Electro-magnetic induction frying device for instant noodles

An electromagnetic induction and instant noodle technology, applied in application, oil/fat baking, baking, etc., can solve the problems of slow heating speed of electric heating tube, easy damage of electric heating tube, and potential safety hazards, etc., to achieve good cooling effect and eliminate Oil corrosion, fast heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

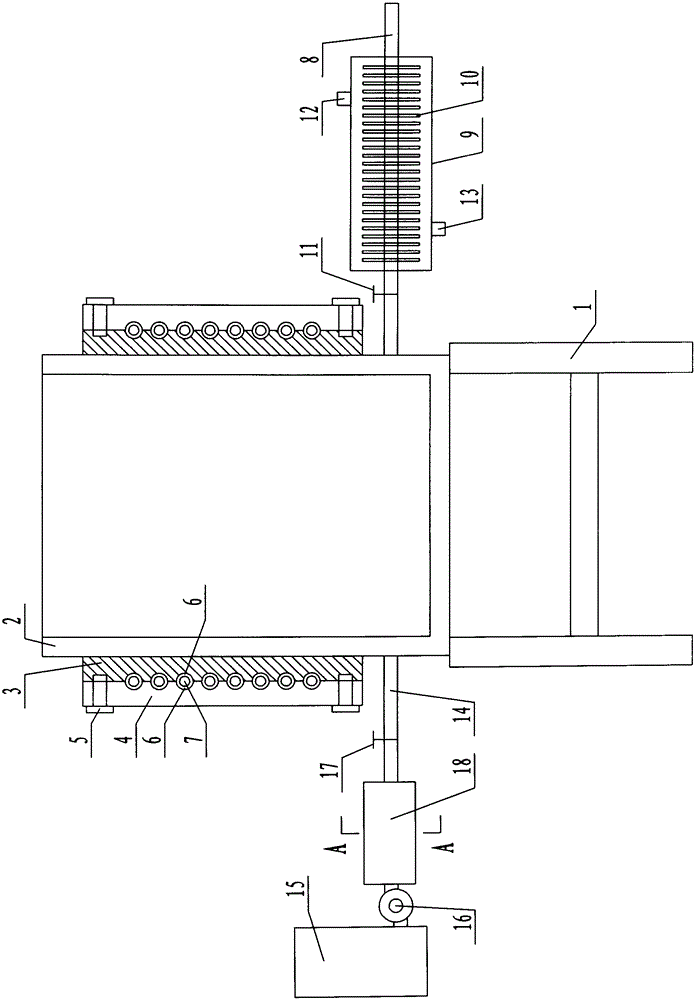

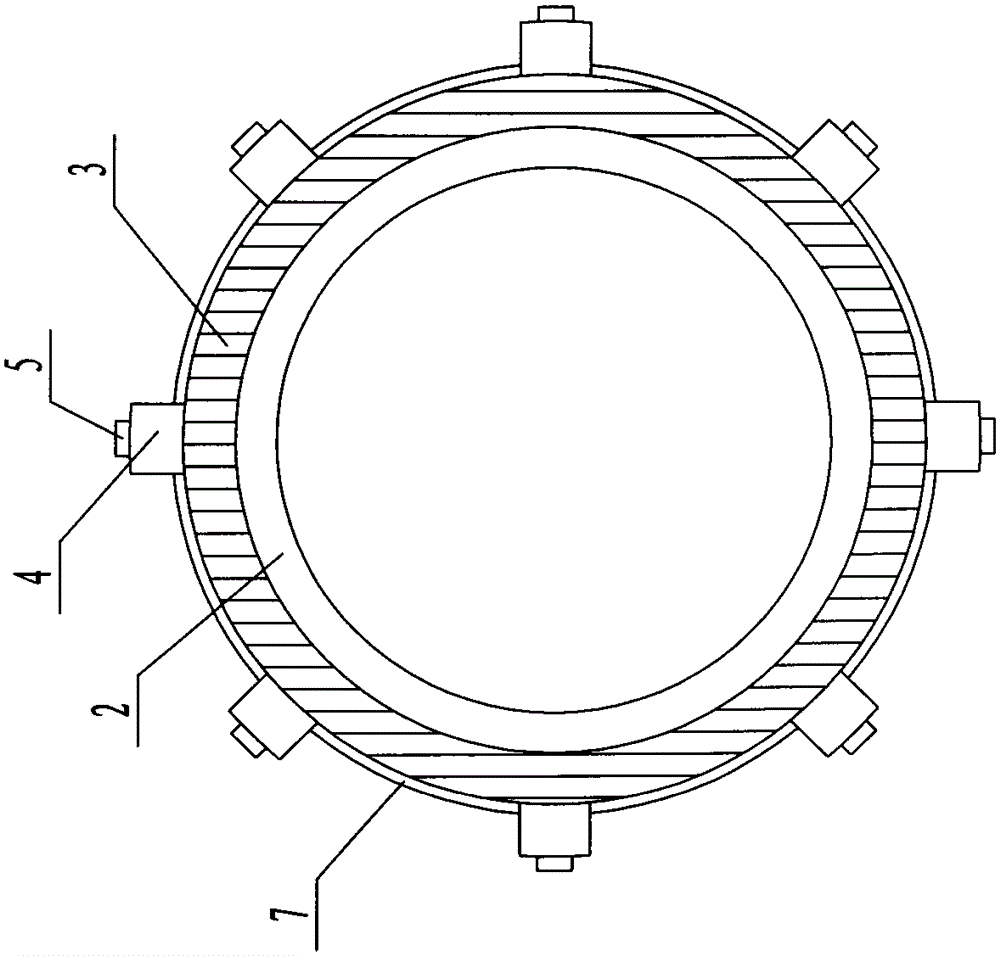

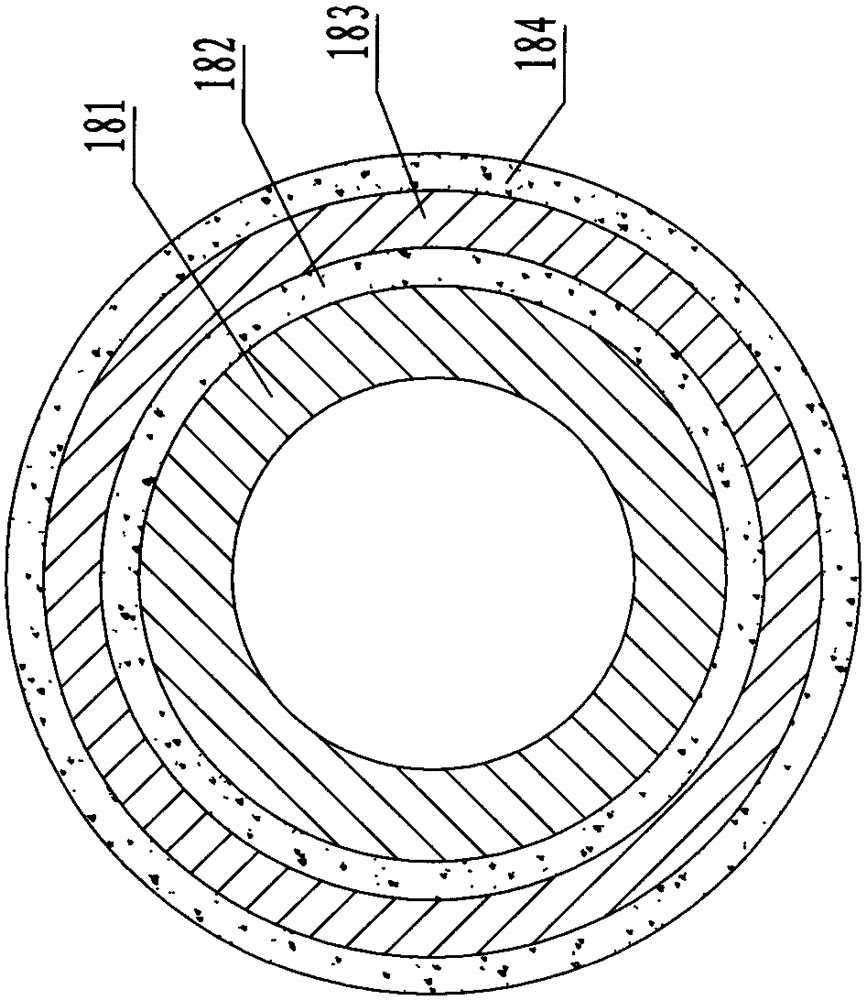

[0011] Such as figure 1 , figure 2 , image 3 As shown, the electromagnetic induction frying device for instant noodles comprises: a frame 1, a metal frying tank 2 arranged on the frame 1, and a polymer insulation cotton 3 is wrapped on the outside of the metal frying tank 2, in which A number of high-frequency induction coil fixing plates 4 are evenly arranged on the outer side of the polymer thermal insulation cotton 3, and the upper and lower ends of the high-frequency induction coil fixed plate 4 are respectively fixed on the polymer thermal insulation cotton 3 by screws 5. A number of semicircular grooves 6 are respectively arranged on the inner side of the frequency induction coil fixing plate 4 and the outer side of the polymer insulation cotton 3, and a high frequency induction coil is wound in the cavity fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com