Induction Heating Fryer

An induction heating and frying furnace technology, which is applied in the field of kitchen utensils, can solve the problems of uneven oil temperature, large oil temperature deviation, and large oil temperature range, so as to reduce the oil content of food, increase the oil usage rate, and reduce the oil consumption. The effect of oil quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

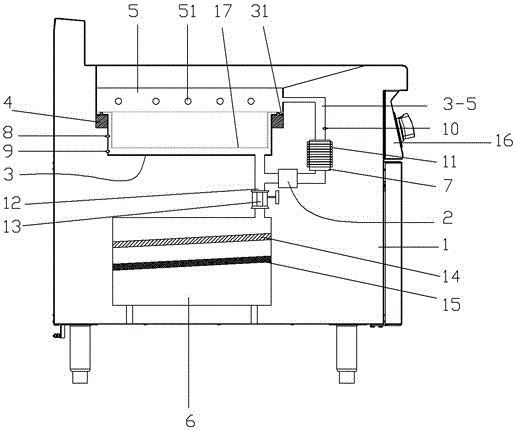

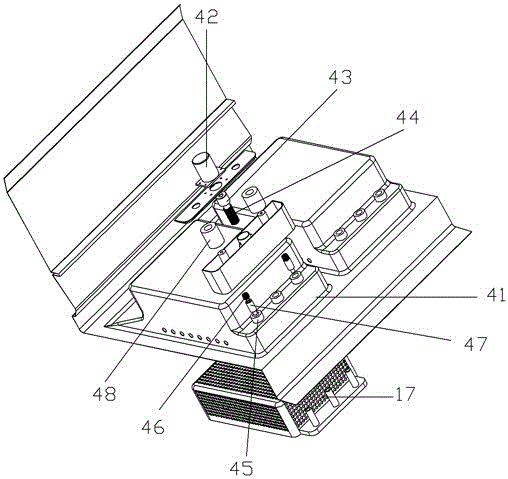

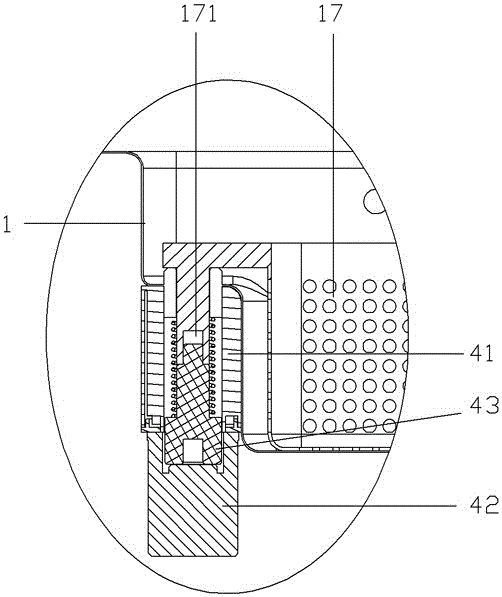

[0034] Example: see Figures 1 to 4 As shown, the induction heating fryer includes a cabinet body 1 and an oil pump 2, and a frying tank 3 is fixed in the cabinet body 1. A frying tank step 31 is formed on the inner wall of the frying tank 3, and the filter tank lifting vibrator 4 is controlled by the housing 41. Cylinder 42, lifting rod 43, lifting return spring 44, vibrating sleeve 45, vibrating returning spring 46, electromagnetic coil 47 and vibrating magnetic core 48. The filter cylinder 17 is formed with a lifting rod socket 171 and a vibrating magnetic core socket 172, the housing 41 is fixed on the cabinet body 1, the cylinder 42 is fixed on the housing 41, the piston rod of the cylinder 42 is fixed with the lifting rod 43, the upper end of the lifting rod 43 is inserted into the lifting rod socket 171, and the lifting Back-moving spring 44 is inserted and sleeved on the lifting rod 43, and the upper end of the lifting rod 43 exerts force on the filter cylinder 17, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com