Electromagnetic induction fryer

An electromagnetic induction and fryer technology, applied in the field of stoves, can solve the problems of short service life of edible oil, uneven oil temperature, spontaneous combustion, etc., and achieve the effects of prolonging life, uniform oil temperature, and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

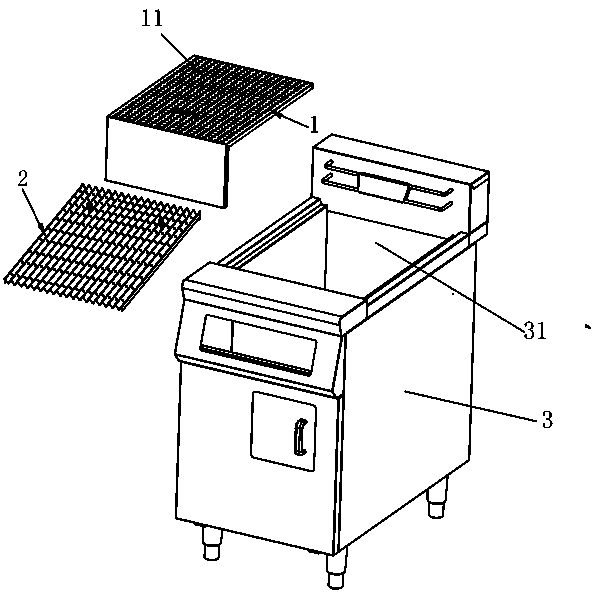

[0015] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

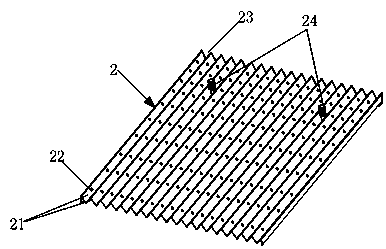

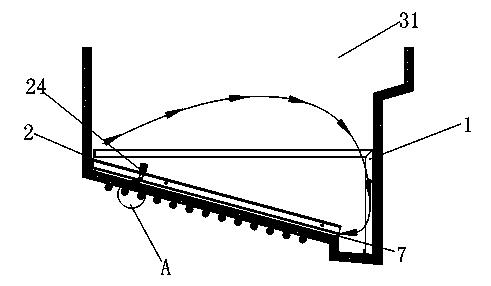

[0016] Such as figure 1 with figure 2 As shown, the electromagnetic induction fryer of the present invention includes a heat convection net 2, and the heat convection net 2 has a plurality of protrusions 21, and a groove 23 is arranged between two adjacent protrusions 21, that is, the shape of the heat convection net 2 is wavy, It can better expand the heating area to accelerate the heating effect, and the groove can play the role of the pipeline. The side of the protrusion 21 is provided with a plurality of openings 22, the spacing between the openings 22 gradually decreases from top to bottom, that is, the spacing between the openings 22 gradually becomes thinner, when the heating steel sheet under the heat convection net 2 The heating causes the oil temperature to rise, so that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com