Barrel heater of extruder

A heating device and extruder technology, applied in the field of extruders, can solve the problems of uneven melting of heated plastic particles in a barrel, uneven heating of the barrel, affecting product quality, etc., so as to facilitate daily maintenance and repair, and improve product quality. The effect of quality, easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0025] The present invention will be described in detail below with reference to the accompanying drawings and examples.

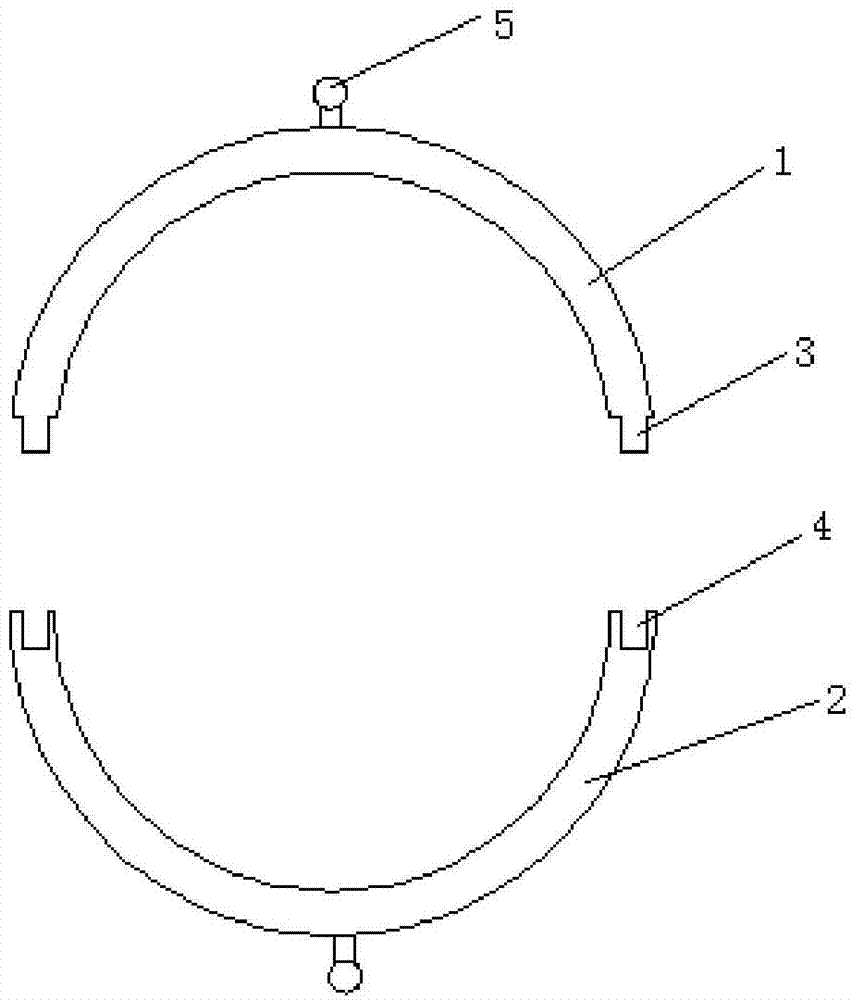

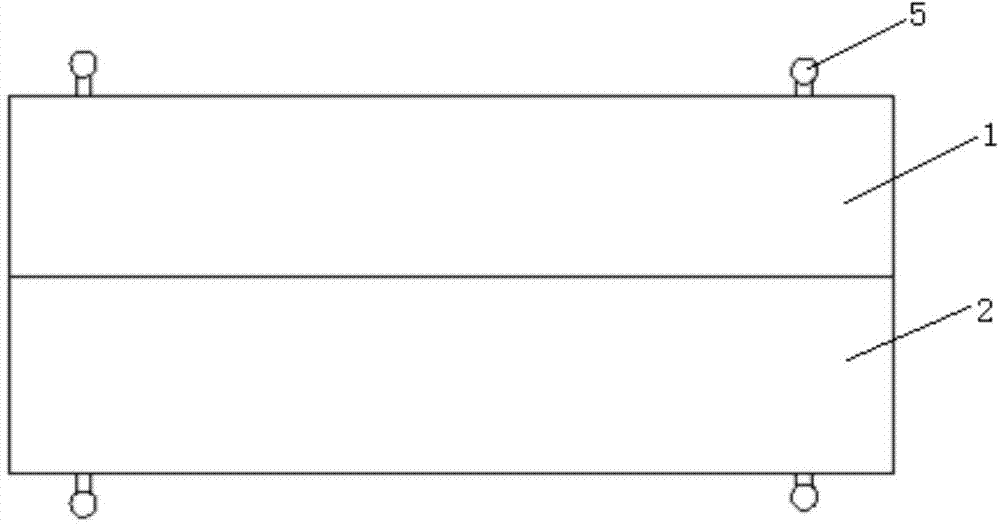

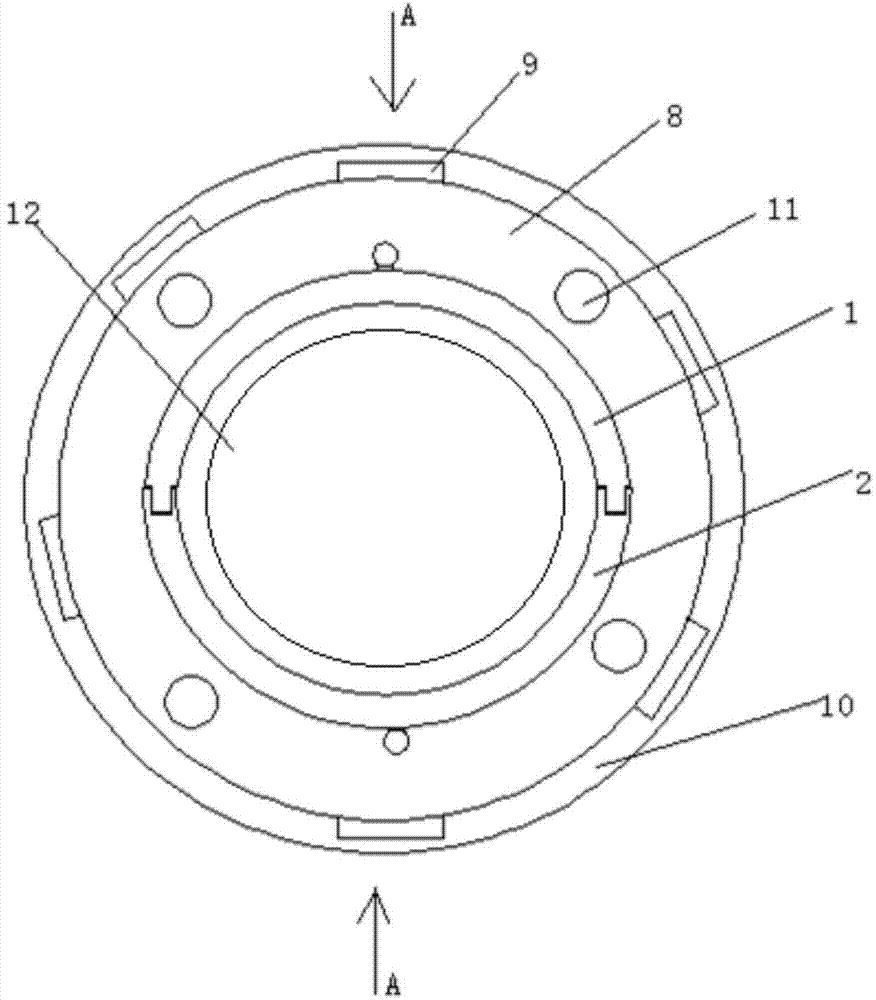

[0026] A heating device for a barrel of an extruder, comprising a barrel, an auger 12, a heating device and a stirring device; the barrel is surrounded by a semicircular upper side plate 1 and a semicircular lower side plate 2 Formed cylindrical structure to realize the split structure of the barrel, a convex slider 3 is provided at the junction of the upper side plate 1 and the lower side plate 2, and a convex slider 3 is provided on the lower side plate 2 with the lower side plate 2 The junction of the upper side plate 1 is provided with a concave chute 4 matching the convex slider 3, and the convex slider 3 is stuck in the concave chute 4, and can be moved along the Described concave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com