Combined type instant noodle oil-noodle separating device

A separation device and technology of instant noodles, which are applied in filtration separation, separation method, oil/fat baking, etc., can solve the problems of insufficient separation of oil surface, insufficient structure, poor frying uniformity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

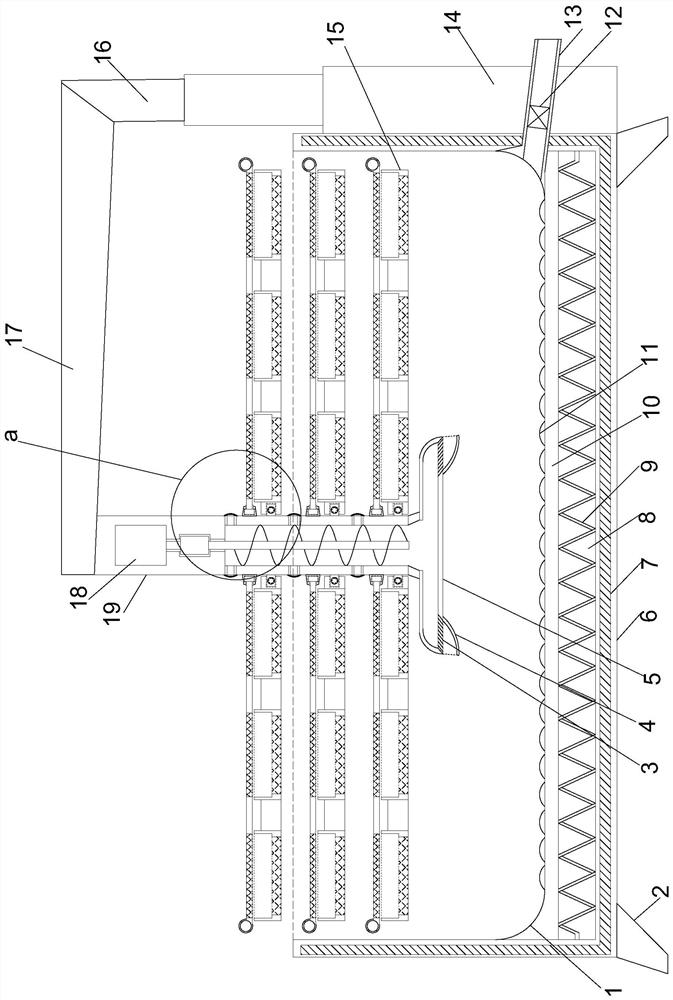

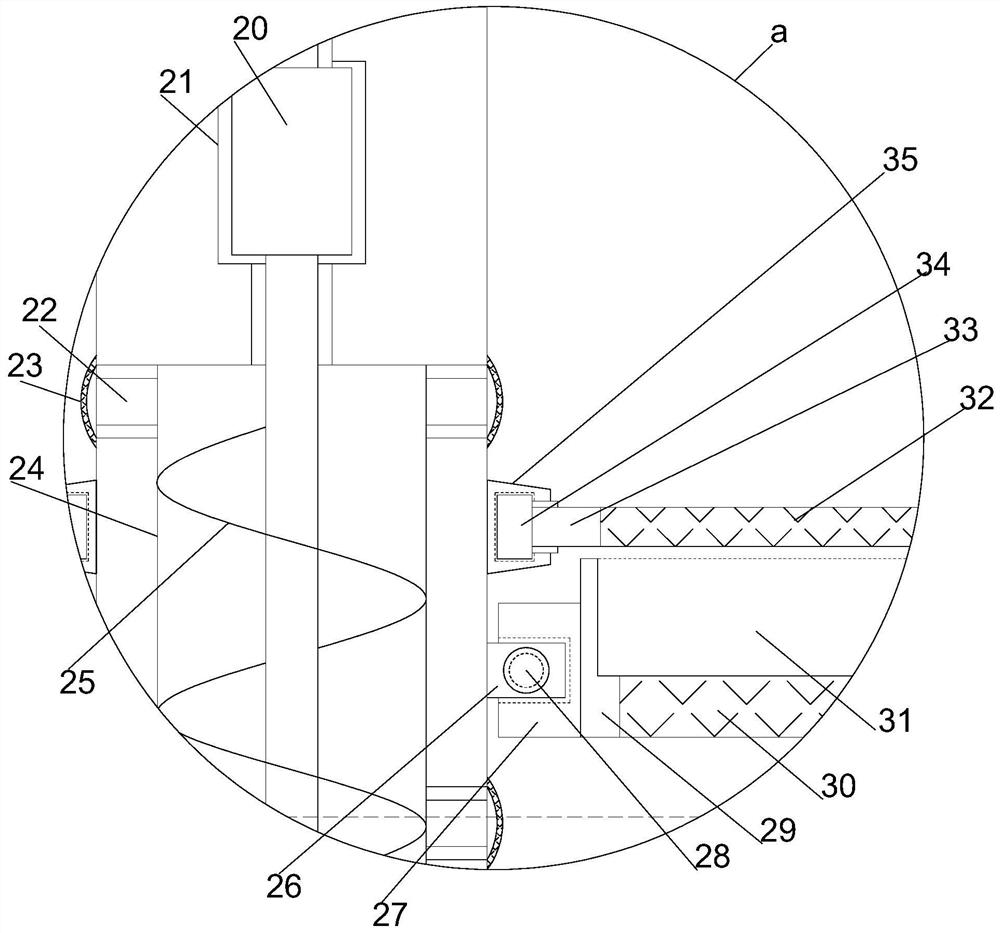

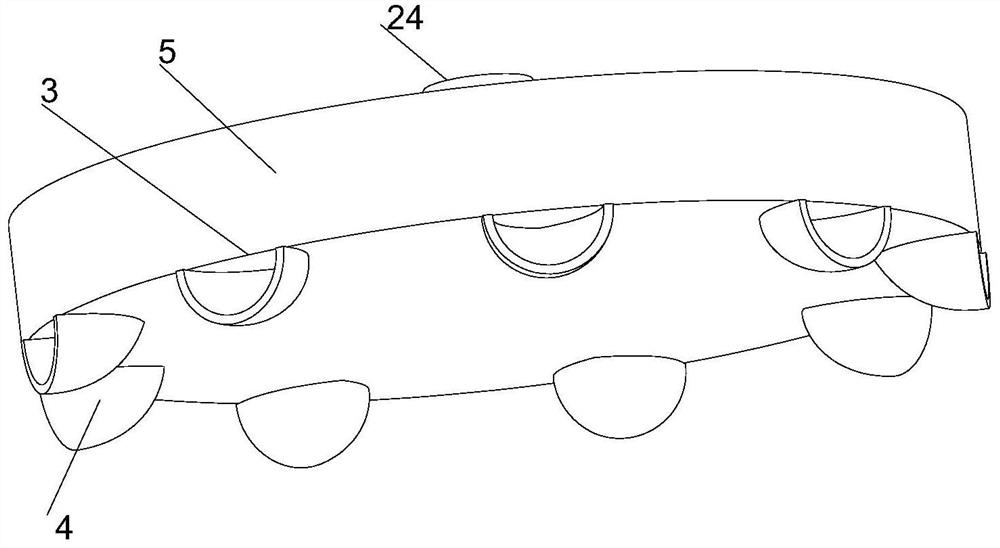

[0022] see Figure 1~3 , in the embodiment of the present invention, a combined instant noodle oil surface separation device includes a vertically arranged support installation cylinder 6, the four corners of the lower end of the support installation cylinder 6 are all provided with support feet 2, and the right end of the support installation cylinder 6 is vertically provided with Support installation plate 14, the upper end of support installation plate 14 is vertically provided with electric control lifting column 16, is vertically provided with lifting installation column 19 directly above support installation tube 6, and the upper end of described lifting installation column 19 and electric control lifting column The upper end of 16 is horizontally connected with a synchronous lifting plate 17, and a heat insulating layer 7 is embedded in the wall of the supporting installation cylinder 6. The lower half of the supporting installation cylinder 6 is horizontally provided wi...

Embodiment 2

[0025] On the basis of Embodiment 1, during the frying process, start the driving motor 18, drive the limit rotating shaft 20 together with the spiral deflector 25, and the spiral deflector 25 rotates at a high speed, so that the internal fluid is guided downward. At this time The external oil enters the lifting guide cylinder 24 and the uniform guide plate 5 through the active guide hole 22, and finally cooperates with the guide cover 4 to lead out from the jet hole 3, so that the jet oil cooperates with the curved guide plate 1 to guide the flow, The oil in the supporting installation cylinder 6 is evenly heated, and the frying progress of the multi-layer cake is synchronized. Through the cooperation of the positioning installation column 26 and the positioning installation sleeve 27, the quick replacement of the assembly installation plate 15 is realized, and the maintainability of the device is improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com