploughing efficiency, unfavorable ploughing and ploughing, and being easily entangled, and achieving the effect of improving ploughing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

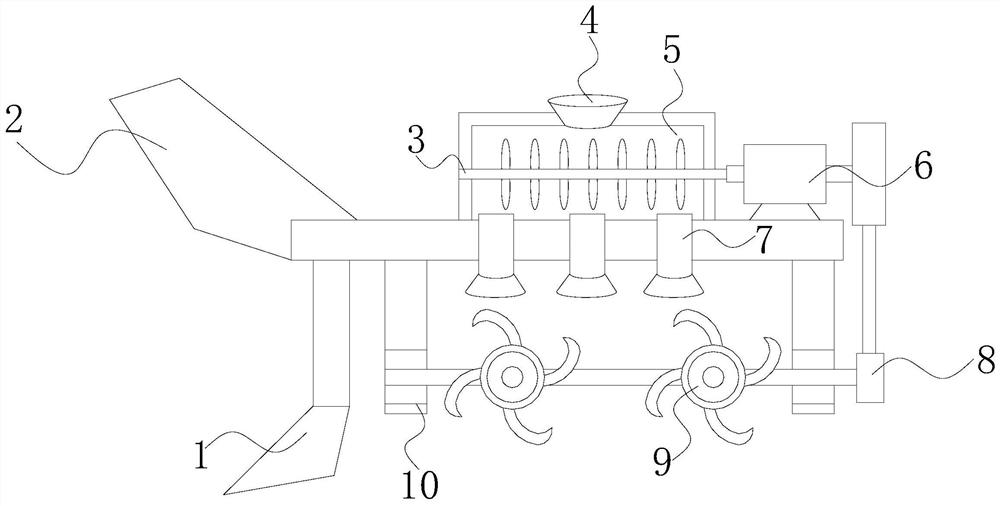

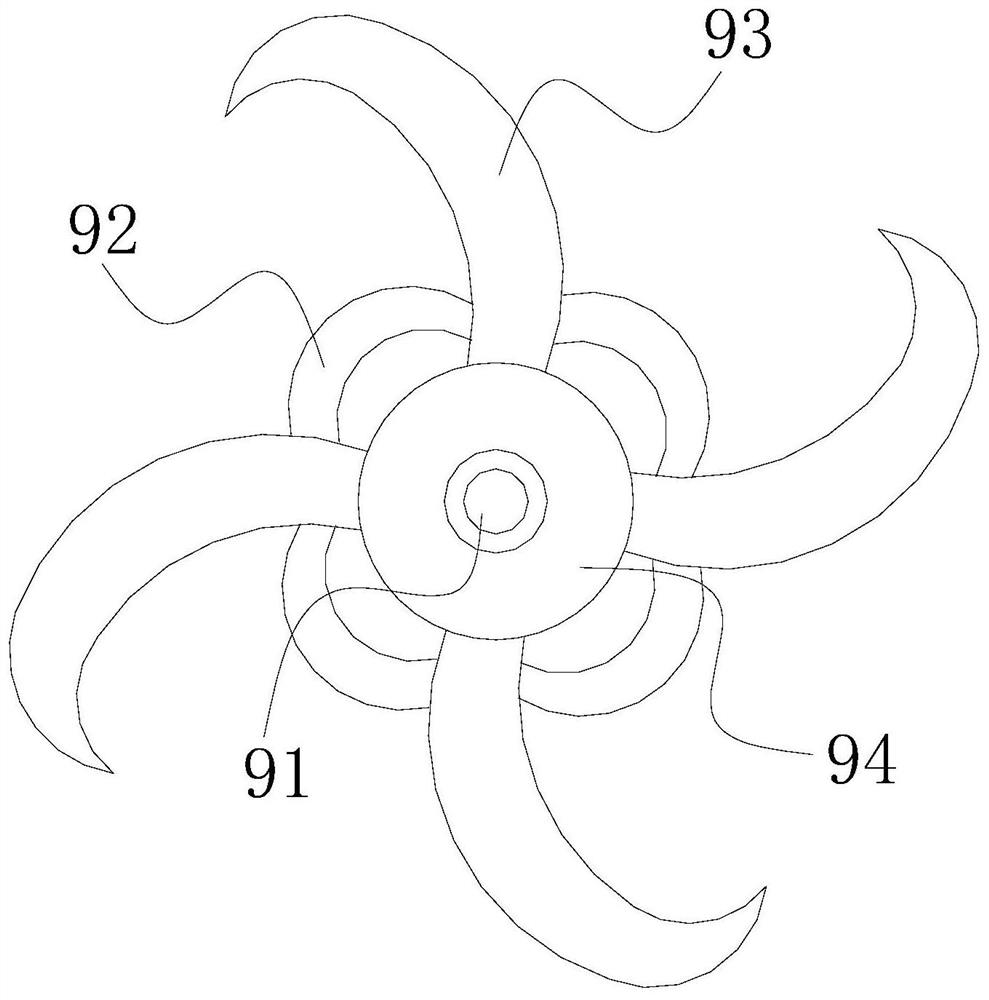

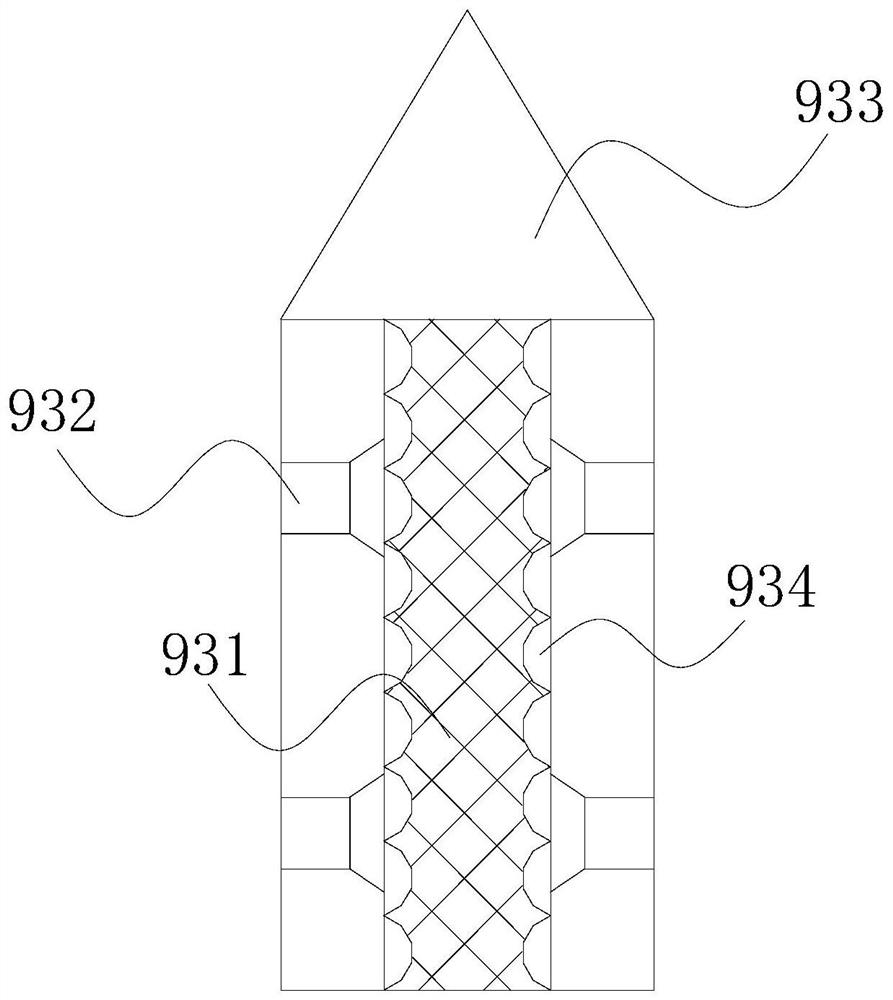

[0032] see figure 1 , the present invention provides a technical solution: an agricultural soil plowing repair system, the structure of which includes a plow 1, a traction plate 2, a stirring rod 3, a hopper 4, a water tank 5, a motor 6, a sprinkler cylinder 7, and a drive bearing 8. Cutting and filtering device 9, body 10, the plow 1 is installed on the body 10, the body 10 is provided with a traction plate 2 embedded therewith, and the traction plate 2 is connected to the tiller through the body 10 The plow 1 is connected, the plow 1 is provided with a water tank 5, a hopper 4 is installed at one end of the water tank 5, and the other end is connected with three sprinkler tubes 7, and the three sprinkler tubes 7 are arranged equidistantly through the body 10, the stirring rod 3 and the water tank 5 are engaged in a movable engagement manner, the stirring rod 3 is connected to the motor 6, the motor 6 is fixed on the body 10, and the driving bearing 8 is provided with two A ...

Embodiment 2

[0044] see figure 1 , the present invention provides a technical solution: an agricultural soil plowing repair system, the structure of which includes a plow 1, a traction plate 2, a stirring rod 3, a hopper 4, a water tank 5, a motor 6, a sprinkler cylinder 7, and a drive bearing 8. Cutting and filtering device 9, body 10, the plow 1 is installed on the body 10, the body 10 is provided with a traction plate 2 embedded therewith, and the traction plate 2 is connected to the tiller through the body 10 The plow 1 is connected, the plow 1 is provided with a water tank 5, a hopper 4 is installed at one end of the water tank 5, and the other end is connected with three sprinkler tubes 7, and the three sprinkler tubes 7 are arranged equidistantly through the body 10, the stirring rod 3 and the water tank 5 are engaged in a movable engagement manner, the stirring rod 3 is connected to the motor 6, the motor 6 is fixed on the body 10, and the driving bearing 8 is provided with two A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com